Sub-caliber bullets and a tungsten carbide conical barrel: the future of small arms?

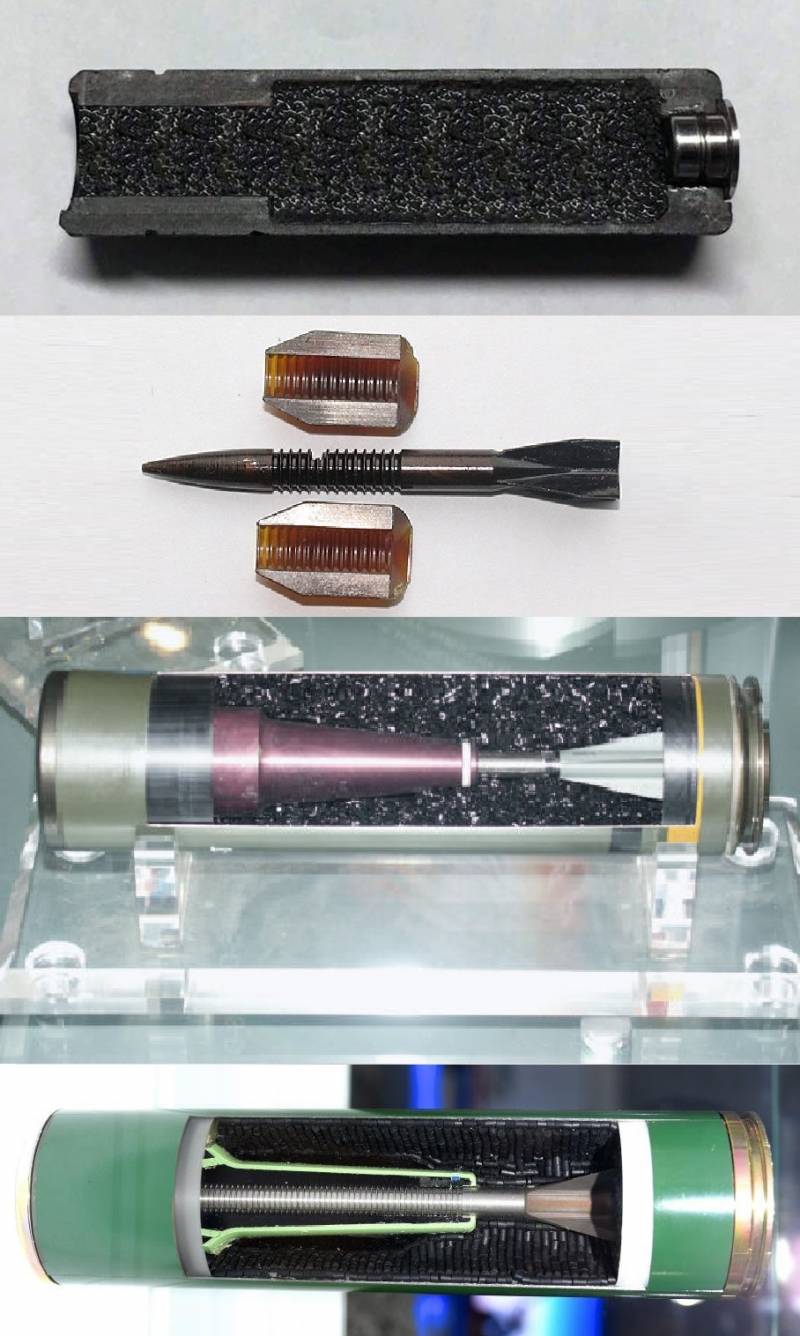

Telescopic cartridge (in the center) - a projectile for a 40 mm automatic cannon 40 CTAS (Cased Telescoped Armament System) in a reduced scale

Article "Forgotten Soviet cartridge 6x49 mm against the cartridge 6,8 mm NGSW" We examined one of the possible ways to respond to the American NGSW program if it is successfully implemented. Possible evolutionary paths of small arms weapons in the Russian Federation in the event of a clear failure of the NGSW program, we considered earlier in the article “The evolution of an automaton in the USSR and in Russia in the context of the American NGSW program”.

