Hybrid electric and fuel cells

The EMILY 3000 fuel cell system has a rated output power of 125 W and a daily charge capacity of 6 kWh. It can recharge several batteries or act as a field generator. The system was created specifically for military applications, including test scenarios in which data on new defensive systems need to be collected and evaluated in the field

Ultimately, hybrid power plants offer comparable or even better benefits to armored vehicles. While fuel efficiency, at least historically, has not been at the top of the list of mandatory characteristics of armored vehicles, it does, nevertheless, increase mileage and / or operation time for a given fuel capacity, increase payload, protection or firepower for a given overall. masses and generally reduce the overall logistic load on the fleet.

The hybrid electric drive may play an important role in the future of military vehicles, but the corresponding cancellation and reduction of many defense programs (not to forget about the famous FCS and FRES) and the struggle to meet the urgent requirements for protected vehicles delayed its introduction on military vehicles for an indefinite period.

However, when applicants for the US ground combat vehicle GCV (Ground Combat Vehicle) were announced in January 2011, among them was a project from the BAE Systems / Northrop Grumman team with a hybrid electric power unit with an EX-DRIVE system from Qinetiq. This can be considered as a kind of gamble because none of the applicants for the program on the lightweight tactical vehicle JLTV (Joint Light Tactical Vehicle), which provided for a hybrid electric drive, did not qualify for the final due to the fact that believe that the technology for this machine is not yet mature enough at this point in time. Those not least story hybrid electric drives in ground combat vehicles has a sufficient number of programs to develop and demonstrate this technology. There is something inexorable and inevitable in the global desire to introduce technology that promises to save fuel, improve performance and survivability, and at the same time meet the growing needs for onboard electricity. This is undoubtedly supported by parallel developments in the automotive industry, prompted by environmental legislation.

War machine manufacturers and system suppliers have invested heavily in this technology, often pushed by a sort of aforementioned ambitious government programs, before facing the particular uncertainty inherent in long-term government plans. AM General, BAE Systems, General Dynamics, Hagglunds, MillenWorks and Qinetiq have developed hybrid drives for British, American and Swedish programs, while Nexter is working on an ARCHYBALD technology development program for heavy vehicles, civilian and military.

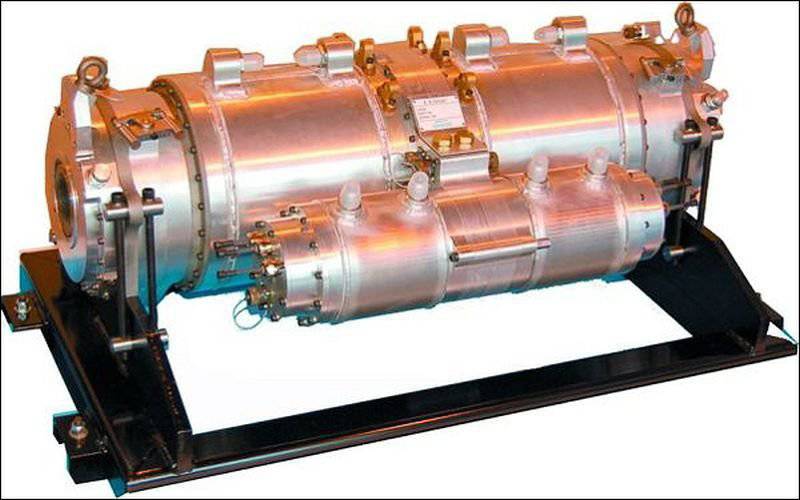

EX-DRIVE electric drive transmission for QinetiQ tracked vehicles, lightweight, compact and efficient system

Hybrid predecessors

Hybrid power plants firmly settled in warships, especially on submarines, trains, and heavy trucks used in open pit and open pit mining. In these applications, a prime mover, such as a diesel engine, a gas turbine, or even both systems, drives a generator that generates current for drive engines and battery charging. Some systems include a gearbox for transmitting mechanical energy to final drives, while in others they are completely excluded.

In warships, hybrid power plants allow the use of complex and widely varying speed profiles, while the primary propulsion systems are operated in the effective speed range: electric motors for silent movement, diesel engines for ordinary movement, gas turbines for acceleration, etc. A submarine operated in the traditional way cannot launch its primary propulsion unit during a dive (if it does not have a snorkel) and, therefore, it is necessary to rely mainly on batteries or another air-independent power plant. Giant earthmoving machines rely on huge torque from zero rpm generated by electric motors due to the fact that manual gearboxes that could do this kind of work will be huge, complex and expensive. Trains are facing the same problem even more, as they have to pull several hundred tons behind them, in many cases to speeds exceeding 150 miles per hour.

