No noise and dust. Part-1

Among the large number of existing types of small weapons specimens of special purpose and, especially, silent firearms, are of heightened interest both in their uniqueness and history development. This is also because the very existence, details and technical characteristics of such weapons became known only relatively recently to both amateurs and specialists. The unified and complex system of “weapons with reduced unmasking factors” created by Russian designers created a real sensation at the beginning of the 90 of the XX century, when information about it became available to the general public. The system includes a pistol, sniper, assault rifle and grenade launcher complexes consisting of special weapons and no less special ammunition. The fact that our system is still the best and has no analogues in the world has not been written only by the lazy ...

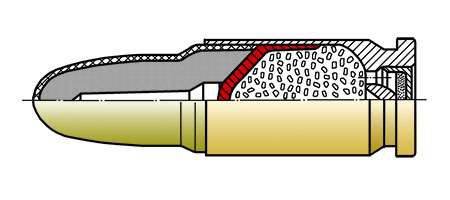

On one of the representatives of this series - the pistol complex and will be discussed in this article. PSS is still the only self-loading pistol in the world for a special cartridge with a cut-off of powder gases in the sleeve. And - regular, that is, officially adopted for service. From which it follows that it fully meets all the requirements for reliability and complies with all other stringent requirements for military weapons.

Is it really difficult to repeat such a construction, or is such a complex “not very necessary”, or is it “not very good”, or are there any other reasons why it remains alone? Let's figure it out. But, for a common understanding and greater validity, we will also consider the background of the issue, paying attention, above all, to the attempts to create a self-loading silent weapon.

In the beginning it is worth noting that in many popular science articles, the founder of the shot silencing systems is the son of the inventor of the Maxim machine gun - Hiram Percy Maxim (1869 - 1936). However, his product became popular and enjoyed commercial success only in 1909, and the first patent for a multi-chamber expansion silencer was obtained in 1899 by Danes J. Burrensen and S. Siegbjørnsen. It is also interesting that hunters were the first to use such silencers so that they would not overshoot the game, and at the beginning of the 20th century silencers for hunting carbines were freely sold to anyone. When silent weapons attracted the attention of criminals, the sale of such devices was limited.

However, the designs of the silencers of that time, their dimensions and, accordingly, the achievable results did not quite suit the military, who also turned their attention to them for use by reconnaissance and various kinds of special units and groups that were undesirable to unmask the shooter and the very fact of the shot . Therefore, the search for other constructive solutions continued.

An alternative to the expansion type silencers and a more effective idea in the field of silent shooting is the way to eliminate the sound of a shot using the method of “cutting off” powder gases, leaving them in the barrel or other closed volume, preventing them from going outside and eliminating one of the main sources of sound shot. Among our compatriots pioneers in this area are the brothers VG and I.G. Mitins who filed an application in 1929 and received a patent for "A revolver for silent shooting using a lead bullet and a larger diameter remaining in the barrel channel of the pallet".

According to the authors, the revolver should have had two drums - one combat, in the usual place, and the second additional, located coaxially with the first at the muzzle of the weapon. Both drums are fixed on a common axis and synchronized in their rotation. Cartridges, as usual, are charged in the combat drum. At the same time in the cartridge case, behind the bullet, there is a special pushing pallet. In the muzzle drum there are nests and each such nest consists of a bullet-hole and a pallet "nest". When fired, a bullet pushed by a pallet under the action of powder gases moves along the barrel, freely passes through a bullet-hole and flies into the target. And the pallet, having a slightly larger diameter than the bullet, is braked and stuck in the “pallet nest” of the muzzle drum. The presence of special seals-seals eliminates the possibility of breakthrough powder gases out through the gaps, including between the movable drums and the fixed barrel ... As a result, the powder gases “are cut off” and remain inside the weapon, in a closed volume, in the three-part “chamber” - in the sleeve (in combat drum), in the barrel and in the muzzle drum. During the next cocking of the trigger, the combat and the muzzle drums simultaneously turn one pitch of a nest. At this point, most likely, the residual pressure of gases from all three “chambers” should have been discharged, after which the aforementioned miracle glands would again have to ensure the tightness of all three chambers as a whole. At the end of the shooting, it was necessary to knock out the spent cartridges from the combat drum, as well as the “shot” pallets from the muzzle. It is not completely clear how the protection from the shot was ensured when the barrel was not removed from the muzzle drum.

