Bolter and bolt bullet

"And the bullet is ... Leaky!" - http://topwar.ru/30331-a-pulya-to-dyryavaya.html

"Sailing bullet" - http://topwar.ru/34895-parusnaya-pulya.html

So let's continue the topic.

We continue with the lyrical introduction

“And the bullet is ... again full of holes !!!”, once again the orthodoxy from artillery and criticism-amateurs on the forums will say, having read this, already the third, article from the series “Weapon from the Pass”.

And again they will be right, indeed the bolt-bullet remained full of holes, but at the same time it flies much better than usual.

They will not convince even the video will be repeated about the installation and special effects.

Yes, "let them say," "dogs bark, but the caravan goes anyway."

If this material had appeared in some Western edition, everyone would have started breathing to talk about a landmark invention. But alas, I am Russian and the idea was born in Russia, respectively, if ordinary Russian Ivan did it, then this is all nonsense, nonsense. In general, I have been through it many times and do not take offense, I perceive it as a harsh Russian reality.

Someone might think, they say, another unrecognized genius appeared, but here's the real storyalthough it is not related to the topic of small arms, closer to the topic of cybernetic, and yet it is a good example of how we do business here.

I am a programmer and do cryptography among other things. About four years ago I managed to increase the speed of the communication channel encoder (according to GOST 28147-89) dozens of times, while significantly improving the security of the encoder.

Two patents have been obtained for this invention, it is now officially used in a commercial product, the firewall "Continent", and has been certified by the FSB. Everything is as it should be, but, it is now, four years later. And in the beginning, it is better not to remember how much time and effort it took me to implement this idea into the brains of specialists.

A new way to implement crypto functions was introduced in the area where I am a professional, where everyone knows who R_T_T is, and nevertheless, the efforts to push the specialists of this invention into the brains were spent much more than went into the realization of the idea itself.

And even now, many “specialists” continue to talk with aspiration about Western encryption methods, unaware that we, Russians, have a much more efficient solution. Moreover, it is already actively used, however, the author himself finds out about it by chance.

With the topic of aerodynamic acceleration apparently something similar will happen. I will spend a lot of energy on introducing it into the brains of mossy specialists, and as a result, the author, in five to ten years, will not even remember. But I'm not mad, let them use it, it's a shame to spend time fighting fools and not solving specific technical problems.

From the lyrical introduction I, as always, turned out to be “the weeping of Yaroslavna”, but having lost snot and tears, we will continue our sorrowful work.

Bolter and his bolt-bullet

Such a "shaven" Russian conscript turned out to be from the American "recruit", for shooting sailing bullets.

But this, nevertheless, is just an air rifle on an external carbon dioxide cylinder.

Under the aerodynamic acceleration of modifications was not carried out, fired from what was designed for the usual bullet pneumatics.

In a previous article, the transfer of a rifle to the use of carbon dioxide instead of compressed air was described. This transition, in addition to the convenience of further experiments, pursued a more important goal: to check the degree of increase in the efficiency of aerodynamic acceleration when using gas with a higher density.

In a previous article, the transfer of a rifle to the use of carbon dioxide instead of compressed air was described. This transition, in addition to the convenience of further experiments, pursued a more important goal: to check the degree of increase in the efficiency of aerodynamic acceleration when using gas with a higher density. For piston acceleration, the properties of gas (its specific density) in the barrel have practically no role, but for aerodynamic acceleration, this characteristic is fundamental.

The benefit of using carbon dioxide is due to the fact that it is heavier than air 1,5 times under the same conditions (equal pressures and temperatures). During aerodynamic acceleration, in contrast to piston acceleration, the density of the gas jet falling on the sailing surfaces is of fundamental importance, and the energy of the gas jet to the pool is transferred to them. And the kinetic energy of gases is greater the greater their mass.

The effect of increasing the power of the shot using carbon dioxide was obtained and demonstrated in the video in a previous article.

