Dampfschlepper steam tracked tractor project (Czechoslovakia)

In 1944, the problem of supplying troops with fuel became particularly acute, which led to the intensification of work on the creation of alternative energy and power plants. Thus, the company Škoda from occupied Czechoslovakia began work on a project of a promising steam engine armored vehicle. The goal of this project was to create a multifunctional (but above all artillery) tracked tractor that does not need scarce gasoline. Such a machine could work on coal or even wood, fulfilling the tasks of transporting people and goods. In case of successful completion of the project and mass deliveries to the troops, such equipment could significantly reduce the consumption of valuable fuel derived from oil.

In the spring of 1944, BMM (Böhmisch-Mährische Maschinenfabrik AG, now Českomoravská Kolben-Daněk) launched mass production of Hetzer self-propelled artillery systems, also known as Sd.Kfz.138 / 2 or Jagdpanzer 38. This chassis was based on a light chassis tank Pz.Kpfw 38 (t). The characteristics of such a chassis made it possible to build on its basis various new equipment, including auxiliary equipment. In addition, such equipment was produced in series, which eliminated significant problems with the supply of necessary components and assemblies. For this reason, the chassis of the Hetzer self-propelled guns was chosen as the basis for a promising steam-powered tractor.

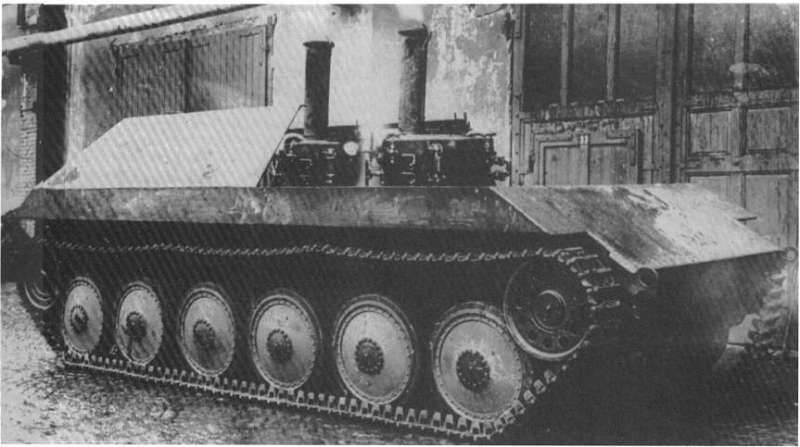

Prototype SK 13 in the early stages of the project. There are still no roof and feed tanks. Photo Forum.valka.cz

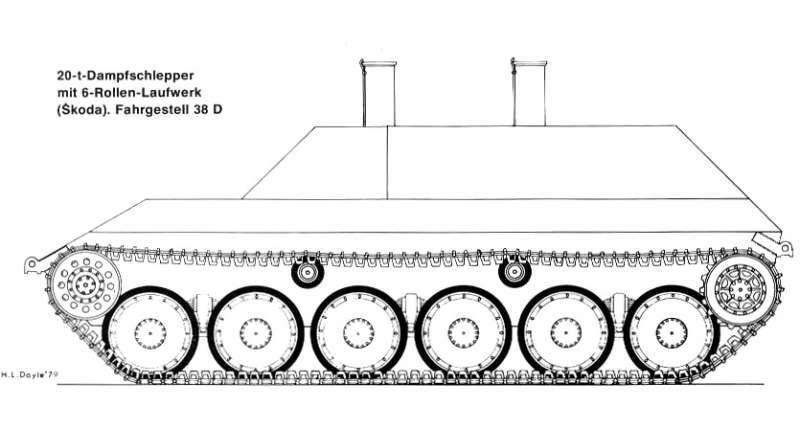

However, the self-propelled chassis in its current form was not suitable for use in the new project. For the construction of the tractor had to significantly alter it. The most significant change was the increase in length: on each side they added two track rollers and accordingly extended the hull. After such changes, the chassis could be equipped with the required equipment and solve the tasks.

