In the wake of IDEX 2015

Raytheon and Nimr Automotive (part of the Emirates Defense Industries Company, EDIC) joined forces and armed Nimr armored vehicles with a Talon laser-guided missile system.

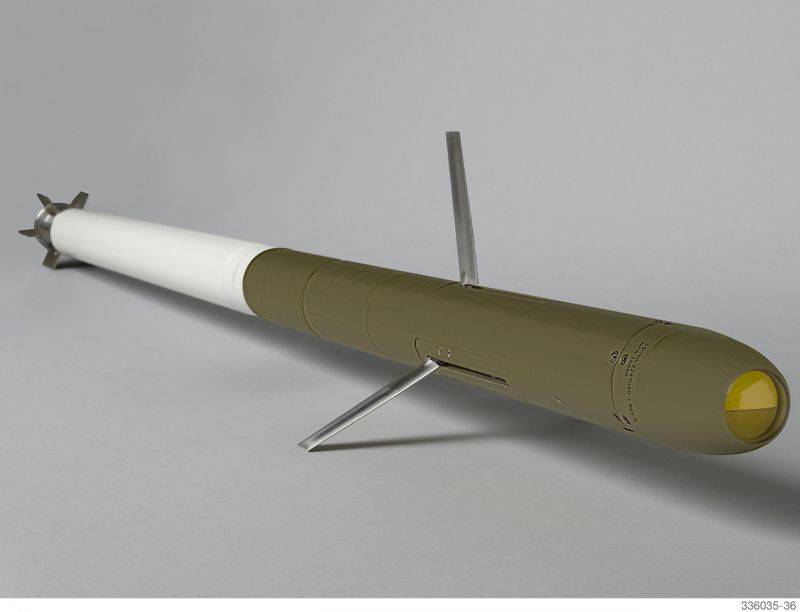

Originally developed by Raytheon, the low-cost Talon LGR digital guidance and control kit based on a semi-active laser was developed with the United Arab Emirates in accordance with the requirements of this country. The Talon targeting section is installed in the nose of an unguided Hydra-70 rocket already in service with an 2,75 shell diameter of an inch.

According to Raytheon, Talon’s architecture and ease of use “make it a low-cost, high-precision weapon to perform tasks in urban environments, as well as for the tasks of fighting insurgents and protecting against massive attacks of speedboats. "

The tactical platform Nimr 6x6 provides integration of a modular system to perform a full range of tasks, including armed reconnaissance, protection of infrastructure facilities, defensive suppression fire and border security.

Each Nimr vehicle will carry 16 Talon LGR missiles mounted on a Raytheon remote-controlled combat module. The module allows Talon to be launched from stationary and moving vehicles, while the retractable sensor kit allows Talon and anti-tank missiles to be launched from closed positions, ensuring mortality and survivability for the ground vehicle.

“In collaboration with EDIC, we provide an affordable, real and reliable solution,” said Michelle Lomeyer, vice president of ground systems at Raytheon. “Integration with the Nimr car once again demonstrates the flexibility of the Talon complex.”

Mobile mortar complex Agrab Mk2

Having received a contract worth 786 million dirham on 72 serial systems, the International Golden Group company (IGG) from Abu Dhabi has now installed 120-mm mortar complexes Agrab Mk 2 from the last installment on vehicles for the UAE armed forces. Ten complexes from the first batch were installed in South Africa, and the remaining 62 complex at the IGG plant in the UAE.

Agrab Mk 2 consists of BAE Systems Land Systems South Africa RG31 Mk 6E mini-protected vehicle and 120-mm Super Rapid Advanced Mortar System (SRAMS), an ultra-high-speed advanced mortar set made by Singapore Technologies Singapore Kinetics. The mortar is mounted on the rear platform and is controlled by Thales South Africa Systems integrated fire control system. The car has a turbocharged Cummins diesel engine rated at 360 hp. at 2600 rpm, coupled with Alliso six-speed automatic transmission, which allows you to develop a maximum speed of 90 km / h.

Serial complex Agrab Mk 2 120 mm has a high off-road terrain

The machine is equipped with a Platt protected combat module with an 12,7-mm machine gun M2 HB plus grenade launchers with an electropatch. 120-mm mortar SRAMS shoots in the rear arc with the restriction of the vertical angles from + 45 ° to + 80 ° and in azimuth 40 ° to the left and right. 120-mm ammunition is supplied by Rheinmetall Denel Munitions. High-explosive and two-spectral smoke and lighting projectiles are currently available; all of them are not cocked until they fly off to the 40 meters from the barrel. The maximum range, as a rule, is 8,1 km for high-explosive mine.

The ST Kinetics 120mm smoothbore mortar system is currently qualified to fire a rocket projectile at a maximum range of 13 km, as well as a laser-guided mortar round for high-precision increase in destruction of targets designated by a forward observer or drone. The fire control system includes automatic guidance, ballistic calculations, which are also based on data from the airborne meteorological sensor, and a common weapons control unit. Under the 120-mm mortar SRAMS installed Selex FIN3110 inertial navigation system with a ring laser gyroscope.

