How to create a submarine fighter project 705

More than 15 years have passed since the last of the 705 project boats was excluded from the Russian Navy, and there are still disputes in the circles of sailors and shipbuilders. What really was the 705 project - a breakthrough into the future, ahead of its time, or an expensive technical adventure?

In the 1959 year, when the Leningrad nuclear submarine Leninsky Komsomol, designed by the Leningrad SKB-143 (now Malachit) project, was already launched into the sea, the leading specialist of the same submarine, the Leninsky Komsomol, was launched in Severodvinsk. SKB A. B. Petrov proposed the creation of a “Small-speed submarine fighter”. The idea was very relevant: such boats were needed to hunt submarines - carriers of ballistic missiles with nuclear warheads, which then began to be actively built on the stocks of a potential enemy. 23 June 1960, the Central Committee and the Council of Ministers approved the project, which was assigned the number 705 ("Lira"). In NATO, this boat became known as the “Alpha” (Alfa). Academicians A.P. Aleksandrov, V.A. Trapeznikov, A.G. Iosifyan became the scientific leaders of the project, and Mikhail Georgievich Rusanov became the chief designer of the ship. He was a talented man with a very difficult fate: seven years in a gulag, and after his release - a ban on entering Leningrad. An experienced shipbuilding engineer worked at the button maker in Malaya Vishera, and only in 1956 could he return to Leningrad, in SKB-143. He started with the deputy chief designer of the nuclear submarine of the 645 project (this experience turned out to be very useful for Rusanov).

Battle with titan

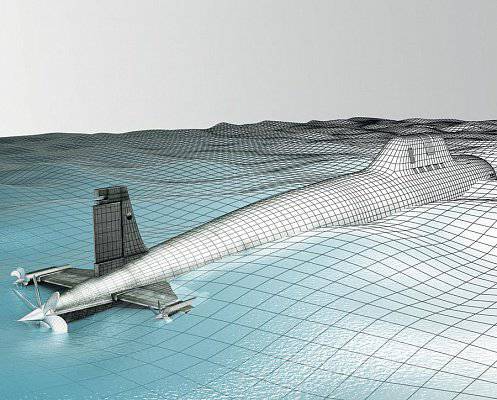

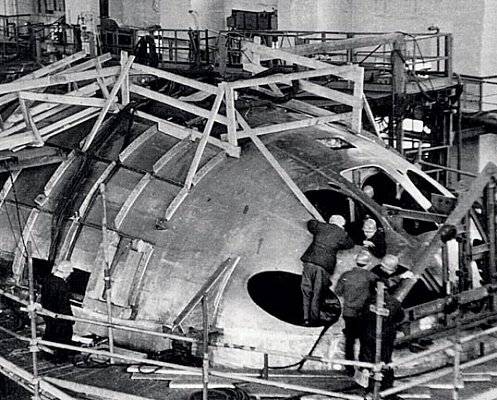

The purpose of the new submarine determined the basic requirements - high speed and maneuverability, perfect sonar, powerful weapons. To ensure the first two requirements, the boat had to have extremely small dimensions and weight, the highest hydrodynamic characteristics of the hull and a powerful power plant, fitting in limited dimensions. It was impossible to do this without non-standard solutions. As the main material for the ship hull, as well as many of its mechanisms, pipelines and fittings, titanium was chosen - the metal is almost twice as light and stronger than steel at the same time, and it is also absolutely corrosion-resistant and low-magnetic. However, it is quite capricious: it is welded only in an inert gas — argon — it is difficult to cut it, it has a high coefficient of friction. In addition, titanium could not be used in direct contact with parts from other metals (steel, aluminum, brass, bronze): in sea water it forms an electrochemical pair with them, which causes corrosion-damaging parts from other metals. It was necessary to develop special grades of high-alloy steel and bronze, and the specialists of the Central Research Institute of Metallurgy and Welding (Prometheus) and the Central Research Institute of Shipbuilding Technology managed to overcome these titanium tricks. As a result, a small ship hull was created underwater displacement 3000 t (although the customer - the Navy - insisted on limiting the 2000 t).

I must say that Soviet shipbuilding has already had experience in creating submarines made of titanium. In 1965, in Severodvinsk, a single submarine of the 661 submarine with a titanium hull was built. This boat, known as the “Golden Fish” (a hint of its fantastic value), remains to this day the record for speed under water - on the sea trials it showed the 44,7 node (about 83 km / h).

Solid innovations

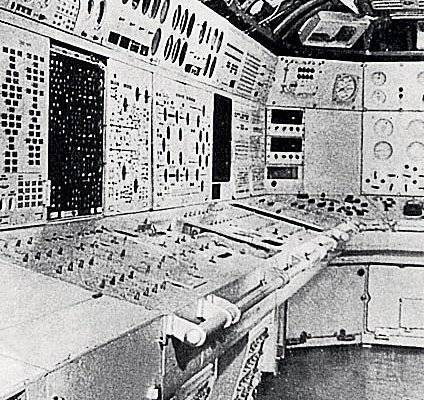

Another radical innovation was the size of the crew. On other submarines (both Soviet and American), 80-100 people carry the service, and in the technical task for the 705 project, the number 16 was named, and only officers. However, during the design, the number of future crews grew and eventually reached 30 people, including five midshipmen technicians and one sailor, who was assigned the important role of coca, and part-time day-care worker (initially it was assumed that the ship doctor will perform the ship's doctor). To combine such a small number of crew with a huge number weapons and mechanisms, the boat had to be very seriously automated. Later, the sailors even called the boats of the 705 project "automatic".