It is obvious that the design of the silent revolver proposed in 1929 by the Mitin brothers was complex and not without many drawbacks. Judging by the data available today, the production of prototypes of such a revolver is not reached. But this invention can be considered not only the original of domestic systems with a cut-off of powder gases, but also the first, albeit a theoretical attempt to create a silent pistol complex. Which would possess, in addition to special, also familiar properties - multiply charged, “turret” shooting, the possibility of reloading and multiple use of weapons.

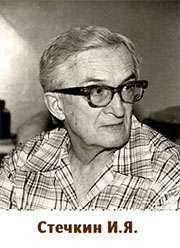

The next interesting stage was the work that arose and was carried out on the basis of the idea and initiative of the Tula designer gunsmith from TsKB-14 - Igor Yakovlevich Stechkin. He proposed an improved implementation of the idea of the Mitin brothers, while solving one of the obvious problems of their design - the need to manually remove the “fired” pallets from the muzzle drum. In the construction of Stechkin, a pusher that pushes a bullet almost also “gets stuck” in the pan at the nest, but made at the end of the chamber in the form of a cone. And the next shot is removed from it - the next bullet “puts on” the pallet as a second shell, picks it up and, pereobzhimaya with it already in the rifled part of the barrel, they leave the barrel as a whole. The sap-cap that pushed the next bullet is braked in the cone (“pallet nest”) and provides for the cut-off of powder gases of the next shot.

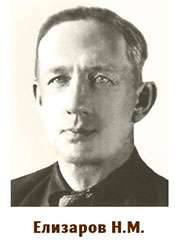

Experiments carried out in Tula by the author himself and their first results interested the Customers and caused the research in the “Research on the possibility of creating a pistol and a special-purpose cartridge for it” in 1953 together with SRI-61 (now TSNIITOCHMASH, Klimovsk) and the CDB- 14 (now - KBP, Tula). Elizarov Nikolay Mikhailovich was appointed the scientific leader of this work, the engineer Gubel Iraida Semenovna was appointed the executive officer.

For experienced firing TsKB-14 was designed and manufactured a mock gun, designed for shooting single shots. It was a simplified stem group, but with all functionally significant structural elements for the implementation of a common idea. The barrel on the inner surface consisted of a chamber under an 9-mm pistol sleeve, a smooth-wall cylinder with a diameter of 9,0 mm. (and not a cone, as some sources erroneously indicate), front rifled parts with a diameter of 7,62 mm over fields (occupying approximately 1 / 3 trunk length) and a smooth connecting cone between them with the angle of inclination of 20 °. On both sides of the connecting cone in the walls of the barrel and the chamber there were drilled several venting holes connecting them with two expansion chambers.

The bullet of the cartridge had a stepped shape, 9,25 / 8,00-mm and in the process of the shot it was re-pressed twice. Leaving the bore, it had a total weight of 8,95 grams and an initial velocity of 120-140 m / s. Initially, according to the design proposed by TsKB-14, the bullet had to have 4 deep longitudinal grooves ("groove") on the front part, obviously, hoping for better connection of the cap with the bullet during their joint rebound in the connecting cone and in the rifled part of the barrel. But in the process of developing the design of the bullet and its manufacturing methods at SRI-61, it turned out that such grooves do not affect the overall functioning of the shot, and also cause a high complexity of manufacturing a bullet with a shell that has a clover leaf in plan (including for breaking through the thin walls of the shell during its manufacture). The overall design of the bullet and pallet were refined and refined, grooves are excluded. But the general meaning of the author's idea remained unchanged.

It is accepted to call this construction “SP-1”, as if emphasizing that it was the first actually worked out and investigated construction. Detailed work on the joint venture-1 described in the third book “Modern domestic cartridges, how legends were created” a four-volume monograph by V.N. Dvoryaninova "Small arms combat cartridges", which contains drawings of an experienced cartridge and ballistic weapons, the history of their development, the technical characteristics of the system and a detailed description of its operation.

As a result of the research, two main results, positive and negative, were obtained, as is often the case.

A positive result was the fact that the stability and degree of silencing of the sound of a shot due to the cut-off of powder gases by the pushing pallet corresponded to the advanced requirements and, quite simply, pleased. In the process of this particular work, domestic cartridge manufacturers for the first time investigated how the pan works during firing and braking. Including its various speeds, thickness, shape, size, and so on. This first and invaluable experience greatly benefited them in the future.

