The saga of the company mortar in the Red Army. Adoption

see the item for hammering nails!

It has extension and a certain mass!

But this will be the tenth, twentieth function of the object,

while using a slide rule

it could be considered!Y. S. Semenov “Seventeen Moments of Spring”

Periodically among enthusiasts interested in history and military affairs, and not only, discussions arise on the topic: what should a company/platoon mortar be like.

Was he needed?

Mortars have been in service with armies around the world for more than 100 years. Mortars of medium and large calibers (from 81/82 mm and more), which appeared back in the distant 20s of the twentieth century, still form a significant part of the artillery fleet and are widely used in military conflicts as close combat weapons (artillery systems).

But the experience of operating light mortars of 50 (60) mm caliber and less during the Second World War was considered unsuccessful; all the main armies of the world abandoned their use and removed them from service due to the weak destructive ability of mines (high-explosive action against wire barriers and a relatively small area of continuous destruction by shrapnel) and a short range of use (certified up to 800–1 m, the actual effective range of use was 000–400 m).

Only in the 1960s, during the Vietnam War, 81-mm mortars, which were in service with US infantry and airmobile units as a means of fire support, were considered unsuitable for conditions of maneuver warfare due to their weight - 48,6 kg. Due to low mobility due to the weight of the mortar and the limited amount of ammunition carried by the crew, the mortarmen could not provide timely fire support to the company throughout the entire depth of its combat mission.

For this reason, some of the M29 (81-mm) mortars were withdrawn from the units and, as a temporary measure, they were replaced with 60-mm mortars of the M2 and M19 models that were stored in warehouses.

In 1970, based on the experience of the Vietnam War, the Pentagon ordered the development of a more powerful 60 mm mortar system. The M224 mortar adopted for service was manufactured according to the classic “imaginary triangle” design and in many ways resembled its predecessor, the M19 (1943).

The following were newly developed:

– sighting system;

- a whole line of new 60-mm ammunition, superior to existing ones, both in firing range and in destructiveness of the warhead;

– a new fuse with adjustable detonation, providing the possibility of detonation at any given distance to the ground from 0,9 m to 3,6 m, and also triggered by contact with the surface or with a delay for firing at buried field fortifications with earthen filling;

– the centering thickening with grooves, which served to reduce the breakthrough of powder gases, was replaced by a plastic seal ring, fixed in a groove on the mine body;

– the shape and method of attaching additional charges have changed. The charge is now a cut ring and is placed directly on the stabilizer tube.

The range of use of the 60-mm mortar ranged from 70 to 3 m; mine weight from 490 kg.

In the Soviet Army, which was preparing for the massive use of nuclear weapons on the battlefield, according to the experience of the Great Patriotic War, light mortars were considered weapons that did not live up to the hopes placed on them, so the topic of light mortars for research and design work was closed.

In the 1970s, to increase the firepower of units in infantry battalions, 82-mm mortars began to be replaced by automatic mortar systems "Vasilyok" and 120-mm mortars mounted on vehicle and tracked chassis. The war in Afghanistan showed that in mountainous conditions there is nothing to replace 82 mm man-portable mortars; military theory has become somewhat divorced from practice.

To enhance the firepower of operational groups (GRU, Airborne Forces, etc.) fighting in Afghanistan outside the territories controlled by Soviet troops, in 1981 employees of the State Research Artillery Range developed a 60-mm silent-firing mortar, but the military not interested: low range (up to 500 m), “weak” fragmentation ammunition.

Let's figure out why this happened. And did the army need a company mortar of 50/60 mm caliber?

The concept of company armament in the first third of the 20th century

Based on the results of the First World War, military theorists made the following conclusions: it is objectively necessary that the commander of a rifle company have at his direct disposal “his own”, on the battlefield, directly subordinate only to him, portable heavy weapons of direct support * (hereinafter referred to as TONP). Using TONP, the company commander could, with a fire maneuver, quickly change the situation on the battlefield in his favor, without wasting time on coordinating with the higher command the use of fire weapons of battalion/regimental subordination.

In their absence, the company's stability in defense and attack was considered unsatisfactory.

Theorists included in the composition of TPO:

– mounted small-caliber machine guns (from which the German single machine gun grew): the task is to suppress the activity of enemy shooters at a distance of up to 800 m from occupied positions;

– grenade launchers (also known as man-portable mortars with a caliber of up to 50 mm), the task is to hit enemy shooters hiding behind uneven terrain or in trenches at a distance of up to 800 m from their occupied positions with fragments of grenades/mines;

- anti-tank rifles, which, in front of the company front, must stop/hit an enemy armored car or a tank with at least bulletproof armor at a distance of up to 300 m. I remind you that, apart from a kinetic impact with a bullet/shell, at that time there were no other methods of remotely destroying armored vehicles and tanks. And the idea of creating tanks with shell-resistant armor was realized only closer to the mid-30s.

