There is a replacement

Are Russian producers in the near future able to provide domestic oil and gas companies with necessary equipment?

Against the background of the US and EU sanctions imposed against Russia, Russian businessmen, including oil and gas equipment manufacturers, open a so-called “window of opportunity”. Despite the fact that during the last 15-20 years Russian oil and gas producers preferred to buy imported equipment, a number of domestic enterprises continued and continue to produce drilling rigs, valves, filters, pump-compressor equipment and other products. And in many cases, one that, according to experts, competes on an equal footing with foreign counterparts. But consumers, despite the existing sanctions, at every opportunity prefer to turn to foreign partners. A paradoxical situation arises - the products of Russian manufacturers are in demand and competitive abroad, but for some reason, sometimes there are serious problems with sales in the country.

What do we have?

The most powerful cluster of oil and gas engineering and industrial science was formed in Russia in Soviet times. By and large, precisely because of this, our country has become the largest producer, and then an exporter of oil and gas in the world. However, many of the existing domestic solutions were developed until the mid 80-s. Perestroika began, and the era of Soviet R & D ended.

In 90, mining companies gained access to free access to foreign markets and, as a result, they began to form powerful foreign exchange resources. Naturally, Russian oil and gas production turned its eyes on foreign producers. The shift to foreign equipment was largely facilitated by the arrival of world oilfield service giants such as Schlumberger, Halliburton, Weatherford and Baker Hughes on the Russian market, who preferred to work in Russian fields with familiar imported equipment (some of which are often produced by their subsidiaries). The flow of orders from Russian manufacturers gradually weakened, leaving most of them without funds for R & D and technological development. It should also be noted that in the 90-e many enterprises literally had to fight for survival.

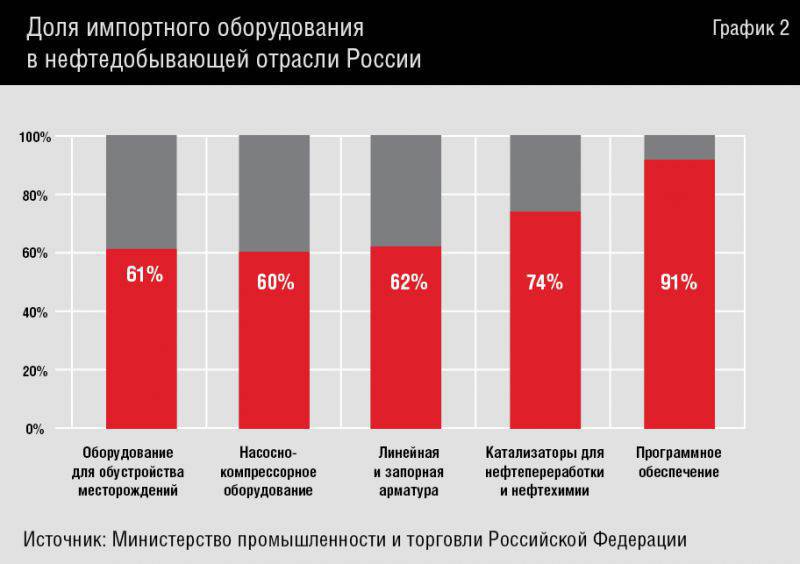

The result, as we see, is obvious. According to the Ministry of Energy, imported equipment today accounts for up to 60 percent of the oil and gas equipment market. Today we have a situation close to critical. It can even be a fairly quick and complete loss of the main production and scientific and technical competencies of Russian science and industry, and as a result - the loss of entire sectors of oil and gas engineering (drilling rigs are actively imported from China, pumps from the UK, Switzerland and Italy, compressors from the USA and Germany, electric motors from Japan, Germany and Italy).

In fairness it should be noted that a number of technologies in Russia did not receive the corresponding development due to various objective reasons. So, until recently, our country simply did not demand technology for extracting hard-to-recover oil and gas reserves, oil and gas production on the sea shelf, and did not find widespread technology for liquefying natural gas. In addition, for a number of reasons, there was a noticeable lag in the area of application software. It is in these areas that the issues of import substitution are most acute, and overcoming them will require considerable effort from all.

In the higher echelons of power, they understand this. Therefore, now with the possible tightening of sectoral sanctions, it is necessary to urgently pursue an import substitution policy. The head of the Ministry of Industry and Trade, Denis Manturov, recently stated that due to the departure of Western service companies and manufacturers of oil and gas equipment, it is necessary to ensure the replacement of imports with domestic products at an accelerated pace.

According to the plan developed by the Ministry of Energy, by 2020, Russia should reduce the share of imports in the oil and gas complex from 60 to at least 43 percent.

