Armored vehicles india

Indian tank building was created in the early sixties, when an agreement was reached between the British company "Vickers" and the Indian government to build a tank factory in the city of Avadi, which is located near Madras. The plant was commissioned in the 1966 year and provided the release for the Indian army of tanks "Vijayanta" ("winner") - the Indian version of the English "Vickers" Mk 1. Initially, Avadi assembled machines from parts and assemblies delivered from England. Later, after Indian specialists acquired the necessary experience, independent production of tanks was established. By the end of the 80-s, Indian industry had supplied about 2200 of such machines, which to this day carry their service as part of the 26 tank regiments of 58 available in the ground forces. The surviving “Centurion” tanks were decommissioned and decommissioned. 70 “Vijayanta” tanks in the early 70s were delivered to Kuwait.

"Vijayanta" It has a classic layout: the control compartment is in the front, the combat compartment is in the center and the engine-transmission compartment is in the stern. The hull and turret of the tank are welded, made of homogeneous armored steel. The driver's seat is located in the front of the case and is shifted from the longitudinal axis of the car to the right - the arrangement of drivers, traditional for England and India, where left-hand traffic is taken. The rest of the crew are stationed in the turret: the commander and the gunner are to the right of the gun, the loader is to the left.

Tank Vijayanta

Main weapons tank "Vijayanta" - English 105-mm rifled gun L7A1, using unitary shots with armor-piercing-sabotage and high-explosive fragmentation with plastic explosives. The initial speed of the armor-piercing projectile is 1470 m / s. Such a gun was used on almost all types of Western tanks, until 120-mm rifled and smooth-bore guns appeared in Great Britain and Germany. Together with the gun, the 7,62-mm machine gun is paired, and the 12,7-mm machine gun mounted on the turret roof is used to determine the range.

In the mid-sixties, the "Vijayanta" (like the English "Vickers" Mk 1) was one of the few foreign tanks with weapon stabilization in two planes, provided by an electric stabilizer.

Currently, the Madras Center for the Provision of Tank Electronics is producing for the tank "Vijayanta" a new fire control system (FCS) Mk 1A (AL 4420). This MSA has an improved connection of the sight with the gun, designed to minimize the backlash between the sight and the gun. There is also a control system for bending the barrel of the gun to ensure that the misalignment of the axes of the barrel bore and the sight caused by the thermal deformation of the gun is eliminated. A more sophisticated MSK MN 1B (AL 4421) was also developed, which additionally includes a British-made laser range-finder and a ballistic computer, which increase the probability of hitting the target with the first shot.

In the middle of 1993, Indian sources said that since the design of the Arjun tank was delayed, the modernization program for part of the Vijayanta fleet was continued, which was originally proposed at the beginning of 1980's called Bison. In accordance with it, it was planned to retrofit around 1100 machines. The upgrade includes the installation of a T-72 M1 diesel engine, a new MSA, additional armor, passive-type night vision equipment, including a thermal sight, navigation system.

The Yugoslavian SUV-T55A, which was developed for the modernization of Soviet T-54 / T-55 / T-62 tanks, was used as an OMS. Its production is organized in India by Bharat Electronics, which must provide up to 600 systems.

The armor, which is equipped with the upgraded "Vijayanta", is a modern combined armor Kanchan, designed for the tank "Arjun".

Although the "Vijayanta" is essentially the English tank "Vickers" Mk 1, its characteristics are somewhat different from its prototype. The ammunition includes 44 rounds, 600 rounds for heavy machine guns and 3000 rounds for machine guns 7,62-mm paired with a gun.

At about the same time that the Indian tank industry was mastering the production of the Vijayanta tank, the army of that country received the T-54 and T-55 from the Soviet Union, which had proven themselves well during the war with Pakistan in 1971. To ensure the long service life of these machines, a tank repair plant was built in Kirkhi. T-54 and T-55 in the amount of more than 700 units are still in the ranks of the Indian armored forces.

Indian designers were developing their own tank, which they started back in 70-s, but not everything worked out right away. Therefore, in order to keep its tank fleet up to date, the Indian government decided to buy a T-72М1 consignment in the USSR. Initially, India intended to order only a small number of tanks (about 200 units), awaiting the start of production at its own plant developed by local designers of the tank "Arjun". However, due to its high cost and insufficient reliability, it was decided to organize licensed production of T-72M1 in Avadi, and the installation batch of machines left the factory gates to 1987.

The first 175 tanks were produced from kits supplied by the Soviet Union, which assisted in the development of Indian heavy industry. The ultimate goal was for India to produce tanks, making maximum use of its own resources, bringing in the future the share of Indian components in the tank to 97%.