One of the priority tasks for promising small arms, which is indicated as the reason for the appearance of the NGSW program, is the appearance in the armed forces of Russia and China existing and prospective means of individual armor protection (NIB).

Despite its apparent simplicity, small arms are incredibly effective in the destruction of enemy soldiers, which shows medical statistics of the largest military conflicts of the XX century, With the cost of re-equipping the armed forces with even complex and expensive small arms is only a small fraction of the cost of financial expenses for other types of weapons.

As we have already considered earlier, there are two main ways to increase the armor penetration of ammunition: increase its kinetic energy and optimize the shape and material of the ammunition / ammunition core (of course, we are not talking about explosive, cumulative or poisoned ammunition). A bullet or core for it is made of ceramic alloys of high hardness and sufficiently high density (to increase mass), they can be made harder and stronger, denser - hardly. Increasing the mass of a bullet by increasing its dimensions is also almost impossible in the acceptable dimensions of handguns. There remains an increase in bullet speed, for example, to hypersonic, but even in this case, developers are faced with enormous difficulties in the form of the lack of necessary gunpowder, extremely rapid barrel wear and high recoil acting on the shooter.

Nevertheless, there are several ways to increase the armor penetration of a bullet: the use of sub-caliber bullets and conical trunks.

Caliber bullets

Active research on the possibility of using sub-caliber bullets (feathered sub-caliber bullets, OPP) in small arms has been carried out since the middle of the XNUMXth century. Prior to this, the creation of armor-piercing feathered sub-caliber shells (BOPS) was considered a more popular and promising direction, which, in fact, was confirmed by their creation and successful operation to date.

Work on BOPS in the USSR began in 1946, and since 1960 at NII-61 the possibility of using BOPS in fast-firing automatic guns under the guidance of A. G. Shipunov was studied. At the same time, work was underway to create a new automatic weapon of 5,45 mm caliber, in connection with which A.G. Shipunov was asked to develop a cartridge with a firearm for small arms.

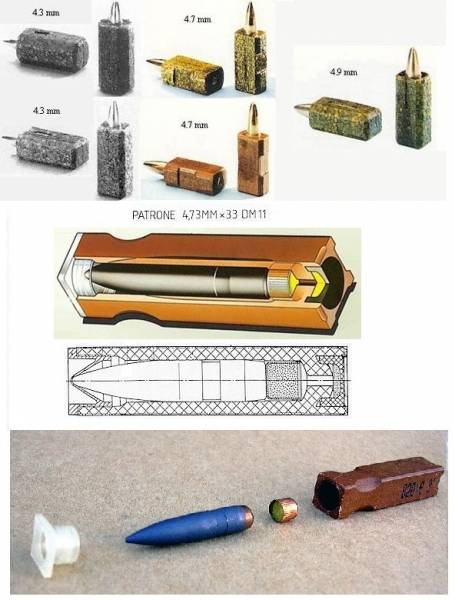

The preliminary design was developed by D. I. Shiryaev as soon as possible. However, theoretical studies have not been experimentally confirmed. The actual ballistic coefficient of swept bullets turned out to be two times worse than the calculated one, the pressed pallet was torn off the bullet, the production of cartridges with AKI required laborious turning, milling, locksmithing and subsequent manual assembly.

In 1962, tests were carried out for the lethal action of arrow-shaped bullets, which, as it turned out, was inferior not only to the requirements of the military for promising ammunition, but also to existing regular ammunition.

A sketch of a cartridge with a feathered sub-caliber bullet developed by D. I. Shiryaev. Photo of the first version of the swept bullet to it and mock-ups of the processed prototype 7,62 / 3-mm cartridges of 1963–64

In 1964, work on swept bullets was resumed by I.P. Kasyanov and V.A. Petrov, who carried out a preliminary design of a rifle-machine gun cartridge of 10 / 4,5 mm caliber with an initial RPM speed of 1300 m / s. Since 1965, young designers Vladislav Dvoryaninov was appointed executive performer for a promising cartridge.

