Protection and booking systems. Challenges, opportunities and trends

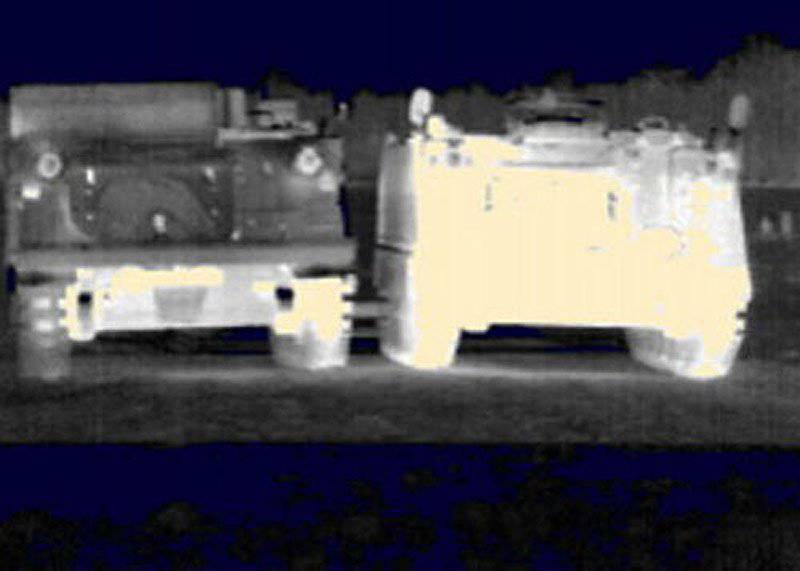

Modern BBM, such as M1117 ASV in the photo, are usually protected by the main structural armor of steel and aluminum, plus components of additional protection made from various alloys, ceramics, composites, or a combination of them

For the US and its strategic partners, the need for improved possibilities of protection and reservation in order to meet current and anticipated tactical obligations it is obvious. The US-led multinational mission in Afghanistan, which nevertheless seeks its logical end, will benefit from the lessons learned in Iraq regarding the tasks and requirements of protecting its troops and building a strategy for creating new initiatives to develop defense systems.

The Protection and Booking System (MSS) (another term Structural Protection) is a strategic tool because it has a significant impact on critical systems and resources and also has a direct impact on the fighter. This mainly refers to an asymmetric operational environment in which threats to stationary positions and perimeter security, as well as dismounted troops and patrol cars, are particularly acute. Although such combat bouts evolve rapidly, having electronic warning systems combined with effective defense solutions can often give the military a decisive advantage, allowing them to survive, counterattack, and dominate. Conversely, the lack of a suitable or effective infrastructure to protect their forces can make both combatant and non-combatant soldiers vulnerable to ambush tactics and this is one of the key, though sobering, lessons of modern operations in regional theaters of operations.

Basic aspects

Structural armor refers to those types of strategic materials that are resistant to ballistic attacks and which can be integrated into stationary, transportable or mobile transport systems and personal ballistic protection solutions. Traditional materials, such as steel and aluminum or reinforced concrete, as well as advanced materials, including nanomaterials and ceramic composites, can be used in the production of SZB. Some examples of the use of structural armor are the manufacture of permanent and temporary structures, such as guard towers, troop or security vans, vehicle protection systems, and personal protection for a fighter. These may include portable shields or protection system of checkpoints and transportable armored fighting positions.

Three attempts to create an exoskeleton concept: BLEEX, Raytheon SARCOS and Lockheed Martin HULC projects

Therefore protection and reservation systems (MSB) can be very helpful in improving the tactical and strategic survivability in combat and other environmental conditions with a high risk. They are a key factor for the protection programs of their forces. They are also the basis for countering many types of asymmetrical attacks, such as roadside mines and RPGs during the execution of tasks in urban conditions and counterinsurgency operations. Since they can be created from lightweight composite materials and other advanced and exotic materials, they can also be useful in managing signatures for the protected infrastructures, such as covering vehicles with more masking materials from ground-based radars. In fact, we can say that the MSB applications are very diverse - as well as materials from which they can be manufactured.

Some materials can be classified of which MSBs are formed as exotic and new materials, ie those that have new properties in addition to the capabilities of traditional materials. For example, nanomaterials including nanotubes and nanofibers, and advanced composite materials can improve the characteristics of armor protection. Structures in the proposed non-combat areas, which were previously regarded as having a low degree of protection for combat attacks, are now included in the plans for implementing the NWB. According to the 2012 sanctioning act of national defense, for example, in military construction, the creation and modernization of existing infrastructure in the United States and NATO countries provides for increased safety standards in military building projects. In the construction of the private sector, the requirements for SZB in new construction projects and the reconstruction of existing buildings are also increasing, due to safety, ergonomic and external considerations, as structural protection also has the ability to reduce noise and increase thermal insulation. However, the requirements for the protection of combatants remain the same and the highest concern for military planners.

