Small arms trunks

The device barrel is determined by the appointment of weapons and the peculiarities of its operation. The barrel as part of the weapon works in special conditions. In order to withstand high pressure of powder gases at high temperature, the friction of the bullet during its movement in the barrel and various service loads, the barrel must have sufficient strength that is provided by its wall thickness and material and the ability to withstand high pressure powder gases 250 - 400 MPa ( to 4 000 kg / sq. cm) at a temperature of up to 3000 ° C. During combat use of weapons, the barrel is subjected to various stresses (during a bayonet strike, since the bayonet is attached, as a rule, directly to the barrel; during combat use of weapons, including when firing from a rifle grenade launcher; during its fall, etc.). The outer outline of the barrel and the thickness of its walls are determined by the conditions of strength, cooling, method of mounting the barrel to the receiver, mounting on the barrel sights, flame arresters, muzzle brakes, as well as parts that protect against burns, handles, barrel linings, etc.

On the trunk distinguish breech, middle and muzzle parts. The muzzle (front) part of the barrel ends with a muzzle cut. The muzzle cut is a cross-section through the front end of the barrel without taking into account the flame arrester (compensator, muzzle brake). The shape of the muzzle excludes accidental damage to the rifles, which impairs the accuracy of shooting. The back of the barrel is called the breech, and its rear end is called the hemp stem.

Inside the barrel has a through channel in which there are: a chamber that serves to place the cartridge; bullet entrance, which is a transitional section of the barrel from the chamber to the threaded part; and rifled part. The channels of the barrels of various types of weapons are approximately the same in structure and differ only in the shape of the chamber, the caliber and number of rifling. The chamber corresponds to the shape and size of the liner, and its design is determined by fixing the liner in it. The chamber should ensure the free entry of the cartridge, a good fixation of the liner and the obturation of the powder gases, as well as a sufficiently free extraction of the liner after the shot. On the other hand, the gap between the sleeve and the walls of the chamber should be minimal, since too large a gap can lead to rupture of the sleeve.

To ensure tight fixation of the liner, the longitudinal dimensions of the chamber are appropriately selected, and the dimensions of these dimensions are determined by the method of fixing the liner (along the rim, along the front ramp), which, in turn, depends on the design of the latter.

If the sleeve has a protruding rim (flange), then usually the fixation is carried out by an emphasis of this rim in the stump of the trunk. With this method of fixation large errors are allowed in the longitudinal dimensions of the chamber and the sleeve itself. However, such sleeves usually complicate the mechanisms for feeding cartridges and are rarely used nowadays, although it is for domestic 7,62-mm rifle cartridge that has a sleeve with a protruding rim, all easel and single machine guns are designed: SGM, PC / PKM, PKB, PKT, and SVD sniper rifle.

If the sleeve has a non-protruding rim (wafer), then usually the fixation is carried out by the slope of the sleeve into the slope of the chamber. In this case, there is a need for sufficiently accurate manufacture of the slope of the chamber, which makes it necessary to increase the accuracy of manufacture of the chamber and liners. Examples of this are the wafer-free 7,62-mm automatic cartridge mod. 1943 g. And 5,45-mm cartridge 7H6 used in Kalashnikov submachine guns and light machine guns.

For pistol cartridges, liner fixation is most often carried out by the front cut of the liner sleeve. This fixation provides the simplest device chamber in the presence of a sleeve without a protruding rim, but for other types of cartridges is unreliable. Therefore, it applies only to pistol cartridges with cylindrical sleeves, for example, a 9-mm pistol cartridge for a PM pistol.