In addition to the stand-alone mode, one 120-mm mortar complex Agrab Mk 2 MMS can control the fire task of 12 platforms with the aim of maximizing the impact on the target.

Shot and drove away

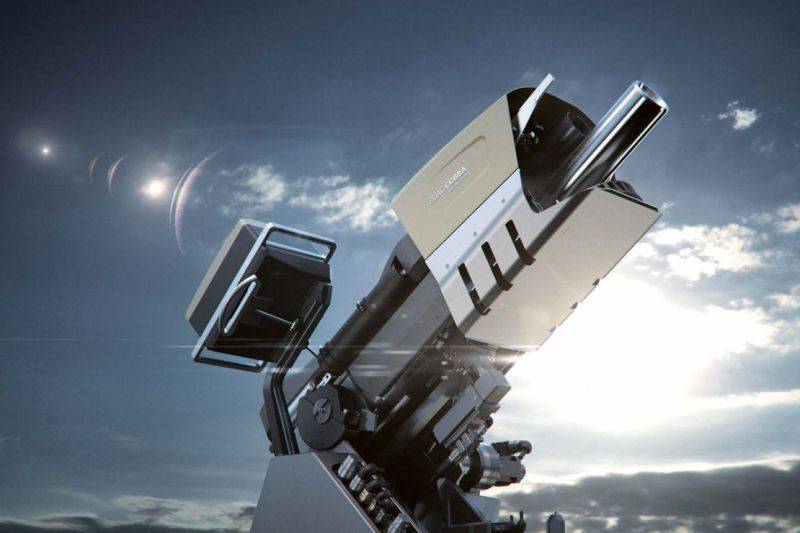

The RUN Cobra 120-mm mortar complex has an onboard fire control system for faster and more accurate guidance.

At IDEX 2015, the Swiss company RUAG Defense presented its 120-mm mortar complex of the new generation Cobra. The company at its own expense led the development of the complex with 2012 year. After completion of the development process upon receipt of orders, the production of this complex can begin.

Cobra is a rotary 120-mm smooth-bore mortar complex, equipped with electric drives of vertical and horizontal guidance with a manual backup branch. To reduce the reaction time, the complex has a computerized fire control system connected to an inertial navigation system that provides automatic guidance.

A mortar can shoot in the mode of multiple round simultaneous impact (simultaneous impact of several projectiles; the angle of inclination of the barrel changes and all projectiles fired at a certain time interval arrive at the target simultaneously) in order to maximize impact on the target. This allows you to use the tactics of "shot and drove away." The complex can take a position and perform a firing task in 60 seconds. Automatic loader reduces crew fatigue and increases the rate of fire.

The Cobra complex weighs only 1500 kg with a loading device, although if necessary it may not be installed. The maximum range depends on the combination of projectile / charge and the type of mortar shot, but RUAG says about the range from 7000 to 9000 meters.

The training system is built into the Cobra complex, it is also possible to insert an insert with a diameter of 81 mm into the barrel. This allows the calculation during shooting practice to fire at shorter ranges compared to the 120 mm caliber system.

Launcher boosts firepower at sea

The Turkish company Aselsan and the British Thales UK signed an agreement on the joint development and sale of ship launchers for precision weapons LMM (Lightweight Multirole Missile - light multipurpose missile) from Thales. The two companies secured their relationship at the signing ceremony at IDEX 2015. The agreement provides for the development of a LMM four-pipe launcher and a larger version for eight missiles.

Based on the experience of developing existing Starburst and Starstreak ground-to-air missiles, the LMM was developed by Thales as an inexpensive laser-guided missile capable of intercepting air, land and sea targets at distances of approximately 8 km. In the original version of the used guidance on the laser beam.

Thales believes that the LMM is well suited for offshore missions, especially to combat the threat of small speedboats. A non-contact laser rocket fuse, which uses low-cost programming technology at the launch point, ensures that the rocket can successfully intercept non-metallic, non-solid targets, such as rigid inflatable boats that many missiles pass through without detonation, while the 3 high-explosive shaped charge with an XNUMX kg mass combines excellent local impact with good penetration characteristics.

The LMM testing tests have already demonstrated the accuracy of aiming at a laser beam against targets like a small combat boat at distances up to 4 km at sea state with wave heights from 4 to 6 meters. Combat shooting demonstrated a zone of damage with a radius of 5 meters. Static tests of the warhead against simulated onboard superstructures of high-speed boats were also successfully completed.

The LMM is currently in the process of qualifying and entering production in order to meet the requirements of the British Future Anti-Surface Guided Weapon (Light) promising surface program. In this application, the rocket will be launched from the new AgustaWestland Wildcat HMA.2 Royal Navy helicopter.

Aselsan and Thales have jointly developed two versions of the LMM missile launcher with the aim of expanding the capabilities of these missiles in the fight against surface targets. The smaller system with four missiles is designed to destroy speedboats. The complex includes a two-plane gyro-stabilized gun platform and four LMM missiles ready for launch, as well as an off-platform stabilized opto-electronic guidance unit (with a laser transmitting device to guide the LMM rocket along the laser beam) and a control unit mounted on the bridge and display. Such a configuration made it possible to achieve a minimal effect of the missile complex on the speed and maneuverability of the carrier platform.