In the medium term to 2018, the priority areas of import substitution include the creation and production of catalysts for oil refineries and petrochemical industry, compressors for liquefying natural gas, high-power gas turbines and pump-compressor equipment. There will also be work on creating software tools for drilling and extracting hydrocarbon raw materials, developing hard-to-recover reserves. And in a more distant future (up to 2020), it will be possible to even more “free” from expensive foreign products.

The operation of foreign equipment in Russia has always been not devoid of a number of features, and in truth, problems. First, imported equipment itself has always been several times more expensive, and today, due to the weakening of the ruble against the dollar and the euro, this factor begins to play a decisive role. Secondly, if repair is required, spare parts will cost completely different money than, say, a year or two ago. And, finally, very often maintenance and repair work requires the presence of foreign specialists. To call them and arrive at the place you need time, and if it does not wait?

Despite this, Russian customers are still moving very slowly in the direction of domestic suppliers. Their approach, as a rule, is as follows: let the machine builders develop the equipment we need ourselves, and we will place orders for new developments after all the necessary tests and several years of trial operation have been completed. At the same time, global experience shows that customers and contractors can and should only work together in the form of technological, or even strategic alliances. So it turns out faster and more profitable for both parties.

It is important to note that a significant part of the required oil and gas complex of the nomenclature is already being produced (and not bad!) In Russia or can be quickly mastered by domestic machine builders in cooperation with consumers.

Who will take?

The market of equipment for oil and gas production and processing remains in Russia almost the only one that will grow in the near future - according to the forecast of the Ministry of Industry and Trade Russian oil and gas companies will increase the costs for this article by 31 percent in the next three years to 19,1 billion dollars. The only question is how much of this money will Russian suppliers get?

Meanwhile, analysts at Deloitte, who published the following estimates at the end of 2014, came to an interesting conclusion: “during 1-3 years, the share of equipment from China, Korea, Singapore will increase in the Russian market, and through 3-5, imported suppliers can replace the years Russian technologies and equipment in those segments where they are not yet represented. ”

Despite such assessments and the dominance of imported products in the Russian oil and gas equipment market, today there are a number of large Russian companies that could not only maintain but also strengthen their market positions. First of all, these are United Machine-Building Plants OJSC (OMZ Group, part of Gazprombank Group), HMS Group (Hydraulic Machines and Systems) and Rimera Group of Companies (ChTPZ Oilfield Services Division) - large holdings with serious scientific and technical potential. and manufacturing facilities. At the same time, along with the market leaders, in Russia there are also over a hundred relatively large and medium-sized companies - manufacturers of the most diverse equipment in demand in the oil and gas industry.

OMZ Group (United Machine-Building Plants):

The main production assets are: OJSC Uralmashzavod, OJSC Izhorskie Zavody; "Uralhimmmash", LLC "Glazov plant Himmash", Skoda JS as (Czech Republic);

Products: land and offshore drilling rigs, capacitive, column, reactor, separation and heat exchange equipment;

HMS Group (“Hydraulic Machines and Systems”):

Main production assets: JSC HMS Livgidromash, JSC HMS Neftemash, JSC Nasosenergomash, JSC Kazancompressomash, Apollo Gossnitz Gmbh (Germany);

Manufactured products: pumps and pumping stations for long-distance oil transportation, pumping systems for oil refining, compressors and compressor units, modular oil field equipment, equipment for repair and cementing of wells, capacitive and separation equipment, systems for measuring oil flow rates;

GK Rimera:

The main production assets are: Izhneftemash, JSC, Alnas, JSC, Connecting pipe bends, JSC, MSA as (Czech Republic);

Manufactured products: submersible pumps for oil production (ESP), drilling pumps, pipeline fittings, connecting pipe bends, equipment for repair and cementing wells;

By and large, this triumvirate, the nomenclature of which does not compete, but rather complements each other, on 2 / 3 “covers” the needs of oil and gas industry workers for technological equipment, not inferior to foreigners in either product quality or after sales service. On the competitiveness of these manufacturers say the numbers and facts. Their products are in demand on foreign markets - in the order book of the pumping division of the HMS Group, more than 30 percent is exported to non-CIS countries, and Izhneftemash, part of Rimera Group of Companies, in certain periods receives more than 40 percent of its revenue from exports.

What to do?

There are several ways to promote the development of the domestic market and its saturation with Russian engineering products.

At the recent meeting of the Interdepartmental Working Group, the Minister of Industry and Trade Denis Manturov said that the state is ready to issue loans for key investment projects with a preferential loan rate of 5% per annum. The money will go from the Industry Development Fund, and the interest rate on loans taken in the period from 2014 to 2016 will be subsidized for research investment projects, research and development. The state is ready to compensate the costs for the implementation of pilot projects in the field of engineering and industrial design.

