Ground robots. From abandoned systems to unmanned traffic convoys (6 final part)

Electronically controlled automatic gearboxes, electronically controlled throttle valves plus electrically controlled steering systems, which are now becoming increasingly standard elements of modern vehicles, for developers of robotic platforms are manna from heaven. Indeed, control signals can now be easily integrated into the existing processor units of these machines, which means that the bulky drives needed before can be gradually sent to a landfill.

The special advantages of such systems are not only that they allow transfer from one machine to another. Ultimately, they will become so cheap that the “embedded control” system will essentially remain at its installation site in the car and simply turn off to return to normal use (ie manual control) of this vehicle.

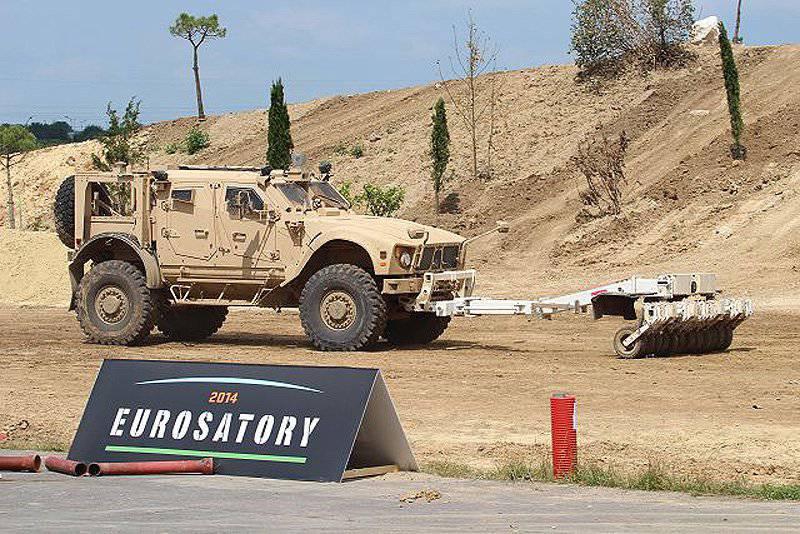

The M-ATV with a roller trawl, shown by Oshkosh at Eurosatory 2014, was equipped with a Terramax robotic kit, whose sensors are visible in the bottom corner of the picture.

Close-up of the sensors installed on the roof Robot Terramax, which provide a clear overview of what's ahead of him, but the question arises - why are the windshields so clean!

Oshkosh: Among American manufacturers of large vehicles, the leader in the field of heavy robotic vehicles, of course, is the company Oshkosh Defense. She began developing robotic technology at the beginning of the 2000-x with the demand of the Darpa Advanced Defense Research Directorate. After several years of development and improvement, in August 2012, the US Marine Corps Fighting Lab and Oshkosh Defense applied TerraMax technology to test a transport convoy, which consisted of five conventional and two unmanned vehicles. The latter were moving offline, albeit under the control of an operator with a remote control unit. While the company maintains its commitment to the Naval Research Authority regarding the cargo robot program, in which the supply convoy will receive robots to maximize contact with the enemy, Oshkosh is also looking for other applications for its constantly upgraded TerraMax system .

At AUVSI 2014 and Eurosatory 2014, Oshkosh presented the M-ATV armored car, equipped with a Humanistic Robotics self-trailer, capable of working offline. The dynamic characteristics of the car were adapted to the trawl and in the next couple of years Oshkosh will continue to experiment in the field of demining routes. The demonstration model shown in Paris was equipped with a roof mounted lidar (laser locator). It is considered as the main sensor and is especially effective in high dustiness conditions, “helping” the radars installed at each corner of the vehicle. In turn, optical-electronic sensors allow the operator to obtain clear and precise visual information about the environment. The modernization of the system mainly consisted in the development and installation of a new and fast computer capable of coping with the higher resolution sensors needed for improved perception of the surrounding terrain, which includes the detection of obstacles and suspicious objects in dust or in green, which in turn allows the car to move faster (just like a motorist at night is able to drive faster in the light of more powerful headlights). The new kit has an open architecture, which allows you to easily install new types of sensors into the TerraMax system.

