Why T-34 lost to PzKpfw III, but won against Tigers and Panthers. About T-34M and wide tower chase

Did the Red Army understand the disadvantages of T-34? Of course. As a matter of fact, already the resolution No. 443ss "On the Adoption of Tanks, Armored Machines, Arttyagachs for the Red Army and on their Production in 1940” from December 19 1939, according to which T-34 was adopted, already contained a list of changes that should have been added to the design of the tank before its mass production began. The same document set a plan for the release of the thirty-fours on 1940 g - 220 units.

Interestingly, the T-34 was adopted even before the start of military trials, which were planned to begin on January 25 1940, but in fact they were launched only on February 13. Of course, during the tests, the observed shortcomings multiplied. During the “running in” of prototypes held in February of 1940, it became clear that the machine would not be ready for the government show scheduled for March of the same year. The first copies of the T-34 did not have time to complete the mandatory test program with mileage 2 000 km. Then the decision was made to send an 2 experienced tank from Kharkov to Moscow under its own power in order to “wind up the counter”, but during this run, the suspension had significant problems: for example, Belgorod had one of the main clutches in one of the cars.

Some historians claim that this was due to the driver’s fault, but generally speaking, the tanks were driven by mechanic testers with exceptional driving experience, who, among other things, “drove” hundreds of kilometers into the T-34 before the start of the race. Consequently, the error looks dubious, and if it was a mistake, it indicates the extreme complexity of management: it is clear that one should not have expected testing qualifications from combat mechanics.

The cars arrived in Moscow on 17 March 1940, and Joseph Vissarionovich Stalin liked them, although the flaws of the machines were not a secret to him. Deputy Director of Defense G.I. insistently pointed out to them both him and Lavrenty Pavlovich Beria who were present there. Kulik and D.G. Pavlov. The latter generally stated: "We will pay dearly for the production of insufficiently combat-ready machines." However, I.V. Stalin ordered that the plant No. XXUMX provide all necessary assistance in correcting the deficiencies of the T-183 and no measures were taken to postpone its mass production. On the contrary, according to further instructions, the production plan of the T-34 on 34 was constantly increased, first to 1940, and then, in early June, to 300 g - and to 1940 machines.

Thus, we see a very strange picture at first glance - a tank that is not fully expressed yet is first put into service, and then launched into a series. How reasonable was this decision? Based on our usual realities - of course, no matter how much.

But in those years ... The first thing I would like to draw attention to is that World War II was in full swing in Europe. True, in March 1940 g still lasted for a lull, since Poland had already fallen, and the invasion of France had not yet begun, but the parties were obviously accumulating strength and preparing for battle. There were no prerequisites for a peaceful, political solution to the conflict. Well, June 7, when the decision was issued, which increased the serial production of T-34 to 600 machines by the end of the year, the French army was already obviously broken and agonized, that is, it became clear that the conflict in the West was not prolonged, and that now only the Red Army stands between Wehrmacht and absolute military domination of the continent.

The second important aspect is the readiness of the domestic industry to release "thirty-five". We should not forget that for this, our plants had to make a very big leap into the future, and this is the point. Until recently, the medium tank T-35 was the heaviest domestic tank (apart from the very small series T-28 monster). It was a very difficult machine to manufacture, so its production was launched at a single Kirov factory (formerly Putilovsky). At that time, this enterprise had the best production capacity, and the qualification of Putilov workers was probably the highest among factories of a similar profile in the USSR. By the time production began, the T-28 plant, in addition to other products, had already produced 9 for years.

However, the production of T-28 was faced with enormous difficulties, which can be divided into 2 groups. The first was based on flaws in the structure, which caused many changes to be made during serial production. The second group could be called the problems of production, and they concerned not only the Kirov factory itself, but also many of its subcontractors who participated in the production of the newest at that time combat vehicle. So, it took a lot of time to eradicate all these problems, which was measured not even months, but years.