The Industry Development Fund has already received more than 35 applications from manufacturers of oil and gas equipment. Among the enterprises that have submitted applications for the provision of preferential financing are manufacturers of electric-welded pipes, pumping equipment, telemetric drilling systems, etc. The total amount of projects for applications reaches almost 10 billion rubles. In addition, investment projects aimed at creating new products for the needs of the fuel and energy complex with a total funding of about 40 billion rubles were sent to the Ministry of Industry and Trade for consideration.

In general, the largest domestic producers could develop independently, without resorting to emergency measures of state support, but a prerequisite for this should be the desire of Russian oil and gas companies to purchase primarily domestic equipment, their readiness for close cooperation with Russian machine builders in the development and mastering the production of new types of equipment and technological solutions. Consumer and producer alliances are the world's best practice, which at one time became the basis for the development of all the largest transnational oilfield holdings, but which, unfortunately, is still taking root poorly in our country.

One of the priority areas of work on import substitution, which the Ministry of Industry and Trade is conducting today, is localization of equipment production in Russia. Leading engineering companies, as one would expect, set the tone for other manufacturers here. OMZ Group is preparing to develop an underwater mining complex for offshore oil and gas production, to expand the range of manufactured heat exchange and column equipment for oil refineries. Rimera Group of Companies has mastered and supplied the Voskhod welding complexes to the customer, which came to replace European-made installations that have exhausted their resources. The Group also plans to develop oil well cementing installations (currently almost all such installations are manufactured in the USA), as well as expanding the range of pumps for oil production at the Alnas plant in Almetyevsk.

In 2014, the HMS group began construction in the Oryol region at the site of HMS Livgidromash JSC for a unique production complex in Russia, which includes the full production cycle of main pumps for transporting oil and oil products, processing pumps for oil refining, and pumps for nuclear and thermal power engineering. The first phase of construction will be completed this fall, the second is scheduled before the end of 2016. As reported in the HMS Group itself, “the volume of investment in the project will be 2,5 billion rubles, and the sales volumes of the company's products in Livny will grow by 5 billion rubles, or more than 2,5 times by 2017 year”.

Perhaps the solution to the problem of import substitution lies in the political plane. Many experts say that more powers should be given to representatives of the state on the boards of directors of state-owned companies. Often, the issues of the formation of investment programs, the purchase of equipment and other issues of the operating activities of controlled companies are out of their sight. If the terms of reference of state representatives in state-owned companies to expand simultaneously with the increase in their responsibility for the volume of purchases from domestic producers, then perhaps Russian equipment could increasingly replace expensive imported equipment.

This can be a significant step for the development of the entire industry - it is the state-owned companies that are the largest customers of equipment and they are the slower ones to import substitution. Thus, according to a recently published study by the Gaidar Institute, in the first quarter of 2015, only 10% of state-owned enterprises announced a decrease in purchases of imported equipment, against more than 50% of import reduction among private companies.

The result?

Speaking about the problem of import substitution, it is necessary to remember that the oil and gas industry is key for the country, and the creation of domestic equipment to ensure the work of this industry are issues that are at the junction of business interests and economic security of the state.

With all the support provided by the state to the industry of oil and gas engineering, domestic demand from the major oil and gas companies is needed. Without orders from our oil and gas industry workers, their own industry risks becoming almost completely dependent on foreign equipment, its manufacturers and the governments of the countries from which it comes to us. And the Russian industry will not receive new opportunities for its further development.

If we abstract away from the “political” context of this topic, then the issue of transition to modern Russian equipment with high-quality service is one of the key aspects of the sustainability of the business of oil and gas producing and processing companies.

In the meantime, according to the plans of the Ministry of Energy, by the year 2016 it is planned to master the technologies and start producing equipment, including for geological exploration, well equipment, as well as equipment for controlling drilling devices. By the year 2018, the development of technologies for the production of catalysts and additives, the processing of hydrocarbon raw materials, the production of equipment for the transportation of oil and gas and the liquefaction of natural gas, as well as the preparation of software should already have begun.

As part of the long-term plans for 2018 for a year and beyond, it is worth creating our own technologies and equipment for offshore projects.

Leading Russian manufacturers of oil and gas equipment are fully capable and, moreover, should be actively involved in these processes, competing with foreign manufacturers on equal terms. There would be only the orders and the will of today's commanders of the oil and gas industry in fact, and not only verbally, to turn to the Russian supplier, and we have high-quality Russian products.

Information