Production T-72M1, known in India as "Ajeya", began with the release of approximately 70 machines per year. The last "Ajeya", left the factory in March 1994. In total, the Indian army has about 1100 such machines. Other sources indicate that a full fleet of Indian T-72М1 is about 2000 machines.

In 1997, information appeared that more than 30 of 125-mm cannon “Ajeya” tank guns had been torn apart during shooting practice, and efforts were made to determine the cause of this problem, which was never specified. Most likely, the ruptures of the trunks occurred from the ingress of soil into the barrel bore, or the guns have exhausted their resources. In other cases, one could only assume how many Western media would be so embarrassing.

Recently, the activity of many foreign companies has been stepped up, offering their services for the modernization of the fleet of T-72 vehicles. Moreover, these services are offered not only by companies of countries where these machines were manufactured under license (Poland, Slovakia, Czech Republic), but also by those countries that have a very vague idea about this tank: Texas Instruments from the USA, SABCA from Belgium, Officiene Galileo from Italy , Elbit from Israel, LIW from South Africa and Thomson-CSF from France.

As a confirmation of these words I will make one digression. At 1998 at the Tridex'98 exhibition in Abu Dhabi (UAE), one of the American companies, like many others, showed a tank gunner's computer simulator. I managed to practice a little on it and even show good results, despite the unusual and inconvenience of all the controls of the gunner’s workplace. The representative of the company-developer made me a compliment, they say, Mr. professional. In turn, I asked him for what tank this simulator. The answer simply stunned me - it turned out it was the T-72М tank gunner’s simulator, although neither the control panel, nor the sight grid, nor even a single button was closely resembling the “seventy-two” ones. I had no choice but to ask whether the developers of this simulator have ever seen T-72. After reading on my badge the military rank and the country I represent, the company representative understood that they were in favor, so he very politely asked me to move away from the simulator.

The planned modernization, at least, of the Indian T-72М1 tank fleet was codenamed "Operation Rhino" in the west. In accordance with this program, it was planned to install new MSAs, a power plant, dynamic protection, navigation and warning systems for laser irradiation, a radio station with a jumping frequency and a system for collective protection against weapons of mass destruction.

The results of such "upgrades" conducted by Western companies of our tanks were well said in an interview with ARMS. Russian defense technologies magazine by the Chief of the Main Automobile and Armored Directorate of the Defense Ministry of the Russian Federation, Colonel-General Sergey Mayev: "When creating both T-72 and BMP-1, a potential opportunity has been laid to improve the technical and combat properties of these machines.Therefore, such a great interest in our equipment from foreign companies, it’s another thing that many of these companies turn military equipment into military goods. they are interested in improving the combat properties of the vehicles, but they are trying to sell them as quickly and profitably as possible, earning profits on it. What happens then the seller is not interested in. The same person who buys this product does not represent all the consequences of such a deal "(ARMS. Russian defense technologies. 2 (9) 2002, p. 5.).

The Indian tank industry has mastered the production of a number of special combat support vehicles on the T-72М1 chassis. For example, on the request of the Indian army, an 155-mm ACS was built with a T-6 turret manufactured by the South African company LIW Division of Denel. However, this car did not go into the series.

On the T-72М1 chassis of local production, a tank bridge laying system BLT T-72 was created. The machine has a bridge in the form of scissors 20 long m, which unfolds in front of the machine.

At the beginning of 1997, Russia offered India to install the Arena-E active defense complex on the T-72М1, as a possible alternative to Pakistan’s recent acquisition of T-80UD tanks from Ukraine. They are in some ways superior to the T-72M1, which until recently were the most advanced tanks in service with the Indian army. However, the Indian government made another decision: to purchase modern Russian T-90С tanks in Russia and subsequently master their licensed production in their own country. At present, India has already delivered 40 of such machines, and all of them were sent to the India-Pakistan border. Another 40 T-90С are being prepared for shipment in April of this year.

T-72M1 Indian aircraft

Having gained sufficient experience in the production of licensed armored vehicles, Indian engineers continued to work on creating their own armored vehicles, including main battle tank "Arjun". The Indian Army developed a tactical and technical assignment to develop a new tank as far back as 1972. It was intended to replace Vijayanta tanks, and a new project began to work on 1974 in a combat vehicle research institute. By the time the first prototype of the Arjun was introduced in April 1984, 300 million Indian rupees (approximately US $ 6 million) has already been spent on the project.

