British armored vehicle modernization programs

Picture of a Scout SV machine in reconnaissance configuration with an installed LMUK twin-turret armed with a 40-mm cannon with telescopic shells and a paired 7,62-mm machine gun

After many years of underfunding, Great Britain is going to spend considerable funds on its ground forces over the next decade, most of which will be spent on combat capabilities. Consider the three main programs for combat armored vehicles.

Over the past few years, the UK has made many false starts in its activities aimed at replacing or upgrading the main part of the fleet of armored combat vehicles (BBM).

Many of the current machines were developed over 30 years ago (and some even earlier), and therefore a whole series of very different programs was launched. It is worth recalling some of them: a promising family of light armored vehicles FFLAV (Future Family of Light Armored Vehicles), a requirement for a tactical intelligence armored vehicle TRACER (Tactical Reconnaissance Armored Combat Equipment Requirement), a multi-purpose armored car Boxer MRAV (Multi-Role Armored Vehicle) and The very recent FRES UV project on the universal Utility Vehicle as part of the Future Rapid Response System Future Rapid Effect System; at the moment they were all unclaimed. Some were canceled after changing operational requirements, some after withdrawing from partner countries' programs, and others after closing funding and changing priorities.

However, now things have gone uphill, as two key programs of the British army are actively moving forward. This is the General Dynamics UK (GDUK) Scout Specialist Vehicle (SV) Special Vehicle Program and the Warrior Capability Sustainment Program (BMRI) of Lockheed Martin UK (LMUK). In addition, a tender for a life extension program is being held. tank Challenger 2 LEP (Life Extension Program), the requirements for the universal UV machine are again announced, the requirements for the Armored Battlegroup Support Vehicle (ABSV) support vehicle are published, and finally, work is underway on Mine-Resistant Ambush Protected (MRAP) machines, which were urgently purchased for military operations and are currently undergoing modernization and standardization in order to get into the main armament program of the British army.

Of all these projects, the largest and most promising is probably the program for the Scout SV machine. GDUK was awarded a contract worth 775,35 million in July of 2010 to fund the demonstration and qualification phase of this project, which aims to replace the remaining members of the CVR (T) Combat Vehicle Reconnaissance (Tracked) tracked combat vehicle family from Alvis Vehicles. It includes, among others, the Scimitar reconnaissance vehicle, which was put into service with the royal armored corps in 1973.

The Scout SV project is being consistently developed, and GDUK is currently in the process of conducting an assessment test. It is manufacturing seven prototypes of the SV machine, which must leave the walls of the plant in 2016.

In order to carry out these tests with minimal problems and reduce the risks of the program, in May 2012, at the plant of General Dynamics European Land Systems-Steyr (GDELS-Steyr) in Vienna, not only the Mobile Test Rig MTR (Mobile Test Rig) was manufactured, but also test stands of the suspension and power unit.

MTR passed trial trials in Austria and then was sent to Spain to conduct a full cycle of performance tests, where he wrapped circles with increased masses and loads at the GDELS test site near Seville. After that, the MTR unit passed another complete series of tests, including tests in cold climates and operational running tests.

According to GDUK, "these operational tests have demonstrated the ability of machines to withstand extremely low temperatures ... during these tests, the MTR towed a total of 92 tons over a distance of 300 km." In addition, the MTR booth passed accelerated life tests of Accelerated Life Testing (ALT) in order to reproduce predetermined combat missions and conditions in order to evaluate system wear rates and predict serviceability.

Installing the MTR Scout SV pulls the 92 tons

By the middle of 2015, the MTR test stand passed over 10000 km and thus provided important data on reliability and performance, which helped in the design and manufacture of seven demonstration prototypes of the SV machine.

The MTR test bench was followed by a second machine in the version of protected mobility and the provision of intelligence PMRS (Protected Mobility Reconnaissance Support), which was manufactured by GDELS Santa Barbara Sistemas (SBS) in early July 2014 of the year. PMRS has a design combat mass of 38 tons with a potential for growth of up to 42 tons when designing.