* Heavy weapons of direct support - they are also group weapons, served by crews of two or more people, moved across the battlefield along with ammunition only by people, without the help of horses and vehicles. This includes heavy machine guns, grenade launchers, light and medium mortars, as well as man-portable anti-tank weapons.

The reference is compiled on the basis of materials posted on the Internet (links are provided whenever possible: some materials are copied one to one on many sites, and it is not clear which of them is the author), and an article by K. V. Cherentsova (St. Petersburg) “From the history of the creation of 50-mm company mortars by Special Design Bureau No. 4 of the Leningrad Machine-Building Plant No. 7 (1936–1940)».

Adoption of light mortars in the Red Army

As the USSR economy recovered, back in the 20s of the last century, funding began for work to improve weapons, including in the field of artillery. Among the military equipment inherited by the Red Army from the army of the Russian Empire and adopted for service, there were mortars with a caliber of 58 mm (in total, 1915 units were manufactured in 1917–3) and 421 mm (in 90–1915, 1917 were manufactured 12 units). These mortars were used on the battlefields of the Civil War in 519–1918 and were in service with the Red Army until 1922.

Since 1927, Group “D” of the Gas Dynamics Laboratory, located in Leningrad, began to work purposefully on the topic of mortars. Its director was N.A. Dorovlev, hence the laboratory index. In October 1929, a Soviet-Chinese armed conflict began on the CER. During the fighting, Red Army units captured several dozen Chinese mortars of the Stokes-Brandt system (81-mm, 107-mm and 152-mm caliber) and hundreds of mines for them.

Based on the results of tests of captured systems carried out by specialists from group "D", mortar designs were developed: company - 60 mm, battalion - 76 mm and 82 mm, and regimental - 120 mm. Already in 1931, the first tests of the developed 82-mm mortar were carried out.

Dorovlev sent working drawings of a 60-mm company mortar to the Art Directorate of the Red Army on January 19, 1932. But the 60-mm mortar samples developed by the laboratory, based on the test results, did not suit the military - low accuracy. As a result, interest in the company mortar faded away, and the laboratory focused on 82-mm, 107-mm and 120-mm mortars.

The production base for the production of prototypes of mortars was initially the Bolshevik plant and Mechanical Plant No. 7 (Leningrad). Since 1932, experimental production of melee guns based on the projects of the “D” group was concentrated at the “Red October” plant (Kharkov, Ukrainian SSR), where a special design bureau was created, which accompanied the introduction into production of products developed by the “D” group.

In this design bureau, under the leadership of engineer B.I. Shavyrin, work was carried out on an initiative basis to design and manufacture: an 82-mm battalion mortar and a 107-mm long-range chemical mortar, and ammunition for them. Serial production of cast iron 107-mm mines developed by SKB was mastered in 1934 at the Kharkov plant "Porshen", previously all mines were sharpened from steel.

Since 1934, the Red October plant was assigned to the People's Commissariat of Local Industry of the Ukrainian SSR, which introduced significant difficulties in the speed and quality of communications between SKB and the production facility where prototypes based on its developments were manufactured.

By the mid-30s, among the specialists of the Art Committee of the Red Army, the opinion was established that it was necessary to replace the Dyakonov grenade launcher (rifle grenade launcher), which they shared with specialists from subordinate factories. The agents reported that in almost all armies of capitalist states (Germany, Italy, Poland, USA, France, Japan, etc.) the infantry company is armed with light mobile melee weapons with a caliber of 50 mm or less. These guns, firing along a mounted or flat trajectory, complemented the company's fire system and allowed it to independently carry out some tasks without involving artillery units for this. In the USSR, work on a light/company mortar has resumed.

By the end of 1935, on the initiative of B.I. Shavyrin, the new location of the SKB was determined to be the Leningrad State Machine-Building Plant No. 7, and Shavyrin himself was appointed its head. In 1936, Plant No. 7 produced prototypes of the new 60-mm company mortar "60-RM", developed on the basis of the drawings of group "D". At the end of 1936, the mortar passed field tests at NIAP (Scientific Test Artillery Range of the Red Army). The mortar did not pass the tests due to poor stability, unsatisfactory accuracy and fragility of the shock absorber.

On May 20, 1937, tactical and technical requirements (TTT) were sent to Plant No. 7 for the design of a 50-mm grenade launcher (mortar)* and a fragmentation grenade for it. The new system was intended to arm small infantry units and was supposed to provide mounted fire at enemy personnel and firing points.

