Active Tank Armor

Initially, the attack on the armor was carried out in the forehead: while the main type of impact was the armor-piercing projectile of kinetic action, the duel of the designers was reduced to an increase in the caliber of the gun, thickness and angle of the armor. This evolution is clearly seen in the development of tank weapons and armor in World War II. Constructive solutions of that time are quite obvious: let's make the barrier thicker; if you tilt it - the projectile will have to go a long way in the thick of the metal, and the probability of rebound will increase. Even after the appearance in the ammunition of tank and anti-tank guns of armor-piercing shells with a rigid non-breaking core, little had changed.

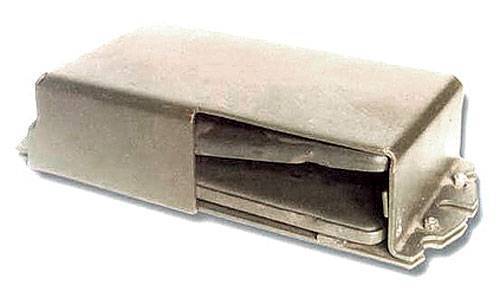

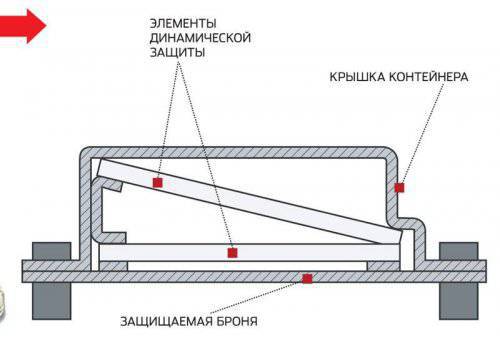

Elements of Dynamic Protection (EDS)

They are sandwiches made from two metal plates and an explosive. EHRs are placed in containers, the lids of which protect them from external influences and at the same time are missile elements.

Deadly spittle

However, at the beginning of World War II, a revolution occurred in the damaging properties of ammunition: cumulative shells appeared. In 1941, Hohlladungsgeschoss (“dredged projectile”) began to be used by German gunners, and in 1942 and in the USSR 76-mm projectile BP-350А, developed after studying trophy samples, was adopted. So the famous Faust-cartridges were arranged. There was a problem that could not be solved by traditional methods due to an unacceptable increase in the mass of the tank.

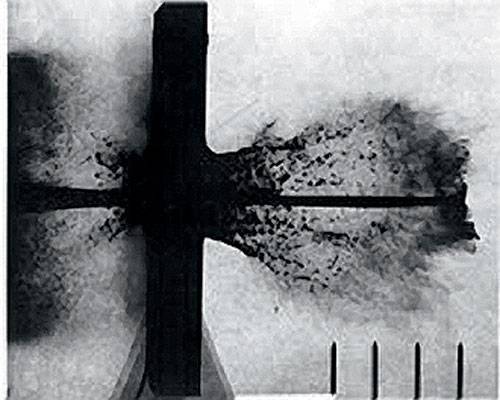

A conical recess in the form of a funnel lined with a thin metal layer (a bell socket) was made at the head of the cumulative ammunition. The detonation of the explosive starts from the side closest to the top of the funnel. The detonation wave “collapses” the funnel to the axis of the projectile, and since the pressure of the explosion products (almost half a million atmospheres) exceeds the plastic deformation limit of the plate, the latter begins to behave like a quasi-liquid. Such a process has nothing to do with melting, it is the “cold” flow of material. A thin (comparable with the shell thickness) cumulative jet is squeezed out of the collapsing funnel, which accelerates to speeds of the order of explosive detonation velocity (and sometimes higher), that is, about 10 km / s and more. The speed of the cumulative jet significantly exceeds the speed of sound in the material of the armor (about 4 km / s). Therefore, the interaction of the jet and armor occurs according to the laws of hydrodynamics, that is, they behave like liquids: the jet does not burn through the armor at all (this is a common misconception), but penetrates into it, just as a jet of water erodes sand under pressure.