Lockheed Martin: Fort Hood, 14 January 2014 of the year. A convoy of four cars, two Palletized Loading System trucks, an articulated M915 truck and a Humvee escort vehicle, crossed the “false city”, coping with all types of obstacles, including local traffic, pedestrians, etc. What made the event exceptional is that, with the exception of the Humvee, all the cars in the convoy were driverless - literally. They were equipped with the Autonomous Mobility Appliqué System (Amas), an optional mobility system developed by Lockheed Martin in accordance with the contract obtained in October 2012. The task was to develop a multiplatform kit that combines low-cost sensors and monitoring systems that could be installed on army and marine vehicles, reducing the burden on the driver or providing full automatic driving under supervision. For the car, the possibility of manual driving remains, but sensors and monitoring functions are added that warn the driver about the danger. According to military statistics, most of the accidents in transport columns are caused by fatigue and loss of concentration. Amas is part of the Cast program (Convoy Active Safety Technology - Convoy Active Safety Technology), in which the experience of Lockheed Martin, acquired with the SMSS robot, was intelligently used. The main sensors here are GPS, lidar and radar plus a control system, which, having a certain level of artificial intelligence, provides decision-making. A second series of demonstration tests was completed in June 2014 of the year at the Savannah River proving ground of the Department of Energy.

Additional Autonomous Mobility System The Autonomous Mobility Appliqué System was developed by Lockheed Martin as part of the Convoy Active Safety Technology Convoy Active Safety Technology program.

An unmanned leader vehicle followed in the tests at a speed of up to 65 km / h a column of six autonomous systems equipped with the Amas system (the length of the columns was also doubled in tests). All the cars were medium and heavy trucks of the FMTV family: one MTVR, two PLS, two M915 tractors and one HET. Further safety tests were carried out in July 2014, followed by a demonstration of performance in July-August 2014.

Mira: The British company Mira specializes in advanced vehicles and systems, among which there are robotics. The company has developed a platform-independent Mace kit (Mira Autonomous Control Equipment - Mira autonomous control equipment), which can be integrated into virtually any ground-based platform to obtain the required level of autonomy (remote, semi-autonomous and autonomous modes), depending on the needs of the customer. Mace was installed on various machines in order to show its potential applications (solutions based on Sherpa and Land Rover vehicles for logistic support of dismounted infantry, while the car equipped with a Guardsman monitoring kit based on the Mace kit worked as a perimeter protection platform 4X4) .

Platform-independent robotic kit Mace, developed by the British company Mira, was deployed in Afghanistan in Land Rover vehicles to detect directional land mines.

Currently, one of the MACE solutions implemented in practice is the Project Panama system, which operates as an unmanned system for checking and clearing routes. The system has been in service since 2011 in Afghanistan, it is used to detect bombs and is based on a Snatch Land Rover (SN2) all-terrain vehicle. The Panama machine is used in remote and autonomous modes at distances up to 20 km in order to ensure maximum safety of personnel. In mid-June 2014, the British army announced that Panama would remain in service until 2030, and Mira guarantees the further development of its MACE technology platform. At AUVSI, Mira showed its ability to test roadsides; after several years of using lidars and radars, the emphasis in the new system was on detecting suspicious objects using technical vision. This is connected not only with the cost - the detection system using technical vision is an order of magnitude smaller than the system based on lidar - but also because the use of additional types of sensors allows you to transfer additional data to the system and, consequently, increases reliability and accuracy.

Ruag: The Swiss company Ruag Defense is also working on a kit that allows you to transform traditional cars into machines with controlled autonomy. The kit was named Vero (Vehicle Robotics) and was first shown in the spring of the 2012 of the year on board the GDELS Eagle 4 light armored vehicle. The system was shown at the Eurosatory 2014 exhibition in remote control mode, it is also able to follow a route planned in advance, indicated by consecutive coordinates. Compared to the machine shown in 2012, which only worked in remote control mode, the car at the exhibition in Paris had a set of obstacle avoidance sensors installed in front of it. Two lidars were installed on the left and right of the bumper (in the end, they would be transferred to the hood to reduce distortion from rising dust), and the radar was installed in the center of the bumper with another device to its right, called the company “special optical sensor”.

According to the company Ruag Defense it is necessary to spend several months of testing for the qualification of software and equipment. Currently, the Vero kit is integrated into two more military vehicles, models of which are not disclosed. And in 2015, the system will be installed on a purely robotic platform weighing approximately three tons, although the choice between tracks and wheels has not yet been made. Ruag is in discussions with partners and has to decide whether it will install its Vero system on an existing or on a specially designed platform.

