The project of the unified combat department "Burlak"

According to the results of the implementation of several experimental design works, the military came to the conclusion that it was necessary to create a unified combat unit, which could be installed on all new tanks. In addition, the new combat module could be installed on existing tanks in the army undergoing modernization. Such a project looked extremely interesting and could have a great future. The proposed unified combat compartment allowed equipping all the existing tanks or, at least, a significant proportion of them with a common set of equipment, such as weapons, fire control systems, etc. The result of this was to increase the characteristics of the upgraded equipment, as well as simplify the construction of new tanks and the operation of existing ones in the troops.

In 2005, the Defense Ministry’s Main Armored Directorate announced a competition for the Burlak design and development work. Several enterprises submitted their applications, but the winner in the competition was the Omsk Transport Engineering Design Bureau (KBTM). According to a well-known specialist in the field of armored vehicles, Aleksey Khlopotov, the victory of KBTM had several reasons at once. The choice of specialists was affected by the presence of previous similar projects, the initially underestimated cost of the project, as well as the desire of the military to support an enterprise that was experiencing serious difficulties.

The goal of the Burlak project was to develop a unified fighting compartment for existing and prospective domestic tanks. It was assumed that the new combat compartment with minimal modifications should be installed on the machines of T-72B, T-80BV, T-90 types and even on the newest T-95 tank. In the course of the new project it was planned to solve several problems peculiar to the existing armored vehicles. Among the objectives of the project was improving the automation of the supply of ammunition, increasing the level of protection, as well as the creation of a certain modernization reserve for the future.

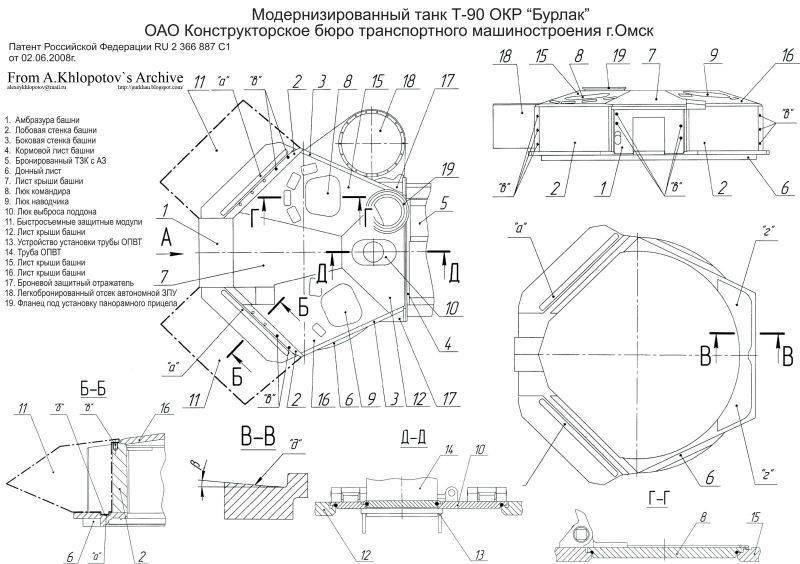

The basis of the new fighting compartment was to become a hexagonal tower, on which it was planned to mount various units. For example, it was proposed to install replaceable protection modules on the front sheets of the tower, and on the stern there was an installation unit for the so-called. transport loading container (TZK) for placement of ammunition. On the right side of the tower, a special platform was provided for the installation of a remote-controlled machine-gun turret. Such a layout of the fighting compartment, as expected, allowed to solve most of the existing problems.

To increase the level of defense of the tower in frontal projection, it was proposed to use a modular reservation system. The front sheets of the tower were to be placed vertically and equipped with fixings for protection modules. The use of a modular reservation system was of particular interest. Such an architecture of protection means in theory allows relatively quickly and simply to increase the level of protection of armored vehicles by replacing outdated components with new ones. In addition, the modular system is quite convenient to operate in conditions of armed conflict. The damaged module can be replaced with a whole, after which the machine is again protected from various threats.

It should be noted that this architecture of tower defense is not without flaws. The main ones are related to the relative complexity of manufacturing and the increased mass of the structure. Due to fastenings, etc. parts modular armor is noticeably heavier and more expensive than similar protection integrated into the tower structure. Nevertheless, the authors of the Burlak project decided to build the defense of the new combat unit by using the modular design with interchangeable elements.

The available diagrams and photographs depict frontal booking modules of various designs that differ even in appearance. So, on some schemes there are wedge-shaped modules, on others (in particular, on photos published a few years ago) - inclined blocks of characteristic shape, fixed at the bottom of the tower. Probably at different stages of development offered different options for modular frontal booking. According to different sources, the front of the tower had to carry both a combined reservation and dynamic protection units.