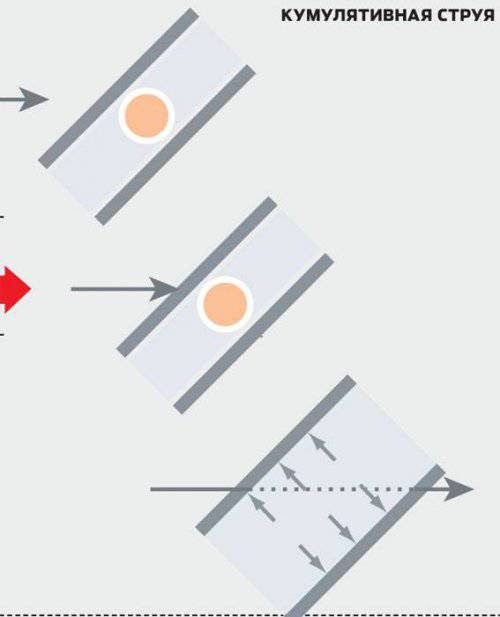

Principles of semi-active protection using the energy of the jet itself. Right: cellular armor, the cells of which are filled with quasi-liquid substance (polyurethane, polyethylene). The shock wave of the cumulative jet is reflected from the walls and collapses the cavity, causing destruction of the jet. Below: armor with reflective sheets. Due to the swelling of the back surface and the gasket, the thin plate is displaced, attacking the jet and destroying it. Such methods increase protivokumulyatnuyu resistance to 30 – 40

Puff protection

The first defense against cumulative ammunition was the use of screens (dual-barrier armor). The cumulative jet does not form instantly; for its maximum efficiency, it is important to blow up the charge at the optimal distance from the armor (focal length). If before the main armor to place the screen of additional sheets of metal, the explosion will occur earlier and the effectiveness of the impact will decrease. During the Second World War, tankers fastened thin metal sheets and mesh screens to protect against faustparons (a bike is common about using armor-beds in this capacity, although in reality special nets were used). But this solution was not very effective - the increase in durability averaged just 9 – 18%.

Therefore, when developing a new generation of tanks (T-64, T-72, T-80), the designers applied another solution - multi-layer armor. It consisted of two layers of steel, between which was placed a layer of low-density filler - fiberglass or ceramics. Such a “pie” gave a gain in comparison with monolithic steel armor up to 30%. However, this method was not applicable for the tower: for these models it is molded and it is difficult to place the fiberglass from the technological point of view. The designers of the VNII-100 (now the Transmash Scientific-Research Institute) proposed to inflate ultra-porcelain balls inside the tower armor, the specific flaking ability of which is 2 – 2,5 times higher than that of armor steel. Experts of the Research Institute began to choose another option: between the outer and inner layers of armor placed packages of high-strength solid steel. They took upon themselves the blow of a weakened cumulative jet at speeds, when the interaction no longer follows the laws of hydrodynamics, but depending on the hardness of the material.

Semi-active armor

Although it is rather difficult to slow down the cumulative jet, it is vulnerable in the transverse direction and can easily be destroyed even by a weak lateral effect. Therefore, the further development of the technology consisted in the fact that the combined armor of frontal and onboard parts of the cast tower was formed due to the cavity open above, filled with complex filler; from above the cavity was closed with welded plugs. Towers of this design were used on later modifications of tanks - T-72B, T-80U and T-80UD. The principle of action of the inserts was different, but used the aforementioned “lateral vulnerability” of the cumulative jet. Such armor is usually referred to as “semi-active” defense systems, since they use the energy of the weapon itself.

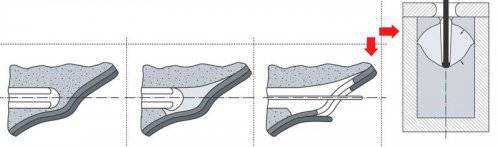

One of the variants of such systems is cellular armor, the principle of action of which was proposed by employees of the Institute of Hydrodynamics of the Siberian Branch of the USSR Academy of Sciences. Armor consists of a set of cavities filled with a quasi-liquid substance (polyurethane, polyethylene). A cumulative jet, hitting a volume bounded by metal walls, generates a shock wave in quasi-liquid, which, reflected from the walls, returns to the jet axis and collapses the cavity, causing deceleration and destruction of the jet. This type of armor provides a benefit in anti-cumulative resistance up to 30 – 40%.

Another option is armor with reflective sheets. This is a three-layer barrier consisting of a plate, gasket and a thin plate. The jet, penetrating into the slab, creates stresses, leading first to local swelling of the back surface, and then to its destruction. When this happens a significant swelling of the strip and a thin sheet. When the jet pierces the gasket and thin plate, the latter has already begun to move away from the back surface of the plate. Since there is a certain angle between the directions of motion of the jet and the thin plate, then at some instant of time the plate begins to fall on the jet, destroying it. In comparison with monolithic armor of the same mass, the effect from the use of "reflective" sheets can reach 40%.

The next improvement was the transition to a tower with a welded base. It became clear that developments to increase the strength of rolled armor are more promising. In particular, in 1980-ies new high-hardness steels were developed and are ready for mass production: SK-2Sh, SK-3Sh. The use of towers with rolled stock made it possible to increase the protective equivalent on the base of the tower. As a result, the turret for the T-72B tank with rolled stock had an increased internal volume, the weight increase was 400 kg compared to the serial cast turret of the T-72B tank. The tower filler package was made using ceramic materials and high-hardness steel or from a package based on steel plates with “reflective” sheets. Equivalent armor resistance became equal to 500 – 550 mm of homogeneous steel.