Aselsan and Thales sign LMM launcher marketing agreement

Aselsan has also developed a larger eight-pipe system, which includes two containers of four LMM missiles each and an optical-electronic system mounted on top. It is intended for larger ships, for which the limitations on volume and mass are less stringent.

The company completed the development of experimental models of two variants of launchers with the first stage of LMM control starts during the 2014 year. In addition, last year Aselsan and Thales conducted target tracking tests in the Istanbul area to test the stabilization and tracking characteristics of an optical electronic sensor kit.

HammerHead makes the first flight

HammerHead's first prototype makes its first flight from Trapani-Birgi airbase in December 2014

Piaggio Aero announced that the PI HH HammerHead UAV, based on the Avanti business class aircraft, made its first flight 22 December 2014 of the year.

The unmanned aircraft under the designation Prototype 001 took off from the military air base Trapani-Birgi in Sicily and made its first flight over the Mediterranean at various speeds and altitudes, during which the main functions of the ground control station were also tested.

Project leader Serzhik Paloni, who then headed the test team, said: “We are very pleased with the results of the first flight. The air vehicle was remotely controlled, there were no errors. ”

For Piaggio Aero, the first successful flight was a significant event. "You can take more risks during a manned flight, you have a pilot who takes control in case of emergency situations," said Executive Director Carlo Logli. “With a drone, you need a greater level of technological maturity.”

To achieve this maturity, Piaggio Aero tested the HammerHead Demo manned aircraft (the Avanti business plane converted to a flying laboratory), which tested the systems of a future drone, but with a pilot on board for reinsurance. During the preparation of the first flight of the Prototype 001, the HammerHead Demo aircraft made flights from 40 to 50.

The first flight marks the beginning of the first stage of the PI HH test, which is expected to fly about 150 hours; This stage should be completed in the summer. If the first flight was controlled manually through the PI HH communication channel, now the test team intends to check not only the automatic take-off and landing, but also the intermediate capabilities of the sensor kit.

The second prototype of the P.1HH should join the trials at the end of this year and will be mainly used to test the functioning of the systems and expand its capabilities regarding full autonomy.

Piaggio Aero showed a full-scale model of the PI HH drone at the UMEX 2015 in Abu Dhabi. The company closely cooperates with Selex ES in the development of PI HH, in this project Finmeccanica supplies control and management systems, a communication channel and a ground control station.

Piaggio Aero is also working with the Emirate-based company ADASI on a coastal manned patrol aircraft aviation, which will also be based on the Avanti business jet. In addition to many new elements, this patrol aircraft will have an increased wingspan, nose and tail horizontal tail. According to the schedule, the first prototype of this option should fly in the third quarter of this year and may be ready to appear at the air show in Dubai in November 2015.

Emirati Helipadron Al Sabr

Alcopter Camcopner S-100 is used as a platform for Al Sabr.

Abu Dhabi Autonomous Systems Investments (a division of Tawazun Holding) develops universal solutions, providing comprehensive services, including consulting, design, development, testing, maintenance, logistics, training and full service support of autonomous systems for air, land and sea applications.

ADASI also manages the Al Sabr program, launched in 2003 to meet the needs of the UAE armed forces in an autonomous aircraft for surveillance and reconnaissance, retransmission of data, border security, monitoring important infrastructure and artillery support.

The Al Sabr system is based on a UAV platform with two support vehicles (ground control station and vehicle) and is offered with several different deployment options in order to increase off-road mobility. The drone can also be adapted to work from stationary operational centers or for operations from the ship. The aerial platform Al Sabr was developed as part of a joint program of the governments of the UAE and Austria. Some of the main components are manufactured in the UAE, the final assembly is carried out there and the drone of the armed forces of this country is being tested.

The Al Sabr drone is based on the Schiebel Camcopter S-100 helipad. This is a completely autonomous, rotary wing UAV made according to the traditional helicopter scheme with a two-blade rotor and tail rotor. As the drone sits down and takes off vertically, it does not need runways or special launch and landing systems.

The case of the device is made of modern composite materials with some components of titanium and aluminum. This provides reliability and structural strength with a relatively small mass and provides excellent performance. The hull is also resistant to environmental influences, particularly in aggressive marine environments.

Helipad Al Sabr has a redundant flight control system; An advanced survey and search optoelectronic system is installed on board. It can stay airborne for up to 10 hours and transmit live video at a distance of up to 180 km.

The drone was certified by Austrian Austrian AustroControl GmbH (ACG) and the European Aviation Safety Agency (EASA). The UAE Armed Forces became the first buyer of the Camcopter apparatus, which was subsequently sold to China, Egypt, Germany, Italy, Jordan, Libya, Russia and the United States.

Materials used:

www.janes.com

www.idexuae.ae

Information