Amphibians: from ship to shore

USMC AAV-7 amphibious assault ship enters the water

The transfer of an infantry unit to the coast during an amphibious assault operation is undoubtedly a difficult task ... and not only for people. Within a short time, the functional purpose of the machine changes: from a swimmer to a runner, from a runner to an armed fighter. The requirements for the mobility of such machines are significantly different from the requirements for other combat vehicles, and to better understand this, let's see what is on the market.

The floating (amphibious) machine changes its traditional characteristics related to terrestrial mobility (speed, power reserve, ground pressure, etc.) for specific characteristics related to mobility on water (speed, elevation above water level, seaworthiness, maneuverability) and subsequent access to the shore (overcoming the surf, maintaining stability during the transition from one environment to another, climbing a steep sandy, muddy, pebble or rocky shore). As a rule, according to the design process, floating machines can be divided into two main families. The first, relatively limited, includes those machines that from the very beginning are designed specifically for work in the ocean. The second family is much wider, it includes infantry fighting vehicles and armored personnel carriers, traditionally used by the army, which can cross rivers (as well as lakes, swamps, and even take part in land-sea-land operations). Their nautical qualities are usually worse than those of specialized machines for the sea, but at the same time, some ground combat vehicles have undergone significant modifications and refinement in order to further improve their nautical qualities.

Floating with some reservations

In recent years there has been a general decline in interest in the amphibious capabilities of many combat vehicles. At the main theaters of war there were no large water bodies and amphibious landings on the shore did not happen very often. In addition, the increased requirements for protection and heavier weapons, which are increasingly found on new machines, do not allow us to obtain a floating machine without preliminary preparation. As a result, machines such as the BRADLEY, WARRIOR, PUMA, CV90, DARDO, STRYKER, VBCI, BOXER, FRECCIA, and others, preferred defense, armament and ground mobility rather than amphibious capabilities. However, some models of wheeled (and even tracked) BTR and BMP have acceptable navigational characteristics.

Despite the presence of heavy weapons, the Russian vehicles of the BMP and BMD families perfectly overcome water obstacles with the help of two water cannons (BMP-2 and BMD). As a rule, the machine has a telescopic air intake pipe that allows you to move afloat at sea state Sea-3 (SS3, waves up to 1,5 meter); in addition, according to the developer, the machine can fire at sea SS2 (up to 0,5 meter), while continuing to move. BMD for the airborne troops have a large power density and on the water reach speeds of up to 9 km / h. During amphibious operations, two electric bilge pumps automatically turn on, a surge plate rises, which increases the stability and displacement of the machine in the water, the driver raises the periscope, allowing you to see over the surge shield. Water cannons provide good maneuverability in the water. The Marine Corps of Indonesia bought BMP-3F (54 vehicles in 2007-2014 years) and BMD-4 (54 vehicles from 2015 onwards). However, the Russian marines mainly operate the traditional wheeled BTR-80 and BTR-82AM, these cars are floating, but with some inherent limitations. The Russian landing doctrine stipulates that amphibious ships approach the coast by a few hundred meters or go straight to the shore, and then amphibious vehicles leave them and overcome a rather short portion of the water surface, while seaworthiness is not so important.

Due to the presence of powerful and reliable engines and the use of modern design and production methods, many modern wheeled vehicles 6x6 and 8x8 are also floating.

The Turkish company FNSS has developed a floating combat vehicle PARS in various versions. Despite its fighting mass of 30 tons, this is undoubtedly a highly maneuverable machine, on land it reaches speeds up to 100 km / h and on water 9 km / h (version with water cannons). The Turkish army ordered 1000 of such vehicles, and the Turkish fleet of 50 vehicles for the Marine Brigade. Another major customer of this advanced machine is Malaysia, a local company Deftech manufactures it under the designation GEMPITA.

BTR-3E1, developed by the Kharkov engineering design bureau for them. Morozov, despite the fact that quite reminiscent of the ubiquitous Russian BTR-80 in 2001, was presented to the public. This vehicle was selected by the Thai Marine Corps and shipped to Thailand in 2011.