For aerodynamic acceleration there is another obvious way to increase the power of the shot without increasing the pressure in the barrel. We are talking about increasing the volume of gas used for the shot. If we talk about piston acceleration, then only the gas that is in the barrel and is limited to the bottom of the bullet participates in the shot.

The aerodynamic bullet is “full of holes” and compressed gas can pass between the walls of the barrel and the body of the bullet flowing around the sailing surfaces. Gas flowing around the sailing surfaces, gives them its kinetic energy and the more it passes, the more energy it will inform the pool. So for a sailing bullet it is important not only the pressure and density of the gas, but also the volume of compressed gas involved in the shot.

While the rifles are developed for a standard piston bullet, respectively, its mechanism provides a small amount of compressed gas to the barrel, this is not enough for aerodynamic acceleration, the sailing bullet needs much more gas.

Therefore, it was the turn of special modifications, from an ordinary rifle we will make the world's first real "BOLTER", and a special "BOLT-BULL" for firing from it.

As the saying goes, "what is good for the Russian, death for the German." In order to adapt the rifle to the specifics of aerodynamic acceleration, special modifications were made, after which the bolt-bullet became “good”. But the possibility of firing ordinary lead bullets after the modifications has disappeared, as they say, "she died forever."

There was only the possibility of shooting steel balls, and that, only because the rammer of the bullet has a magnetic pusher.

The power of the dark side of aerodynamic power

"And now, appreciate the power of the dark side of the aerodynamic force," so said the Emperor from the movie "Star Wars."

True, about aerodynamics, I have already added from myself that it was more understandable. But the essence remains the same.

He shot at a reinforced professional flooring 0.9mm thick. This is a serious test, even from a short distance of 5 meters.

Holes turned out with a diameter of 5mm. With a real bolt-bullet diameter in 4,4mm., This is unusual for a rifle bullet.

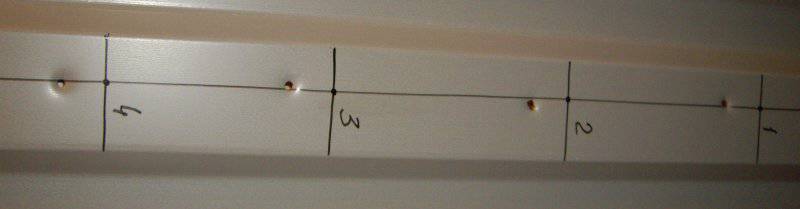

Below is a photo of a real shooting from a bolter. Four breakthroughs from bolt-bullets, while the first two shots are weaker. Although the first bullet pierced the metal, it rebounded, while the second one overturned and collided with a target. The rest of the bullets began to pierce a sheet of metal through. Such a variation in power is due to the presence of air in the hose when connected to a rifle, respectively, the first shots were fired with air, and the shot power was significantly less.

Shooting was made from five meters, I do not have a greater distance in a straight line in the kitchen. Indirectly, the shooting power of a bolt-bullet can be estimated from the breakdown of a steel sheet of professional flooring 0.9mm thick., Such a sheet is an air rifle caliber 4.5mm. It does not pierce, even at close range, how much gas is not pumped into it.

The power of the bolt-bullet is already approaching the power of a small-caliber rifle shot.

We’re not going to talk about accuracy yet, there’s nowhere to take it, a homemade bullet dangles in the barrel, balancing it is done what is called “by eye”. You can estimate the accuracy by the deviation from the aiming mark on the target (the point in the line crossing); the light marker was calibrated along the axis line of the bore.

And do not think that I am so accurate, I shot from an improvised “machine tool” made of a vice screwed to the window sill, into which I clamped the rifle barrel, my hands and myopic eyes will certainly not provide such accuracy.

Now more about the modifications that turned the air rifle into a bolter and about the bolt pool itself.

Now more about the modifications that turned the air rifle into a bolter and about the bolt pool itself.Bolter

To begin with, once again, I walked around the grinder on a rifle, and cut down the remaining unnecessary parts at the root, that's what happened as a result, it looks brutal.

Already a real Russian "recruit" and not some kind of American "recruit".