The main requirements for the grenade launcher were lightness, portability and ease of use, as well as simplicity and low cost of production. The system had to provide a firing range of at least 800 m and a rate of fire of at least 20 rounds per minute.

The grenade launcher had to allow for firing from a sitting or lying position, ensure ease of carrying on the back, and its design had to allow for high speed of preparation for battle and rapid transfer of fire from one target to another. The 50 mm fragmentation grenade was supposed to have a shock effect and provide a ground explosion with damage on any terrain. The production of grenades was supposed to be simple and cheap.

* The term “mortar” had not yet become commonly used in the mid-30s; the term “grenade launcher” was more often used.

The design bureau at plant No. 7 again reworked the drawings of the 60-RM mortar. At the end of 1937 - beginning of 1938, successful factory tests of a 60-mm company mortar from Plant No. 7 were carried out at NIAP.

At the end of 1937, the GAU approved the basic scheme of mortar armament of the Red Army, on the basis of which in January 1938 they developed (tactical and technical requirements) TTT No. 33 for a company mortar (grenade launcher), which indicated the following characteristics:

– caliber – 50 mm;

– weight of the feathered projectile (mines: fragmentation, smoke) – 1 kg;

– longest firing range – 800 m;

– shortest range – 100 m;

– elevation angle – from 45° to 80°;

– rate of fire – 30 rounds per minute;

– system weight – 8 kg.

The new TTT pointed out the need to develop two ways to change the firing range: using a remote tap through different combinations of changing the volume of the chamber, elevation angles and the position of the remote tap. As a sight, it was proposed to use a level to control the elevation angle and a simple sighting device for horizontal aiming.

General Staff Directive No. 43557 of March 16, 1938 ordered comparative tests of various types of mortars and grenade launchers, which took place at the end of May 1938. The tests were aimed at selecting from among the samples being developed one that most corresponds to the tactical and technical requirements. The tests were carried out from March 25.03.1938, 03.04.1938 to April XNUMX, XNUMX. The following samples were submitted for testing:

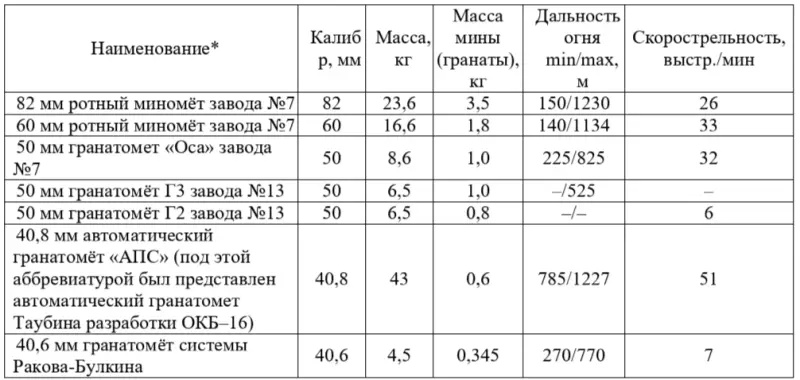

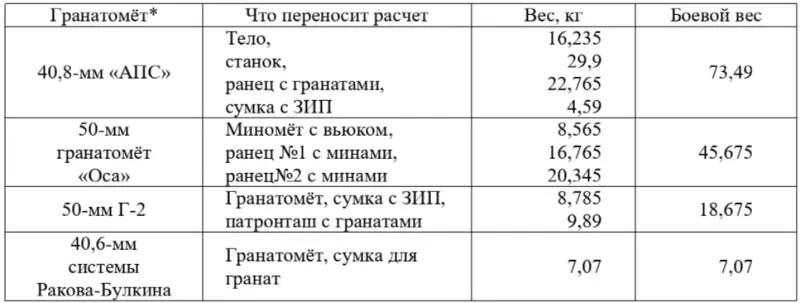

Table 1. Comparative tactical and technical characteristics of the tested samples.

Table 2. Indicators of combat weight of systems.

Readers interested in the details of the tests are referred to the article in the magazine Kalashnikov. Weapons, ammunition, equipment. No. 2, 2012, p. 87. Tables No. 1 and 2 are taken from the same source.

Based on the test results, the 50-mm Osa mortar from Factory No. 7 was declared the winner.

Let us dwell in more detail on the test results of mortars of 50, 60 and 82 mm caliber.