United States Army Corps of Engineers (USACE) are responsible for the US government program for the construction of military, civilian infrastructure and national security infrastructure, both globally and domestically. Perhaps the most famous project built by the USACE, the Pentagon, stands as a reminder of the importance of the safety and security programs and their compliance with ongoing operations and tasks of national security and the protection of troops. The construction was completed in 1941, a small amount of metal was used due to the lack of strategic raw materials in wartime, the Pentagon was built almost entirely of reinforced concrete. In conclusion, the building state study group, made by the American Society of Civil Engineers immediately after 11 September, said that elements of the original design and construction of the Pentagon contributed to its stability during the attack of a jetliner, they limited physical damage and human casualties. Structural integrity characteristics, redundancy and energy absorption were highlighted in the group's report. It was said that such elements "should be included in the future in the design of buildings and other structures in which the progressive degradation resistance is regarded as very important."

Similar if not identical properties and requirements apply to stationary and mobile government facilities at home and abroad, large and small, they should include elements of enhanced security, for example, to counter ballistic attacks, as built-in structural elements in order to protect against real-world threats. Consequently, the MSB are of key importance in the whole range of military and civilian efforts and will likely become commonplace in the future.

Rules of thumb for creating protection

Monolithic systems

The stronger, the better, "adequate" will destroy the strength of the shell

The vyazche, the better, "adequate" toughness resists cracking

The thicker the better

The heavier the better

One thick plate is better than two thin laminated plates.

The greater the slope (meeting angle) the better

Multi-material systems (hybrid)

Harder is not always better, but the hard facing is usually present

More viscous is not always better, but a viscous base is usually present.

Thicker is not always better

Heavier is not always better

Two thin plates may be better than one thick.

A larger slope is not always better.

Adaptive benefits

Traditional armor materials showed limitations to new security challenges, while advanced materials, including composites and nanomaterials, showed significant advantages over older systems, increasing the survival rate of the soldier even in extreme conditions.

The disadvantages of existing defense systems may be one of the legacies of the Cold War. The military doctrines of that time did not focus on military operations in built-up areas (MOBA - Mobility Operations For Built-up Areas) or urban military operations (MOUT - Military Operations in Urban Terrain). Similarly, the doctrines that emerged after the Gulf war were based on deployable high-tech, high-precision capabilities in shock and awe scenarios for a limited time frame. This, of course, did not happen in Iraq, where high-tech offensive systems and tactics were important mainly in the early stages of the conflict, and the need to withstand the operational pace for a long period of time became critical.

MSB offer advantages forces involved in long-term operations, the level of theater or region, including those that occur in the context of MOUT campaigns. Many of these advantages, for example in the protection of military equipment and valuable objects in the presence of high risk, are obvious, some others are less obvious. These may include environmental issues and ergonomic safety and hardening, sealing and protecting combat electronics and other critical information infrastructure from potentially damaging asymmetric effects. However, SZB as a set of technologies will also have a wider significance than even those that go through the entire field of defense technology. This is due to the fact that structural armor is a common technological sector for all branches of the military, which affects other defense applications and military equipment categories, tasks and applications of national security.

You can extend the above. In the MSB, they must be included in the requirements for the protection of nuclear and strategic facilities (in view of their suitability for stationary, semi-and fully mobile systems under all combat conditions), the military and civilian sectors in unbuilt areas of built-up areas (because buildings will benefit from measures to improve safety and new methods of construction, which will increase resistance to terrorism and natural disasters, such as hurricanes and earthquakes), modernization and initiatives to transform the troops, combat electronic and data processing and (in relation to its ability to increase the protection of electronic infrastructure) and military vehicles (due to its ability to create reliable ballistic protection for mobile personnel).