In the process of designing a new cartridge, solutions were implemented that increase the lethal effect: a flat in the front of the OPP to provide a tipping moment when it gets into dense fabrics and a transverse groove along which the arrow was bent under the influence of the arising tipping moment.

The most difficult task was to increase the accuracy of firing with sub-caliber feathered bullets to the level of accuracy of bullets fired from rifled barrels. It was necessary to eliminate the influence of the pallet sectors on the runway at the time of their separation after departure from the trunk. In 1981, the tests of experimental 10 / 4,5-mm cartridges with an OPP in the OTK TSNIITOCHMASH showed accuracy of 88-89 mm with requirements not exceeding 90 mm.

It should be separately noted that the laboriousness of manufacturing an experimental cartridge with an OPP was only 1,8 times higher than the laboriousness of manufacturing a standard 7,62 mm rifle cartridge, and the resource of smooth-walled machine-gun barrels when firing this cartridge exceeded 32 thousand shots. For comparison: the resource of the barrel of the AK-74 assault rifle of 5,45x39 mm caliber is 10000 rounds, the PKM machine gun of the caliber 7,62x54R 25000 rounds.

Simultaneously with the development of the main 10 / 4,5-mm variant, a single-bullet 10 / 3,5-mm cartridge with an initial OPP speed of 1360 m / s and a three-bullet 10 / 2,5 mm cartridge, which could be used as a single cartridge for the machine gun, were developed and a light machine gun.

Comparative characteristics of experimental cartridges with OPP, as well as serial and experimental cartridges for rifled trunks

A single-bullet 10 / 3,5-mm cartridge could be used at long ranges, while the use of a three-bullet cartridge would provide a higher destructive and stopping effect at close range. As we said in the article “Stop cannot be killed. Where to put a comma? ", if we consider the stopping effect as a dependence of the probability of death on time, from the moment a bullet hits the target, then hit at the same time several munitions with a high probability will provide a higher probability of damage to vital organs and, accordingly, the speed of death.

The ammunition with the OPP was never taken into service. Formally, priority was given to the more classic 6x49 mm cartridge for rifled weapons, which we talked about in the article "Forgotten Soviet cartridge 6x49 mm against the cartridge 6,8 mm NGSW". At that time, the characteristics of the 6x49 mm cartridge fully met the requirements of the military, while its development in production would be an order of magnitude simpler than cartridges with AKI. In addition, some tests pointed to a potential shortage of ammunition with an AKP - too wide an expansion of pallets that could hit their own soldiers located in front of the gunner. On the other hand, it was suggested that these tests were used as a formal reason to give priority to the cartridge 6x49 mm, since earlier tests did not show significant problems with the expansion of pallets.

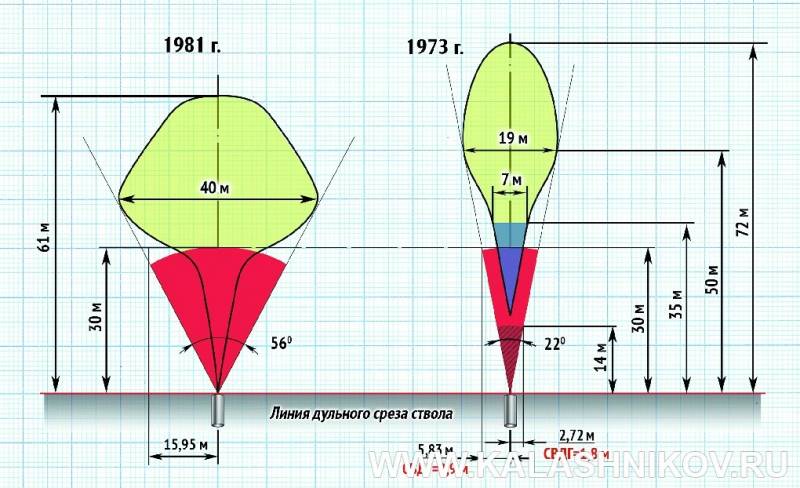

The zones of expansion of the sectors of the pallet of cartridges with OPP on tests conducted in 1973 and 1981

However, the collapse of the USSR drew a line both over the topic for cartridges with AKP, and with the topic for the cartridge 6x49 mm.