A hybrid power plant can save fuel, allowing you to use a smaller, more economical prime mover without degrading the performance, because the system, when the driver completely depresses the gas pedal, complements the main engine with electric motors powered by batteries. Electric drives also make it possible to damp the prime mover when driving at low speeds, when it may be relatively inefficient. Modern hybrid cars can also accumulate kinetic energy (for example, through a regenerative braking system) and use it to charge their batteries. Additional savings are achieved by operating the primary propulsion most of the time in the most efficient speed range, as well as using any additional energy to charge the batteries and / or power the on-board power consumers.

Modern military vehicles require more and more electrical power to operate communication systems, command and control equipment, surveillance and reconnaissance sensors, such as optoelectronics and radars, remotely-controlled combat modules and mufflers of improvised explosive devices (SVU). Prospective systems, such as electric armor, will further increase consumption. The use of all installed capacity for the operation of electrical systems, in theory, is at least more efficient than having one system for movement and one more for specialized equipment.

Increasing emphasis is being placed on the possibility of observing and collecting information in counterinsurgency tasks, and in this connection, requirements for silent observation are being put forward in an increasing number of armored vehicle programs. This further increases the importance of consumed electrical power and makes fuel cells more attractive.

Hybrid electric drive systems fall into two broad categories: parallel and sequential. In parallel systems, the internal combustion engine and the electric motor (or electric motors) rotate the wheels or tracks through the gearbox, either separately or together. In successive hybrid systems, the prime mover drives only the generator. The sequential system is simpler, all the driving power in it must go through the electric motors and therefore they must be larger than the electric motors in the parallel system with the same requirements for the operating characteristics of the machine. Both types of systems have been developed.

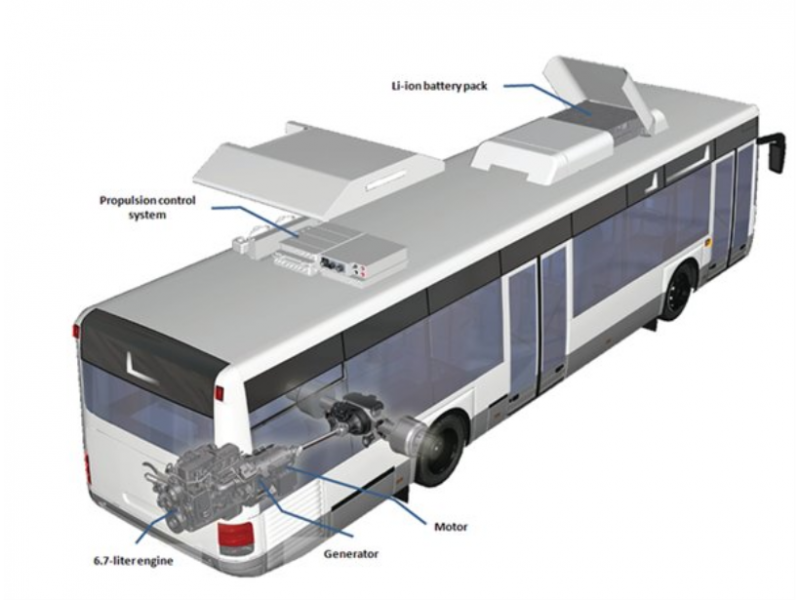

Innovations in hybrid-electric drives and in the field of fuel cells can be taken from commercial technologies. For example, BAE Systems manufactures hybrid electric buses, technologies from which can be used to demonstrate energy efficiency and improved exhaust emissions characteristics of modern hybrid electric vehicles.

Increase vitality

Hybrid systems also increase survivability due to a more flexible layout and the exclusion of transmission components, which could become a side projectile when undermining a mine or IED. Wheeled armored vehicles especially benefit from this. When integrating drive motors into wheel hubs, all drive shafts, differentials, drive shafts and gearboxes associated with traditional mechanical transmissions are eliminated and replaced by power cables and therefore they cannot become additional projectiles. The exclusion of all these mechanisms also makes it possible to raise the crew compartment above the ground at a given vehicle height, which makes passengers less vulnerable during blasting under the hull. This type of design was used in the General Dynamics UK AHED 8x8 demonstrator and the wheeled version of the SEE vehicle from BAE Systems / Hagglunds, the crawler version of which was also manufactured (and subsequently safely forgotten).

Electric motors built into individual wheels allow you to control the power delivered to each wheel very precisely, and this, according to GD UK, almost eliminates the advantages of tracks over wheels with respect to increased off-road terrain.

A prospective ground combat vehicle will move on tracks and in the BAE Systems / Northrop Grumman proposal, it is indicated that Qinetiq's EX-DRIVE electric transmission will be lighter, more compact and more efficient than traditional transmissions. It also allows for improved acceleration along with fault tolerance and is configured for a wide range of machines and technology deployment programs, the company says.