Cosmetic changes have touched the point of connection of the high-pressure pneumatic hose and the design of the receiver of bullets.

Bolt-bullets are significantly longer than standard bullets for pneumatics, it’s impossible to insert them into the breech in the usual way, and in the old manner, through the barrel, it’s somehow embarrassing to load the weapons of the third millennium. Therefore, the bolt-bullet receiver was redone, besides this, an optical sight was removed, it prevented the weapon from being charged.

Instead, he put the LCC (Laser Target Indicator), at short distances it is more convenient. Well, and improved the grip ergonomics, changing the configuration of the forearm and handles, it became almost a pistol type. Now the product lies in the hands as poured.

But this is just a makeup, the pool is neither hot, nor cold ...

Technological refinement of the rifle to the level of the bolter was made in terms of increasing the volume of the gas charge, flow sections and configuration of the caster. For a classic piston acceleration system, such a modernization is practically useless, but for aerodynamic acceleration, these modifications are very important and directly affect the power of a bolter shot.

A few explanations for those not familiar with the device pneumatics, here's a cut of such a rifle:

In addition to the barrel in pneumatics, a valve is involved in the shot, which is connected to the trigger and an accumulation tank for compressed gas. When you press the trigger opens the valve and the entire volume of gas from the storage tank goes into the barrel, through the bypass hole, pushing a bullet out of the barrel like a conventional firearm. In other words, the power of the shot is determined by the parameters of the valve, as well as the pressure and volume of gas in the storage tank.

With a valve, everything is simple, the faster it opens and the larger the orifice in it, the faster and with less losses to “bypass” the gas energy from the storage tank will go to the receiver and will accelerate the bullet. Therefore, the Recruiter drummer was weighted, and his spring was strengthened. This was the first revision.

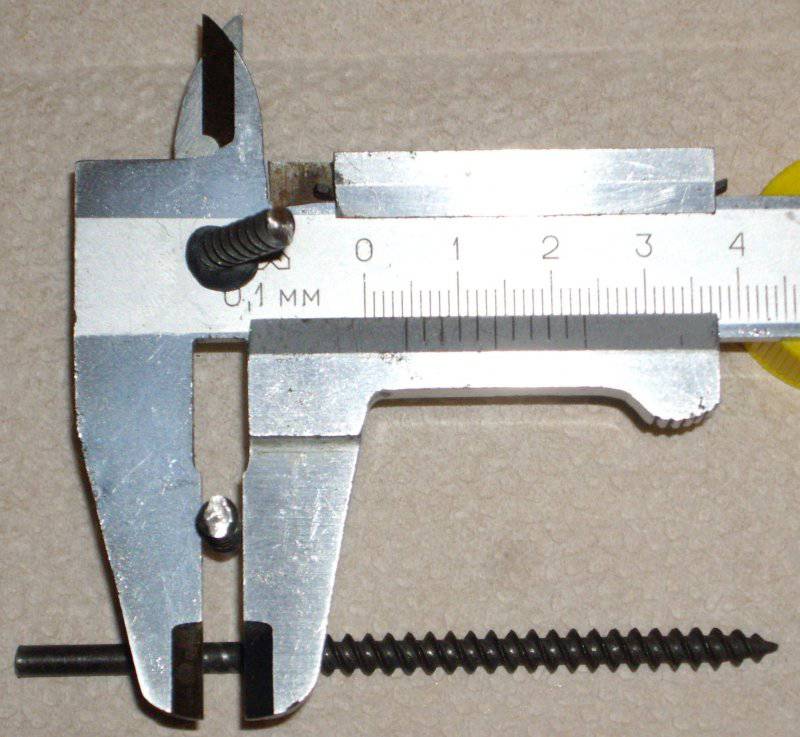

The second refinement was the increase in the cross section of the bypass channel. In the Recruit rifle, the valve bypass valve was 3 millimeter in diameter, after upgrading the Conscript bolter became the owner of the bypass hole in 5 millimeters, such as a minor revision, but the gas passage area increased two and a half times (quadratic dependencies). Accordingly, gas from the storage tank quickly began to fall into the barrel two and a half times faster.