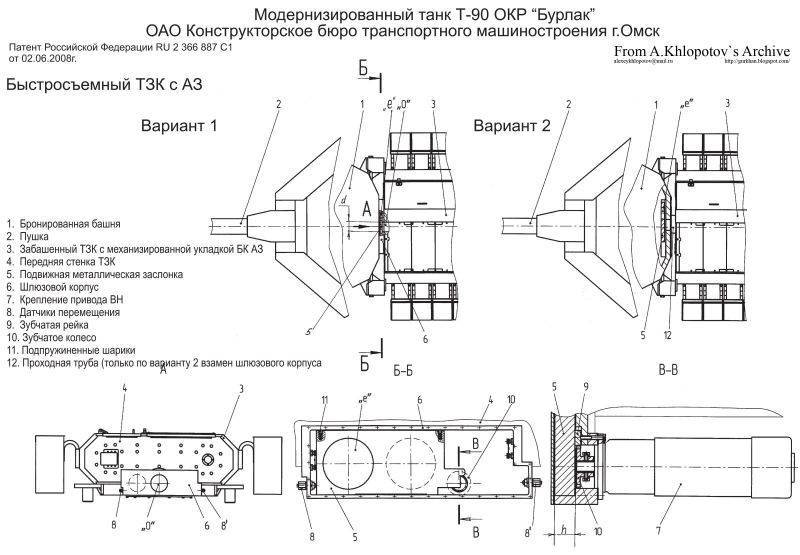

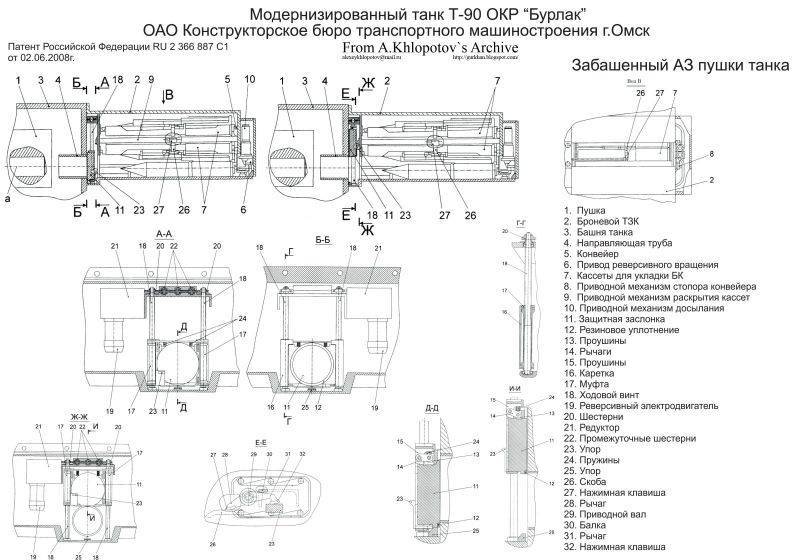

An important innovation of the project "Burlak" was a new automatic loader with ammunition rendered outside the habitable volume. At the stern of the tower, mounts were provided for a removable transport and loading container that served as a mechanized stacking of ammunition. Inside the refueling complex it was proposed to place the packing with the automatic feed of shells. Dimensions of the developed container allowed to place in it up to 32 shells of caliber 125 mm. At the command of the crew, the automatics had to bring the projectile of the desired type to the window connecting the fighting compartment with the container. After that, the gun was supposed to go on the line of unloading and a special pusher could charge it. As planned by the authors of the project, such an automatic loader should have a lot of advantages over similar units of existing tanks.

The first advantage was associated with the removal of ammunition (both completely and most of it) beyond the limits of habitable volume, which allowed reducing the risks for the crew. In the event of the defeat of the refueling complex, the detonation of the ammunition should not lead to the death of the crew, since the burning or explosions occur outside the tower. In addition, as a means of improving crew safety, dynamic protection modules installed on the refueling complex can be used, as well as expelling panels on the upper surface of the container.

The removal of ammunition beyond the limits of manned volume also allows you to increase the size of the crew compartment, designed to accommodate the crew and various equipment. According to some reports, the rejection of the "classic" automatic loader in favor of the refueling complex should have led to savings around 2,5 cube. m space. In addition, simplified loading ammunition. It was possible to remove the refueling complex with used ammunition and install a new one. Such a feature could significantly speed up the preparation of the tank for the combat mission, but it had a negative effect on the cost of the whole complex of facilities, modernization and operation of armored vehicles.

It is known that in the combat department "Burlak" two automatic loaders were provided at once. One proposed to be placed in a removable refueling complex, the second - at the bottom of the case. The lower automatic carousel loader allowed to increase the total tank ammunition, and also gave some other advantages. In particular, he allowed to continue the fight in case of damage, destruction or use up of ammunition located in the container.

A curious feature of the Burlak fighting compartment with original blocks of frontal protection and a transport-loading container was the balancing of the aggregates. The use of two large nodes located on the front and aft parts of the tower, allowed them to balance. In other words, the refueling complex allowed to strengthen the protection, and the frontal armor made it possible to use the container for ammunition. Naturally, all this led to a noticeable increase in the mass of the tower and the load on the epaulet.