A negative result was the obviousness of the fact that the proposed design, in spite of its basic performance, could not be considered as the basis of a combat, real-life weapon. In addition to the inconsistency of the TTT in terms of accuracy, penetration, as well as identified problems with a large and unstable loss of speed of the bullet in the process of its "connection" with the pallet and their joint passage along the cuts, as well as insufficient obturation of the liner of powder gases and other "trifles", revealed the main problem - extremely high sensitivity of the structure to small changes in the weight of the powder charge of the cartridge, that is, to the energy of the shot.

So, for example, when 0,16-0,18 g powder was used, 30% of bullets stuck in the rifled part of the barrel, and as the charge weight increased to 0,24 g, 100% of caps flew out of the barrel, not slowing down in the transition cone and giving sonorous shots. And this is under ideal conditions of shooting from the same ballistic weapon! That is, there were inevitable serious problems under difficult operating conditions and different temperature conditions, according to the typical domestic requirements for reliability. Plus, ensuring a stable performance of the system in the manufacture of its components in actual production, taking into account the inevitable tolerances for the accuracy of manufacturing both ammunition and weapons.

That is why, seeing and objectively evaluating the current results, in the 1954 year I.Ya. Stechkin proposed to improve the design. Namely - to produce braking of the pushing pallet at the level of the cut-off of the end of the cartridge case, as if transferring the brake cone from the weapon chamber. More precisely, using a dulce sleeve as such a cone. As a result, the cut-off of powder gases should now have been carried out in a cartridge case, at the end of which the shot pan stuck. And the removal of the pallet from the weapon would occur along with the removal of the spent cartridge case. So began work on the cartridge SP-2, which became the first domestic silent cartridge with a cut-off of powder gases in the sleeve.

As a result, the cartridge SP-2 was adopted in 1956 year, along with the original weapon - a scout knife shooting (LDC), developed by the designers of the Tula arms factory, which combined the traditional edged weapons and single-shot shooting device, placed in the handle of the knife. Much later, in 1962-65, they also developed an 7,62-mm double-barreled non-automatic SME pistol (“Small-sized special pistol”). Both samples later used the SP-3 cartridge, the size of which was identical to the SP-2 cartridge cartridge case and cartridge case. Stechkin I.Ya. designed his shooting device TKB-506А, externally made in the form of a cigarette case. Three SP-2 cartridges were charged into it and reloaded manually, for each of them inside the “cigarette case” there was its own receiver group and a percussion mechanism. The design and details of testing the SP-2 are also given in the third book. monographs V.N. Dvoryaninova "Small arms combat cartridges".

Analyzing the testing of SP-1 and SP-2 cartridges, it is necessary to note some fundamental points that are important both for a common understanding of the further development of domestic "silent" ammunition and weapons, and for historical justice.

When comparing the cartridge configuration of the cartridge SP-2 before and after the shot, as is clearly seen in the photo, it is noticeable that the sleeve sleeve “disappears”. This is a result of the dynamic braking of the pallet. In the process of which there is a plastic deformation of the sleeve liner and, in part, of the pallet itself. Having thus consumed its kinetic energy, the pallet gets stuck in the cut of the cartridge sleeve, cutting off and plugging the powder gases in the cartridge case, which is the main idea embedded in the design of the cartridge. Obviously, this process cannot be called simple at all, especially since it is necessary to ensure its 100% stability both in different operating conditions and in the industrial production of all elements of the cartridge. Needless to say, domestic cartridge manufacturers are confronted with a whole bunch of design and technological problems in this regard, but it was precisely by working on the SP-2 that they found ways to solve them. Both the strength of the stamped pallet and the liner strength and the stable ballistic characteristics of the shot were ensured.

In the process of testing the cartridge faced the problem of the stability of the bullets on the flight. In search of a solution, the dimensions of the bore through the rim fields and the traditional, 4 rifled barrel with the 240 mm rifling pitches were refined, was replaced with the 6 rifled steeper with a steeper 160 mm pitch. That allowed essentially to reduce the number of oval holes and had a positive effect on the accuracy of shooting. This is the main reason for using an abnormal barrel for this and subsequent domestic ammunition of this type.