Although the system includes four permanent magnet engines, the powertrain in the EX-DRIVE is not fully electric; power recovery during cornering and mechanical gear shift, the latter using a cam clutch. This scheme is a low-risk solution that minimizes loads in engines, gears, shafts and bearings. The use of a transverse shaft circuit for the regeneration of mechanical power in a steering mechanism is an alternative to using independent drive wheels in a purely electric transmission.

One of the innovations in the heart of the EX-DRIVE is the central gearbox (known as the adjusting differential), which combines the torque of the steering engine, the torque of the main engine and the previously mentioned mechanical recovery mechanism. In addition to minimizing torque loads, it eliminates the bulkiness and weight of the outer transverse shaft used in traditional solutions and other hybrid electric drive systems.

Successes in electrics

Permanent magnet electric motors are a technology industry where, in recent years, the efficiency and power density of electric drive systems have been significantly increased in all applications. Permanent magnet motors for creating magnetic fields in stator components are based on naturally occurring powerful magnets made of rare earth metals, and not on the current-carrying windings (electromagnets). This makes the engines more efficient in particular due to the fact that only the rotor must be supplied with electric current.

Modern power electronics is also a key technology for all types of hybrid electric machines. Electric motor controllers based on an insulated gate bipolar transistor, for example, regulate the flow of energy from a battery, a generator, or fuel cells to determine rotational speeds and output torque from an electric motor. They are much more efficient than electromechanical control systems and significantly increase the characteristics of electric drives with adjustable rotational speed — technologies that are much less mature than electric drives with fixed speed, which are widely used in industry.

The New Jersey company TDI Power is an example of an investor investing in liquid cooling power electronics for electric and hybrid vehicles for civilian and military use. The company manufactures standard modular DC converters and inverters that exceed current SAE and MIL standards.

Electric drives in military machines benefit from extensive research and development on variable speed drives for industry, spurred by the prospect of overall energy savings around 15-30%, which can be realized if machines with fixed gears are replaced by variable speed drives for most industrial users, like set out in a recent study by the University of Newcastle commissioned by the British Department of Science and Innovation. "Increasing the potential efficiency of the loads on the drives, as planned, will save the UK 15 kW of billion hours per year, and in combination with the increased efficiency of the engine and its drive, the total savings amount to 24 billion kWh," the study says.

One of the important ways to increase the efficiency of power transmission in any electrical system is to increase the voltage, since Ohm's law dictates that for any given power, the higher the voltage, the lower the current. Small currents can pass through thin wires, which will allow compact lightweight electrical systems to provide the necessary load. That is why very high voltages are used in power transmission systems in national power systems; British power systems, for example, operate their power lines at voltages up to 400 000 volts.

It is unlikely that voltage will be used in electrical systems of military machines, but the days of 28 volts and similar electrical systems are likely to be numbered. In the 2009 year, for example, the British Ministry of Defense chose Qinetiq for research on the generation and distribution of electrical power using 610 volt technology. Qinetiq led the team, which included BAE Systems and the electric machinery specialist Provector Ltd, which converted the WARRIOR 2000 BMP into a demonstrator capable of powering consumers with high 610 volts as well as existing 28 volt equipment. The machine is equipped with two 610 volt generators, each of which provides twice as much energy as the original machine generator, which actually increases the Warrior's electrical output fourfold.

Energy for a vehicle using fuel cells from SFC

Soldiers in the field need a reliable source of energy for their vehicles. It must supply current to onboard devices such as a radio station, communications equipment, weapon systems and optical electronic systems. But if necessary, it should also work as a charging station for soldiers on mission.

Often there is no possibility when the task is executed to start the engine to charge the batteries due to the fact that it may reveal the location of the unit. Therefore, soldiers need a way to obtain electric current - quietly, constantly and independently.

The SFC's EMILY 2200 system is based on the successful EFOY fuel cell technology. Installed on the machine, the EMILY unit ensures that the batteries remain constantly charged. Its built-in regulator constantly monitors the voltage in the batteries and automatically recharges the batteries if necessary. It works silently and its only "exhaust" are water vapor and carbon dioxide in an amount comparable to the child's breath.