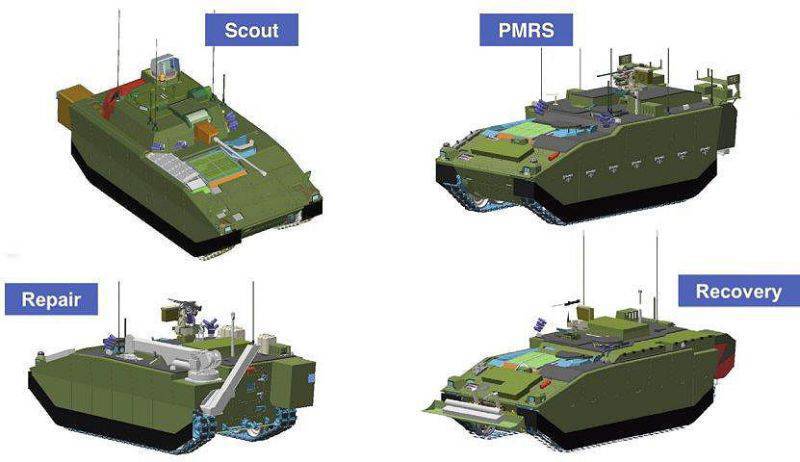

For the PMRS option in April 2014, the expertise of the base platform project was successfully completed, followed by project reviews for all four options: PMRS, repair, evacuation and reconnaissance Scout.

Along with the repair and evacuation options, and one “special” version, three more pre-production Scout Reconnaissance machines are being manufactured. Production of all these machines, manufactured in Spain, should soon be completed.

Under the contract with GDUK, LMUK is developing a twin turret for the Scout SV, along with a separate project to develop a new turret under the WCSP program. Both types of turrets are armed with a 40-mm telescopic weapon system manufactured by CTA International, supplied under a public procurement program.

To the relief of GDUK, which is still feeling losses from the agonizing FRES UV project, the British Department of Defense in September 2014 of the year gave it a contract for mass production. Under this contract, the cost of 3,5 billion pounds provides for the manufacture and supply of the British army 589 Scout SV machines in 2017-2024 years, plus the initial provision and training. This contract is divided into parts (blocks), corresponding to the key stages of the tests to test the increase in reliability, which all British BBMs must undergo.

The contract for 589 machines Scout SV provides the following options: Scout - 198 combat reconnaissance, 23 fire control, 24 ground surveillance (with a portable radar); PMRS - 59 BTR, 112 command and control, 34 intelligence and surveillance, 54 engineering intelligence; Evacuation - 38 machines; and Repair - 50 machines.

Contract work began and, in addition to the three pilot towers ordered for the current demonstration phase, LMUK should produce 245 twin towers for the Scout reconnaissance vehicle under another contract from GDUK. LMUK, in turn, transferred part of the work to Rheinmetall under a contract worth 142 million dollars, concluded in August 2015.

If everything goes according to plan, the training center and the first division will receive Scout SV cars by the middle of 2019, which will allow the crews to start training, and the first team will receive cars by the 2020 year.

GDUK initially announced plans to manufacture the first 100 Scout SV platforms at the GDELS SBS plant in Spain, followed by a gradual transfer of production to the UK to an unnamed factory. The details became known in mid-July of 2015, when the Department of Defense announced that it had issued a new contract to GDUK that cost 390 millions of pounds to provide technical support for the machines up to 2024. As a result, GDUK will finalize the build, integrate the subsystems and test the machines in Wales starting with the 101 machine.

The plant in Wales must leave the machines in a state of near completion, although there will still be some work to be done on the ground. For example, the installation of the Bowman tactical communication system will be carried out after the transfer of machines to the Ministry of Defense, since this system is classified as state equipment. According to the company GDUK, "there is a significant proportion of British components in special systems, such as sights and sensors, electronic architecture and integrated solutions to increase survivability."

The PMRS option was manufactured by GDUK in June 2014 of the year. Pictured is a machine with a Kongsberg Protector Dubbi installed, armed with an 12,7-mm machine gun M2 HB

Looking for opportunities

After being put into service, Scout vehicles should dramatically increase reconnaissance capabilities in comparison with the outdated CVR (T) tracked vehicles. Scout SV sizes will surprise some who are accustomed to the small size and cramped Scimitar interior, but on the other hand, the protection level has increased significantly compared to the existing platform, and its new sensor systems will allow you to seamlessly distribute video and data inside the machine and share data not only with other platforms machines on the battlefield, but also with the upper echelons.