Also had to deal with the effect of a sheaf of sparks, which accompanied the shot and was unacceptable, as a serious unmasking factor. Some sources mistakenly indicate that this is caused by the breakthrough of powder gases when the pallet moves in the sleeve. However, as a result of research during the development of the SP-2, it turned out that the main reason is the movement of a bullet through the barrel bore and the state of deterioration of the bore. To eliminate this effect, I also had to find my own little know-how. As well as for many other structural elements and their manufacturing technology.

Carefully reviewing the design of the ballistic weapon for the SP-1 cartridge, we note that at the beginning of the rifled part of the barrel, immediately after the brake cone for the drip pan, a number of bypass holes were made. Which, as stated, served and “To eliminate the vacuum that forms (with a good obturation of the cap) between the cap and the bullet as it progresses along the bore”. We are talking about the effect, well known to anyone who disassembled a bicycle pump. When removing a well-fitted piston from the pump body, if you tightly close the hole for the hose with your finger, you will feel its serious resistance to extraction, and when the piston leaves the body, cotton follows. The author of the general idea I.Ya. Stechkin, having entered into the design of the above-mentioned bypass holes. This is true only a deep theoretical assumption, later repeated several times in the national history of ammunition mining with the cut-off of powder gases and weapons under it. And also still present in almost all popular publications on this topic. The fact is that in practice it is not possible to ensure the absolute absence of a breakthrough of powder gases when the pallet moves between it and the walls of the liner. In addition, the bullet, pereobzhimyasya, cuts the shell into the grooves during its movement along the barrel is also not uniform and does not "overlap" it like a pump piston. There are always gaps, which is why we cannot speak about the formation of a vacuum behind a bullet.

Ending the background to the development of ammunition with a cut-off of powder gases in the sleeve, it remains to clarify some common points. There is no doubt about the talent and ingenuity of our designers. They were and will remain the first to succeed in putting this into practice, bringing the general theoretical idea to the adoption of a combat cartridge and its introduction into mass production. Therefore, the history of the beginning of the creation of this class of domestic ammunition and weapons does not need additional decoration and a description of false victories or merit. The initiative and general ideas of the design originated, undoubtedly, from the CDB-14 and I.Ya. Stechkin, who himself tested the first options. But the development of the design of the cartridge SP-2 and its testing were fully implemented in the Research Institute-61 Elizarov Nikolai Mikhailovich and Gubel Iraida Semyonovna.

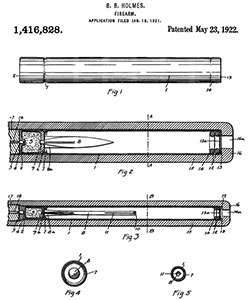

It is also worth noting that the very idea of the cut-off of powder gases was not first put forward either by the Mitin brothers or Igor Yakovlevich. There are, for example, US patents No. 1,416,827 and No. 1,416,828 issued by 23 on May 1922 of the year to Bradford Holmes (Bradford B. Holmes, New York, NY, USA). In the description of the latter, the author indicated that his “The invention is intended for silent, flameless and smokeless firing of pistols, automatic rifles, machine guns and, in general, whenever fast [automatic] firing is necessary.”

The cartridge was supposed to be a barrel-case, in which the primer was placed, a powder charge and a snapped feathered bullet, which was set in motion by a bowl-shaped piston, and “An automatic brake muzzle device for slowing down and stopping the piston in a Dultz, but allowing the bullet to exit.” Braking of the pallet should have been ensured by the deformation of the shock-absorbing rings placed at the end of the acceleration of the bullet in the barrel part of the liner. When braking the pallet, the bullet should have “ripped” the rivet from the pallet, which had previously fastened the shank of the bullet to the pallet and continued its flight to the target. And the rivet hole formed in the pan was intended to relieve the residual pressure of the powder gases. What is interesting is that the groove in the bottom part of the sleeve (7) was provided not only for fixing (fixing) the pallet and the bullet in the sleeve when assembling the cartridge, but also for the pallet, "Straightening it" when moving "Slightly increased the original length of the sleeve" and the sleeve, starting from the front end of the chamber, gave the shutter the necessary energy to reload the weapon and extract the spent cartridge, thus providing the possibility of creating an automatic self-loading weapon. Such a curious suggestion ... To be fair, the general idea with the cut-off of powder gases is correct (except for the rivet hole in the pan), but the design proposed by Bradford Holmes in 1922 was not rigorous in its detailed analysis, especially taking into account practical experience and knowledge accumulated by the designers-patrons for the past almost 100 years.