From the commission's conclusion:

• “The 82-mm mortar from plant No. 7 does not meet the technical specifications for the following indicators:

– heavy system (23,6 kg);

– heavy ammunition – two soldiers can carry no more than 12 mines;

– large crew – 4 numbers and a commander;

– difficulty in delivering ammunition in battle due to its heavy weight.”

• “The 60-mm mortar from plant No. 7 was found unsatisfactory:

– heavy system;

– heavy ammunition, as a result of which a crew of 4 people can carry no more than 20 minutes;

– a developed mine produces too small fragments when it explodes;

– difficulty in delivering ammunition in battle due to its heavy weight.”

• “The 50-mm Osa grenade launcher was found satisfactory. The grenade launcher is capable of conducting overhead fire at a range of 100–800 m. The crew of the grenade launcher is 2 people. They can carry 14 grenades (mines) in pouches, and, if necessary, also a pack of 42 grenades, which allows them to hit 5-6 targets.

The grenade launcher also showed satisfactory results when shooting at box-shaped and flat targets. In order to increase stability during testing, the grenade launcher was modified - the front opener was replaced with a two-legged support. As a result, the stability of the grenade launcher has improved, and the sight no longer goes astray when firing. The rate of fire of the grenade launcher was 30 rounds per minute.”

Thus, according to the test results, the 50-mm Osa grenade launcher SKB-4 from plant No. 7 was recognized as the only option for further testing.

It was necessary to make a number of changes to the design of the mortar: to fully develop the components of the shot (mine, charge, fuse), to introduce a sight into the design, to change the design of the support biped (modeled on a 60-mm company mortar), to work out the scales of the remote crane, to design new devices for carrying, make 200 mines. and work out the charges for them.

The deadline for finalizing the system and ammunition is August 1, 1938. On a pilot series of 30 pcs. grenade launchers, the drawings had to be worked out and mass production of the systems began.

If we compare the main characteristics of the Dyakonov grenade launcher and the 50-mm Osa mortar: weight 8,2 kg (grenade launcher complete with rifle) and 8,6 kg (mortar), ammunition weight 0,33 kg (grenade launcher) and 1,0 kg (mortar), the firing range of both types of weapons is up to 800 m, it becomes clear that the military experts of Artkom had no understanding of the peculiarities of using mortars, and the replacement of a grenade launcher with a mortar was done in the style of “being no worse than others.”

Military tests of the Osa grenade launcher were carried out in the Transcaucasian and Leningrad military districts. Based on their results, according to the Scientific and Technical Journal (NTJ) of the Red Army AU No. 0177 dated September 1, 1938, the system was put into service as a “50-mm company mortar mod. 1938."

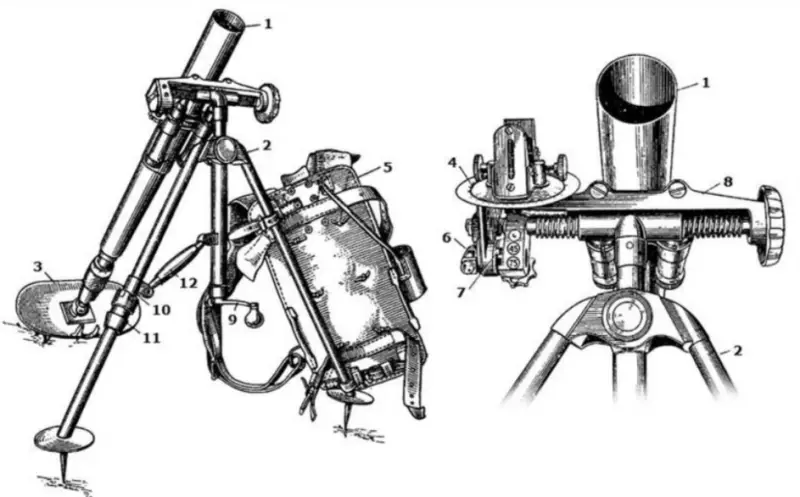

1 – mortar barrel; 2 – biped; 3 – plate; 4 – sight; 5 – pack for carrying the system; 6 – sight level; 7 – protrusion of the sight bracket; 8 – swivel; 9 – handle of the lifting mechanism; 10 – clamping sleeve; 11 – clamping sleeve nut; 12 – bushing.

50-mm company mortar RM-38 "Osa"

Simultaneously with the Shavyrin bureau, plant No. 50 engineer V.N. Shamarin, who first worked at SKB-7, then moved to the artillery design bureau of the plant (under the leadership of L.I. Gorlitsky), joined the creation of a 4-mm company mortar on his own initiative. On January 12, 1938, one prototype of a 50-mm mortar designed by V.N. Shamarin was sent for factory testing. In May 1939, field tests were carried out at NIAP.