Scout SV is essentially a further development of the ASCOD project (Austrian Spanish Co-Operative Development - a joint Austrian-Spanish development), which was modified to meet specific British requirements. The base body, welded from armor steel, weighs about 22,3 tons without an advanced booking kit (as for the exact classification of machine protection levels, GDUK and the Department of Defense are very sensitive and refuse to voice them, noting that they are “high”). In order to reduce the cost of the entire lifetime, the entire family of machines is based on the so-called common base platform CBP, which means the same basic hull structure, the same power unit, final drives, suspension, chassis, driver's seat, air conditioning systems and protection against OMP , additional fuel tanks and battery compartment.

All cars are also equipped with the so-called common (standard) vehicle architecture from GDUK, which simplifies upgrades and maintenance, controls and controls on all systems of the car, and also maximizes the number of common components.

Given the combat experience of Afghanistan and Iraq, the Ministry of Defense determined the requirements for the car, which should have an increased level of protection against mines and improvised explosive devices (IEDs). The Scout SV machine has a slightly curved one-piece bottom, composite panels are installed on it, which increase protection levels, and all its crew members are provided with explosion-proof seats attached to the roof.

The overall layout of the standard machine Scout SV traditional, the driver is located in front of the left, the power unit in front of the right, double tower in the middle, in the stern there is additional space; while the other options naturally differ slightly.

The power unit includes a diesel engine MTU 8V199 (the same is on the BTR Boxer MRAV 8x8), but with an improved air intake and a two-stage impulse air cleaner that allows you to develop an increased power 600 kW (800 hp), which is more 70 kW than more base model. Engine power to the tracks is transmitted through an automatic transmission Renk 256B, which allows the driver to control the tracked vehicle like a car. The declared gross mass of the machine is Scout 38 tons, power density is 21 hp / t, and the maximum speed on the highway to 70 km / h.

In case of unavoidable weight gain of the machine, it is possible to add power due to additional adjustment of the engine. At this stage, the combat weight of the Scout SV machine is defined in 34 tons, while it is planned to increase it to 38 tons with a clearly defined growth potential to 42 tons.

GDELS SBS recently signed a contract with Rolls-Royce Power Systems for 80 million euros to supply Scout 569 MTU engines (20 less engines than Scout SV machines in different configurations) from 2016 to 2022 a year. The contract also includes a cooling system and two generators per machine with a total capacity of 550 Ampere.

Compared to the original ASCOD project, the Scout SV not only increased engine power, but also significantly improved the suspension, which now includes two subsystems - torsion shafts and hydraulic shock absorbers, providing greater comfort for the crew and more stable firing on rough terrain.

The most noticeable and most influencing system Scout system is, of course, the new tower. The LMUK project has a relatively traditional layout, at least for the crew, the commander is located on the right and the arrow on the left. At each place there is a hatch, and access to the building is carried out through the lower part of the tower basket.

Like the hull, the all-welded turret is made of steel armor and has space for mounting mounted armor plates, which allow an increase in the level of ballistic protection. The turret support ring has a diameter of 1,7 meter, but it can be extended to a 1,9 meter, which allows the tower to be installed with an 120-mm smoothbore gun.

The standard configuration of the CTC's 40-mm weapons system on the Scout machine allowed the cannon to be installed according to the monitor, freeing up space in the tower. This weapon system passes advanced fire tests, and fire control and stabilization systems allow you to accurately hit stationary and moving targets during movement in almost any weather conditions.

Guidance guns electric drives with a manual backup branch for the commander and the shooter, which allows in the absence of power supply to direct and fire from the main armament.

Thales UK supplies the sighting system, which consists of independently stabilized day and night sights for the commander and the gunner, and a laser rangefinder is installed at every workplace.

The shooter has a stabilized DNGS T3 sight, duplicated by a Saber day sight, rotating in a certain sector, and the Orion periscope system mounted on the left side of the turret is capable of rotating 360 °. Existing Scout capabilities have also been enhanced by automatically detecting and tracking targets, which reduces the burden on the operator and increases combat effectiveness. A search device with a wide field of view and an optional laser target designator for pointing missiles with a semi-active laser homing head are also added.