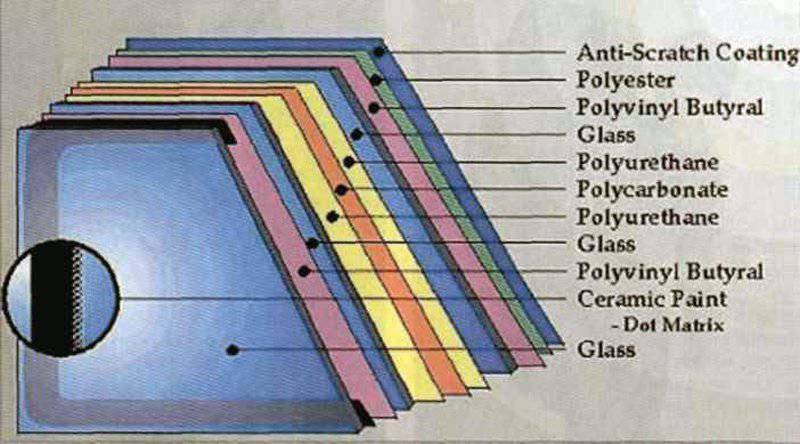

The structure of a typical multi-layered panel of transparent armor

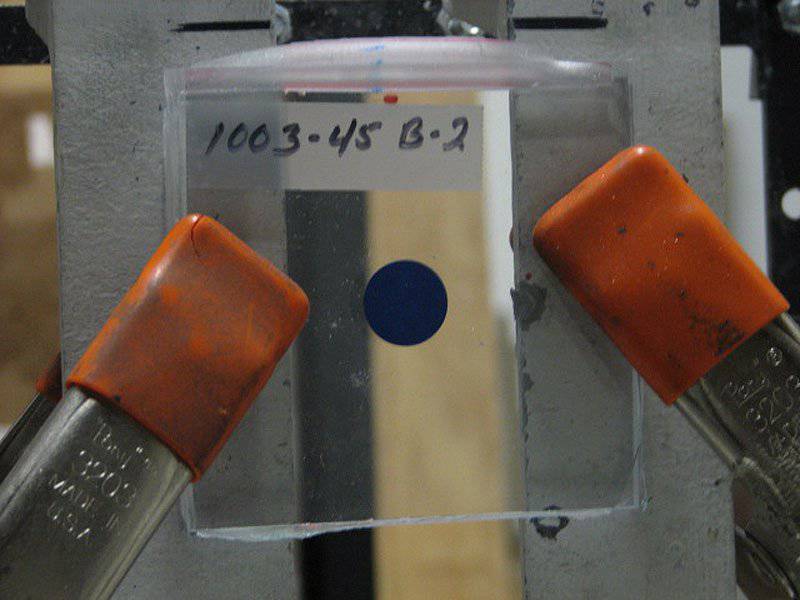

The structure of glass used by most manufacturers of bullet-proof glass: first glass as the outer layer, several layers of glass and polyvinyl butyral in the middle, then polyurethane and, finally, polycarbonate. The advantages of this method lies in the ability to expand and polycarbonate to "catch" the fragments formed by a solid glass surface. A similar expansion is possible over two inches.

MSB is also consistent with the fiscal reform initiatives. This is due to the fact that some applications in this technological area allow modernizing and repairing existing facilities and systems without high costs and creating a completely new infrastructure, which in turn allows us to have the advantages of a stable budget for other components of general programs and modernization initiatives. For example, in the US Department of Defense budget for 2010, 1,4 billion dollars were allocated to military construction programs, 15,2 billion dollars to defense initiatives (the largest single request after military intelligence appropriations) and 1,5 billion dollars to fight IEDs (improvised explosive devices). MSB can improve the cost-effectiveness of defense in these sectors. Consequently, it is a technology with potentially large payments for the development of programs for national and international security and the fight against terrorism, such as embassies and other long-term engineering projects, for the protection of important persons and the protection of personnel involved in critical situations.

Other advantages of adopting SZB and their integration into the development of military programs include the fact that the materials themselves and advanced methods of their production and the subsequent processing and refinement share a common basic platform for developments in the field of exotic and newest materials, including nanomaterials. They can be embedded in the MSB in order to provide additional features, such as an embedded sensor matrix and biometrics, which themselves become part of the security system itself. Currently under a number of global initiatives for the development of structural protection, production and development and use of the MSB, which uses its own unique set of characteristics for use in a variety of applications.

Ceramtec Piezoelectric Components

In the US, the MSB materials and processes developed in the centers and services of the Ministry of Defense Industry and the private sector. Among the most important research and development centers conducted are the ARL military research laboratory, whose weapons and materials research department deals with protection initiatives in programs for a promising truck, weapon system and future car. The Center for Composite Materials of the University of Delaware also conducts research on advanced defense materials, funded by the Ministry of Defense, and other NSS design centers will also be noted.

Advanced Nanomaterials

Structural protection can be made from a variety of materials using an extended range of advanced methods of development, manufacturing and molding. The rates of development of materials are among the fastest in defense technology and the sphere of applied sciences, stimulated by strategic objectives. It relates to the discovery of new materials, as well as to continuously improve the use of existing products with valuable properties for the defense, which are suitable for transformational development in the protection of their forces.

Nanomaterials are widely used in development programs in this sector of applications, many revolutionary manufacturing processes are under development or have gone into industrial production. At the forefront of advanced materials development is graphene, the first time discovered in 2004, a graphite homologue, whose unusual characteristics make it promising for a number of applications, including the potential use of structural protection. Graphene - a sheet of graphite just one atom thick, which makes it, therefore, the finest material open to date. Due to the fact that it is approximately two hundred times stronger than steel, graphene is also one of the strongest materials ever created in the laboratory. Graphene also has unusual electrical conductivity properties, which portends its revolutionary use in the field of semiconductor microprocessors. This makes the graphene material with great potential in a number of key technology areas. However, although all this is promising, the use of graphene for the development of military programs still remains in the future due to the lack of applied research on this very new material, the difficulties of production in industrial quantities while maintaining high profitability. (For “advanced experiments with two-dimensional material — graphene”, A. K. Heimu and K. S. Novoselov were awarded the Nobel Prize in Physics for 2010 a year).

The M2 / M3 BRADLEY BMP uses armor made of aluminum alloy 7039-T64 (upper half) and 5083-H131 (lower half). However, the combat experience in Iraq has led to increased protection due to an additional layer of multi-layer steel armor plus elements of passive (composite) and reactive armor, which we see in the photo

However, carbon nanotubes (CNT) are much more well-known in the field of research and development initiatives and have already found numerous practical applications not only in the military sphere, but also in the field of national security and law enforcement. Advanced armor materials can be made from long carbon nanotubes of various shapes and structures, including sheets, fibers, plates, and molded shapes. End "nanouluchshennye" materials are light, but very strong, and their electro-thermal properties can be changed in the manufacturing process. In the manufacture of composite structures, CNT-based armor provides a flexible, lightweight solution that provides excellent protection against ballistic attacks on vehicles and other fixed or mobile combat infrastructure. Under an existing contract with Natick Labs, Nanocomp Technologies developed CNT-based composite panels only a few millimeters thick for personal protection of personnel, they stop the 9 mm bullet from close range.