A few more advanced 8x8 combat vehicles with good amphibious characteristics can be mentioned: Boomerang Military Industrial Company (shown on May Victory Parade 2015 year), KESTREL Tata Indian Company, ENIGMA Company Emirates Defense Technology, CM-32 CLOUDED LEOPARD by Timoney Technology, PIRANHA -IIIC (purchased in different versions of Spanish and Brazilian marines) by General Dynamics European Land Systems (GDELS), AMV by Finnish company Patria, TERREX AV81 by Singapore’s ST Kinetics, YAVUZ AV82 by Turkish Otokar, ZBL-09 or VN-1 (purchased by Venezuelan Marine Corps) Chinese Comp SRI Norinco and VBTP-MR GUARANI Iveco company. In 2005, GDELS-Steyr-Daimler developed the PANDUR-II variant for the Portuguese Marine Corps, which differs from the military version in more light armor (3 Level, STANAG 4569 Level), with two water cannons, as well as a stern ramp, rather than doors. Unfortunately, in 2012, the contract was suspended due to budget constraints.

When adapting existing projects for amphibious tasks, a different approach was adopted. The South Korean army gets a new K21 NIFV (Next Infantry Fighting Vehicle) infantry fighting vehicle from Doosan. This modern 25 ton vehicle is almost entirely made of fiberglass-ceramic composite material, it has a turret armed with an 30-mm cannon, the 9 landing force people and three crew members are located inside. K21 was supposed to float without any preparation, but a couple of accidents during the tests led to the fact that two inflatable pontoons were added on the sides to increase buoyancy.

Until recently, the Chinese army and marines had three amphibious combat vehicles in service: the 105-mm light tank ZTZ-63A, the BTR Type-63C with 13 paratroopers and the BMP Type-86B (copy of the BMP-1). The first of them is equipped with water cannons, and the second and third are the development of previous military models, an air intake pipe, bow and stern removable pontoons were added to these machines. They also installed outboard engines - a simple solution that allowed them to sail for short distances at a rather high speed, albeit on calm water.

Created for the ocean

Very few cars were designed, in which particular attention would be paid to sea landing and in which the rich experience of the Second World War would be fully utilized. Definitely the most common and typical vehicle in this category is the AAV-7A1 (Assault Amphibious Vehicle) amphibious amphibious vehicle from BAE Systems, since 13 countries have adopted it. A new assault vehicle began to enter service with the US Marine Corps (ILC) in 1972 in the year under the designation LVTP-7 (in 80-ies, the machine received the current designation). AAV-7A1 can float at a speed of 8 nodes over a distance of 56 nautical miles during a sea SS3 and stay afloat during a sea SS5 (up to 4 meters). During her long career, her remarkable seaworthy qualities were used very rarely due to the lack of “real” landing operations, while the sheer size resulted from the requirement to transport a group of fully equipped infantrymen from 25.

After such a long and glorious life, the AAV-7 needed an urgent replacement. In this regard, the AAV-7 modernization program was launched, which was designated as RAM-RS (Reliability, Availability, Maintainability-Rebuild to Standard - reliability, availability, maintainability - upgrading to standard). In March, XICUM SAIC was awarded a contract to upgrade the first batch of AAV-2015A7 (1 + 10 machines). This program provides for upgrading a total of 52 machines by increasing the level of protection and mobility on land and water (engine overhaul, new transmission, upgraded suspension, new water cannons, improved side and bottom protection, energy-absorbing seats, etc.). The first upgraded machines should be ready for the 390 year, after which their lifespan will be extended to about the 2018 year. This program is a kind of intermediate since the original replacement program under the designation EFV (Expeditionary Fighting Vehicle) was canceled in the 2035 year after the cost of it became huge, exceeding 2012 billions of dollars. The characteristics of the EFV were amazing: the speed on the water 15 km / h, the cruising range 46 nautical miles, the speed on land 65 km / h, heavy armament and good protection, the machine was able to take three people to the 72 infantry. The next program after it the program will be described below (see “In search of a solution”).