The cartridge was supposed to be a barrel-case, in which the primer was placed, a powder charge and a snapped feathered bullet, which was set in motion by a bowl-shaped piston, and “An automatic brake muzzle device for slowing down and stopping the piston in a Dultz, but allowing the bullet to exit.” Braking of the pallet should have been ensured by the deformation of the shock-absorbing rings placed at the end of the acceleration of the bullet in the barrel part of the liner. When braking the pallet, the bullet should have “ripped” the rivet from the pallet, which had previously fastened the shank of the bullet to the pallet and continued its flight to the target. And the rivet hole formed in the pan was intended to relieve the residual pressure of the powder gases. What is interesting is that the groove in the bottom part of the sleeve (7) was provided not only for fixing (fixing) the pallet and the bullet in the sleeve when assembling the cartridge, but also for the pallet, "Straightening it" when moving "Slightly increased the original length of the sleeve" and the sleeve, starting from the front end of the chamber, gave the shutter the necessary energy to reload the weapon and extract the spent cartridge, thus providing the possibility of creating an automatic self-loading weapon. Such a curious suggestion ... To be fair, the general idea with the cut-off of powder gases is correct (except for the rivet hole in the pan), but the design proposed by Bradford Holmes in 1922 was not rigorous in its detailed analysis, especially taking into account practical experience and knowledge accumulated by the designers-patrons for the past almost 100 years.We repeat once again that domestic specialists were and will remain the first to manage to put the general idea into practice, creating a simpler and, most importantly, really efficient design of the silent cartridge SP-2.

His development gave impetus to the creation of even more advanced cartridges of similar design. At the end of 1950-x - the beginning of 1960-x. Specialists of research and development structures of the special services developed the 9,1-mm cartridge “Phalanga-A” for silent pistol shooting (Product “D” and “DM”) and the “Mouthpiece-A” cartridge unified with it, designed for silent throwing grenades “Lizard” ". At the same time, approximately in 1961, the 7,62-mm silent Snake (“PZ”) cartridge was developed for the C-4 “Thunderstorm” double-barreled pistol, then its advanced versions - “PZA” and “PZAM”. These cartridges had greater power and better accuracy of fire, they used a regular bullet from the 7,62x39-mm cartridge arr. 1943 of the year. At the same time, they had larger dimensions, greater weight (especially the “Phalanx-A”) and a complex structure, and were also not technological and expensive to produce.

Therefore, considering the advantages and disadvantages of the available standard cartridges silencer, before designers TSNIITOCHMASH at the end of 1962 years has been tasked to develop a more technologically advanced and cheap 7,62-mm silent cartridge, instead of cartridges SP-2 and PZAM but interchangeable with the cartridge SP-2 in overall dimensions. The last requirement was explained by the fact that the cartridge SP-2 was used for firing from the scout knife of the NRS. In addition, under the cartridge SP-2 planned development of a special gun.

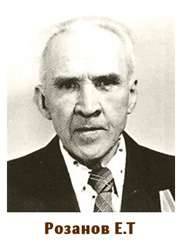

This cartridge was named SP-3 and was developed mainly during 1963-1964's. In 1965, a copyright certificate No. 34306 was obtained for the design of a cartridge in the name of E.T. Rozanov. (executive in charge of the work), Smekayeva K.V. (supervisor) and Nikishin G.I. (customer representative).

In the cartridge SP-3, in accordance with the technical task, a standard bullet with a steel core from the 7,62x39-mm cartridge arr was used. 1943 of the year and the sleeve from the cartridge SP-2. The "highlight" of the design was a telescopic pushing device consisting of a sleeve and a rod located in it, which ensured that the bullet was guided through the barrel when fired and the gas cut off in the sleeve. In the technology of manufacturing elements of the cartridge and its assembly there was a number of "know-how" to reduce sparks when fired. The use of the telescopic design of the master made it possible to create a cartridge SP-3 in the dimensions of the cartridge SP-2, with the best accuracy in 2 times. At the same time, the cartridge SP-3 is 30% shorter than PZAM. The braking elements of the master device at the SP-3 are more stretched over time, and the braking force is significantly reduced due to the sequential braking of the sleeve and stem and plastic deformation of the liner core. This, in turn, made it possible to use a thin-walled sleeve and reduce the weight of the cartridge compared to the PSAM cartridge by 3,5 times, improve manufacturability and reduce the production cost by 3 - 4 times. Details on the history of development, subsequent modernization, design and technical characteristics of the cartridges SP-3, PZAM, PFAM and PMAM can be found in the third book of the monograph of V.N. Dvoryaninova "Small arms combat cartridges".