Ground Unmanned Support Surrogate robotic complex was developed by Torc Robotics based on Polaris MVRS700 6x6 chassis

The Swiss company Ruag is working on its Vero kit, which is currently installed on the GDELS Eagle 4. Some of the sensors are installed on the roof, and some are installed on the bumper

Torc Robotics: This American company, a specialist in robotic solutions for the military, mining, engineering and agricultural sectors, is currently working on the Marine Corps program for ground support robot Ground Unmanned Support Surrogate (Guss). From 2010, Torc Robotics has been involved in the development of a light machine capable of delivering supplies to troops in combat conditions, transporting cargoes of the Marine Corps or evacuating the wounded. With the help of robotic modules, Torc Robotics transformed four Polaris M VRS700 6x6 buggy vehicles into robotic tools capable of accepting loads around 900 kg.

The AutoNav module is a key element that allows you to get a robotic vehicle with three different modes of operation: navigation through the specified points, follow me and remote. The interface is the manual WaySight device, which allows the operator to select the mode of operation, as well as either monitoring or monitoring the machine. This technology was then refined and transferred to the M1161 Growler, the vehicle chosen by the Marine Corps to be transported inside the convertible V-22 Osprey. The program is currently known under the abbreviation Guss AITV (Autonomous Internally Transportable vehicle - autonomous machine transported inside). The touch kit includes an inertial navigation system, cameras and a lidar. He was first tested in actual exercises during the Rimpac 2014 exercises in Hawaii in June, showing his practical value in operations to evacuate the wounded and relieve the burden on infantrymen. After the exercise, the need for some technological improvements was identified. The company's additional modular system was also used to develop the Robotic Assault Zone Terminal Evaluation Kit, capable of evaluating potential soil heterogeneity on runways in order to reduce the risk for special groups of surveyors inspecting aerodrome runways. The kit uses many technologies developed for the Guss robotic car, and it is installed on a Polaris LTATV vehicle equipped with a Mosquito soil sampler from MDA.

Polaris LTATV robotic vehicle equipped with a Robotic Assault Zone Terminal Evaluation Kit with a Mosquito soil sampler from MDA (right in working position)

Polaris cars have recently been selected by the Darpa Advanced Defense Research Authority to participate in the Robotics Challenge competition with the simulation of disaster relief scenarios of various origins. Polaris Ranger XP 900 EPS cars, which were supposed to serve as vehicles for robots, were equipped with robotic kits, as well as the remote control technology SafeStop Electronic Throttle Kill and Brake Actuation (electronic throttle control and brakes), which allowed to ensure the mobility of vehicles at the site for modeling natural and man-made disasters. On the platform with a load capacity of 453 kg, a robot power supply system was installed, and inside the cabin a bench and steering column with an adjustable inclination to ensure sufficient space for the robots to work with the machine.

Polaris Defense is more and more thinking about "robotization" when creating their cars. Her Ranger XP 900 EPS was chosen by Darpa to participate in a competition of robotic platforms simulating a disaster recovery operation.

Torc Robotics used the experience gained in the Guss program to robotize the M1161 car transported in the Osprey convertoplane. The resulting Guss AITV system was demonstrated at the Rimpac 2014 exercises.

Kairos Pronto4 Uomo is an optional kit that closely resembles human functionality. It can be installed in just a few minutes in the cab of a standard, man-operated vehicle.

Kairos Autonomi: Why not replace the driver with a mechanical design that mimics the structure of the human body? Kairos Autonomi’s engineers followed this path by creating an additional robotic kit, Pronto4 Uomo, which can be installed on a standard machine in ten minutes in order to provide remote control and control over GPS coordinates. The system was shown in 2013 year, it weighs only 25 kg and folds into a suitcase. The metal construction simulates the movement of a person, two “legs” press on the brake and gas pedals, and the “arm” on the universal joints turns the steering wheel. The system can operate on a standard BA5590 military battery and since the connection to the on-board network of the machine itself is not required, this reduces the installation time of the kit.

The Kairos Autonomi catalog also has a more traditional complementary set Pronto 4. This modular system can robotize an ordinary machine, giving it a different level of automation, ranging from remote control to semi-autonomy. Installation of the kit takes less than four hours. A set of Pronto 4 - this is several modules among the role of the "brain" performed by a computer module, the interface modules (steering wheel, actuators for brakes, gas and gear) allow you to connect it to the car. The system is available in various configurations, the total weight is about 10 kg.