Surprisingly, the Chinese company NORINCO was able, oddly enough, despite the lack of experience, to design and manufacture what is today the best amphibious assault vehicle in service. The family of these machines is under the general designation Type-05: BMP armed with an 30-mm gun (ZBD-05), commander and engineering versions, 105-mm light anti-tank installation (ZTD-05) and 122-mm self-propelled howitzer PLZ-07B, in which the tower of the military howitzer PLZ-05A was installed on the ZBD-07 case. Their overall body is distinguished by a long nose and the most unusual element - a gliding body, which allows the staggering speed of 25 km / h to be developed on the water. The large foreplate and stern flaps with hydraulic actuators together with the flat bottom of the hull form a gliding surface with significantly reduced hydrodynamic resistance. Two large water cannons are driven by an engine that develops the power of the HP 1475. on the water and 550 hp on the land. The telescopic air intake pipe also rises afloat. The ZTD-05 carries a crew of three people and seven foot soldiers. The twin turret, created in Ukraine, is armed with an 30-mm cannon, a 7,62-mm machine gun and two RED ARROW-73C ATGMs. The lightweight ZTD-05 anti-tank machine has the same gliding flap system, while the heavier PLZ-07B self-propelled howitzer naturally overcomes water hazards at lower speeds.

The 105-mm cannon of the ZTD-05 can also fire laser-guided missiles at a range of 5 km, which makes it possible to fire targets at the coast while sailing. The ZBD-05 and ZTD-05 in 2014 were sold to Venezuela for its marines, replacing the outdated LVTP-7. In general, the ZBD-05, although somewhat less advanced than the EFV, is alive and well ...

The basic version of the PARS company FNSS, floating, in the water is driven by two water cannons installed in the stern. Swim speed is at least 10 km / h, standard equipment includes all steered wheels, an automatic gearbox, an auxiliary power unit with a power of 2,2 kW (16 hp) and a hydraulic winch for self-pulling with a power of 133 kN

The 8x8 multipurpose amphibious wheeled vehicle from Mitsubishi Heavy Industries (MHI) may be based on the 8x8 fighting vehicle Manoeuvre Combat Vehicle (MCV), which was developed by the Japanese Institute of Technology and manufactured by MHI. Tests are scheduled for 2014-2015 years, and the entry into service on 2016 year

Challengers to the KMP program for the ACV 1.1 (Amphibious Combat Vehicle, substage 1.1) floating program focus on the potential requirements of the 1.2 substage - improved buoyancy and a large number of places, which suggests that these substeps will be combined in the future

Looking for a solution

After the cancellation of the EFV program, the USCM launched the Amphibious Combat Vehicle (ACV) combat floating machine program. According to the project, this highly mobile 8x8 vehicle is capable of transporting 17 infantry at speeds of 8 nodes to 12 nautical miles; It was expected that the first batch of 573 machines would go into service in the 2012 year. The program was divided into two batches: ACV1 includes several hundreds of existing machines, less expensive and less complex, deployed by airborne assault vehicles on the air cushion LCAC (Landing Craft Air Cushion) and other landing craft. In 2013, KMP released a set of 30 requirements, according to which the promising ACV2 option should have more advanced features, including the speed of 13-15 nodes and the turret with an 30-mm gun.

The ACV 1.1 sub-step provides for the initial shipment of MPC (Marine Personal Carrier) 200 machines. The MPC program was started back in 2008, but was suspended in 2013 and reanimated in 2014. ACV 1.2 provides for the purchase of 400 vehicles, including MPC and other specialized options (commander, evacuation, engineering, fire support, etc.). At the end of March, the 2015 of the year, the United States Commissar issued a request for proposals, expecting to receive the first vehicles for evaluation in the 2016 year. At the end of the first series of tests, most likely in 2018, two final projects will be selected and each applicant who qualifies for the final will be ordered on 16 machines. The final decision will be made by 2020; it is assumed that it will be based on the “optimal value”: not the lowest cost, but not the highest performance.