The cartridge SP-3 is the best and most perfect representative of the family of domestic silent cartridges with a pushing rod-rod, not only incorporating all previous experience of their development, but also having improved significantly compared with them. Experts still consider it the quietest and most elegant among them. In 1973, for his development, K.V. Smekayev. (scientific director of research) Sabelnikovu V.M. (Director of TsNIITOCHMASH) and Nikishinu G.I. (customer representative) was awarded the title of Laureate of the USSR State Prize, and Ye.T. Rozanov (Executive officer) was awarded the Order of Lenin.

The SP-3 cartridge was adopted only in the 1972 year. And during 1971 - 74, its so-called “implementation” was going on at the ammunition factories. Thus, the development of the cartridge SP-3, together with the development of its production, took a very long time - 12 years. Such a long period was required for testing all the nuances of the design and its manufacturing technology, as the patrons were faced with a lot of problems and questions. Several times it seemed that the mastering of the cartridge was finally completed, but more and more nuances and surprises “surfaced”.

August 24 1972 by order of the Minister of Defense of the USSR No. 145 "Small-sized special pistol" (SME) under the cartridge SP-3 was adopted and received the index 6П24. Knife scout shooting (LDC) has not undergone major changes and it also now used the cartridge SP-3. But no self-loading (automatic) weapon for this cartridge was ever created.

2 - 7,62-mm non-automatic dual-charge pistol SME chambered for SP3;

3 - 9,1-mm C4M non-automatic dual-loaded pistol chambered for PFAM.

In articles on the history of small arms it is often stated that a self-loading pistol chambered for the SP-3 cartridge could not be developed due to the fact that its rod protrudes by a significant amount from the sleeve. However, this is not entirely true. And not only because the length of the fired cartridge with the extended rod is only a few millimeters longer than the length of the cartridge with the bullet before the shot (see the figure).

The development of a self-loading pistol chambered for SP-3 was done in 1969 - 70. at the Tula Arms Plant, then in 1971, at TsNIITOCHMASH. These works showed the fundamental possibility of creating a self-loading weapon, even under a low-power cartridge with a gas cut-off in the sleeve. But the cartridge SP-3 turned out to be unsuitable for this purpose, basically, and paradoxically, because of one of its merits - the use of a thin-walled pressed sleeve. During the extraction of the spent cartridge case of the SP-3 cartridge, immediately after the shot, a primer fell out or a transverse breakage of the upper part of the sleeve body under the action of a high residual pressure of the powder gases. In order for it to decrease to an acceptable value due to the cooling of gases, it was necessary to remove the liner from the chamber during semi-automatic shooting with a significant time delay. This forced to increase the free motion of the bolt carrier to values unacceptable from the point of view of gun dimensions, and the speeds of the moving parts of the automation in the extreme positions were obtained significantly less than was required to ensure reliable operation of the gun. Additional difficulties were caused by the metamorphosis of the SP-3 liner case and, especially, by its barrel when braking the pallet. By the way, this is what forced gunsmiths to use in the design of C-4 pistols and SMEs not quite the standard way of fixing the cartridge in the chamber - due to a special clip that held two cartridges by grooves in the cartridge cases and was inserted with them into the gun cartridge when loading.

Since the need to create an automatic self-loading pistol was obvious, in the 1971-1972's. the search for technical solutions was continued by the designers of TsNIITOCHMASH (46 department), in parallel with the specialists of the research and development structures of the special services. It was clear that we would have to develop both a new cartridge, a different design, and a non-standard design pistol, since the known automation schemes were not suitable. And new, reassuring solutions and constructive schemes of the weapon and cartridge were found!

In other words, such results are called inventions.

Продолжение следует ...

Information