Images from both sights are displayed directly on the Barco 13-inch display; In order to increase situational awareness on the driver’s seat, another display has also been installed.

Standard equipment for the entire SV family of machines consists of an onboard monitoring and diagnostics system and a life support unit (including a thermal management system and a system for protecting against weapons of mass destruction), powerful enough to maintain comfortable conditions for the crew and onboard systems in conditions not only of hot desert, where in the past decade the British army acted, but also in the Arctic.

Only the Scout variant will have an auxiliary power unit, which will allow all subsystems to work with a muffled diesel engine, which is very suitable for the monitoring mode.

Previously, the contract for the Scout SV project was divided into so-called Intelligence Machine Blocks, but subsequently their number was simply reduced to six options. The engineering intelligence option and the command and control option were joined by the four previously mentioned machine options (PMRS, repair, evacuation and Scout). All 589 machines covered by the current manufacturing contract will be delivered in these six versions.

The sanitary option from the 2 Block and six options from the 3 Block were excluded: the medium weight armored vehicle was supposed to be the base for an artillery installation armed with an 120-mm smoothbore gun, as well as repair and evacuation options. Also, after the next revision of plans in 2011, three combat support systems were excluded: an armored engineering tractor, an armored vehicle for engineering troops, and an armored AVLB bridge laying system.

Although the project was developed to meet the needs of the British army, GDUK noted that "it continues to discuss the export potential of Scout SV with customers."

British Army's BMP Warrior with a new twin-turret from LMUK, armed with a 40-mm cannon with telescopic ammunition and a paired 7,62-mm L94A1 machine gun

Program for BMP Warrior

The Warrior infantry fighting vehicle, developed by GKN Defense (currently part of BAE Systems Combat Vehicles UK), became the basis of the British Army motorized infantry units; Since 1988, 789 machines have been delivered in total. The machine was operated in several hot spots, served in the Balkans, Iraq and Afghanistan, and since the last years the BMP Warrior was supplied to the army (more than 20 years), it has undergone several modernization and improvement programs.

As part of the last urgent modernization of the then-company Defense Support Group (now Babcock International), under the overall control of BAE Systems Combat Vehicle UK, the 70 Warrior machines were upgraded to the standard Theater Entry Standard (Herrick). As a result of these phased upgrades, specially conducted for a specific theater, the Ministry of Defense, having now a mixed fleet of vehicles, decided to modify them all to a common standard as part of the Warrior Capability Sustainment Program (WCSP), extending their lifespan to 2035 / 2040 of the year.

As a result of tense struggle, LMUK won BAE Systems and in November 2011 of the year received a contract to demonstrate WCSP, which also included an option for production. Works under this contract are in full swing, but in August 2015 of the year a decision on production had to be made and, therefore, the project could theoretically be closed, although the army would then need to urgently send forces to eliminate the platform’s flaws and identify new ways to ensure its motorized infantry mobility and fire power.

The WCSP Demonstration Contract was originally valued at approximately 200 million pounds, and the production contract was 642 million pounds, but due to amendments to the contract, the cost of the demonstration phase now increased to 225 million pounds, and the value of the production contract to be issued can also increase in future. The total cost of the WCSP program at the present time, including the costs of the Department of Defense, as well as the cost of weapons and equipment supplied by government organizations, is at around one billion pounds, although the UK Accounting Chamber has suggested that it could grow by another third.

The WCSP tower will be produced at a new site worth 5,5 million dollars, which is being built at the LMUK plant in Bedfordshire. There, two years of research facilities and an experienced workshop already function, where the first towers were made. The construction of the new site will be completed at the beginning of 2016, the total investment of LMUK in this production near the Millbrook test site in the last 10 years will be about 23 million dollars.

Under the WCSP program of the hull, the Warrior machines will undergo a major overhaul and be refined at the factory of Babcock International, which has extensive experience in the maintenance, repair and upgrading of the Warrior BMP. Plans have changed over the years (in particular, with the sale of the Defense Support Group, which added some uncertainty), but in July 2015, LMUK carried out work to integrate the hull and tower at Babcock International.