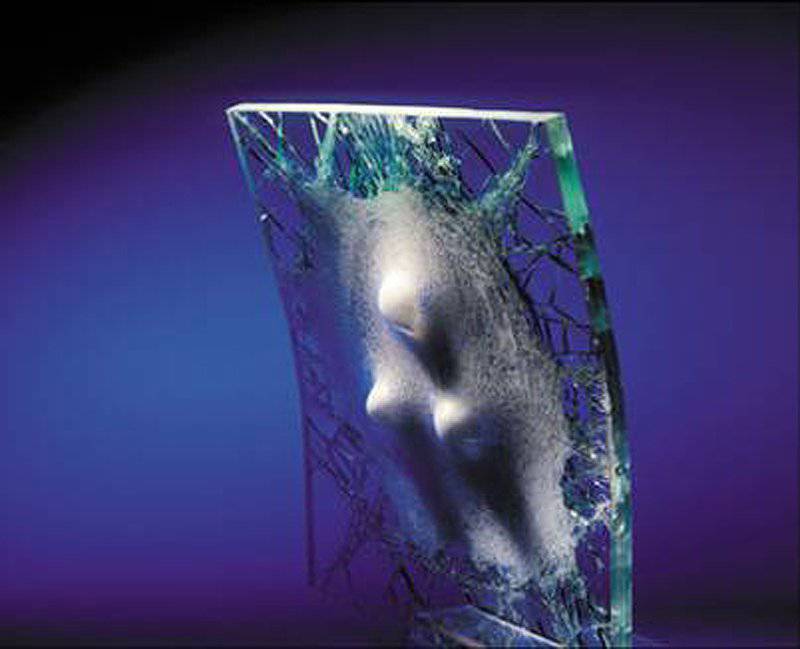

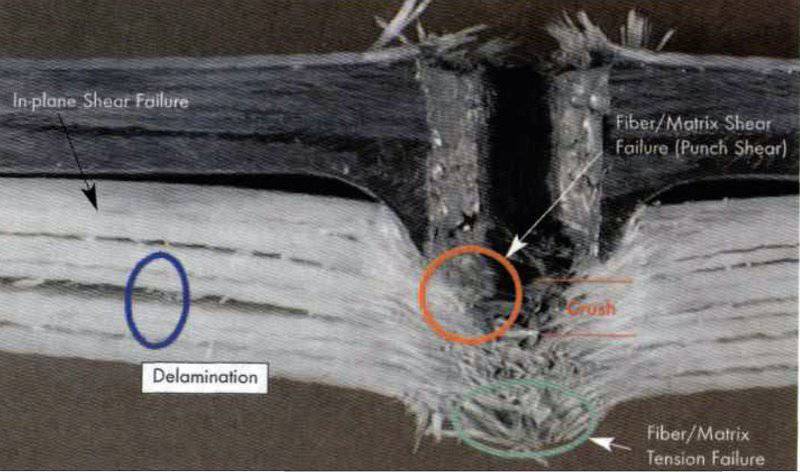

Damage during penetration of composite material

Composite materials

To some extent similar to metal alloys, composite materials differ essentially in that they are insoluble in each other and can be formed from the constituent materials differently than elements or mixture of metal phases. However, like alloys, composite materials can be formed from two or more components, which can vary considerably in shape or structure. Composite materials may be constructed in accordance with a variety of processes. They include new bonding methods, for example, lamination, sanding, sintering, particle casting under pressure, fiber interlacing, and nano-production methods, such as microcompression. When produced as systems for ballistic protection, they are classified as composite structural armor (CSA) composite composite armor and form a number of new materials, such as metal-intermetallic laminates (MIL) and ceramic matrix composites (CMC).

Ballistic composite materials are usually made in the form of honeycomb structures and laminates consisting of a thick-walled composite, rubber and ceramic layers, which are combined to ensure an optimal balance of structure and ballistic characteristics with a minimum mass. Among these laminates are opaque, translucent and transparent armor composite materials, which are used as a blast-resistant glass replacement for vehicles. Epoksistekloplastik and fiberglass composites provide superior protection vehicles in combat areas where there is high risk of attacks IEDs. The closed-cell aluminum foam CCAF (Closed-Cell Aluminum Foam) has a low mass combined with high strength, rigidity, absorbs energy well, its manufacturing characteristics can be different due to the structure of the microstructure that forms them. When the ballistic impact CCAF shows a significant non-linear distortion and attenuation of stress waves. Composite armor panels containing a CCAF can withstand the blows of 20-mm fragmentation shells according to information provided by the US ARL laboratory.