In most types of automatic weapons, the beginning of the extraction (extraction) of the liner occurs at a time when the pressure of the powder gases in the barrel is still quite large. Good obturation of powder gases is carried out by a snug fit of the walls of the liner to the walls of the chamber at a sufficiently large length. For this purpose, in cases where the cartridge moves back with a high pressure of powder gases (in systems with free and semi-free valves), sometimes a cylindrical surface is made in the back of the chamber that eliminates the breakthrough of powder gases even with large backward displacements. Such a surface substantially reduces the jamming of the tapered part of the liner in the chamber after the shot and after the fall of the longitudinal deformations of the locking assembly, since the areas of the bottom portion of the liner usually undergo the greatest amount of jamming. In some types of weapons, the friction forces arising between the cartridge case and the chamber can be so large that when removing the cartridge case, it can be transversely broken or damage to the rim of the ejector. To reduce the indicated friction forces, Revelli grooves are sometimes used in the chamber rooms, which, by creating back pressure on a certain part of the outer surface of the liner, facilitate its removal (extraction). Due to the complexity of manufacturing, rapid contamination and difficulty in cleaning the Revelli grooves in modern weapons are rarely used.

The bullet entrance connects the chamber with the threaded part of the barrel bore and serves to accommodate the bullet head to ensure its smooth cutting into the barrel rifling. In a rifle, the bullet entry consists of two cones, the first of which reduces the diameter of the chamber to the diameter of the rifling fields. The second cone serves to ensure the gradual cutting of the bullet into the grooves (in a smooth-bore weapon this cone is absent). The accuracy of the weapon’s fight depends on the size and shape of the pool entrance. The length of the pool entrance ranges from 1 to 3 gauges.

Caliber - a unit of measurement adopted in the weapon for measuring the inner diameter of the barrel and the outer diameter of the bullet. The caliber of a rifled stem is defined as the distance either between two opposite fields of the trunk, or between two opposite rifles. In Russia, the barrel caliber is measured by the distance between two fields. In this case, the caliber of the bullets in relation to the weapon exceeds the caliber of the barrel, in order to ensure that the bullet penetrates into the grooves in order to acquire a rotational motion of the bullet. Thus, the diameter of the Makarov pistol PM in the rim fields is 9 mm, and the diameter of the bullet is 9,2 mm. The caliber of the weapon barrel is indicated in the system of measures adopted in the country-manufacturer of the weapon. In countries with a metric system of use, the notation in millimeters is used, and in countries with an inch system of measure - in fractions of an inch. Thus, in the USA, the caliber is indicated in hundredths, and in the UK - in thousandths. In this case, the caliber is written as an integer with a dot in front, for example, the American Colt M 1911 А1 pistol of the .45 caliber.

Different forms of rifling are taken in different armies. In the Soviet Union / Russia, a rifle-shaped rectangular section was adopted, while the depth of the rifling was 1,5 - 2% of weapon caliber. The remaining rifling profiles are used in various foreign specimens, for example, a trapezoidal profile — by the Austrian 8-mm magazine rifle Mannlicher M 95; segment profile - in the Japanese 6,5-mm Arisaka magazine rifles type 38; oval profile - by Lancaster; beveled profile - in French 7,5-mm machine guns Chatellerault M 1924.

The direction of rifling in the trunk can be right (in domestic samples) and left (in England, France). Different advantages of the rifling direction do not have any advantages. Depending on the direction of rifling, only the direction of derivation (lateral deviation) of the rotating bullet changes. In domestic small arms, the right direction of the rifling is taken - from left to right to right as it moves along the barrel channel from its breech to the muzzle. The angle of inclination, attached by rifling, provides rotational movement of the bullet, while its stability in flight depends on the speed of rotation of the bullet. The length of the rifling stroke (the length of the bore on which the rifling makes a full turn) also has a significant effect on the accuracy of fire. The pitch of the AKM rifle is 240 mm, the DShKM machine gun - 381 mm, the KPV machine gun - 420 mm.

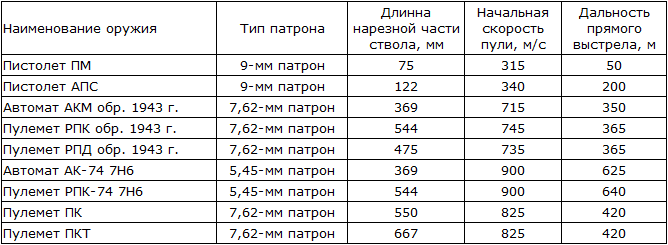

The length of the rifled part of the barrel of each weapon is selected from the condition of obtaining the required initial velocity of the bullet. The use of the same cartridge in samples of weapons with different barrel lengths allows to obtain a different initial velocity of the bullet (See table.).