As always, many foreign companies, including German Krauss-Maffei, (MTU engine), Renk (automatic transmission), Diehl (tracks) and Dutch Oldelft, have joined the project.

The main problems when creating a new car arose with the engine. Originally it was planned to install a gas turbine engine with an 1500 horsepower, but later it was decided to use a newly developed 12 air-cooled cylinder diesel engine with variable compression ratio of the same power. However, the first engine models developed only 500 hp. His further improvement has increased this figure to 1000 hp when installing a turbocharger.

Suspension tank hydropneumatic. Aluminum alloy track tracks with rubber-metal joint and asphalt shoes. Caterpillar tensioning mechanism has built-in overload protection.

Initially, six prototypes of the Arjun tank were built, equipped with the German MTU MB838 Ka-501 diesel engine with an 1,400 hp power. with Renk automatic transmission. It is reported that none of them was armored, but had steel hulls and towers.

Serial cars are planned to be produced with the new Kanchan combined armor, developed by the Metallurgy Laboratory of the Indian Defense Ministry (Indian Defense Metallurgical Laboratory). It will be manufactured by Mishra Dhatu Nigam. Thermal sighting equipment was developed by DRDO.

In 1983-1989 India is reported to have imported an 42 engine totaling US $ 15 million for building prototypes. By the end of the 1987, the 10 experienced tanks "Arjun", or MBT 90, as they were sometimes called, were built under the designation Mark I. Of these, six vehicles were handed over to the Indian army for military tests, and the remaining four were left for work to further improve them at the Research Institute of Combat Machines (CVRDE).

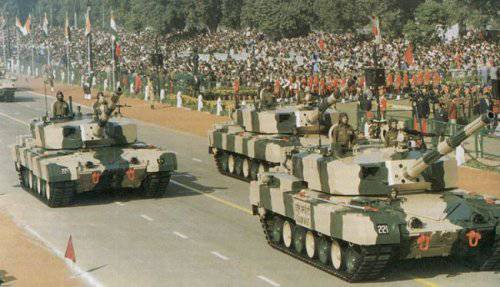

Arjun Main Battle Tank

The "Arjun" tank control system, consisting of a laser range finder, a ballistic computer, a thermal sight, a stabilized panoramic sight of the tank commander, an additional telescopic sight and electronic units, is guaranteed to provide a high probability of hitting the first shot. According to CVRDE estimates, the third-generation OMS combined with an 120-mm rifled gun (also developed in India) and an electronically controlled sight allows the gunner to detect, identify, accompany and successfully hit moving targets when firing on the move.

The main aim of the gunner combines day, thermal and laser distance measuring channels and a single stabilized head for all three channels. The overall mirror of the sight head is stabilized in two planes. The day sight has two fixed increases. The thermal sight provides the possibility of target detection by the gunner and tank commander in conditions of complete darkness and smoke.

Panoramic sight of the commander allows him to conduct a circular observation of the battlefield without turning the head and looking away from the sight and without rotating the tower. The field of view of the sight is stabilized in two planes with the help of a gyroscope mounted on the platform of the head mirror. The sight has two magnifications.

The ballistic computer determines the initial settings for firing in accordance with the information provided by a variety of automatic sensors installed in the machine and from manual data entry. It produces electrical signals proportional to the angles of elevation and azimuth required for firing.

EX tank

To improve the accuracy of shooting, the OMS is equipped with a coincidence window, which allows firing from a gun only when it is in a certain position in accordance with the signals of a ballistic calculator (on Russian tanks, an electronic resolution block is used for this).

The machine is armed with a 120-mm rifled gun, for which the Indian Research Institute of Explosives in Pune developed unitary shots with a partially burning cartridge case with an armor-piercing, cumulative, armor-piercing plastic shells and smoke projectiles. The powder charge of high energy, developed by the same institute, makes it possible to impart high initial velocity to the projectiles and thus, providing them with high armor penetration. In addition to the previously mentioned ammunition, a special anti-helicopter projectile is being developed. The gun is made of special steel, manufactured using electroslag remelting technology and equipped with a heat-insulating casing and ejector. Together with him paired 7,62-mm machine gun. 12,7-mm anti-aircraft machine gun designed to combat low-flying targets.

The propulsion drives of the turret and gun are electric prototypes, and were supplied by FWM from Germany. Currently, tanks "Arjun" equipped with electro-hydraulic drives. On both sides of the turret, nine-barrel bombs of smoke grenade launchers are installed, having five barrels on top and four on the bottom.