In details story the creation of sub-caliber ammunition for small arms is described in the article “Swept bullets: the path of false hopes or the history of missed opportunities?” (Part 1 и Part 2).

Conical trunk

Article “9 mm caliber and stopping action. Why was 7,62x25 TT replaced with a 9x18 mm PM? ” the “Gerlich bullet” was mentioned as an example of creating a small-caliber cartridge with extreme damaging parameters.

Initially, the idea of using a conical barrel belonged to the German professor Karl Puff, who in 1903-1907 developed a rifle for a bullet with a belt for rifled firearms, with a slight taper of the barrel. In the 1920s and 1930s, this idea was finalized by the German engineer Gerlich, who managed to create weapons with outstanding characteristics.

In one of the experimental samples of the German Gerlich system, the diameter of the bullet was 6,35 mm, the mass of the bullet was 6,35 g, while the initial velocity of the bullet reached 1740-1760 m / s, muzzle energy - 9840 J. At a distance of 50 m, the Gerlich bullet broke through steel armor plate with a thickness of 12 mm, a hole with a diameter of 15 mm, and in a thicker armor made a funnel of 15 mm in depth and 25 mm in diameter. The usual 7,92 mm Mauser rifle bullet left only a small depression of 2-3 mm on such armor.

The accuracy of the Gerlich system was also significantly superior to conventional army rifles: at a distance of 100 meters 5 bullets weighing 6,6 g fit into a circle with a diameter of 1,7 cm, and when firing at 1000 meters 5 bullets weighing 11,7 g laid in a circle with a diameter of 26,6 see. Due to the high speed of the bullet, it was practically not affected by wind, humidity, air temperature. A flat flight path simplified aiming.

Images and photos of ammunition 28 / 20x188 mm with Gerlich bullets (shells) for the German anti-tank rifle sPzB 41, below is a general diagram of the work of Gerlich's bullets

The weapons of the Hermann Gerlich system did not receive distribution primarily because of the low resource of the barrel, which is about 400-500 shots. Another possible reason, most likely, is the complexity and high cost of manufacturing both the bullets themselves and the weapons.

Technology promising automatic rifle (machine gun)

Why in promising small arms we may need feathered sub-caliber bullets and a conical barrel?

Several key factors are important here:

1. Feathered sub-caliber bullets can be dispersed to substantially higher speeds than rifled bullets, without increasing barrel wear.

2. The weapons of the Gerlich system can significantly increase the speed of the bullet, in fact, to hypersonic speeds, and it can be assumed that the main reason for the wear of the weapons of the Gerlich system was previously the presence of rifling in it.

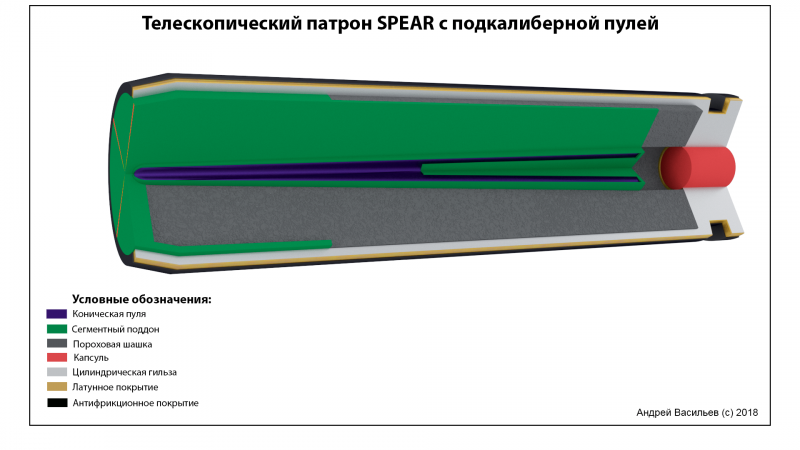

Based on this, it can be assumed that in a promising small arms can be combined feathered subcaliber bullet and a conical barrel. The role of the obturating rings, which are programmably deformed during the shot, will be played by the pallet of the feathered sub-caliber bullet of a certain configuration. In this case, barrel survivability corresponding to or superior to existing modern small arms can be obtained.