For a piston acceleration system, an increase in the perforations for compressed gas is not a significant factor, but for aerodynamic acceleration it is a very important parameter, it determines the speed of the outflow of the gas jet through the sailing surfaces and, accordingly, the acceleration of the bolt-bullet.

The third refinement was the change in the configuration of the stump part of the barrel, where the bullet is at the time of opening the valve and feeding high-pressure gas into the barrel. The kazetnik, in the area of the bypass hole, was bored out under the diameter 6mm.

Accordingly, the lead bullet in the initial position, due to its small length, began to buckle and wedge at the moment of the shot. They can not shoot a bolter now. The ball is naturally difficult to mow, and it is held by the magnet on the rammer in the right position, so this refinement is not critical for shooting balls.

For an elongated bolt-bullet, this is an important refinement, the fact is that gas enters the barrel from the side (usually a bypass hole at the bottom of the barrel) and when the bullet starts to move, it tritely presses against the wall of the barrel with a stream of gas from the bypass. In order to loosen this clamping, the coaster was drilled and the rammer himself was shifted so that the sailing bullet did not fall into the cross section of the bypass hole.

The fourth, most important refinement was the increase in the volume of the storage tank, its volume increased from 5 to 10 cubic centimeters. Accordingly, one shot was spent twice as much gas. For a conventional bullet, this will lead to an increase in the power of interest on 10, everything else goes to “nowhere”, is simply lost (goes to “beep”). But for aerodynamic acceleration this additional volume of compressed gas will increase the energy of the shot exactly twice due to the transfer of part of its energy to the sailing surfaces of the bullet.

Theoretically, naturally, what happened in reality was visible on the shooting video. So to say, the criterion of truth is practice, the power of the shot doubled, of course, did not increase, it boosted the percentage of 50, which is also a very decent result.

Bolt bullet

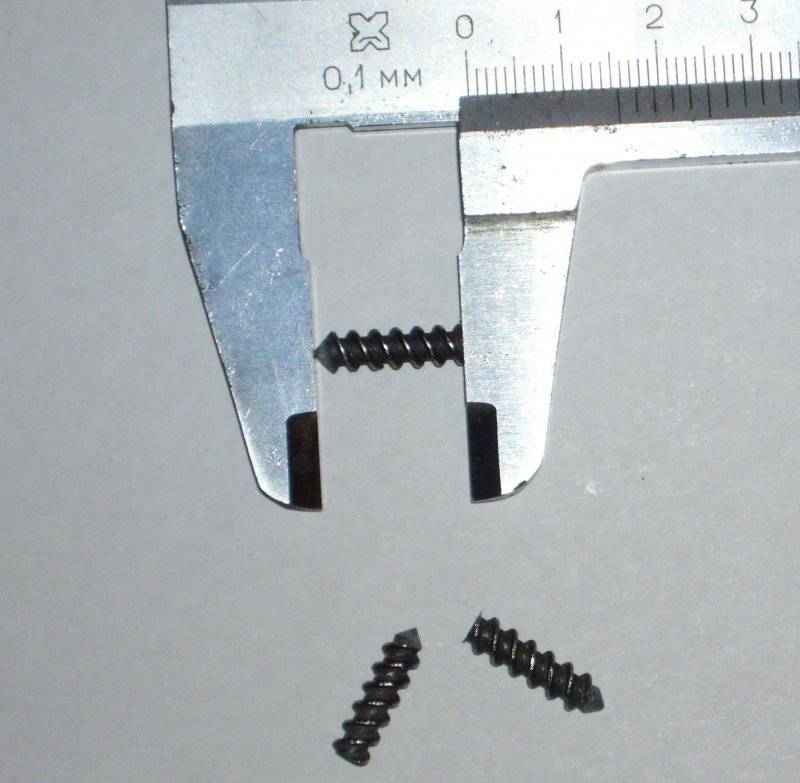

Sharpened a bolt-bullet from a self-tapping screw with a diameter of 4.8mm, manually sharpened, as always, using an electric drill, a file, and “some kind of mother”.