The table shows that the range of the direct shot increases with an increase in the initial velocity for the same cartridge, which affects the improvement of the flatness of the trajectory and the increase in the space affected. As the initial speed increases, the effectiveness of the bullet on the target increases due to the greater energy of the bullet. Thus, at a distance of 1000 m, the bullet emitted from the barrel of a PC machine gun has energy 43 kgf / m, and the bullet ejected from the barrel of a machine gun is 46 kgf / m.

In shotgun hunting weapons, the guide part of the bore is smooth (without rifling), and its muzzle may be narrowed (conically or parabolic) or expanded. Channel constriction is called choke. Depending on the size of the restriction, which improves the accuracy of shooting, there are paychecks, medium choke, choke, strong choke. The expansion in the muzzle, called the flare, increases the dispersion of the fraction and can be made in the form of a cone or have a different shape.

The trunks in small arms are structurally different on the trunks - monoblocks and bonded trunks. Trunks made of solid metal billet, called monoblock trunks. However, to increase the strength of the barrel, they are made of two or more pipes, fitted one over another with an interference fit. Such a trunk is called bonded. Barrel fastening was not widely used in automatic weapons due to the complexity of manufacturing. The connection of the barrel with the receiver with tension can be considered as a partial bond.

Rational cooling barrels for modern automatic weapons is extremely important. The leading parts of the bullet, crashing into the grooves, receive significant plastic deformation and, thus, exert additional pressure on the walls of the bore. Worn bore is caused by friction on its surface of the bullet shell moving with high friction force at high speed. Moving after the bullet, as well as partially breaking through into the gaps between the walls of the barrel and the bullet, the gases produce an intense thermal, chemical and erosive effect on the bore, causing it to wear out. Rapid abrasion of the barrel bore surface leads to the loss of some properties necessary for effective firing (the dispersion of bullets and shells increases, stability is lost in flight, the initial speed decreases below a given limit).

With a strong heating of the trunk, its mechanical qualities decrease; decreases the resistance of the barrel walls to the action of the shot; this leads to increased metal wear and reduced barrel survivability. When the barrel is very hot due to the appearance of upward air flow, it is difficult to aim. The high temperature of the breech breech can lead to the fact that the cartridge, sent to the chamber, after firing, can heat up before self-ignition, which makes the handling of the weapon unsafe. In addition, the large heating of the barrel makes it difficult to operate the weapon. In order for the shooters not to suffer from burns, special shields, handles, etc. are mounted on the arms.

The high temperature of the powder gases due to the rapid heating of the barrels of automatic weapons during firing. It follows that the intensity of heating of the barrel depends on the power of each shot and the mode of fire. For weapons intended for single shooting with low-power cartridges (pistols), barrel cooling is of secondary importance. For weapons firing powerful ammunition (machine guns), cooling should be the more effective, the greater the capacity of the magazine (tape) and the longer continuous shooting should be from this type of weapon. Increasing the temperature of the barrel above a certain limit reduces its strength characteristics and service life. All this ultimately limits the mode of fire (i.e., the permissible number of shots in continuous shooting).

The special methods for cooling the shafts include: rapid replacement of the heated barrel with the cooled stem; increase in the surface of the cooling barrel due to the ribs using various nozzles (radiators) for the same purpose; artificial blowing of the outer or inner surface of the trunk; the use of liquid coolers, etc. Currently, two types of barrel cooling are the most widely used - air and water.

Air cooling has become the most widespread among modern types of weapons due to its simplicity, but it does not provide a high heat transfer rate to the air.