Selex ES: This company has resorted to the help of the Milanese company Hi-Tec in its work to reduce the risks for patrol groups by robotization of vehicles (where possible), especially robotization of machines that are less protected and, therefore, cheaper. For the developed system, Acme (Automated Computerized Mobility Equipment), Hi-Tec provides actuators, navigation systems, data processing, and software, while Selex supplies infrared and day vision systems with narrow and circular (on 360 °) fields of view, infrared illumination, system analysis of sensory data and simulators.

Selex ES has now approved the final configuration, the final prototype is expected in the fall of 2014 of the year. The current Acme system, which is completely free from the restrictions of the International Trade Rules weapons, must be ready for mass production at the start of 2015. Selex ES is already negotiating with many potential customers. The interface and driving system are installed in half an hour. The carbon-fiber steering system version weighs 7 kg, in contrast to its steel counterpart, 12 kg. A stepper motor with a torque of 28 Nm provides rotational speeds from 18 to 180 rpm. Navigation sensors include QinetiQ Canada’s two-antenna GPS robust GPS with seven antennas (Acme compatible with Galileo and GLONASS), as well as an inertial measurement semiconductor unit with 0,5% deviation per hour (this unit is used when the GPS signal is lost, usually short time). A roof mounted laser scanner avoids obstacles. The system mass is 60 kg, in automatic mode the maximum speed is 40 km / h, and in remote mode, the company does not advise to exceed 100 km / h. Although it should be noted that the Acme system should always remain under the supervision of the operator. It is able to repeat a predetermined route with an accuracy of two centimeters with deviations in speed to 0,5 km / h. The throttle stepper motor provides kg force 14 at a speed of 300 mm / s. The pneumatic system is used for clutch and brake actuators, providing an 60 kg force with a speed of 300 mm / s. For the Acme system, new georeferential maps can be used (with reference to the terrain). A hardened push-button control console was developed, since Selex ES decided to move to game-type control systems, which are more common for young soldiers. Selex ES is currently working on a program for “stitching” images in order to obtain a circular view, which ultimately (possibly by the end of 2015 of the year) will be implemented in an 3D helmet, designed for remote driving.

Acme Automated Computerized Mobility Equipment (Automated Computerized Mobility Equipment) from Selex ES has recently been upgraded with new sensors. The company is also working on developing new human-machine interfaces.

Oto Melara: The Italian company Oto Melara offers an additional system, which was originally developed for civilian purposes. The remote control kit includes several actuators that can move the steering wheel, pedals, and other controls. The system can be installed and removed in about one hour, but Oto Melara is currently working on new systems in response to the needs of a “smart transport column”.

The Israeli company G-Nius, drawing on the rich experience gained with the Guardium series of robots, developed a robotic kit that allows you to transform a ground-based platform into an unmanned system, the “brain” of which is represented in the photo

G-Nius: In addition to the robotic machines described above, the Israeli company G-Nius has developed a new robotic kit that allows you to turn any ground platform into an unmanned system with obvious mechanical variations in order to adapt to a particular machine. If the previous G-Nius system consisted of many black boxes, the new product consists of a single box, which includes a functional computer, a navigation unit, a video-audio system and a power distribution unit.

Standard sensors include a day / night uncooled thermal imaging camera, rear and side cameras and a communication system, and an obstacle avoidance system can also be added. The system allows you to work in four modes of different levels of autonomy. In direct line of sight, operation is guaranteed at a distance of 20 km, but satellite communications can be added for longer distances. The new robotization kit does not depend on the connected equipment, and thus, all types of devices, from reconnaissance systems and silencers to weapons, can be connected to the kit. G-Nius offers its kit for various types of platforms, from light wheeled vehicles to tracked infantry fighting vehicles.

Materials used:

www.otomelara.it

www.hdtglobal.com

www.nexter-group.fr

www.irobot.com

www.reconrobotics.com

www.novatiq.com

www.oshkosh.com

www.lockheedmartin.com

www.mira.co.uk

www.ruag.com

www.torcrobotics.com

www.kairosautonomi.com

www.selex-es.com

www.g-nius.co.il

Information