Grandfathers - turner refused to grind off Chinese hot metal, and cannot even find grinding machines in Russia in the “afternoon with fire” ...

The gap between the barrel and the bullet is too big, the pitch, height and profile of the thread are not optimal, but for now it will do.

There is no limit for perfection and we will leave it for the future, for subsequent, already specially carved, bolt-bullets.

The bolt-bullet has become longer, the size has increased from 12 to 15mm. and it now has an 3 turn of a pair of oppositional rifling, this is a true bolt-bullet, albeit a primitive one. The problem of stability of a bolt bullet in flight and during target breakdown at such long / diameter ratios (1: 3,5) has disappeared due to the increased speed of rotation and the resulting axial balancing.

Axial balancing was achieved through the use of exotic and rare self-tapping screws with two symmetrically arranged grooves (two-thread thread).

The real diameter of the thread edge was about 4.4mm., The gap in 0,1mm. in the barrel for a bullet too big, of course, but it was not possible to provide more “knee” technology. The weight of a bolt-bullet is two grams, this is serious, not a single ordinary air rifle will accelerate such a bullet to acceptable speeds for a shot.

Speed for a bolt-bullet is important. And two speeds, flight speed and rotation speed. The faster the bullet rotates, the more stable it is in flight and in a collision with a target, due to the gyroscopic effect. Since the bolt-bullet has sailing surfaces and rotates, then in flight it will work as a “propeller”, this is of course bad, but the negative braking effect will be only at subsonic speeds. As soon as, instead of aerodynamic wrap, a shock wave begins to form on the tip of the bullet, the effect from the negative will begin to turn into a positive one.

The laws of physics will not deceive, the friction will remain, but not the energy of translational motion, but the energy of rotational energy will be wasted on friction, the bullet will start to decrease its rotation speed due to friction. This is not so scary, this energy can be stored in abundance and it will not be wasted.

In reality, holes with a diameter of 5 millimeters with a bolt-bullet diameter of 4.4 millimeters formed in the steel plate. This happened due to the rotation of the bolt-bullet around its axis with precession, so that the rotational energy of the bolt-bullet is also transferred to the target, and not lost. Only it is spent not on breakdown, but on increasing the diameter of the breakdown, which ultimately is the same on real targets.

In custody

The main thing is bolt-bullets.

While bolt-bullets are made in an artisanal way from a less suitable self-tapping screw.

Apparently in the future they will have to order the hardware production, where they make screws.

Let them be not the most perfect, but at the cost of a penny (in modern times, the ruble).

Screws with two opposition threads (even better with three) will be just right, because they solve the problem of centering the bullet relative to the axis of rotation. You just have to order special matrices for toolmaking for their rolling, but this is not a problem. This is only time and money, all this can be found, since "such a suit has gone."

And of course it will be necessary to turn the current "recruit" into a real Russian "recruit", with whom it is convenient to train, it is not a shame to speak at official competitions and use them effectively in hunting.

To do this, you have to transfer the bolter to normal compressed air. Carbon dioxide does not “work” at low temperatures, its pressure drops to 30 atmospheres at low temperatures due to condensation, and compressed air with decreasing temperature keeps the pressure almost unchanged.

Accordingly, when switching to compressed air, the working pressure in the barrel of the rifle will be around 150 atmospheres against 60 at the present time.

Standard modern cylinders are designed for 300 atmospheres, a liter cylinder (empty weight about a kilogram) is enough for 100-150 shots with full power (using the gearbox on 150 atmospheres naturally).

You can of course put the gearbox on the 300 atmospheres, the strength of the shot will increase significantly, but then the gas consumption will double, and the energy of the bolt-bullet will constantly decrease, knocking down the sight. For practical shooting, this is certainly not an option.

So when I do everything slowly, I will undoubtedly accomplish and take pictures, but with the involvement of professionals, the topic has outgrown the “kitchen level” and “on the knee” I will not do anything more.

Information