Most likely, the most optimal format for a promising cartridge will be a telescopic munition, in which the projectile is completely sunk in a powder charge. In fact, there are two charges in it. The knock out charge is the first to fire, pushing the bullet / projectile out of the sleeve into the barrel and fill the freed space with the combustion products of the knockout charge, after which the main charge of high density is ignited.

A telescopic cartridge with a fully recessed bullet will give developers a wide field for experiments, will provide opportunities for creating automation of small arms, different from those implemented for weapons with classic ammunition.

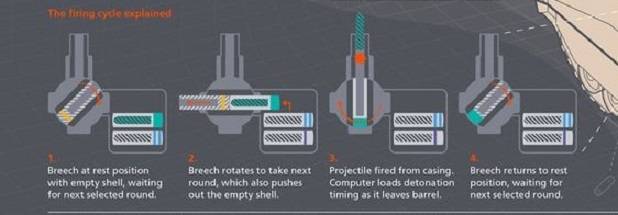

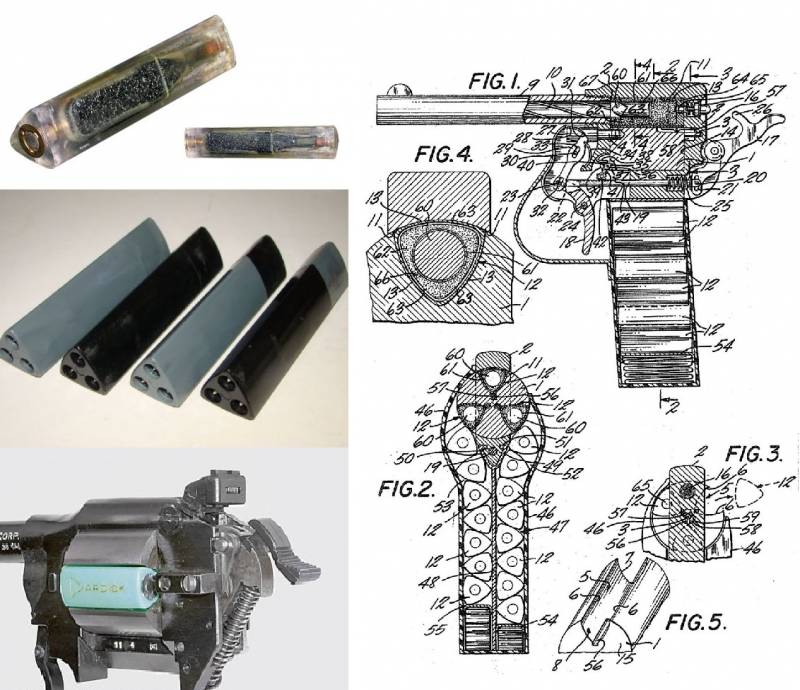

Automation of the prototype rifle, with a vertical-movable chamber, created by Textron as part of the NGSW program under a telescopic cartridge

To optimize the density of ammunition in the weapons store, advanced cartridges can be made not only round, but also square or triangular in cross section.

Caseless telescopic ammunition for the German experimental rifle G-11 by Heckler & Koch

The shell case is likely to be made of polymer, this will reduce the mass of the cartridge, keeping it at the level of low-pulse cartridges of 5,45x39 mm, therefore, prevent the ammunition of the fighters from being reduced.

The spread and improvement of computers, as well as specialized software, can lead to the appearance of sub-caliber ammunition, significantly different in layout from those that were developed in the Soviet period.