Ballistic composite materials of this category are suitable for the anti-explosion protection of vehicles, for example, ballistic shielding of MRAP vehicles deployed in urban combat environments. They can also be applied in other areas, such as barrels of guns. They are often manufactured in the form of overlaid plates or panels that are installed inside and outside of the protected machines as bottom plates, anti-shrapnel casings and undercoats. Ceramic composites can be made in the form of structural armor with good anti-explosion and anti-splinter characteristics (many secondary fragments and debris). This makes ceramic composites well suited for use as structural armor, especially for MRAP and other small and medium combat vehicles, whose design must be a compromise, given the weight limitations due to the fact that heavy armor is bad for machine mobility. However, larger vehicles, including tactical trucks and armored vehicles (for example, the Rhino Runner armored bus), are the best candidates for integration with standard metal armor solutions.

When nanomaterials are included in advanced composites, the resulting nanocomposites can provide additional levels of characteristics or protection over non-reinforced materials or the same levels with decreasing mass. The polymers and monomers, polymers including plastics may also be produced for use as advanced composites for use as structural protection. One characteristic of nanopolymers implanted with nanoparticles - this is a wavelength less than the wavelength of visible light (about 400 nanometers) - suggests that the finished materials may be transparent. Several types of such polymized strategic materials were manufactured with similar characteristics. It is obvious that these properties are strategically valuable in the modification or replacement of conventional armored glass in combat vehicles and safety vehicles.

SmartArmour is a multi-layered, multi-functional reservation system manufactured by SmartNano Materials of Piano, which can be supplied according to end-user specifications transparent or opaque, it withstands armor piercing bullets, a blast wave, fragments of shells and an explosion at the IED. However, Vitreloy metallic glass from zirconium and beryllium is also manufactured with similar properties by Amorphous Technologies International. The RDECOM research and development center of the ARL military research laboratory developed liquid armor for ballistic protection, based on a shear thickening fluid consisting of solid silica nanoparticles suspended in polyethylene glycol; It has been successfully tested for bullet-proof vests with Kevlar.

The manufacture of a device (device-processing term) is the saturation of materials from structural armor with nanostructures that can combine high performance semiconductor processors into booking elements. Such "smart materials" can be embedded in armored walls, an example of use is piezoelectric. These are natural materials that produce electrical impulses when shaken, deformed, or compressed. Piezoelectrics that have previously found commercial use in the needles of players can be embedded in armor structures, such as panels, elements of modular structures and installed in the supporting walls in the form of thermal, vibration sensors and shock sensors.

The project, funded by the US Department of Energy and carried out by the University of California Berkeley laboratory, develops modern piezoelectric materials based on piezomaterials having a perovskite crystal structure. However, Acnelent Technologies, a Minneapolis defense company specializing in structural monitoring, developed a software and hardware system called the SMART Layer, which integrates sensors into structural components, such as panels and walls. The system of this company uses embedded multi-sensors, which use thermal, stretching and fiber-optic sensors based on microprocessors to determine changes in the integrity of the observed structures using the patented method of active scanning. Diaform Armor Solutions, a division of Ceradyne Inc., has created lightweight solutions for structural armor using thermoplastic composites for the rapid manufacture of three-dimensional structural forms that can form modular elements of reinforced structural assemblies.