It was planned that the Kirov Plant would launch mass production of the T-28 in 1933, but in fact it was possible only in 1934, and the first domestic medium tank was saved from numerous childhood diseases only by 1936.

So, according to the plans of 1940, it was supposed to launch the production of T-34 in two factories: Kharkov Machine-Building (№183) and the Stalingrad Tractor Plant named after Dzerzhinsky (STZ). Plant No.183 was in the best position, since before this it produced the BT-7 tanks, but the STZ only tractor and tracked tractors. But the fact is that the BT-7, as you know, was just a light tank that had almost twice as little weight as the T-34 and a carburetor engine instead of a diesel engine (however, the BT-7M, produced in 1940 g, was all the same diesel B-2). In other words, the plant number 183 and STZ obviously had a long and complicated way of “tilling the cones” in mastering the production of T-34, and it was obvious that the sooner they got down to business, the sooner the Red Army would receive full-fledged combat vehicles. It was impossible to use the Kirovsky plant for the release of the thirty-fives, since it had its own “super task” - to move from the production of medium T-28 to heavy KV-1.

In other words, in 1940, before the leadership of the Red Army, industry and the country were, in general, about the same tasks as in the distant already 1933 with the release of the T-28: there was a frankly raw project, in the absence of a developed technological chain of its production on head manufacturers. Naturally, the chains of industrial cooperation also existed only on paper, because the mass production of parts, components and assemblies at the related enterprises also had to be mastered. But in 1933, the war was not at the threshold of the USSR, and in 1940, the situation was completely different.

Of course, it would be possible to take the “right” path - not to take the T-34 into service, until the tank completely arranges the military, and only then proceed to its mass production. That's just what then we would get in the end? By the time of the fascist Germany’s attack on the USSR, in this case, absolutely nothing would have been prepared for the production of T-34 in the series, and the same Kharkiv number 183 would continue to rivet the spent BT-7. But would it be better?

After all, BT-7 had most of the disadvantages of the T-34, while not having its merits. Did the T-34 crew consist of 4 people and it was not enough? There were three of them in BT-7. Small, cramped tower? At BT-7, it was no better. Bad review from the car? Fully applied to BT. Lack commander's turret? So on the BT-7 it never existed. But BT-7 still had neither a powerful 76,2-mm cannon, nor a projectile reservation, and both of them were extremely useful in combat. The only thing that BT-7, perhaps, was superior to the pre-war T-34, is in technical reliability, but it is very difficult to say whether this superiority was realized in the first battles of World War II, where our mechanized corps lost huge masses of BT-7. Yes, and this advantage was, perhaps, only in older BT-7, because BT-7М, most likely, had similar T-34 problems with its diesel engine.

In other words, T-34, of course, in 1940, was not yet communicated by the designers. But even in this form, it was more valuable for the Red Army than the light tanks that preceded it, which were manufactured by plant No. XXUMX, and for the STZ, by and large, which tank you start to master is all one thing new, and many "cones" were guaranteed. In view of the above, sending T-183 to mass production made a lot of sense: the minus of this decision was that the Red Army would receive raw tanks for the first time, plus the fact that full-quality, quality T-34 would receive the same Red Army much earlier in terms than in some other options in which the launch of the machine in the series was postponed.

Of course, it was possible not to put the T-34 in the series, assemble, almost manually, the installation batch in a couple of dozen cars and send it to the military trials, find flaws in the structure, fix them, make a new batch, etc. But in this case, the “thirty-four” would hardly have begun to be mass-produced before the start of the war, and the plants would have no opportunity to work out in practice all the necessary cooperation that they would have to somehow organize already during the course of hostilities. And when in this case, the T-34 began to arrive in the army in commercial quantities? It is difficult to assume, not knowing all the nuances and characteristics of production, but definitely not in 1941, and in 1942, probably not immediately.