Managed bullet concept. Probably, it can be considered as a basis for creating a promising unmanaged OPP

The concept of a telescopic cartridge SPEAR with a conical striking element, proposed by Alexander Vasiliev

By varying the mass of the OPP in the range of 2,5-4,5 grams and the speed of the OPP in the range of 1250-1750 m / s, you can get the initial energy in the region of 3000-7000 J. For three-bullet cartridges, the initial energy, respectively, will be 1500-2000 J per striking element, with a mass of one element of 1,5 grams. Based on the above table comparing the energy and recoil force of various ammunition, we can expect returns in the range from the level of the cartridge 7,62x39 mm to the cartridge 7,62x54R. At the same time, a line of ammunition with various types of equipment designed for combat in various tactical situations can be released.

For example, if the battle is conducted in an open area, with the primary defeat of targets at a long distance, then single-bullet cartridges with an energy of about 6000-7000 J are used, which are more effective when shooting with single fire. In the event that there is a battle in a city building where penetration of a large number of obstacles (duvalls, relatively thin walls of buildings, thickets of vegetation) is required, then single-bullet cartridges with an energy of 3000-4500 J are used, which are more effective when firing in bursts. If penetration of obstacles is not required, but it is necessary to ensure maximum density of fire at close range, then three-bullet ammunition is used.

This will provide an advantage over weapons developed under the NGSW program, in the entire range of ranges of weapons, in various tactical situations.

OPP speeds of up to 1360 m / s were obtained at the stage of development of this topic by Vladislav Dvoryaninov, during the Soviet era. This means that a combination of new gunpowder and a cone-shaped barrel can reach OOP velocities of the order of 2000 m / s. With such an initial velocity of the AKP, approximately 500 seconds will elapse between shots and hitting the target at a distance of 0,3 meters, which will greatly simplify shooting and reduce the impact of external factors on the AKP.

The manufacture of the core of the OPP from an alloy based on tungsten carbide in combination with high speed and a small diameter of the OPP will ensure the penetration of all existing and promising NIB.

To reduce friction and reduce barrel wear, the OPP pallet can be made of modern polymer materials, for example, those used to make the leading belt in new Russian shells for 30-mm automatic guns.

Russian 30-mm shell with a leading belt of polymer material

Despite the lack of rifling and the use of OPP pallets made of polymer materials, the high speed of the bullet and the pressure in the barrel, combined with the taper of the barrel, may require measures to increase the barrel's strength of a promising automatic rifle. And here a smooth barrel is a significant advantage, simplifying the technological operations for its manufacture. For example, a combination of a steel or even titanium (hereinafter referred to as titanium alloys) barrel with an insert made of an alloy based on tungsten carbide can be realized.

Pre-billet preparation can be formed by 3D printing, followed by mechanical processing on high-precision machines.

Scientists at the Rhenish-Westphalian Technical University of Aachen and the Fraunhofer Institute for Laser Technology of the Community (Germany) have begun research on laser powder 3D printing with tungsten carbide and cobalt carbides. To do this, an upgraded version of a 3D laser printer is used, supplemented by emitters in the near infrared spectrum with a power of up to 12 kW, installed above the work area and heating the sintered layers. The emitters raise the temperature of the upper layer of the consumable material above 800 ° C, after which sintering lasers come into play.

One of the proposed scenarios for the use of such equipment is the integration of cooling channels directly into the manufactured tools and parts. The production of such structures by conventional sintering is either very expensive or technically impossible at all. The manufacture of such products using 3D printing technology by selective laser sintering allows you to equip them with internal cavities of complex shape.

The use of 3D printing with tungsten carbide and steel / titanium will allow the formation of internal cavities along the entire length of the barrel, which in turn will ensure its effective cooling, for example, by blowing air along the entire length, or even an analog of heat pipes used in modern electronics.

A heat pipe is a smooth-walled or porous closed pipe made of heat-conducting metal (e.g. copper) with a low-boiling liquid inside (from liquid helium for ultra-low temperatures to mercury or indium for high-temperature applications, in most cases, ammonia, water, methanol and ethanol are used). Heat transfer occurs due to the fact that the liquid evaporates on the hot end of the tube, absorbing the heat of vaporization, and condenses on the cold, from where it moves back to the hot end. Heat pipes with a filler (wicks, ceramics) can work in any position, since the liquid returns to the evaporation zone along the filler pores under the action of capillary forces

3D printing can also be used for the manufacture of the main parts of weapons, both plastic and metal. Elements of the receiver can be made with hidden cavities to cool the weapon and reduce its weight. Polymer elements can be made in the form of a honeycomb structure, again, to reduce the weight of the weapon, and / or with the aim of additionally absorbing the recoil momentum.