Bulletproof Security Module Protech

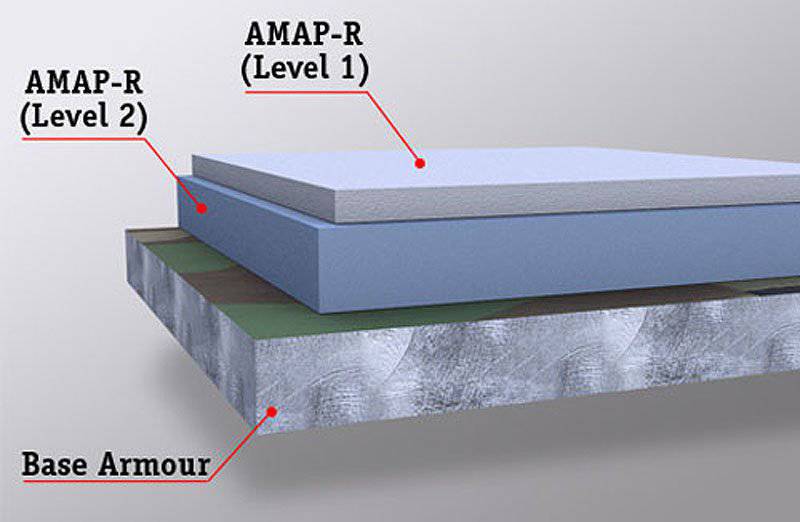

The concept of advanced multi-layered armor from IBD Deisenroth

Elements of a modular design that meet the standards of the BAM (ballistic armor matrix) ballistic armor matrix also find expanded use in new designs, additions and modifications to existing structures, where increased safety and resistance to ballistic attacks are the most important characteristics. The BAM specification, patented by Antiballistic Security and Protection (ASAP), Inc., describes multi-layered armored structural elements, such as walls, ceilings and floors, consisting of layers of solid aramid fiber sheets and hardened tool steel (for example, Thermasteel, manufactured by Thermasteel Corporation), or hardened steel mesh. Specifications according to the BAM criteria include BAM-1, BAM-1A, and BAM-8; each of them describes increasing levels of structural protection. Zagros Construction has developed its system for walls, ThermalBlast, which, as they say in the company, has high resistance to ballistic attacks and invasion by force. It uses a proprietary BAM-8 system consisting of a protective, lightweight bulletproof inner wall (or BAM Inner Matrix), partly consisting of a ballistic Kevlar, which can also be included in ceilings and the floor and other ThermaSteel panels. The company recommends its ThermalBlast system for embassies, governments and post offices, military facilities, ammunition depots and other important facilities. US Bullet-proofing manufactures its range of bullet-proof steel panels as a solution for a single ballistic sheet, which the company assesses as complying with the level of armor protection IV according to the classification of the National Institute of Justice (NIJ).

Materials for SZB also find application in some offensive systems, for example, in the inner lining of rocket shafts and launch tubes and containers carried on mobile anti-missile systems that require good resistance characteristics to thermal abrasion and kinetic impacts. The HyperShield system developed by the American company V-System Composites, which uses integrated armor tiles and advanced composite structures, is a cheap, light bulletproof booking solution and has a level of protection according to the NIJ standard Level III for missile defense, which also includes transport vehicles and ballistic requirements for aircraft. Structural armor materials can also be used in a nuclear-type nuclear warhead, for example, the American B-61, while nuclear munitions intended for ground detonation during the so-called “carpet bombing”, such as the American B-53 bomb, will also require the reservation of the ammunition case from shock loads.

With the support of the Natick Army Center, Frontier Performance Polymers has successfully developed breakthrough polymer technology and an innovative production method for light transparent armor to protect the eyes and face. This material with a surface density of 0,16 kg / cm2 has such ballistic characteristics as that of aramid / phenolic materials used in military helmets, but costs 10 times less

Traditional materials

However, traditional materials used in the production of protective structures, such as unalloyed steel and reinforced concrete, are by no means materials of the past. Metal alloys in particular remain the preferred materials in connection with their proven protective characteristics and existing production facilities for their production and use for defense purposes. These so-called “strong” armored solutions not only relate to ballistic steels and strategic alloys, but also to advanced composite materials with good ballistic properties. This also applies to armor types made from or reinforced with fiber, or from tightly woven mesh. As a structural armored material, concrete has the desired characteristics and continues to be widely used, while having a low manufacturing cost.

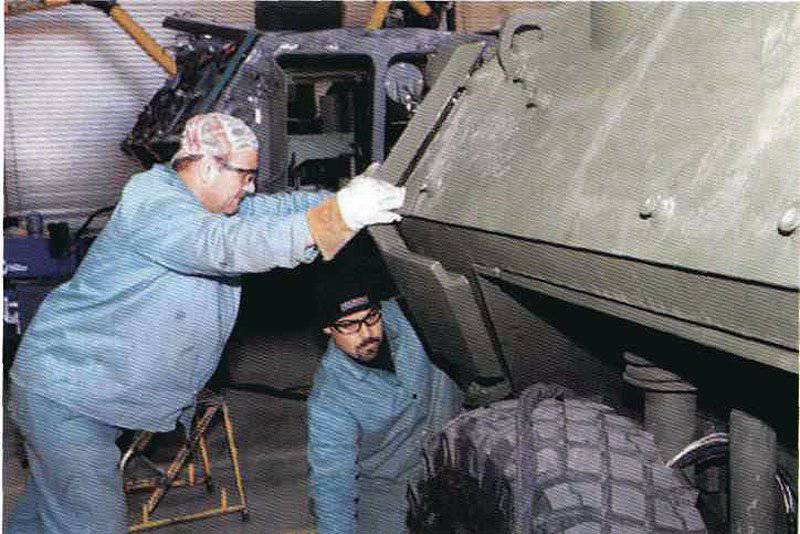

The US Marine Corps LAV 8x8 receives additional composite armor elements over its aluminum alloy hull as part of its ongoing modernization program.

The AMAP-S IBD Deisenroth armored material performs an important auxiliary function, reducing the thermal signature of the vehicle.

The Expeditionary Combat Vehicle EFV (Expeditionary Fighting Vehicle) of the Marine Corps is the first armored vehicle that uses 2518-787 armor, an alloy of aluminum, copper, manganese. Although this alloy is durable and has good ballistic properties, it has poor ballistic viscosity in butt welds made by conventional welding. This forced the manufacturer to exclude butt welds and main corner seams from the structure in order to increase the impact strength, the slab on the slab is now mechanically fixed. In the end, many of the problems associated with this program have led to the closure of this promising project.

Alloys are one of the most durable materials from which structural armor can be made. Alloys are a compound of two or more chemical elements-metals (or metallic and non-metallic elements), usually "fused" together or dissolved in each other during the melting process. The result is a material with higher characteristics than each component separately. Titanium and its alloys are common elements of structural armor. Their use includes “traumatic” plates in personal booking systems, which gives a high degree of protection to highly vulnerable parts of the body. Beryllium-aluminum alloy has also successfully shown itself in many cases. The special strength and rigidity of this alloy surpasses these characteristics of conventional titanium alloys, which leads to a lower structural weight and increased operational characteristics. Armor steels are also materials that are strategic materials suitable for use as structural armor.