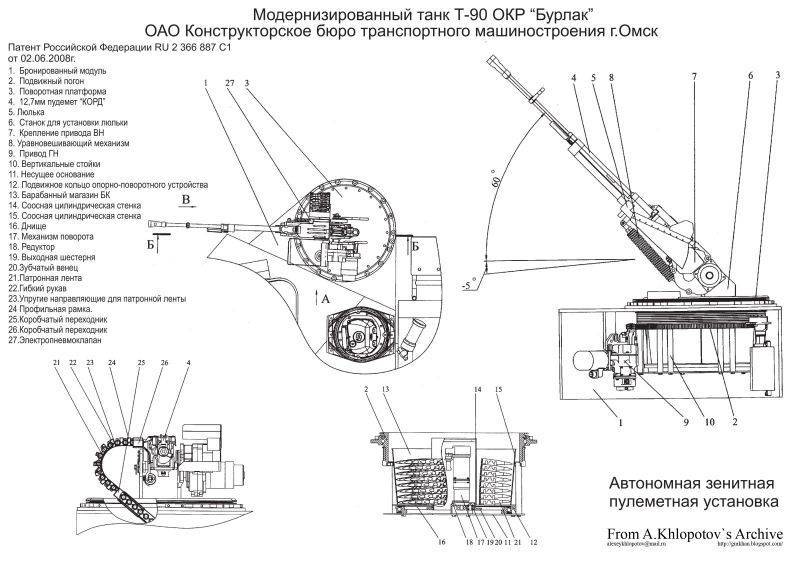

An important innovation of the ROC Burlak was a remote-controlled machine-gun installation, placed on a special platform outside the tower. Modern tanks need machine guns equipped with a remote control system, so the appearance of such a unit on a promising turret was logical and expected. The removal of the machine gun on the side platform made it possible to optimize to a certain extent the placement of the units on the upper surface of the tower, in particular the hatches of the crew. An interesting fact is that the onboard platform of the machine gun did not stand for the projection of the frontal defense units.

In general, the list of the main advantages of the Burlak combat unit looked as follows:

- an increased level of protection due to the use of a combination of armor and dynamic protection;

- the possibility of a relatively simple repair and modernization of protection due to the change of individual units or the whole set of them;

- placing the entire ammunition in automated laying under the floor of the fighting compartment and in the transport-loading container;

- reduction of risks for the crew through the use of a separate refueling complex;

- the possibility of increasing the ammunition through the use of two stowages (a variant of the refueling complex with a capacity of 32 projectile was developed);

- compatibility with modern and promising tools and fire control systems;

- the ability to attack manpower and unprotected vehicles using a remote-controlled machine gun turret.

It is known about the existence of a prototype of an updated tank, built on the basis of the serial T-72B. This car was equipped with a model of a promising combat compartment. The exact time of the appearance of such a tank is unknown. It was probably collected in the second half of the past decade. Photos of an experimental car with a tower covered with a tarpaulin were freely available only in 2011, when, as far as is known, all work on the topic of Burlak was discontinued. These photos show some features of the proposed combat compartment, although the fabric does not allow to get acquainted in detail even with the appearance of the resulting machine.

In addition to a number of noticeable advantages, tanks with the Burlak combat compartment should have some drawbacks. First of all, it is a relative difficulty with the development of new technology. Modernized tanks with a new combat compartment for some time had to be operated in parallel with the existing types of equipment. Thus, there was a risk of complicating an already not too simple situation with the simultaneous operation of several types of tanks. Thus, in addition to the T-72B, T-80BB and T-90 tanks, similar vehicles with new turrets were to appear in the troops. In other words, the troops were threatened with a true doubling of the number of types of equipment used. A similar situation could persist until the full transition to new combat modules.

It should also be noted that the Burlak combat compartment was too heavy due to a number of new units. The latest modification of the T-90 tank, the T-90MS, equipped with the Breakthrough turret of the classic layout, has a combat weight of 48-49 tons. Thus, the T-90MS fits into the military requirements for the weight of new armored vehicles associated with the capabilities of the military transport aviation. Preliminary calculations showed that the T-90 chassis with the Burlak tower would weigh at least 49,5 tons. Further development of the fighting compartment threatened to increase the weight of the entire tank with corresponding consequences for mobility.

Work on the topic "Burlak" continued until the end of 2009 year. For some reason, the project was closed. Probably, the specialists of GABTU analyzed its current state and came to the conclusion that it was useless to continue the development. It was decided to abandon the project of gradual modernization of the existing fleet of tanks, focusing on the creation of new combat units for promising main tanks.

Approximately at the same time as the Burlak project was closed, specialists from the Uralvagonzavod Corporation began the development of the promising unified tracked platform Armata. As part of this project, it was planned to create a line of different vehicles, primarily a new main tank, which in the foreseeable future should replace the existing vehicles. Whether any developments on the topic of Burlak were used in the development of the Armata tank is unknown.

On the materials of the sites:

http://gurkhan.blogspot.ru/

http://btvt.narod.ru/

http://otvaga2004.ru/

http://bastion-karpenko.ru/

http://vpk-news.ru/

Information