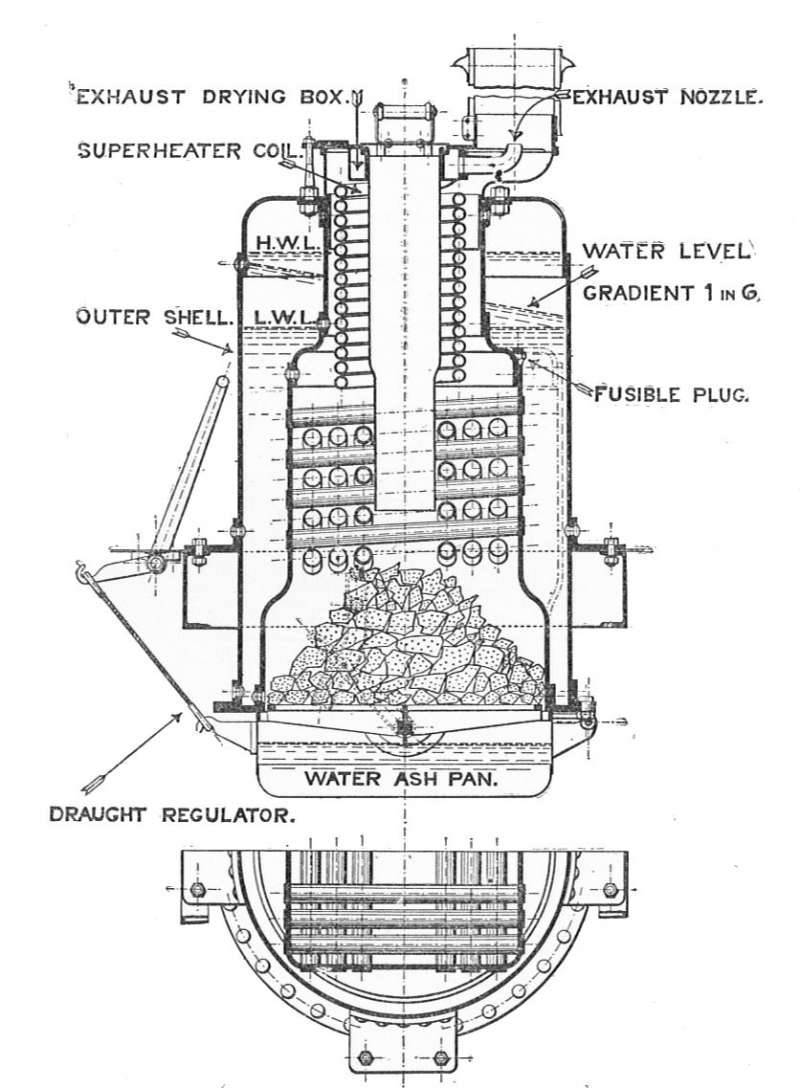

In addition to the chassis, it was proposed to borrow from existing equipment and steam boilers with piston machines for use as a power plant. These units should have been taken from an outdated Škoda Sentinel steam truck. In the mid-twenties, the Czechoslovak plant agreed with the British company Sentinel Waggon Works to deploy a licensed production of steam engine trucks. These cars, which received the new name “Skoda-Sentinel”, were equipped with 70 hp steam engines. and could transport cargo up to 5 tons. Production of licensed trucks in Czechoslovakia continued until the mid-thirties. At a certain stage of the serial assembly of machines, Czechoslovak specialists carried out a modernization of the original project, which led to a noticeable increase in truck performance.

The first variant of the promising tractor, based on the Jagdpanzer 38 self-propelled units and the Škoda Sentinel truck, was given the designation SK 13 Dampfschlepper (“Steam tractor”). Subsequently, several more similar projects were proposed, based on general developments on the first SK 13. A curious feature of all subsequent projects was the use of a common chassis, developed by Skoda based on ACS Hetzer units. The composition of other units is constantly changing.

Truck Škoda Sentinel. The steam boiler is located in the front of the machine - a chimney and a movable bottom cover are visible. Photo of Wikimedia Commons

The basis for the first experimental machine SK 13 was the self-propelled chassis Hetzer. To solve the basic layout problems they proposed to seriously rework the hull structure. The existing armored unit was extended by about a quarter and equipped with two additional pairs of road wheels, which made it possible to maintain an acceptable load on the ground. The shape of the individual units was also changed. A sloping frontal sheet of small height was preserved, and box-shaped shelves appeared above the tracks. In the stern of the hull aggregates of various shapes and sizes could be located. The design of the stern was revised several times due to the need to solve certain problems.

Information about booking a tractor is not available. It can be assumed that the use of ready-made units led to the preservation of part of the armor of the base sample. In favor of this version, in particular, say the weight indicators of the prototype. Thus, the steam tractor could have armor from 8 to 60 mm thick, able to protect the crew and units from small weapons and some artillery systems. This made it possible to use a promising vehicle in some combat formations with other armored vehicles of the troops, without fear for its safety. In this case, however, a relatively strong armor led to the weighting of the machine.