However, before the war, the question of removing the T-34 from mass production was raised twice. The first time this occurred as a result of comparative tests of the German T-3 with the “thirty-four”: it must be said that the contrast in ergonomics and visibility provided by the relatively spacious three-seat tower of the German tank, which also had a commander's turret, seemed striking. But the German tank had other advantages. One of them, oddly enough, speed - T-3 managed to develop 69,7 km / h on the highway, overtaking not only T-34 (48,2 km / h) but also BT-7, which even on wheels showed 68,1 km / h. However, by and large the maximum speed is a very unimportant parameter for the tank, especially since the T-34 engine provided the tank with an excellent specific power, but the next parameter was more significant is noise. T-3 while driving was heard for 150-200 m, T-34 - for 450 m.

Then Marshal G.I. Kulik, having familiarized himself with the test report, suspended the production of the T-34, but later, under pressure from industry representatives and the head of the STC GABTU, I.A. Lebedev managed to resume it. The second time the proposal to stop the production of T-34 was made after the first production vehicles set off for the military trials.

However, another point of view prevailed. It was decided to continue the release of the T-34 in its present form, modifying only those flaws that can be eliminated without changing the design. And, at the same time, create a project of a modernized tank, and in fact there were even two of them. In the first project, which received the cipher A-41, it was intended to eradicate only those flaws with which it was possible to cope without changing the structure of the hull and retaining the existing power unit. I must say that A-41 was quickly abandoned, he never left the drawings, did not go beyond the “paper” design stage.

The second project was A-43, which later received the designation T-34M, and the abundance of changes and additions makes it difficult to define it: here we must speak either about the most thorough modernization of T-34, or about creating a new machine, -34.

The T-34M case turned out to be taller, longer and narrower than what its “ancestor” had. The tower had a shoulder strap 1 700 mm (1 420 mm in T-34) and was a triple, there was a commander's pinnacle, the crew was 5 people. Christie's suspension was changed to torsion bar. For the T-34M, the new B-5 engine was developed, but the gearbox, unfortunately, is still the old one (and the work on the planetary gearbox was already underway). However, a multiplier was added so that the T-34M had 8 front speeds and 2 rear speeds. The radio was moved to the body, the driver and the radio operator were swapped, the ammunition and fuel supplies were increased. And with all this, the tank also turned out to be almost a ton lighter than the T-34, its speed should have been on the order of 55 km / h, exceeding that of the “thirty-four”, and only than the T-34M was worse than its “ progenitor ”- this is some increase in pressure on the ground, as it used a caterpillar with a width of 450 mm place 550 mm. The latter figure, of course, remained within the normal range.

The project was introduced in January by 1941 and was extremely liked by the “high authorities”, who recommended only using the existing weight supply to increase the thickness of frontal armor plates up to 60 mm. In addition, in February 1941, it was decided to develop a planetary gearbox for this tank.

In other words, the T-34M was a kind of symbiosis of the ideas embodied in German and domestic tanks and promised to become an extremely successful combat vehicle, in all respects superior to German tanks. At the same time, its release was planned for 1941. The Resolution of the Council of People's Commissars of the USSR and the Central Committee of the CPSU (b) “On the Production of T-34 Tanks in 1941” adopted by 5 in May 1941, read:

In total, 1941 was supposed to receive from the industry 2 800 medium tanks, while the plant number X NUMX was to produce 183 1 T-300 and 34 T-500M, and STZ - 34 1 T-000. In the future, the production of T-34 was planned to be gradually phased out in favor of the T-34M completely.

Unfortunately, these plans were not destined to come true, and there was one reason - the B-5 diesel engine, which, unfortunately, did not see the light. As a result, the plant number 183 during the evacuation to Nizhny Tagil "grabbed" with itself 5 towers (perhaps already with guns installed), as well as 2 hulls with suspension, but without rollers, engines and transmissions, and no more work on this tank was made.