A number of so-called “superalloys” or “high performance alloys” were also produced commercially under trademarks. Among them is a high-strength Hastelloy alloy, whose main component is a transition metal - nickel; Kovar, a cobalt-nickel alloy, valued for its excellent coefficient of thermal expansion; nickel-copper-iron alloy Monel; and Inconel nickel-chromium alloy.

Laser hardening is one of the processing processes, which improves the functional characteristics of base metals and alloys. There are other types of improvement of properties, including microcompression - processing, which uses the method of focused ion beam to saturate advanced materials with substructures in order to obtain additional strength and durability. The method of superplastic shaping is also used, which results in the production of metal and ceramic products with extremely high tensile strength.

The NETL laboratory (National Energy Technology Laboratory - National Energy Technology Laboratory) was assigned by the US Department of Energy TACOM (Tank-Automotive and Armaments Command) and the ARL military research lab to perform a program to develop cast steel armor plates for American military vehicles, including the BRADLEY BMP. According to it, NETL-TACOM-Lanoxide Corp and DARPA jointly developed a cast hatch, and a side result of the program was receipt of invoice armor. Later, according to the program, a plate made of titanium armor was developed (use of aviation alloy Ti-6Al-4V) for the MBT hatch M-1A1 ABRAMS in collaboration with TACOM and the main contractor General Dynamics. More recently, NETL has developed high-strength armor for BBM using alloys of titanium powder, molded during sintering, which increases the strength of the final material. Armor materials made from silicon infiltrate (SiSiC) and sintered silicon carbide (SSiC) are products of CeramTec of North America from New Jersey, the American branch of the German company CeramTec AG. These materials demonstrate good chemical thermal stability and high resistance to tribological stress (tribology is a scientific discipline that studies friction and wear of machine components and mechanisms in the presence of lubricants).

Ohio-based AT&F Advanced Metals of Orville is a privately held company that specializes in the fabrication and processing of durable metals and alloys, including titanium, zirconium, niobium, nickel alloys and duplex stainless steel, supplying civil and defense customers. Even more specific is the Steel Solutions and Nuclear division of this company. It also manufactures materials for SZB based on high strength low alloy steel, carbon steel, steel based alloys. The company also deals with structural armoring of nuclear facilities, including reactor internals and containers for nuclear waste.

Other programs

Other SPM programs are conducted throughout the spectrum of stationed forces and the global array of military operations. Their immediate requirements and tasks are directly related to the current and future protection of their forces, because these areas of application cover ballistic protection of vehicles, upgrading the “soldier as a system” and contribute to the survival of military infrastructure with various asymmetric threats commonly encountered in regional peacekeeping operations.

Advanced booking of vehicles, military and government buildings and locations of military personnel on the front lines and in the rear will benefit from the availability of deployed capabilities. While many applications are improvements and upgrades to existing capabilities and systems as such, for example, new types of additional armor for combat vehicles to protect against IEDs, others are innovative and future generation systems.

The German company IBD Deisenroth Engineering AG manufactures AMAP High-Tech Vitality Enhancement System. This is a series of structural armor solutions using several production methods and advanced materials, including high-strength alloys and composite materials. Among them is the AMAP-IED, which combines ceramic armor and anti-splinter tamping technology and which can be supplied in the form of modular elements and which is designed to enhance the protection of military vehicles. IBD calls the next generation AMAP-IED protection system and classifies it as protection against shrapnel of artillery shells in caliber up to 155 mm, as well as roadside mines and IEDs. AMAP-T is a transparent armor made using ceramic glass, which the company describes as having excellent transparency and extreme durability corresponding to 1 Levels - 4 STANAG.

The roof protection of vehicles is provided by AMAP-R and AMAP-ADS, which are materials optimized for armament; the first is made of ultra-light composite materials suitable for booking roofs of vehicles. The most interesting armor solution is AMAP-S. It is optimized for ballistic protection and control of signatures, reduces the visibility of military vehicles when scanned by reconnaissance sensors in the visible, infrared, radar and acoustic spectra. These materials can be used as an addition to existing machine housings, that is, be installed on new models or machines that are already in use.

Accellent SMART Layer Sensor Samples for Sensors

The BAE division of the US corporation ProTech offers a range of structural booking solutions that include several types of anti-bullet and civilian armored combat positions, including armored booths and security towers, mobile security barriers and mounted defense systems for tower soldiers. The stationary structural armor solutions of this company are represented by a number of prefabricated armored combat positions AFPS (armored fighting positions), which are able to protect against 9 mm - 12.7 mm bullets. ProTech's other AFPS solutions include transportable armor structures that are optimized for perimeter security and roadblocks, protection of vital facilities, security at the guard houses and border checkpoints.