It should be noted that during the development, construction and testing of the hull of the SK 13 prototype underwent some changes. Thus, the initial design of the tractor for the front meant the installation on the chassis of a polygonal cabin, assembled from several sheets inclined inside and a horizontal roof with openings for chimneys. However, the prototype did not receive such equipment. In some photographs, it is captured only with the stern inclined parts of the sides, while in others there are large box-shaped tanks for fuel and water, located above the roof of the engine compartment. In this version, the car also had a light metal curved roof mounted on racks.

The layout of the SK 13 due to the use of a nonstandard engine was very unusual. The front of the case was given under the office of management with the workplace of the driver. In the center of the tandem placed two steam boilers of the existing structure. Stern allocated under the piston engines of the steam engine and transmission units. In the central part of the roof (if installed), the machine should have openings for two chimneys.

Chassis prospective tractor had six road wheels on each side. They were interlocked on three trolleys with spring suspension. The location of the drive wheels has not changed: they remained in the stern. The guides, in turn, retained their place in front of the hull. Despite the relatively large diameter of the road wheels, the set of supporting rollers had to be kept in the undercarriage.

The SK 13 steam power unit was developed on the basis of Škoda Sentinel truck units, some of which were used in the basic configuration, without any changes. The basis of this engine was a cylindrical steam boiler. Inside the outer casing was placed a cylindrical furnace for burning coal or other solid fuel, through which a large number of tubes passed. Water was poured between the furnace and the external body of the boiler. During the burning of the fuel, the water had to flow into the tubes of the furnace and contact with its walls. At the same time, water boiled (the total heating area is more than 5 sq. M), then steam was passed through the superheater and entered the piston cylinder.

To supply air to the fuel, the lower lid of the furnace was made in the form of a movable plate with water that serves as an ashpit (capacity for solid combustion products). The access of air was carried out through the gap between the body of the furnace and the bottom cover, the dimensions of which could be changed using a special lever mechanism.

With steam pressure at the level of 19 atmospheres and 230-mm two-piston stroke in two cylinders, the steam engine could produce up to 250 revolutions per minute and power up to 70 hp. A British truck was equipped with a capacity for 300 kg of coal and a tank for 800 liters of water. This allowed him to carry up to 5 tons of cargo and accelerate to 20-25 km / h. Cruising on the transported fuel was 40 km.

A promising SK 13 tractor received two steam boilers that were mounted one after the other in the center of the hull. Piston cars of two engines carried to the rear of the hull and mechanically connected to the existing transmission. In the free volumes of the hull placed containers for water and fuel. Subsequently, fuel and water were placed in two large rectangular tanks that were installed in the rear of the hull. It is noteworthy that due to the larger hull and the corresponding volumes for the placement of the fuel, it was possible to achieve a significant increase in the cruising range in comparison with the Sentinel truck. On the other hand, the increase in the amount of fuel and water led to an additional increase in the mass of the machine.

Due to rework of the base machine, the length of the SK 13 Dampfschlepper prototype increased to 6,5-7 m. Other dimensions remained the same. At the same time, modifications to the design and use of the new engine led to a significant increase in mass compared to the “Hetzer”. Despite the lack of weapons and even armor cutting, the SK 13 weighed around 20 t. The calculated payload was determined at the level of 9 t.

The crew of the experimental armored vehicle consisted of three people: the driver, the commander and the mechanic. The task of the latter was to monitor the work of steam boilers and piston machines. In addition to controlling the parameters, he had to throw coal into the fireboxes, as well as regulate the flow of water to two boilers. Direct control of the car, such as the choice of speed and direction of movement, was carried out by the driver using a set of levers and pedals.

Already in 1944, Škoda completed the development of the SK 13 project and built the first prototype machine. During the assembly and preliminary tests, it underwent some changes, primarily related to the exterior finish. In particular, a light roof and feed tanks for the angle and water appeared, and on the upper frontal part, steps were provided for getting inside the hull. We can not exclude and refine the design.