An increase in the recoil momentum compared to small arms using low-pulse cartridges of 5,45x39 mm or 5,56x45 mm caliber will require the comprehensive implementation of recoil compensation systems to an acceptable level.

First of all, it can be a silencer - a muzzle brake compensator (DTC) of a closed type, similar to what is supposed to be used in weapons developed under the NGSW program.

Automation circuits can also be implemented with an accumulation (offset) of recoil momentum providing accurate firing in short bursts at a high rate, or other advanced recoil damping / absorption systems.

Weapons with a biased recoil momentum: automatic machine AN-94, automatic machine TKB-0146, rifle G11

Interesting to consider is proposed by Alexei Tarasenko, recoil vibration absorption circuit.

No less difficult problem than the development of the weapon itself and the cartridge for it is the organization of large-scale production of promising ammunition. The production of advanced cartridges can be based both on the basis of classical improved automatic rotary lines, and on the basis of new technological solutions, using 3D printers capable of printing with metal and polymers, high-speed delta-robots, high-precision optical scanning systems that allow you to analyze received ammunition on the fly and sort them by accuracy class.

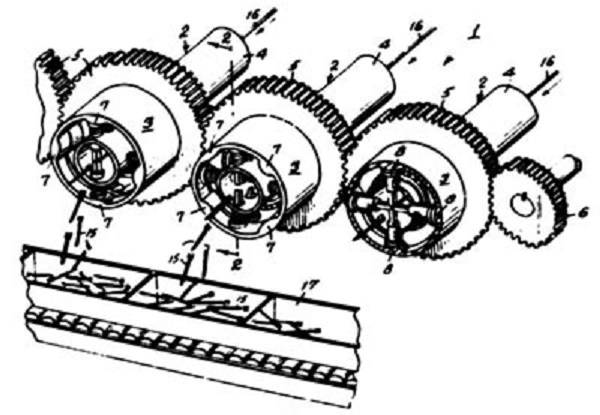

Drawing of a production line for the manufacture of feathered sub-caliber bullets

Production of plastic bullets on a 3D printer

It can be assumed that large-scale production of promising telescopic cartridges is not an unsolvable task, at least due to the fact that production of 30 mm caliber BOPs for automatic guns, which are also far from being sold in individual copies, has long been debugged. At the same time, the French-British consortium CTA International is already mass-producing telescopic ammunition for the 40 mm 40 CTAS automatic cannon, including a variant with BPS, and in the USA, Textron is preparing to produce telescopic cartridges for small arms under the NGSW program.

Also, do not worry about the shortage of tungsten for these purposes - its reserves are quite large in Russia, and more than large in neighboring China, with which we still have fairly smooth partnerships.

Distribution of reserves and volumes of tungsten production in Russia and in other countries of the world

As for the high cost of promising weapons and ammunition, this is quite normal for new equipment. In the end, everything depends on the criterion of cost-effectiveness, which shows how promising a weapon-cartridge complex surpasses existing models. At the initial stage, special units are equipped with promising weapons, then the most warring units, in parallel there is a refinement of the design and technological processes for the manufacture of weapons and ammunition in order to reduce their cost.

Without this, it is almost impossible to create a breakthrough weapon-cartridge complex. Recall how they reacted to the creation of the first assault rifles: they say that it is impossible to produce so many cartridges to provide them with an army armed with assault rifles, and what this led to in the future.

History is made in a spiral. Many designs and technologies that were previously discarded as unrealizable can be re-examined, taking into account the emergence of new materials and technological processes. It is possible that rethinking the feasibility of using feathered subcaliber bullets in a promising small arms in combination with the conical barrel of the Gerlich system at a new technological level will allow us to create small arms that are significantly superior to existing models made according to established traditional schemes and technological processes.

Information