Here, many dear readers will probably want to remind the author that the plant number XXUMX could not produce tanks with epaulettes 183 1 mm until the lend-turning lathes were transferred to his disposal. Indeed, a number of publications indicated that if it were not for 700-2 turning-rotary machines (and in some sources they managed to be called carousel-gear cutting, which, of course, completely erroneous), obtained from the USA, then our evacuated plant No. 5 didn’t could produce t-xnumx-xnumx. And it would be okay if the matter concerned some Internet sources, or odious authors like the same Corned beef. But this is what M. Baryatinsky, a respected historian who specializes in armored vehicles of the Second World War, wrote:

In general, the shortage in the USSR of turning and rotary machines for the production of tanks with a wide shoulder strap tower has long been a "talk of the town." Therefore, let's stop a little in the description of the process of improving the “thirty-fours” in order to highlight this issue in more detail and never return to it.

So, judging by the information available today, the respected M. Baryatinsky still was mistaken in his judgment about the presence in the USSR of turning and rotary lathes of the appropriate size.

The first thing that makes one doubt the accuracy of the text is an error in the description of the technical operation, namely, the phrase “there was nothing to treat the ring gear of the tower” as the turning-and-boring lathe does not serve for this purpose. In short, the turning-and-boring machine represents a spinning table (faceplate) over which the tool hangs. The latter can be moved up-down and left-right, so that the cutter, coming into contact with the rotating workpiece, performs its processing.

To be more precise, the caliper "hangs", containing a turret on several types of incisors, which can perform a number of operations, such as machining external surfaces, drilling holes, trimming the ends of the part, etc. But no teeth on the turning-rotary machine can not be processed, it is simply not designed to work with such surfaces. However, maybe we simply misunderstand the idea of a respected author, and in fact he meant only preparatory operations, and the incisors were cut with another tool afterwards.

The second - generally speaking, the first turning-rotary machine in the USSR was manufactured at the plant named after GM. Gray in 1935. What is interesting is that the machines of the “first releases” are still “kept” at some enterprises.

And in 1937, in the USSR, at the same factory, two turning-boring machines 152 with a processing diameter of 2000 mm were manufactured. The exact number of machines produced, alas, is unknown, but the decision of the Council of People's Commissars for 1941, the plant allocated 23 million rubles. to bring the annual output to 800 per year: accordingly, it can be assumed that even before this release was significant.

Third. M. Baryatinsky says that turning and rotary lathes were not in NKTP, but what is this NKTP? Some readers might have mistakenly assumed that NKTP is the People’s Commissariat of Heavy Industry (“Narkomtyazhprom”), but this is not true, because the latter was abolished much earlier than the events described by M. Baryatinsky, 24 in January 1939 of NKTP - this is just Narodny the commissariat of the tank industry, and besides it there was a mass of other Commissariats, in which, of course, there was a lot of any equipment that was missing in the NKTP.

So, it is completely unclear how the USSR could exist and develop at all without turning-and-boring lathes with a large faceplate diameter. For example, a typical project of a locomotive factory assumed the presence of 15 turning-boring machines on each, while the diameter of the driving wheels of the most common locomotive of the IC was 1 850 mm. How to do them without a turning lathe?

And the excavators? The rotary mechanism of an excavator is the same shoulder strap of a tank tower, while in the USSR excavators were made starting from the 30s. Before the war, in 1940 g, even career ones were made.

In general, it turns out one of two things - or in the USSR they completely mastered the production of turning-and-boring lathes with a diameter of machining 2 000 mm and more, or they invented some magical way to do without them. The first one believes much more than magic, and if, nevertheless, somewhere in the depths of the people's commissariats magic wands are lying around, allowing them to produce excavators and wheels for locomotives without turning and rotary machines, then who prevented the same “technology” to be applied to tanks?