The fundamental difference between this system and the standard 50-mm company mortar RM-38 (design SKB-4) was a different type of remote crane device (valve type) and a simpler leveling mechanism. The ballistic characteristics also differed from the 50-mm mortar adopted for service.

50 mm rotary mortar PM-41

The V.N. Shamarin system (RM-41) with a barrel elevation angle of 50° and the corresponding settings of the remote crane made it possible to fire at a distance (in meters) of 100, 120, 140, 160, 180, 200, 300, 400, 500, 600 , 700, 800. At an elevation angle of 75°, the firing range with the same crane settings will be half as large.

In September 1939, to resolve the issue of choosing the best design of a 50-mm company mortar for a serial order for 1940, comparative tests of the RM-38 and RM-41 were carried out at ANIOP. Based on the results of tests during 23 firings, the best ballistic qualities were demonstrated by a prototype of a 50-mm company mortar designed by V. N. Shamarin. In general, this system largely satisfied the characteristics specified in TTT No. 33 and in terms of weight.

During the Soviet-Finnish War (1939–1940), the combat use of a 50-mm company mortar mod. 1938 revealed a number of design flaws:

• long minimum range (200 m);

• had a relatively large weight;

• had large dimensions, which made it difficult to camouflage;

• the remote crane device is too complex;

• the scale of the remote tap did not correspond to the range;

• the outlet hole in the remote valve is directed downward and forward, due to which, when firing, the escaping gases, hitting the ground, raised dust (snow) and thereby made the work of the crew difficult;

• unreliable and complex sight mount;

• weakness of ammunition.

SKB-4 promptly responded to the military’s comments and modified the RM-38. On February 27, 1940, tests took place in the combat area of the 85th Infantry Regiment of the 100th Division. According to their results, the 50-mm company mortar “recovered” to 11,5 kg, and was “recommended as the best existing model of company mortars for arming active armies with it” (in the Commission Act this system was called “Osa-40”).

On April 26, 1940, at a plenary meeting of the GVS RKKA (Main Military Council of the Red Army), a decision was made on the need to modernize the 50-mm company mortar for the purpose of removing gases, and from two design options - B. I. Shavyrin and V. N. Shamarin - K E. Voroshilov was instructed to choose the latter option.

At the end of April 1940, SKB-4 was disbanded, work on improving 50-mm company mortars continued in the department of the chief designer of plant No. 7. In parallel with this, work was carried out on company systems at NII-13, where the VIII mortar department was organized, which headed by B.I. Shavyrin.

Serial production of a 50-mm company mortar mod. 1938 began in 1939, when 1 units were delivered. By August 715, 1, 1940 mortars were manufactured, and in just one year - 18 units. As of January 994, 27, the GAU KA had 805 mortars on its balance sheet, of which 1 required routine repairs, 1941 needed major repairs, and 29 were subject to write-off. Between 340 and 227, more than 90 thousand model mortars were produced. 11.

The ammunition loads of the 50-mm RM-41 mortar and mortars of the 1938 and 1940 models are absolutely identical and consist of a steel six-feather fragmentation mine 0-822 and a cast iron four-feather fragmentation mine 0-822A.

50-mm four-fin fragmentation mine arr. 1938 O-822 weighing 922 grams was equipped with a 90-gram TNT charge. The charge of gunpowder in the tail cartridge of the mortar weighed four and a half grams. However, these four and a half grams were enough to make the mine fly out of the barrel at a speed of 97 m/s, rise to a height of 216 meters and then fall 800 meters from the mortar.

Subsequently, in 1940, the six-fin mine O-822Sh mod. 1940, which had an 850-gram mass and a tail charge reduced to 4 g. Its firing range did not differ from the firing range of the four-feathered one.

Due to lack of effectiveness, 50-mm company mortars were withdrawn from service in 1943, when Soviet troops began massive offensive operations in the second half of the Great Patriotic War.

Explanation of why the Red Army chose the 50-mm mortar

By the end of the 30s, the Red Army infantry was still in an orphan position in terms of logistics - trucks went primarily to artillery and armored forces.

Therefore, the painters believed that TONP* (see above) should be wearable not only on the battlefield, but also in marching formations, i.e., be as light as possible. For the infantry, it was primarily planned to transport ammunition and food. The rifle company had to carry all its weapons independently.

Of course, according to regulatory documents, for the transportation of mortars, machine guns and ammunition there were horse-drawn carts assigned to the crews, but in fact they were listed in the service platoon according to the battalion staff, along with field kitchens and a food train. The Kraskoms perfectly understood the realities of army life.

Продолжение следует ...

Information