Although changes were made to the program, which also affected its schedule, in order to minimize risks, additional vehicles and towers were added and now LMUK is confident that the date of entry into service, scheduled for the 2020 year, will not change.

The WCSP program consists of three subprograms: a program to improve the combat qualities of the Warrior BMP under the designation WFLIP (Warrior Fightability & Lethality Improvement Program), the improved electronic architecture of the Warrior BMP under the designation WEEA (Warrior Enhanced Electronic Architecture) and the modular protection system of the Warrior BMP under the designation WMPS (Warrior Modular Protection System).

WCSP project at Eurosatory 2014

If everything goes according to plan, it is expected that the WCSP program will upgrade the 380 BMP Warrior and its variants, of which new towers will be installed on the 285 machines.

At an early stage of development, LMUK planned to leave the original two-seat Warrior BMP with an unstabilized 30-mm L21A1 RARDEN cannon with a low rate of fire, designed and manufactured by the then Vickers Defense Systems, and install a new 40-mm CTC cannon into it. But the dimensions of this tower ultimately did not allow it to be done and the company was forced to design a completely new two-seat tower with a larger volume and easier integration of all subsystems, which together allow for broader upgrades in the future.

Separation of components

The development of the new tower allowed the company to increase the level of unification with the tower of the Scout machine. For example, both towers have the same weapons and ammunition systems, quick-change electronic components, controls, communications equipment, a fire control system and corresponding displays. Like the Scout tower, this tower is welded from armored steel and has mounted armor to match the ballistic protection of the hull.

The ability to conduct accurate fire in motion, achieved through the installation of a new weapon system, sights and MSA, greatly enhances the combat capabilities of the new systems compared to machines armed with a RARDEN cannon. However, in order to preserve its capabilities, in the 21 century, the rest of the platforms that did not receive new towers also underwent a major overhaul.

The hulls will be cleaned and stripped to bare metal, further restored to the state of "new cars" and equipped with a number of new systems, for example, a driver control panel and situational awareness system developed by Ultra Electronics Command and Control Systems. This combination of the Selex ES Drivers Night Vision System driver’s night vision system and Ultra’s compact HUBE cameras mounted around the perimeter of the vehicle allows you to monitor the surroundings and monitor images of the driver, commander, gunner and landing force.

The WMPS modular protection system is a new mounting location on the case to which the user can quickly attach passive and active protection depending on where the machine is deployed and what threats are expected there. Existing fixable protection kits are not part of the WMPS system, as they relate to the systems supplied by the state, but according to the design, the attachment points will be standardized so that special solutions developed as part of the latest urgent upgrades can be installed.

Other elements to increase the survivability include fragmentation basement of the turret and corps, as well as energy-absorbing seats for commanders and shooters, which initially only drivers had.

Like many other machines, the Warrior BMP currently needs more electricity to operate various systems and, in this regard, the auxiliary power unit is installed in the front right sponson (top of the tracks) under the WCSP program.

In accordance with the latest plans, WCS 12 machines are being manufactured: nine infantry fighting vehicles (including two branch commanders), one commander, one repair and one evacuation one. Two more complete towers are also being manufactured for additional reliability tests, the first Accelerated Growth Turret tower was to be tested in September 2015 of the year.

The previous shooting tests of the CTC cannon without a crew installed in the new LMUK turret were completed in the 2014 year. After them, at the end of the same year, static shooting tests were conducted with the crew, then at the beginning of 2015, shooting tests with the crew on more complex targets were conducted at the test site in Scotland, when the vehicle was successfully hit moving target.

The entire program passed its preliminary analysis of the project in December 2013. The slight delay in the schedule was affected by amendments to the contract to further reduce risks. Following a preliminary analysis of the project in May, 2015 successfully passed a critical analysis of the project.

The WCSP program manager at LMUK announced that “in accordance with current plans, the demonstration phase should be completed by the end of 2017, and we are striving to meet this deadline. In advance, in accordance with the contract, we will start ordering products with a long production time. ”

Challenger 2 tank programs

Although the British army became a pioneer in the use of tanks, the armed forces of this country were not overly concerned about protecting their once-praised Challenger 2 tanks.