To increase the heat transfer of the barrel, its surface is usually increased using special transverse or longitudinal ribs. The effectiveness of this method is determined by the size and number of ribs of the trunk. The use of ribs on the outer surface of the trunk, although it increases the total area of heat exchange with air, but leads to uneven heating of the metal of the trunk and ultimately reduces its overall heat capacity. However, an increase in the ribs of the trunk leads to its weighting, which is disadvantageous. Known attempts to use worn on the ribs made of lightweight alloys. However, this method has not become widespread due to the complexity of manufacturing such trunks. To increase heat transfer, devices were designed that improved air circulation by blowing the barrel bore and blowing its outer surface. For example, in the Lewis M 1914 manual English machine gun, a radiator with longitudinal ribs of light alloy was worn on the barrel, and a casing in the form of a pipe was worn on the radiator. During firing, a jet of powder gases emerging from the barrel formed a vacuum in the front of the casing, as a result of which air was sucked into the casing from behind and passed between the ribs, increasing the intensity of their cooling. The use of such a design increased the intensity of cooling of the barrel during firing, but it was found that in the intervals between the bursts the housing prevented the flow of fresh air, which ultimately did not lead to an improvement in the cooling of the trunk.

At present, modern models of automatic weapons with air-cooled barrels (large-caliber machine guns) often do not have ribs on the barrel or are made very small using quite massive barrels, for example, in the Austrian AUG 5,56 assault rifle on the barrel simply screw-cut with pitch approximately 1 mm. For light weapons (machine guns and light machine guns), either the fire regime is limited, or (for light machine guns and machine guns), quick-change barrels are used, which make it possible to quickly replace a heated barrel in a combat situation and thus ensure a high shooting mode. In this case, the barrels of automatic weapons have, as a rule, large safety margins. A thicker barrel, having a greater heat capacity, is less heated from shot to shot, which increases the duration of continuous fire to achieve a dangerous overheating of the barrel and increases its service life. In this regard, the barrels for the same cartridge in a weapon intended for use in a hard fire mode (for example, single PC / PKM machine guns) have a thicker barrel than in a weapon with a relatively low practical rate of fire (SVD rifle).

Especially effective is the water cooling of the barrel, which has received wide application in heavy machine guns in the past. Its feature is a sharp lowering of the barrel temperature with minor interruptions in firing due to intensive heat transfer from the barrel to the coolant. To cool the barrel of a normal-caliber machine gun, it is enough to have a supply of water in the casing of the order of 3-4 l, and for a large-caliber machine gun 5-8 l. This cooling system allows continuous fire until all the water boils away. However, the presence of a casing with water greatly complicates the design of the weapon and its operation, and also increases the vulnerability of the weapon itself in battle. An example would be the domestic 7,62-mm machine gun Maxim arr. 1910 g. In addition, the water cooling of the barrel has several disadvantages: a constant supply of water is required; at low temperatures, water freezes, which can cause damage to the casing and the barrel; the mass of the weapon increases to the detriment of maneuverability; the difficulty of preparing weapons for shooting; high vulnerability of weapons in combat, etc.

Because of these drawbacks, water cooling of the barrels in modern small arms is not used, but is successfully used in stationary-type automatic weapons, for example, in ship installations.

There are two main types of mounting the barrel to the receiver: a detachable connection of the barrel with the receiver of the weapon, providing for a quick change of the barrel without disassembling the weapon, and all-in-one, not providing.

In most modern models of small arms, the service life of which is the same as that of the barrel (SVD rifles, AKM / AK-74 assault rifles, RPD / RPK / RPK-74 submachine guns and PM pistols) that do not have a quick barrel change device, the barrel is connected to the receiver one-piece connection. This may be a threaded connection with an interference fit, such as, for example, in the Dragunov self-loading rifle, or a pairing of a cylindrical surface with an additional pin fastening. Assembly trunks with receiver boxes in this case is carried out in the factory.

Mount detachable during disassembly of the trunks can be performed using a bayonet and threaded connections, earrings or studs. The last two types are used in some pistols, providing ease of disassembly and cleaning. An example is the mount of a Tokarev TT pistol. In addition, detachable connections of barrels with receiver boxes (which do not provide a quick change of barrels) are commonly used in easel, single and large-caliber machine guns of PC, CPV, DShKM, NSV and their modifications. Detachable connections allow the replacement of the heated barrels in the process of using the weapon and thus make it possible to conduct intense and continuous fire (while shooting from one barrel, the other is cooled). In addition, the presence of a replaceable barrel increases the survivability of the weapon.

