Project of heat steam locomotive TP1

The appearance of the idea of a heat steam train was to some extent facilitated by the fact that before the beginning of the forties, the creators of locomotive technology had specific views on the appearance of promising machines. At that time in our country it was believed that the diesel locomotive of the future should have a diesel engine and a mechanism for direct transmission of torque to the driving wheel sets. The similar architecture of the locomotive, used on locomotives, did not fully fit the technology with diesel engines. The diesel engines of that time could work normally only when the crankshaft rotated at a speed of at least 120-130 revolutions per minute. This meant that a direct-drive diesel engine would simply not be able to start the engine in the parking lot and move off without help.

By the mid-thirties, several variants of promising locomotives were proposed, in which the diesel engine was used in one or another role as part of the power plant. So, a student of the Moscow Electromechanical Institute of Transport Engineers L.M. In 1935, Maisel proposed to create a locomotive equipped with both a diesel engine and a steam engine. Preliminary calculations showed that both engines will be able to work both independently of each other and together. People's Commissariat of Communications became interested in this idea and initiated the development of such a technique, called the “heat steam train”. Over the next years, designers of a number of locomotive-building enterprises and related organizations developed several projects of promising locomotives.

Work on the subject of heat steam locomotives lasted for several years, but the first successful project of such equipment started only in July 1939. Its authors were engineers of the Kolomna Locomotive Plant. Leading the development was carried out by L.S. Lebedyansky, M.N. Schukin and A.I. Kozyakin. Despite the complexity, Kolomna specialists quickly coped with the creation of the project and the construction of an experienced locomotive. All this work took only five months. Already at the end of the 39-th began factory tests of the new prototype.

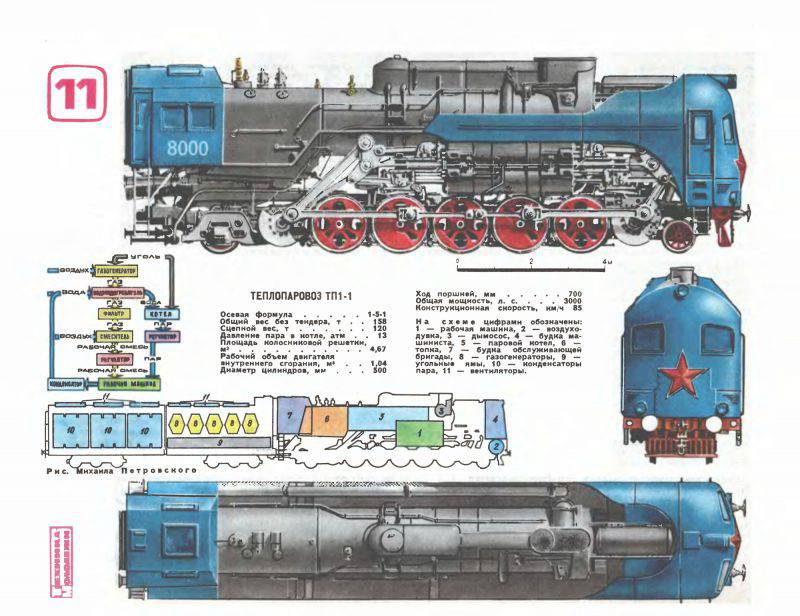

The project of the Kolomna Locomotive Plant was given the clear and obvious name of the TP 1 - “Heat steam locomotive, the first one”. To designate the locomotive used in the tests, the index TP1-1 was used. In the future, TP1-2, TP1-3 and other machines of the series could appear, but this did not happen.

In accordance with the technical task of the People's Commissariat of Communications, Kolomna engineers had to develop a heat steam locomotive with a traction force at the level of the FD locomotive or better. He had to develop a power order of 3000-3500 hp With this up to 2000 hp should have been obtained from the gas engine, and from the steam engine it was planned to remove no more than 1000-1500 hp. Such requirements affected the design of the locomotive, and also required the use of some new ideas.

In the framework of the new project, it was proposed to use a number of original and bold technical solutions that could provide a solution to the tasks. In addition, to simplify all the work, it was planned to widely use the existing components and assemblies, as well as well-developed ideas. The result was a locomotive of the original design, which differed from the equipment of that time both in appearance and internal structure. At the same time, in its construction, aggregates of serial steam locomotives that existed at that time were widely used.