Perhaps more than any other British BBM tanks, the Challenger received less funding, and due to the lack of operational requirements for main battle tanks (MBT), after the first invasion of Iraq, their number decreased, and the characteristics could no longer satisfy the military. The development of the unsuccessful L30A1 rifled gun, which limits the range and lethality of the Challenger 2, which theoretically allows many tanks to gain superiority on the battlefield, did not help to solve the problem.

The lethality of a cannon firing a CHARM 3 piercing projectile with a depleted uranium core at some armored targets now raises many questions; The situation is complicated by the lack of uniformity with other Allied MBT armed with 120-mm smooth-bore guns.

However, after several upgrades, the army seems to have decided to start a project to extend the life of the Challenger, albeit to a lesser extent than the complete modernization envisaged for the Warrior BMP.

Vickers Defense Systems manufactured for the British army a total of 386 Challenger 2 tanks at its plants in Leeds and Newcastle upon Tyne, the last shipments were made in April 2002 of the year. Currently, both of these plants are closed, but BAE Systems Combat Vehicles UK maintains two Challenger 2 tank warranty groups in Newcastle and Telford that service Challenger combat vehicles: repair and recovery vehicles, Titan AVLB bridge engineering and Trojan engineering machines .

The Challenger 2 OBT was expected to be upgraded in the middle of the 2000's Capability Sustainment Program (CSP), which was to include the Challenger Lethality Improvement Program (CLIP) with the installation of an 120-mm smoothbore L / 55 Rheinmetall gun. But the CSP program eventually began to slip and was closed.

According to the CLIP program in 2005-2006, an experimental installation, which is a Challenger 2 tank with a smooth-bore gun, was tested at an armored vehicle test site in Bovington. But at the moment, all plans to install a new gun on the park of the Challenger 2 OBT remained plans.

While there were discussions about how to refine and extend the life of the tanks, approximately 120 of them were deployed in Kuwait before the invasion of Iraq. Like the BMP Warrior, these machines in the Kuwaiti desert were modernized several times, since a battle was assumed with an experienced adversary. During Operation Telic, the number of tanks was reduced to one battalion in Basra, but these tanks were continuously refined by BAE Systems in accordance with urgent operational needs.

During these upgrades, additional sets of reservations were installed, including plates on the bottom (after one tank damaged an RPG while climbing the slope, and another one was damaged by VCA), the Selex Enforcer remotely controlled combat module (SDM) was installed on the roof of the tower 7,62-mm machine gun, allowing the crew to fire, while under the protection of armor, also added a wire cutter, a modified cooling system, a modified air filter for the power unit, new night vision devices, rear-view cameras and this ics device for muffling VCA.

All these improvements with the time raised the total weight of the Challenger 2 from 60 tons to about 75 tons. As a result, the specific power of the Challenger 2 has decreased compared to other NATO deployed MBTs, for example, Leopard 2, Leclerc, and M1A1 / M1A2 Abrams.

Numerous upgrades of existing machines and long-term storage of the remaining ones have led to the Challenger 2 tank fleet becoming very “unsuited”. And in the middle of 2013, the Ministry of Defense confirmed that work was under way on a life extension program for the Challenger 2 LEP (Life Extension Program) tank — less ambitious in scale than the CSP program; the remaining machines should be upgraded to a more modest configuration. This coincided with a significant reduction in the fleet, at the moment officially the number of vehicles “on the move” has been reduced to 227, but in fact, each of the three armored regiments is assigned to 58 tanks. However, according to the joint resource management scheme, they have at their disposal only one battalion for daily combat training, while the remaining tanks are kept in reserve for possible participation in future conflicts.

According to the project, in addition to standardized repair and maintenance, outdated subsystems, such as optoelectronics and communication facilities, will be replaced. Many of these subsystems were created 25 years ago (after all, work on creating the Challenger 2 began in 1987, at the initiative of Vickers Defense Systems) and naturally all the technological limitations of that time are characteristic of them.