Split connections of quick-change trunks with receiver boxes are usually made of rusk or wedge. These connections are used mainly for light and heavy machine guns. Dry-threaded connections are made most often screw, for example, in the 12,7-mm machine gun DShK arr. 1938 g. Sometimes when connected, the barrel rotates, and sometimes a special coupling. In some cases, the barrel is simply embedded with its croutons in the corresponding grooves of the receiver. In systems with a movable barrel, special protrusions on the barrel are sometimes used to attach barrels to stem boxes (spikes in the Maxim machine gun, sample 1910). In addition, the interchangeable barrel is also connected to the receiver with a wedge connection. Thus, in the DShKM machine gun, the connection of the barrel with the receiver is carried out by a wedge. Despite the simplicity of the design, such a connection is inconvenient in operation, since to replace the barrel it is necessary to unscrew the nut and knock out a wedge. A more sophisticated design of this type is used in the NSV large-caliber machine gun. In systems with a fixed barrel - PK / PKM, SGM machine guns and their modifications - an adjustable wedge is used to compensate for the wear of the bolt stop stops. Adjusting the distance between the bottom of the gate cup and the breech cut (mirror clearance) ensures complete locking of the shutter and prevents the appearance of a delay in the form of a transverse rupture of the sleeve when fired. In order to facilitate the separation of the barrel from the receiver in a heated state, the outer surface of the breech of the PKM / PKT machine guns is chrome-plated.

At the muzzle of the trunk can be mounted devices for various purposes. So, on the barrel of AKM 1959 - 1962 automatic rifles of release a coupling was installed to protect the thread from damage, and on the barrel of AKM 1963 - 1975 automatic rifles, a compensator is attached to increase the accuracy of the fight when firing on the move, standing and from the knee. The compensator has a threaded part, which serves to connect with the muzzle of the barrel. The front part of the compensator is made in the form of a protrusion with an oblique cut. Inside the protrusion made groove, forming a compensation chamber. Powder gases after departure from the bore create an overpressure that deflects the muzzle of the barrel in the direction of the protrusion (left down). In the AK-74, a two-chamber muzzle brake compensator is used, simultaneously performing the role of a flame arrester, which greatly increased the stability of the weapon when fired. On the trunks of the PKK, PK / PKM machine guns, the SVD sniper rifle and the AKM assault rifle, which are mounted under a night sight, are mounted slotted flame arresters designed to reduce the intensity of the glow of high-temperature powder gases and burning powder particles at the exit of the barrel. Reducing the visibility of the muzzle flame is achieved by the fact that most of it is closed by the side walls of the flame arrester. PKT, SGM, KPVT, NSV machine guns have flame arresters with a conical socket. In this flame arrester due to the influx of ambient air into it, intense burning out of the powder particles is provided and, thus, the brightness of the muzzle flame decreases when fired.

The flame arrester of the KPVT machine gun has a more complex structure, consisting of the flame arrester itself, the base of the muzzle, bushing and piston of the barrel. In this regard, the flame arrester of the KPVT machine gun besides reducing the brightness of the muzzle flame provides an increase in the recoil energy of the moving barrel.

The trunks can also be installed on the trunks, designed to reduce the recoil energy of the barrel due to the removal of a part of the powder gases in the lateral directions and reduce its flow in the axial direction.

On the trunks of the weapon, working on the principle of using the energy of a part of the powder gases discharged through a side opening in the wall of the barrel, gas venting devices are mounted. These devices have a narrow inlet part connected to the barrel bore and a wider outlet part - a gas chamber. Gas regulators are installed in the gas chambers of PC / PKT, SGM, RPD, SVD shafts, which ensure the reliability of the automation in various operating conditions. This is achieved by changing the amount of powder gases acting on the bolt piston.

There are the following ways to control the intensity of the gases on the bolt piston:

- change of the minimum cross-sectional area of the gas pipeline through which gas flows from the barrel into the gas chamber of the machine guns (FCT, SGMT). This design of the gas regulator allows reducing gas pollution inside the tank combat vehicle;

- discharge of gases from the chamber to the atmosphere (SVD rifle, PK / PKM machine gun). The maximum speed of the bolt carrier will be with closed holes, as in this case the maximum amount of gases will be fed to the bolt piston.

Information