Serial tanks "Arjun" will have an engine that develops power 1400 hp, in conjunction with a semi-automatic planetary transmission with four forward gears and two reverse, developed by local engineers. Braking of the car is carried out by high-speed disk brakes with a hydraulic actuator.

The tank has a collective defense system against weapons of mass destruction, developed and created by the Atomic Research Center (Atomic Research Center) in Bhabh (BARC). To increase the survivability of the machine on the battlefield there is an automatic fire extinguishing system. The ammunition is stored in waterproof containers to reduce the possibility of fire.

BMP-2 indian aircraft

In March 1993, it was reported that "Arjun" successfully completed the tests. During a demonstration in the Rajistan desert in western India, two prototypes of the machine hit stationary and moving targets at distances from 800 to 2100 m, overcame various obstacles, elevations of 60% steepness and maneuvered at the barrier sites. The prototypes were built at the Heavy Vehicle Factory in Avadi, but it is expressed that in the future the private sector will be more involved in the production of tanks.

In the middle of 1998, it was announced that the total number of Arjun tanks built was 32 units. These include 12 prototypes, two tanks with torsion bar suspension, one test tank, one BREM and one Arjun Mk II tank. The latter was demonstrated at the arms exhibition Defexpo India 2002, held in Delhi in February of this year. In the future, it is planned to carry out the release on the chassis of a BREM tank, an engineering vehicle, a tank-laying bridge, an anti-aircraft missile or anti-aircraft artillery complex, and a self-propelled artillery installation of field artillery.

The latest development of the Indian Research Institute of combat vehicles is the EX tank. This machine is an example of combining the tank chassis "Ajeya" (and in fact T-72М1) with the armament complex of the tank "Arjun". Another option is to install a new turret on the seventy-twos chassis. Thus, the tank lost its automatic loader, increased in size, but got a thermal sight. Most likely, this machine will be offered for sale, and here it is appropriate to once again recall the words of Colonel-General S.Maev about the various options for foreign modernization of our technology, given in this article.

In addition to tanks under construction in India under license infantry fighting vehicles BMP-2 called "Sarath" at the State Artillery and Technical Plant in Medak. The first vehicle, assembled from components supplied from the Soviet Union, was handed over to the Indian Army in August 1987. Since then, the number of locally-made infantry fighting vehicles in the Indian army has increased year by year, and by 1999 it was about 90% of the entire fleet of these vehicles.

The Sarath, like the BMP-2, is armed with a 30-mm 2A42 automatic cannon with double feed, an 7,62-mm PKT machine gun and mounted on the turret roof with AT-5 Spandrel launcher with a maximum range of fire 4000 m.

Since the start of production of the BMP-2 in India, many improvements have been made to the car, including the installation of a new radio station and the modernization of the weapon stabilizer (AL4423), as well as other minor improvements.

The State Artillery Technical Plant in Medake is responsible for the manufacture of the hull and turret, the final assembly and testing of the vehicle, as well as the manufacture of the suspension, engine, 30-mm and 7,62-mm ammunition, ammunition power supply system, fuel system, ATGM launcher and missile control systems.

Other companies involved in the BMP construction program include: the Trishi Artillery Technical Plant - the launch of the 30-mm gun; the MTPF plant in Ambarnas produces turret and cannon drive drives, as well as some parts of the PTUR launcher; a gun carriage factory in Jabalpur manufactures a gun mounting kit and smoke grenade launchers; OLF plant in Deharadun is engaged in day and night observation devices and a sight; BEML KGF supplies transmissions and drivetrains; BELTEX in Madras - stabilizer weapons and electrical equipment; BDL in Medack - missiles and ATGM launchers.

By some estimates, by the beginning of 1999, the total release of the BMP-2 in India was approximately 1200 units. In addition to them in service with the Indian army there are approximately 700 (according to other sources - 350) BMP-1, supplied from the Soviet Union earlier.

Using the experience gained in the construction of the BMP, Indian designers, as in the case of the T-72М1, engaged in developing their own armored vehicles on its chassis. One such vehicle is the AAV armored ambulance. It is currently in mass production and is a modified version of the BMP-2 to perform the functions of an ambulance with the preservation of the tower, but removed the weapons. The machine is designed for quick and effective evacuation from the battlefield of the wounded with the provision of emergency medical care. It has excellent mobility in any terrain conditions and has the ability to overcome various obstacles and water barriers by swimming. Like the BMP, it is equipped with a collective defense system against weapons of mass destruction.

The machine can be quickly converted to carry four wounded on a stretcher or two wounded on a stretcher and four seated, or for eight sitting wounded. She has a crew of four, including a driver, a commander and two doctors. Gross weight machine 12200 kg.