The basis of the heat steam locomotive TP1 was the crew part with the axial formula 1-5-1, in the design of which the effect of the FD steam locomotive was visible. On the frame there was one running axle, five driving and one supporting. The running and supporting axles were equipped with small-diameter wheels, the driving axles were large, with a diameter of 1,5 m.

On the frame of the crew of the boiler installed, developed on the basis of units of the steam engine Su. After some improvements in the design, a number of parameters of the base boiler changed in one direction or another. As a result of all the improvements, the boiler TPPNNXX had an evaporating surface of 1 m2 and a steam superheater of area 170,6 m2. There was a grate 80,5 sq. M. The vapor pressure in the boiler was reached up to 4,67 kgf / sq. Cm. It was assumed that the boiler will be used to move at low speeds. During overclocking, it was proposed to connect a heat engine to work.

Thermal steam boiler TP1 had a curious arrangement of units. A front cabin with a driver’s workplace was installed in front of the boiler. Such a cabin with windshields improved visibility and allowed the driver to follow the road, signals, etc. with greater convenience. At the same time, the cabin of the “classic” design was preserved behind the boiler. There should have been a maintenance team responsible for the operation of the boiler, fuel supply, etc.

Behind the main machine docked tender, consisting of two parts. In the front there were fans, gas generators and a coal pit. The back of the tender, in turn, was equipped with a water tank, steam condensers and some other units. To save space on the steam engine, the gas generators of the heat engine, steam condensers and a number of other components used by the power plant were mounted in the tender. The locomotive and the tender were connected by a set of pipelines for the transfer of generator gas, water and steam, as well as screw conveyors for solid fuels.

The greatest interest in the project TP1 was the design of the power plant, which combined the features of a steam engine and a diesel engine. On the sides of the boiler, in the central part of the locomotive, it was proposed to install two cylinders with a diameter of 500 mm each. Inside the cylinder were placed two pistons with a stroke of 700 mm. The pistons were arranged in such a way that the cylinder was divided into three separate chambers. In total, the composition of such a power plant had four cylinders, eight pistons and 12 chambers.

Cylinders of each side were placed horizontally, one above the other. Pistons were connected with connecting rods, sliders, rocker arms and other parts that converted their reciprocating movement into rotation of the baffle shafts with flywheels. The design of the crew part was attended by two such shaft, in front of the driving axles and behind them. The fender rollers were equipped with breathers connected to the driving wheels.

When using such an engine in the steam engine mode, steam distribution was performed using the Marshall mechanism. Spent steam was not emitted into the atmosphere, and through pipelines sent to the steam condensers of the tender. This has significantly reduced water consumption. The work in the diesel mode was provided by a turbo-gas blower providing the gas-air mixture to the cylinders. In addition, the cylinders were equipped with electric candles.

The power plant of the steam locomotive was supposed to work in the first machine mode at the beginning of movement and acceleration to speeds of the order of 15-25 km. When this speed was reached, the frequency of movement of the pistons made it possible to switch to the use of a diesel engine.

Five gas generators installed in the tender had to consume solid fuel (anthracite) and produce a combustible gas in an amount of about 4800 cubic meters per hour. To improve performance, the gas generators were equipped with a steam-turbine pump with an 300 horsepower, which pumped 200 cubic meters of air per minute through them.

The generator gas was fed to a heat exchanger to heat the water entering the boiler. In special waste-heat boilers, the gas was cooled from 700 ° C to 200 ° C, after which it was fed to the air heater and two filters. In the course of filtration, all coal dust was removed from the gas, and in addition, it was additionally cooled to 100 ° C. After that, the combustible gas was mixed with atmospheric air and fed into the central chambers of the four cylinders. Front and rear cameras were used only for steam supply. With the oncoming movement of the pistons, the gas-air mixture was compressed, after which the mixture ignited from the spark of an electric candle. Exhaust gases were thrown out.

A characteristic feature of the project TP 1 was the use of common cylinders designed for use in all modes of operation. When driving, accelerating or decelerating, the perspective heat-steam locomotive had to use steam generated in the boiler, and at speeds above 20-25 km / h, it was possible to connect a heat engine that markedly increases the overall power of the power plant.

The use of the original power plant and a number of new units affected the mass of the structure. The total operating mass of the TP1 heat steam locomotive without tender reached 158 t, the coupling weight was 120 t. For comparison, the FD steam locomotive, which was a kind of benchmark in the development of a new project, in working order weighed no more than 145 t, 110 t.