Four competing projects based on options for existing foreign machines (hence with reduced risk) have already been evaluated during MPC tests in 2013. The ACV 1.1 sub-vehicle will transport 10-13 foot soldiers and three crew members with a two-day supply, and have mobility on land comparable to mobility tank M1 ABRAMS and have buoyancy comparable to the current AAV-7A1. She will leave the landing ship about 8 km from the coastline, go along the sea with a wave of SS3 and overcome the surf 1,2-1,8 meters high. The machine will have a remotely controlled combat module in the marine version of Kongsberg's M153 CROWS-II 12,7 mm. BAE Systems and Iveco offer their SuperAV (Amphibious Vehicle - a floating vehicle), which is a slightly elongated version of the Italian Iveco VBA. Among the competitors, SuperAV is probably the largest and heaviest (26 tons) machine, but at the same time it has some of the best seaworthiness. It can carry 3 + 13 people with a three-day supply, which is a good application for the next ACV 1.2 sub-step. The machine has a V-shaped body made of armored steel, with excellent anti-mine characteristics.

The General Dynamics solution is an extended version of the LAV 6.0 (based on LAV-IIIC, a modernized Canadian LAV-UP and experienced LAV 5.0), capable of carrying two-day stockpiles of 2 + 10. According to the company, its innovative double V-shaped case offers the best protection against mines. In turn, SAIC (currently responsible for upgrading the AAV-7 fleet), in cooperation with Singapore-based ST Kinetics, offers the TERREX-II machine. This is a variant of the TERREX passenger capacity 2 + 12, which is currently in service with Singapore.

As for the other rivals, it turned out that they had already fulfilled the requirements of MPC regarding mobility, seaworthiness, passenger capacity and survivability. The non-traditional systems include the camera system of circular vision, which provides the crew with an increased level of situational awareness even with closed hatches.

The company Lockheed Martin originally offered the car HAVOC, a modification of the Finnish armored personnel carrier Patria AMV, which was successfully tested. Then, in May 2015, the collaboration was discontinued, and Lockheed Martin will propose another machine, which is currently undeclared.

In addition, the fifth unexpected challenger emerged - Advanced Defense Vehicle Systems (ADVS) with its upgraded DESERT CHAMELEON 8x8 vehicle.

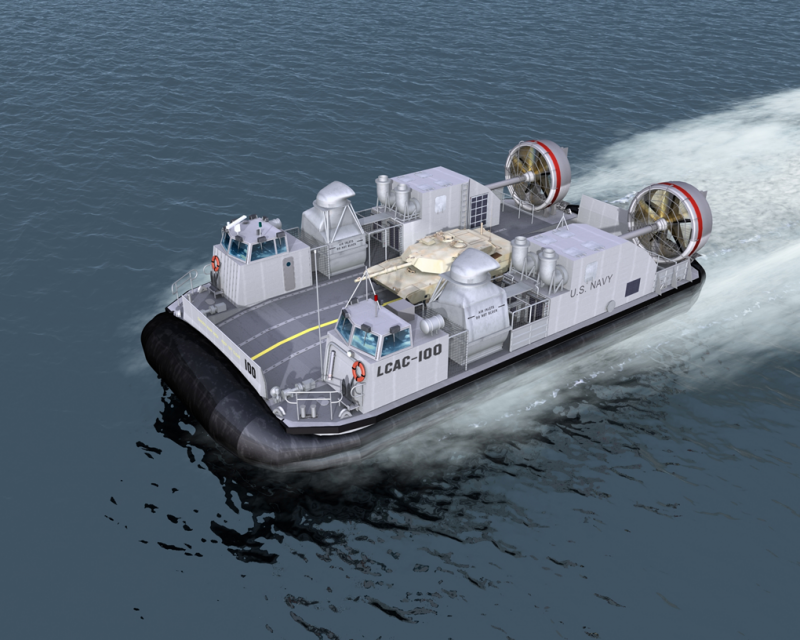

It must also be said that the Japanese company Mitsubishi Heavy Industries is actively working on the amphibious version of its new machine 8x8, which should offer a significant increase in the speed of water compared to the current AAV-7A1. An experimental model of the base case was shown at Eurosatory 2014. The Japanese company is currently discussing possible cooperation on the development of a new machine with BAE Systems and GD, including promising export deals. The entire ACV 1 program to reduce risks is based on the availability of new high-speed amphibious landing craft that will deliver amphibious vehicles from the amphibious task force operating in 40-120 km from the coast to shore. Prospective internal combustion engines will be able to produce cars in 6-8 km, and not plant them directly on the beach. LCAC (three cars), LCAC-100 (four cars) and high-speed vessel SPEARHEAD (30 machines) are of this type.