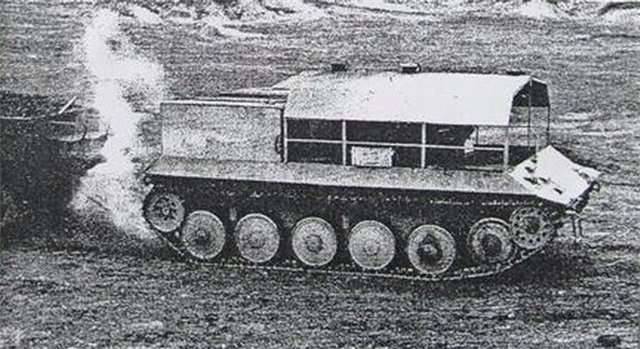

Prototype SK 13 on trial. Photo Shusharmor.livejournal.com

Perspective armored vehicle received two steam engines with a total power of 140 HP. Such a power plant could be of interest, but did not meet the expectations placed during the tests. With a curb weight of the machine at the level of 20 t 140-powerful engines gave a specific power of no more than 7 hp per ton. For comparison, the self-propelled Hetzer (mass 15,75 t and the engine power 160 hp), this parameter exceeded 10 hp per ton, which allowed it to accelerate to 40 km / h. Thus, according to the driving characteristics, the SK 13 should have been significantly inferior to the base machine, not to mention other types of armored vehicles.

During the tests, it was found that the existing steam engine is capable of accelerating the Dampfschlepper of the first model only up to 12-15 km / h. The transportable supply of fuel and water was enough only for 150 km. Apparently, these figures concerned only traffic on the highway, and when driving on rough terrain, the characteristics should have dropped significantly. It is easy to see that, in terms of its mobility characteristics, the steam tractor was significantly inferior to the existing “gasoline” equipment and could not compete with it. Even the cost-effectiveness in terms of the cost of fuel could not open the way to the troops for SK 13.

The tests of the SK 13 prototype allowed us to come to two main conclusions about the future of steam technology. The first concerned the possibility of creating a tractor or other military vehicles, including armored ones, with steam engines. The second conclusion presented new requirements for steam engines for similar equipment. Tests clearly showed that the two boilers from an outdated Škoda Sentinel truck with an 70 horsepower of hp. cannot provide the required mobility of a relatively heavy and large tracked vehicle.

Shortly after the formation of the updated technical appearance of the new technology, the second participant joined the work. BMM proposed its own design of a steam tractor for the troops, designated SK 23. As in the case of the SK 13, it was proposed to use the finished chassis in a modified form. At the same time it was planned to use steam engines of a new type. This equipment was to be supplied by Krupp. Due to the use of modern steam engines, it was planned to provide a significant increase in performance in comparison with the previous SK 13. Assumed certain advantages in speed and power reserve. The profitability of operation, in turn, should have been ensured by the use of cheap fuel.

For various reasons of production and administrative nature, BMM did not manage to build a prototype SK 23 and take it to the test. This project remained on paper. Various factors contributed to this project completion, including problems at the front and the need to concentrate on building other equipment.

According to the test results of the SK 13, Škoda continued to develop the existing project, resulting in the emergence of the SK 33 project. In order to increase the mobility of the tractor, it was proposed to reduce the weight of the structure and increase the power of the steam engine. Due to the removal and processing of certain units, the curb weight of the tractor was reduced to 18 tons. The power of each of the two engines was to increase to 80 hp. Thus, the power density could grow to 8,7-9 hp per ton with some positive effects on mobility.

[Center]

Model tractor. Photo Panzer-modell.de

The Škoda SK 33 project suffered the same fate as the SK 23 competing firm. By the end of 1944, the situation on the Eastern Front had seriously deteriorated. In addition, the forces of the anti-Hitler coalition developed an offensive in Western Europe. In such conditions, the industry of Germany and the occupied states was no longer able to engage in promising projects that could threaten the fulfillment of other orders. As a result, the Czechoslovak industry focused on the production of serial equipment and refused to develop new projects. Under the reduction got a lot of new developments, including steam tractor SK 33.

The Czechoslovak steam haul program for the benefit of Germany ended at the end of 1944 or at the beginning of 1945. By this time, two machine-building enterprises managed to create three projects, of which only one reached the stage of ground tests of the prototype. Checking the machine SK 13 allowed to collect information necessary for the further development of promising areas. However, further events at the front and in the rear did not contribute to the successful completion of the work.

Due to a number of objective factors, the caterpillar steam tracked machines of the Czechoslovak development, before reaching mass production, could not reach the troops. For this reason, until the end of the war, the problem of shortage of fuel was solved by other methods. In particular, a fairly widespread technique with gas generators, using wood or coal chips. In addition, the operation of a number of steam cars continued. However, all this lasted for a relatively short time. In the spring of 1945, Nazi Germany capitulated, which removed from the agenda the issue of creating military equipment with alternative power plants.

On the materials of the sites:

http://forum.valka.cz/

http://feudal.cz/

http://gunm.ru/

http://shusharmor.livejournal.com/

Information