According to calculations, the first domestic heat and steam locomotive should have sufficiently high performance. Thus, the design speed was determined at the level of 85 km / h. The estimated efficiency was 11%. For comparison, the analogous parameter of locomotives of that time did not exceed 6-8%. Thus, a promising locomotive markedly surpassed the existing equipment in terms of efficiency and therefore was of great interest to railway workers.

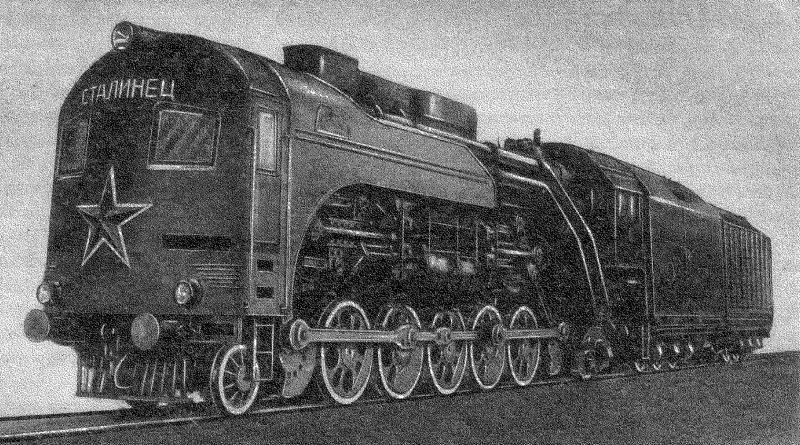

Work on the TP1 project began in the middle of the summer of the 39, and the construction of the experimental heat and steam locomotive was completed in the middle of December. December 26 locomotive with the symbol TP1-1 and the personal name "Stalin" for the first time went to the railroad tracks. On this day, the first test drive on the existing line from Golutvin station to Ryazan was carried out. Subsequently, the Kolomna Locomotive Works conducted some other tests, the results of which were used to refine the structure.

Factory testing and design improvements continued until June 1940 of the year. After that, the modified locomotive was sent to Moscow, where they were to be tested on the basis of the Research Institute of Railway Transport. The experimental heat locomotive was tested on the experimental ring of the institute from June to November of the same year. During this time, 76 (according to other data, 78) test trips were performed, during which the locomotive overcame 1790 km.

During testing in Moscow, new design flaws were identified. This time it was about the design of the original power plant. Experts of the Research Institute of Railway Transport have established that the combined engine can only operate stably in the steam engine mode. When feeding the gas-air mixture, problems started. When accelerating to speeds at the level of 40-45 km / h, the power plant worked stably for no more than 10-15 minutes. After this, premature fuel flashes began, which occurred already at the stage of the mixture supply to the cylinders. The similar problem did not allow to continue movement, not to mention the further acceleration.

In November 1940, an experienced locomotive TP1-1 was sent to Kolomna to make the necessary improvements. Over the next few months, factory workers fixed a number of minor flaws, and also refined the power plant. Calculations showed that the cause of the unstable behavior of the engine and the premature ignition of the gas-air mixture is an increased pressure in the central chambers of the cylinders. To reduce the pressure to an acceptable level, we had to reduce the length of the piston heads, thereby slightly increasing the size of the central chambers.

Improvement of the steam boiler “Stalinets” was completed at the beginning of the summer of 1941. In the very near future it was planned to begin a new phase of testing and refinement, which in the end could open the way for the locomotive to mass production and use on the country's railways. Nevertheless, the Great Patriotic War began, because of which a lot of promising projects were frozen or closed due to the impossibility of continuing the work. The project TP1 added to the sad list of projects that were not implemented due to the start of the war.

The subsequent fate of the first domestic heat steam locomotive, released for testing, is unknown. Probably for some time it was stored at one of the enterprises, and then it was disassembled for parts or disposed of. However, it cannot be excluded that the experienced locomotive was used for its intended purpose for the carriage of goods, but there are no data to that effect. Anyway, the only specimen of the TP1 heat sink did not live up to our days.

It should be noted that, in the prewar period, not only Kolomna was engaged in the development of heat steam locomotives. Voroshilovgrad plant named after October revolution. Before the Great Patriotic War and immediately after it, the specialists of this company developed two projects of promising heat steam locomotives, which are also of great interest from the point of view of technology and stories.

Based on:

http://rzd-expo.ru/

http://ivan1950.tripod.com/

http://mstrainsim.narod.ru/

http://zdrus.narod.ru/

Kurikhin O. Kolomna teploparovos // Technique - youth, 1980. No.11

Information