ProTech also produces modular systems that can be designed to meet end-user specifications. Such systems, based on transportable armored containers produced by EADS, were developed in collaboration with KMW under a contract with the German Federal Agency for Defense Procurement. An armored container system called TransProtec that can accommodate an 18 man, including equipment, is optimized to protect ground forces from IED attacks, sniper fire, shrapnel, mines and weapons mass destruction and is currently in service with the Danish and German armies, in the latter the system is called MuConPers (universal container for transporting people).

Plasan North America, a division of Israeli Plasan Sasa, also developed structural armor solutions in accordance with a multi-million dollar contract with the United States Department of Defense issued to protect new MRAP machines. According to the contract, Plasan is the main contractor in the joint production program with BAE Systems as a subcontractor for the supply of reservation systems for Oshkosh M-ATV machines, most of which work in Afghanistan under a contract with the TACOM command of the US Army. Plasan is the world leader in designing additional reservation systems and systems “from an explosion under the bottom” to protect tactical vehicles in the military and civilian spheres.

Advanced soldier protection systems fall within the scope of structural protection applications and include power-driven combat exoskeletons. They promise to have a significant impact on ground combat operations, if such systems reach their full potential. In the United States, several major initiatives have been opened on the technology development program of the Department of Defense and the private sector. One of these programs is performed by the Natick Labs Research Center of the American Army according to the concept of the Future Warrior, which provides a fully integrated system for the soldier, which includes six main subsystems. The NSRDEC (MIT Natick Laboratory of the Massachusetts Institute of Technology for Soldiers Nanotechnology (ISN) and the SSIL Soldier Systems Integration Lab) also work on these programs. The ultimate goal of SSIL is to develop what SSIL calls the 21 century combat suit, which combines high-tech capabilities with a small mass.

The laboratory for robotics and human engineering at Berkeley (BLEEX), a program sponsored by the DARPA Advanced Defense Research Program, has developed a prototype self-propelled exoskeleton consisting of two anthropomorphic legs with a drive, a power plant, and a backpack-type frame, on which various loads The exoskeleton allows the user - or "pilot" - to carry extremely heavy loads, while at the same time facilitating walking and running on the ascending and descending slopes throughout the entire range of normal movement without the operator using physical force.

The Raytheon Sarcos initiative is underway at Raytheon's Salt Lake City plant. It represents a more ambitious effort to develop a soldier's exoskeleton, which Raytheon says is essentially wearable. robot, increasing the wearer's strength, stamina and mobility. The XOS exoskeleton, which originated from the original experimental system developed by Sarcos, currently allows the pilot to lift up to 200 pounds and perform tasks requiring great effort, such as climbing stairs and inclines without fatigue, but its hydraulic drive is currently requires a stationary external source of energy. Also introduced is Lockheed Martin's HULC exoskeleton, which is also designed to carry loads of 200 pounds for any period of time and over any terrain, it is conceived so that it has a fully hydraulic drive that does not require an external power source. The HULC system includes an on-board microprocessor connected to sensor interfaces, which allows the exoskeleton to sense the pilot's intentions and move in interaction with him. The HULC system is highly modular to allow quick and efficient field replacement of major components, and features an energy-saving design that will allow battery operation during extended missions. However, HULC, like the exoskeleton from BLEEX, is conceived more as a system for carrying cargo, and not a replacement for the natural physical capabilities of a soldier. Currently, the Japanese company Cyberdyne of Ibaraki is developing HAL (Hybrid Assistive Limb - a hybrid limb for assistance), it is a generally powerful system designed to increase a person's physical strength from two to 10 times. Despite the appearance of Iron Man, its adaptability to future military tasks remains in question.

Further actions

Summing up, it can be said that an important task for a SZB can be broadly defined as reducing vulnerability to hostile actions, especially ballistic attacks, for which many traditional materials do not provide adequate levels of defense for the time being.

Fighting often gives commanders harsh lessons that seemed obvious in the past. One of the most difficult modern lessons of military operations is the inadequacy of armor protection against improvised threats, which include suicide bombings on vehicles at military and civilian targets and attacks by IEDs on vehicles and personnel located in the theater of war. Old habits, especially military habits, die off especially hard. But with historical from a point of view, these habits tend to disappear under the pressure of battle, for example, French cavalry against English bows during the Hundred Years War or the mismatch of Soviet-style Iraqi armored vehicles to attacks of high-precision guided munitions and more advanced MBTs during the Gulf War.

Responding to challenges quickly and with appropriate countermeasures is the key to military success and power stability. So, if they are considered seriously regarding the protection of troops and are the main defense issue in this transformational era of power restructuring, then structural protection and SZB using this technology should become a priority in defense procurement and research tasks for all military leaders. Current asymmetrical threats to military and civilian infrastructure, as well as asymmetric hostilities in regional combat operations, affect defense policy development and system development and procurement on a global scale. In a predictable future, it should be so.

Such armored military systems were mainly considered as additions to other priority decisions, and not as an integral element of many and most combat systems. But everything changes. Security and booking systems represent great potential and increase capabilities in 21 century operations. Their application will expand and become the standard for many, if not most defense systems at all levels.

Materials used:

www.monch.com

www.lockheedmartin.com

www.ceramtec.com

www.smartnanomaterials.com

www.protecharmored.com

www.frontierpolymer.com

www.acellent.com

www.plasansasa.com

Information