Since BAE Systems Combat Vehicles UK bought Vickers, it retained overall Challenger 2 project management. At the same time, the Ministry of Defense stated that “it has all the possibilities for future upgrades”, which can be interpreted as an intention to issue contracts in which BAE Systems will not participate. With this in mind, the organization for military equipment and maintenance should begin a competition for the implementation of the LEP program, in which, besides BAE Systems, at least three applicants are expected to take part: GDUK, Krauss-Maffei Wegmann and LMUK.

Requests for information were published in 2014, a list of companies that have been pre-screened is expected at the end of 2015, and an invitation to bid will be published in 2016.

The Challenger 2 tank was originally called the 2028 year, but gradually it began to be pushed back further and is now called the 2035 year (taking into account the work that has not yet begun on the LEP program).

With constant funding, the British army must start to regain significant losses in ground combat capabilities in the future, or at least stop their reduction.

The universal utility vehicle, which, most likely, will have the wheel formula 8x8, is still waiting for financing. The machine also supports the support of the combat group ABSV, which is a Warrior platform modified for this task.

There has been some progress under the Scout SV and WCSP programs, but here one cannot discount the tests for verification of improved reliability, which clearly showed that additional modifications are needed before the vehicles enter service.

Also of serious concern is the situation with the Challenger 2. While its protection is excellent and mobility is acceptable, its dominance on the battlefield is limited to the cannon and the lack of modern ammunition. As a result, the army in future conflicts is likely to continue to rely on fire support for artillery systems and near aviation a cover, not a Challenger 2 tank.

Tank Challenger 2, upgraded in accordance with urgent operational requirements. A new booking kit is installed on it, as well as on the roof of the Selex Enforcer DBMS with a 7,62-mm machine gun

Comment

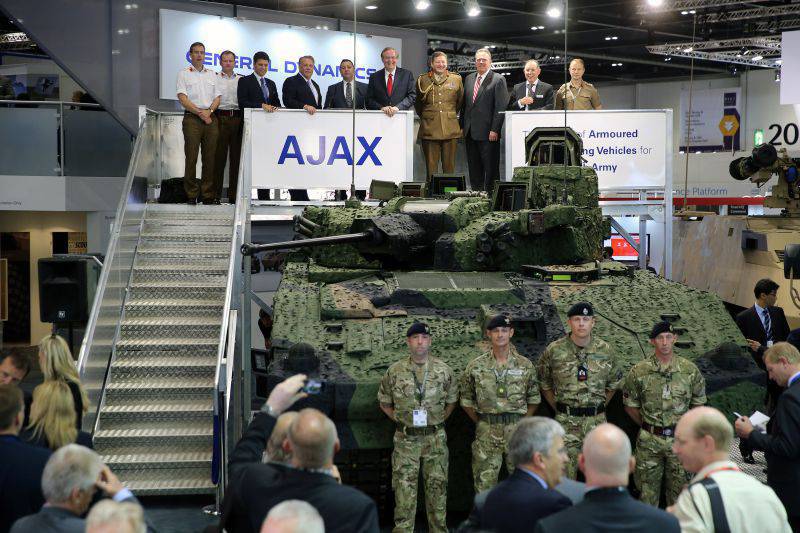

General Dynamics UK presented at the DSEi 2015 international exhibition a prototype of the AJAX platform, formerly known as SCOUT SV.

The company for the first time demonstrated a variant of the family on the basis of a tracked armored personnel carrier last year. The flagship version of the AJAX program, armed with a turret, is the second prototype from this family to be presented by General Dynamics UK, and the first to demonstrate the turret designed for this Lockheed Martin UK program. This tower is designed to meet the needs of the modern British army.

The AJAX platform is one of six options that will be supplied to the British army by General Dynamics UK from 2017 to 2024. It is a promising combat armored vehicle (BBM) for the British Army, providing best-in-class defense and survivability, reliability and mobility, as well as enhanced observation and reconnaissance capabilities.

The SCOUT SV family will allow the British army to carry out a full range of expeditionary operations using network capabilities, which will require less logistical burden. It can work in general and multinational situations, in various promising operating environments.

AJAX Platform Presentation at DSEi 2015 in London

Materials used:

www.janes.com

www.baesystems.com

www.gov.uk

www.gdels.com

www.lockheedmartin.co.uk

www.vpk.ru

www.wikipedia.org

Information