Addition. Implementation of the US Navy Amphibious Assault Equipment Program

Landing Craft's new Air Cushion (LCAC) hovercraft, developed as part of the Ship-to-Shore Connector (SSC) program, will replace the existing the fleet Landing and landing equipment built by Textron Systems, whose life is nearing the end

The SSC (Ship-to-Shore Connector) amphibious landing program will significantly enhance the future amphibious capabilities of the US Navy and ILC. The new LCAC (Landing Craft, Air Cushion) airborne amphibious assault landing craft under the SSC program will be a natural substitute for the existing Textron Systems LCAC fleet, whose service life is nearing its end.

This program is very significant in scale, as it provides for the replacement of 73 by LCAC vessels of the US Navy (one training and 72 working vessel).

Textron Systems, the main contractor for the SSC program, assembled a team of experienced and qualified US and foreign companies. A partial list of companies includes: Rolls-Royce Naval Marine - development of engines for new ships; Alcoa Defense - aluminum construction; L-3 Communications - information and control systems; and GE Avionics Dowty Propellers - propellers for these vessels.

Bill Kizaya, Vice President of Marine Systems Division at Textron Systems Marine & Land Systems, said that “the closest and main points of the contract include the completion of the LCAC 100 training and test vessel and LCAC 101 working vessel in 2017 and eight production vessels, which should be delivered by 2020 ".

At first glance, there are no significant differences between the obsolete LCAC of the US Navy and the new ships. However, Kayzayah drew attention to the not so elusive differences of the new ships built under the SSC program, compared to existing means: more powerful engines with reduced fuel consumption, extensive use of composite materials, simpler and more efficient power drive, the use of aluminum alloys and dual control of the “steering-second steering”.

Mr Kizayas continued: “In addition, the new LCAC ships will have a payload capacity of 67 tons, while existing LCACs can take a load of just 54 tons. The crew of the new ships will consist of two people (the helmsman [commander] and the second helmsman) compared with the crew of three people of the existing LCAC ships. Also, new vessels will have an improved design of the skirt (flexible curtain), an advanced skirt instead of a wide skirt, this will reduce the hydrodynamic resistance and the weight of the vessel. "

The document of the US Navy Department responsible for the SSC program says that the payload of 67 tons is as follows: “the protected personnel transport module can be loaded on board, it can accommodate up to 145 infantrymen in combat gear or 108 wounded.” Another significant advantage of ships under the SSC program will be that the commander of the expeditionary corps will be able to send its forces from landing ships or mobile airborne assault vehicles at a distance of 25 miles from the coast. This distance will allow ships to increase the ability to combat missiles of coastal defense systems, which stand on the coast of many countries around the world.

Textron Systems has significant capabilities and all the conditions in order to manufacture vessels under the SSC program and deliver them to the customer to the US Navy and Marine Corps. Kizayya noted that his company has a shipyard with an area of more than 560000 square. meters, located in New Orleans, which is specifically designed for the construction of hovercraft. “We use our many years of experience and our own research to ensure that the production process is highly efficient, we consolidate production in order to carry out work fairly quickly with a significant reduction in labor costs. Immediately after construction, these vessels will leave the assembly slipways to the open sea and be ready for delivery to our fleet. ”

In addition, Textron Systems has invested more than 50 million dollars in the automation and robotization of production, instruments and tools used in the construction of ships, which will save thousands of man-hours and increase the safety of personnel. Kizayz continued: “Our new systems, such as automated welding panels, robotic assembly and installation lines, hull assembly lines and other improvements of our shipyard, will allow us to deliver the ships we build to our customers at home and abroad, and to supply the best products at more competitive prices.”

The SSC program is quite capable of going international. Kizayya said that in collaboration with the US Navy, Textron Systems is leading a discussion on the supply of hovercraft SSC to a number of fleets and armies, including potential customers in Asia, Europe and the Middle East. He added: "As the construction of such vessels continues, we see a keen interest of potential customers seeking to add this world-class landing craft system to their fleets."

Materials used:

www.fnss.com.tr

www.baesystems.com

www.generaldynamics.com

www.textron.com

www.mhi-global.com

www.wikipedia.org

www.wikipedia.ru

Information