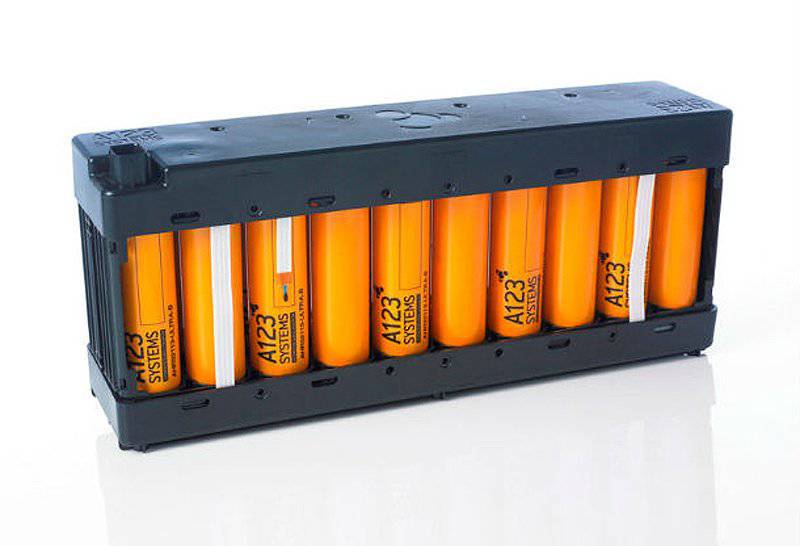

Large machines need large batteries. This package of lithium-ion cells is part of the hybrid propulsion technology for BAE Systems buses.

Are fuel cells possible?

Fuel cells that use chemical processes for direct conversion of fuel into electric current with high efficiency have long been considered as a technology that can be widely used in the military sphere, including setting the machine in motion and generating electricity on board. However, there are significant technical obstacles that need to be overcome. First, fuel cells work on hydrogen and mix it with oxygen from air to produce electrical current as a by-product. Hydrogen is not readily available, it is difficult to store and transport.

There are many examples of fuel cells that drive electric vehicles, but they are all experimental. In the automotive world, Honda’s FCX CLARITY is probably the closest to a commercial product when it’s ready, but it is also available only in areas where there is a certain infrastructure for refueling with hydrogen and only under leasing agreements. Even leading fuel cell manufacturers, such as Ballard Power, recognize the current limitations of this technology for use in automobiles. The company says that “mass production of fuel cell vehicles is in the long term. Today, most automakers believe that the organization of mass production of fuel cell vehicles is not feasible until about the 2020 year, due to the fact that the industry is facing the issues of hydrogen distribution, optimization of durability, energy density, the possibility of starting without heating and the cost of fuel cells. ”

However, all the world's major automakers are investing heavily in fuel cell research and development, often conducted jointly with fuel cell manufacturers. Ballard, for example, is part of Automotive Fuel Cell Cooperation, a joint venture of Ford and Daimler AG. The military pose another obstacle to the adoption of fuel cells in the form of their demand that everything should work on "logistics" fuels. Fuel cells can run on diesel or kerosene, but they must first be modified to extract the hydrogen they need. This process requires complex and cumbersome equipment, affecting the size, mass, cost, complexity and efficiency of the system as a whole.

Another limitation of fuel cells when operating as the primary engine of a military vehicle is the fact that they work best with constant power settings and cannot respond quickly to necessary changes. This means that they must be supplemented with batteries and / or supercapacitors and appropriate power control electronics to meet peak power loads.

In the area of “supercapacitors”, the Estonian company Skeleton Industries has developed a range of modern SkelCap supercapacitors, which are five times more powerful per liter of volume or more than four times more powerful per kilogram compared to first-class military batteries. In practice, this means a 60 percent increase in power and four times more current compared to the best military batteries. SkelCap “supercapacitors” provide an instantaneous power boost and are used for a wide variety of tasks, from fire control to turret towers tanks. As part of the United Armaments International (UAI) group, SkelCap carries out various specialized orders as well as advanced programs through the UAI group, based in Tallinn.

Supercapacitors from Skeleton Industries

However, this does not mean that fuel cells will not find a place in hybrid and electric military vehicles. The most promising closest applications are auxiliary power units (VSU) in machines performing tasks of silent observation of the ISTAR type (information gathering, target targeting observation and reconnaissance). “In silent monitoring mode, the engines of the machines should not work, and the batteries alone cannot provide enough energy for long-term operations,” say the American Army Engineering Research Center, which heads the development of solid oxide fuel cell generators and APUs that can work on military fuels, diesel and kerosene.

This organization is currently focused on systems up to 10 kW with an emphasis on the full integration of fuel systems with the operating needs of a fuel cell kit. Tasks that need to be addressed in the development of practical systems include the control of vaporization and pollution, especially the struggle with sulfur due to desulfurization (desulfurization) and the use of sulfur-resistant materials, as well as the elimination of carbon deposits in the system.

Hybrid electric drives have a lot to offer for military vehicles, but it will take some time before the benefits of this technology become tangible.

Materials used:

www.armada.ch

www.baesystems.com

www.qinetiq.com

www.sfc.com

www.skeletontech.com

Information