Medical equipment includes a stretcher, containers with blood or plasma, equipment for blood transfusion, oxygen equipment, containers with ice and hot or cold drinking water, tires and plaster, medicine kits, pillows and pillowcases, instrument trays, urinal and vessel.

An engineering reconnaissance vehicle, the ERV, was commissioned by Indian engineering troops. The machine has a body and a turret BMP-2, but in addition to the smoke grenade launchers, all weapons have been removed. ERV has retained the ability to swim. Movement through the water is provided by rewinding the tracks.

The machine is equipped with all the necessary equipment for obtaining intelligence information, its recording and transmission to the command post, giving the opportunity to have the necessary information about the nature of obstacles and water barriers. Using its equipment, ERV can provide headquarters with detailed information on the height and slope of river banks, the bearing capacity of soils and the profile of the bottom of water obstacles.

The equipment installed on the ERV includes gyroscopic and satellite navigation systems, a radio compass, a plotter with a tablet, a device for determining the density of the soil, an electronic theodolite, a log, a sounder, a laser range finder, a pointer installation device and a tailing instrument.

The automatic pointer installation device is installed on the left side of the vehicle body closer to the stern and allows the ERV to quickly mark the route for the vehicles behind. When moving the pointer is in a horizontal position, if necessary, their use, they are installed in a vertical position. Pointers are shot into the ground with the help of an electropneumatic system from a shop with a capacity of 50 pointers. Each pointer is a metal bar with a height of 1,2 m and 10 mm in diameter, with a flag attached to it.

All equipment on the ERV is connected via a serial interface to an IBM compatible computer. The standard equipment of the machine includes a roof-mounted air conditioning system, a protection system against MLE, two suction pumps and a gyro semi-compass. Originally developed for military use, ERV is now also being considered for civilian use.

In accordance with the requirements of the Indian engineering troops, an AAD armored amphibious dozer was also developed. It is an BMP-2 chassis with a turret removed and plenty of additional equipment to perform new specific tasks. The car has a crew of two people, consisting of the driver and the operator, located back to back, which provides a duplicate control of the machine. The equipment includes an 1,5 m3 hydraulic bucket on the stern of the machine, an 8 traction winch, a blade-mounted mine sweep mounted in front and a rocket engine anchor similar to that installed on a British engineering tractor that has been in service with the Indian army for several years. The rocket engine anchor is used for self-pulling and has a maximum launch range from 50 to 100 m depending on conditions. The car has a maximum speed of 60 km / h and afloat 7 km / h. It is equipped with a collective defense system against weapons of mass destruction.

The BMP-2 chassis is also widely used in Indian air defense. On its base created the air defense system "Akash" and "Trishul". For them, the chassis was somewhat elongated and has seven track rollers on each side. Rotating launchers with three ground-to-air missiles are installed on the roof of the vehicles. The multifunctional 3-x coordinate radar used with the "Akash" air defense system was also made on the same base.

In the near future it is planned to begin production of the Namica combat vehicle with the Nag (Cobra) ATGM system developed by the Indian company DRDO. On the BM "Namica" launchers there will be 4 ready for launch of an anti-tank missile system, and additional ammunition is placed inside. Reloading missiles produced from inside the machine under the protection of armor.

The NGT system refers to third-generation complexes that implement the principle of "shot and forget." The launch weight of the rocket is 42 kg, the firing range of more than 4000 m. Tandem cumulative warhead capable of hitting the main battle tanks, equipped with dynamic protection.

An attempt was made to establish production on the chassis of the BMP "Sarath" light tank with an 90-mm gun. It is the body of the BMP-2 with a twin TS-90 turret manufactured by the French company Giat, with a 90-mm cannon and an 7,62-mm coaxial machine gun.

This machine was designed to replace the Soviet-made PT-76 light tanks that are in service with the Indian army. It was released only two prototypes, after which their production ceased.

The chassis of the BMP "Sarath" was also used to create an 81-mm self-propelled mortar. Fire from it is carried out from within the car. Vertical mortar pointing angles range from 40 to 85 degrees, on the horizon - 24 degrees in each direction. The mortar support plate is also included in the machine kit for use in the external version. Ammunition is 108 shots. The self-propelled mortar armament complex includes an 84-mm Karl Gustaf anti-tank grenade launcher with 12 shots and an 7,62-mm MAG Tk-71 machinegun with 2350 ammunition ammunition. The crew of the car is 5 people.

In conclusion, we can say that at present India has become another country that produces its own development of armored vehicles, while having powerful potential.

Information