The principle of dynamic protection

When a DZh element breaks through with a cumulative jet, the explosive in it detonates and the metal plates of the hull begin to scatter. At the same time, they cross the trajectory of the jet at an angle, constantly substituting new sections for it. A part of the energy is spent on breaking the plates, and the side impulse from the collision destabilizes the jet. DZ reduces the armor-piercing characteristics of the cumulative agents on 50 – 80%. At the same time, which is very important, the DZ does not detonate when firing from a small weapons. The use of DZ was a revolution in the protection of armored vehicles. There was a real opportunity to influence the penetrating attack vehicle as actively as it had before affecting passive armor.

Bang

Meanwhile, technology in the field of cumulative munitions continued to be improved. If during the Second World War, the penetration rate of cumulative projectiles did not exceed 4 – 5 caliber, then it later increased significantly. Thus, with the 100 – 105 mm caliber, it already amounted to 6 – 7 calibers (in steel equivalent 600 – 700 mm), with the 120 – 152 mm caliber, it was possible to raise the armor to 8 – 10 calibers (900 – 1200 mm homogeneous steel). To protect against these munitions, a qualitatively new solution was required.

Work on anti-cumulative, or "dynamic" armor, based on the principle of counter-explosion, was carried out in the USSR since the 1950-s. By 1970, its design had already been tested at the All-Russia Research Institute of Steel, but the psychological unpreparedness of high-ranking representatives of the army and industry prevented its adoption. Only successful use by Israeli tankers of similar armor on the M48 and M60 tanks during the Arab-Israeli war 1982 helped them convince them. Since the technical, design and technological solutions were fully prepared, the main tank fleet of the Soviet Union was equipped with the Kontakt-1 anti-cumulative dynamic protection (DZ) in a record time - in just one year. The installation of the DZ on the T-64A, T-72A, T-80B tanks, which already already had sufficiently powerful armor, almost simultaneously devalued the existing arsenals of anti-tank guided weapons of potential opponents.

Against scrap there are tricks

Cumulative projectile - not the only means of destruction of armored vehicles. Much more dangerous opponents of armor are armor-piercing sabots (BPS). By design, such a projectile is simple - it is a long scrap (core) of heavy and high-strength material (usually tungsten carbide or depleted uranium) with feathering for stabilization in flight. The diameter of the core is much smaller than the caliber of the trunk - hence the name "sabot". Flying with a speed of 1,5 – 1,6 km / s, a “dart” with a mass of several kilograms has such kinetic energy that it can penetrate more than 650 mm of homogeneous steel when hit. Moreover, the above-described methods of enhancing protivokumulyativnoy protection practically do not affect the sabot projectiles. Contrary to common sense, the slope of the armor plates not only does not cause a rebound of a sabot projectile, but even weakens the degree of protection against them! Modern “working” cores do not ricochet: when in contact with armor, a mushroom tip is formed at the front end of the core, which plays the role of a hinge, and the projectile turns to the perpendicular to the armor, shortening the way in its thickness.

The next generation DZ became the system "Contact-5". Experts of the Research Institute began to do a lot of work, having solved many contradictory problems: DZ had to give a powerful side impulse to destabilize or destroy the BOPS core, the explosive had to reliably detonate from the low-speed (compared to the cumulative jet) BOPS core, but the detonation from hits of bullets and splinters of shells were excluded. The construction of the blocks helped to cope with these problems. The DZ block cover is made of thick (about 20 mm) high-strength armor steel. Upon impact, the BPS generates a stream of high-speed fragments, which detonate the charge. The impact on the BPS moving thick cover is sufficient to reduce its armor-piercing characteristics. The effect on the cumulative jet is also increased compared with the thin (3 mm) “Contact-1” plate. As a result, the installation of a DZ "Kontakt-5" on tanks increases the anti-cumulative resistance in 1,5 – 1,8 times and provides an increase in the level of protection against BPS in 1,2 – 1,5 times. The Kontakt-5 complex is installed on the Russian T-80U, T-80UD, T-72B tanks (starting with 1988 of the year) and T-90.

The last generation of the Russian DZ is the Relikt complex, also developed by specialists of the Steel Research Institute. In advanced EDS, many deficiencies were eliminated, for example, insufficient sensitivity when initiating low-speed kinetic projectiles and some types of cumulative ammunition. Increased efficiency in the protection against kinetic and cumulative ammunition is achieved through the use of additional projectiles and the inclusion of non-metallic elements in their composition. As a result, armor penetration of the sabreuse projectiles is reduced by 20 – 60%, and due to the increased exposure time to the cumulative jet, a certain effectiveness has been achieved with cumulative means with a tandem warhead.

Information