In other words, we can fully trust the judgment of a respected historian that the machine tools needed for the production of tank shoulder straps were not enough in the NKTP. After all, before the appearance of the KV tank, the only plant that needed them was the Kirov Plant, which created medium-sized T-28 tanks, whose towers with an 76,2-mm gun had an 1 620 mm shoulder strap. The rest, even after the transition to the T-34, by and large in the "wide" turning-boring machines did not need. So why should they be in NKTP in any appreciable quantities? But this does not mean that such machines were not in other Commissariats.

Fourth, in spite of the above, these machines still were in a certain amount in NKTP before the war. This is evidenced by a letter from the chief of the 1 division of the 3 division of the armored command of the GABTU KA, lieutenant colonel I. Panov, who supervised the work on T-34 addressed to Lieutenant General Fedorenko. The letter is dated 13 December 1940 and contains the following lines:

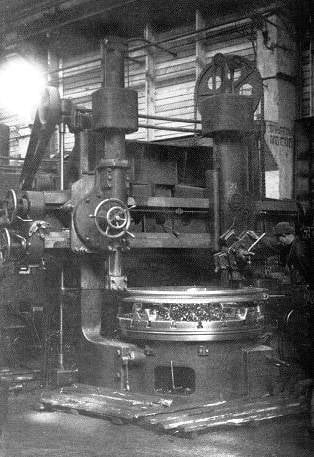

Taking into account the fact that the T-34 diameter of the shoulder strap was 1 420 mm, it turns out that the machine for processing the shoulder strap approximately on the 1 620 mm was at the factory. In addition, there is a photograph of a turning-and-boring lathe, made in 1942, at the plant number 183.

The scale is not visible very well, but let's pay attention to the 2 machine stands (one of them is just turned up by the worker on the right) - they indicate that we have a large machine. The fact is that two-rack turning and rotary lathes made exclusively those that were intended for machining parts with a diameter greater than 1 500 - 1 600 mm. As a matter of fact, the very first “big” machines of this type (the 152 mentioned by us earlier) made in the USSR had only one rack, but it quickly became clear that this was an erroneous decision, and the plant named after GM. Sedin moved to release 152M, with two racks. That is, even if we saw a large single-pillar large machine, it is possible that it was 152, capable of processing parts with a diameter of 2 000 mm and quite suitable for the production of a wide tank shoulder strap. But we see a machine with two racks, and this clearly demonstrates its “professional suitability” for the manufacture of parts, even for T-34М, even for T-34-85.

Fifth, it is necessary, finally, to pay attention to the number of turning-and-boring lathes necessary for tank production. Consider the production of the EC-2, a heavy tank with a shoulder strap 1 800 mm. No historian has ever claimed that we received lend-lease for the machine park for the EC-2.

So, the plant №200, on which the production was carried out, was equipped with turning-and-boring lathes with a large faceplate diameter (up to 4 meters) in the shortest possible time. At the same time, as far as can be judged, NKTP itself managed to find only 2 of such machines, taking them from UZTM. And the rest of the machines were “taken out” by the State Defense Committee (GKO), in Resolution No. 4043ss of 4 September 1943, “On the Adoption of an IS Tank”, which obliged the State Planning Committee to find turning-turning machines with a 5-3 faceplate diameter for the 4 plant , and “14 special machine tools for the processing of the shoulder strap” to produce until the end of 1943 year.

And yet, characteristically, they searched and did. Without any Lend-Lease.

Now pay attention to that. The plant, which had 7 carousel machines and plus 14 special machines, produced during the war years, and after it, a maximum of 250 tanks per month. Plant No. 183 supported the production of T-34-85 at levels above 700 machines per month (up to 750), that is, almost three times more than the plant No. XXUMX. And if the latter required 200 lathes and rotary boring machines with a large faceplate diameter, how many plants does it need for the plant No.7 and our other plants producing T-183-34? After all, the cumulative release of T-85-34 at all plants in other months exceeded 85 1 machines!

And what, someone can seriously believe that all this was done on several machines from the United States? No, of course, you can try to refer to the fact that they say American machines were “one hundred million times more productive” than domestic ones, but this argument shatters the fact that the USSR did not only have turning lathe machines of domestic production, but also foreign ones acquired before the war, for example - the company "Niles".

But this is not all, because there are still “sixths,” which is the banal mismatch of the delivery time of the Lend-lease machines to the factories and the release of T-34-85. The fact is that turning-and-boring machines for our tank plants for Lend-Lease were actually ordered, for example, according to the decree of GOKO No. XXUMXss "On the production of T-4776-34 with 85mm gun at factory No. XXUMX Narco-Tankoprom" from 85 Commissar of Foreign Trade commissioned , among other things, “for plant No. 112 NKTP 15.12.1943 of rotary-boring machines with faceplates from 112 to 5 meters ... ... with delivery in 2,6 quarter of 3.”.

But the thing is that the plant number 112 started producing T-34-85 tanks from January 1944, producing them, respectively, in January - 25, in February - 75, in March - 178 and in April (extremely difficult assume that the machines with the delivery “in the 2 quarter” by this time could have been installed at the factory) - 296 tanks. And the most interesting thing - after the arrival of American machine tools, the output increased extremely slightly, the plant produced a maximum of 315 tanks per month!

The situation described above perfectly shows the real need for turning and boring lathes - only for one plant producing all 315 T-34-85 per month, it took 5 of such American-made machines, in addition to the existing machine park, which already had machines with large diameter faceplate! In general, the version of the miraculous performance of American machines crumbles to the ground.

As for plant # 183, the decree with the permission to order machines abroad required organizing the supply of large rotary machines until July 1 1944, while the first T-34-85 tanks with a wide shoulder strap tower (for some time the factory produced tanks with the 85-mm cannon in the old, narrow pursuit), the plant passed in March - 150 machines, April - 696, May and June - 701 and 706 machines, respectively. There is also a diary of Malyshev, in which he leads a conversation with I.V. Stalin:

But here it is not clear, Malyshev speaks about the need for turning and rotary lathes with a large faceplate diameter in addition to the existing same (or is it different?) Machine tools. However, the fact that the T-34-85 was released with a wide shoulder strap from March 1944 speaks for itself - under no circumstances could the plant No. 183 be able to get a turning-and-boring machine under the lend-lease by the specified deadline. At first it was necessary to coordinate their delivery with the United States, but this took time, then they needed to be manufactured, and the production cycle of such a machine was long enough. Then these machines still needed to be delivered to the USSR and it is clear that in the month of 1-2 it was all impossible to do. And this means that turning and boring machines with large faceplate diameters were in plant number XXUMX and before the lend-lease supplies.

There is one more nuance. We know that such machines were going to be ordered under Lend-Lease, but we do not have a complete picture of how many large turning and rotary machines were actually ordered, how many were delivered (some could die on the way), and how many of the machines supplied in the end it was transferred to NKTP.

True, dear readers may ask: if the USSR was doing so well with turning-boring lathes with a large face plate diameter, why was it ordered abroad? The answer, apparently, was that since NKTP itself did not have such machines, for the production of tanks it was necessary to “peel” other commissariats, that is, in fact, to produce tanks at the expense of some other technology, did not cover the needs of all commissariats at once. So they were ordered abroad, since there was such an opportunity. From this, of course, it does not follow that without the above machines, the USSR could not organize mass production of T-34-85, and certainly it does not follow that, on the eve of the war, the plants did not have turning-rotary machines for the T-34М production program . In the end, we must not forget about the scale: according to the planned targets, throughout the entire 1941 of the year, Plant No.183 was to produce 500 T-34М, while in the USSR military, the same plant produced T-34-85 to 750 tanks monthly.

But back in the 1940-41 years, to the production of T-34 tanks.

To be continued ...

Information