For the first time in the country (and probably in the world), global automation covered everything: ship traffic control, weapons use, the main power plant, all general ship systems (diving, surfacing, trimming, retractable devices, ventilation, etc.). One of the key and very controversial issues in the development of automation systems (a whole number of research institutes and design bureaus, including the Central Research Institute Aurora, Granit, Agat) was involved in the selection of the current frequency for the ship's electrical network. Considered options 50 and 400 Hz, each had its own advantages and disadvantages. The final decision in favor of 400 Hz was made at a three-day meeting of the heads of several organizations involved in the topic with the participation of three academicians. The transition to an increased frequency caused a lot of production problems, but it made it possible to significantly reduce the size of electrical equipment and appliances.

Atomic heart

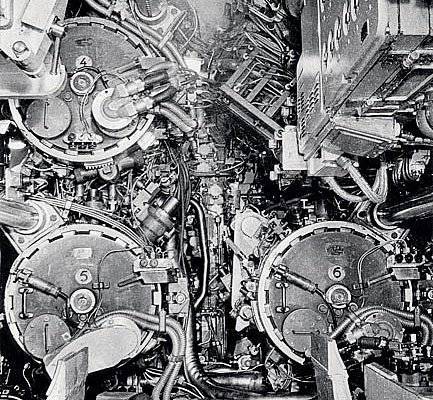

Yet the main innovation that determined the fate of the entire project was the choice of the main power plant of the ship. It has become a compact atomic fast-neutron reactor (BN) with a liquid metal coolant (LMT). This made it possible to save about 300 t displacement due to the higher steam temperature and, consequently, better turbine efficiency.

The American submarine Seawolf (1957) became the first submarine in the world with a reactor of this type. The design was not very successful, during the sea trials, the primary circuit was depressurized with sodium ejection. Therefore, in 1958, the reactors were replaced with water-cooled reactors, and the military in the United States no longer contacted the reactors at ZhMT. In the USSR, they preferred to use lead-bismuth melt, which is much less chemically aggressive than sodium, as a heat carrier. But the K-1963 nuclear submarine, built in 27, was also unlucky: in May 1968, during the hike, the first circuit of one of the two reactors broke. The crew received huge doses of radiation, nine people died, and the boat was dubbed "Nagasaki" (the nickname "Hiroshima" was already occupied by K-19 in 1961 year). The submarine was so radioactive that it could not be repaired, and as a result, in September 1982, it was flooded off the northeast coast of Novaya Zemlya. To her "titles" naval wits added "forever underwater." But even after the tragedy of K-27 in the USSR, it was decided not to abandon the tempting idea of using reactors from ZhMT to nuclear submarines; engineers and scientists under the guidance of academician Leipunsky continued to work on improving them.

The development of the main power plant for the 705 project took two organizations. Podolsk OKB "Gidropress" created a block two-unit installation BM-40 / A with two circulation pumps. Gorky OKBM issued an OK-550 installation, also a block one, but with a branched first circuit and three circulation pumps. In the future, both installations were used on the submarine of the 705 project: OK-550 was installed on boats under construction in Leningrad (four ships), and on three boats built in Severodvinsk according to the version of the 705K project, the BM-40 / А was installed. Both units provided power to the turbine shaft up to 40 000 l. pp., which allowed to develop the speed of 40 nodes provided by the technical specifications.

The longest boat

In total, nuclear submarines of project 705 were built seven pieces, they became the first in the world of serial boats equipped with reactors with LMW. The first boat, K-64, laid in June 1968 in the same old boathouse, where the famous cruiser Aurora was built 70 years before, was transferred to the Navy in December 1971. The main problems of the pilot operation were associated with the reactor, which was fundamentally different from the well-known pressurized water. The fact is that the lead-bismuth alloy crystallizes at + 145 ° C, and in the operation of a reactor with such an LMC, in no case should the temperature in the primary circuit be reduced to this value. It is as a result of non-compliance with this condition in the pipelines of one and then the second loop of the first circuit that traffic jams from the frozen melt began to appear, which was no longer possible to return to the liquid state. The steam generating unit was “frozen”, accompanied by depressurization of the primary circuit and radioactive contamination of the boat, which at that time stood at the berth at its base. It soon became clear that the reactor was irretrievably ruined, and the boat could no longer go to sea. As a result, in August 1974 she was decommissioned. fleet and after much debate, it was cut into two parts, each of which it was decided to use for crew training and the development of new technologies. The bow of the boat was towed to Leningrad, and the stern with the reactor compartment remained in Severodvinsk at the Zvyozdochka shipyard. The black cross of the cut-off feed stabilizer K-64 with horizontal and vertical rudders remained there as a mournful monument. Among the sailors and shipbuilders for a long time there was a joke riddle about the "longest boat in the world."

Real life

The construction of the series, which was already actively conducted in Leningrad and Severodvinsk, was suspended, but resumed a couple of years later, and from 1977 to 1981, six submarines of the 705 project were transferred to the fleet. These ships quite intensively and successfully served in the Northern Fleet, causing serious concern among the NATO countries. Taking into account the sad experience of K-64, on all serial submarines of this project an “electric boiler” was additionally installed, the task of which was to maintain the required temperature in the primary circuit of the reactor when it was brought to minimum capacity when the submarine was stationed at the base. To operate the boiler required to supply electricity from the shore. There were disruptions to this, and since the crews of the boats were desperately afraid to destroy the reactor, it was not maintained at the minimum power level, which accelerated the production of nuclear fuel. In addition, the displeasure of the naval base authorities caused the need to organize special laboratories for periodic inspections, adjustments and repair of automation, which was packed with boats of this type. So a lot of cares have been added to the coastal services of the Navy. Increasingly, there was talk on the topic that new ships, despite the unique fighting qualities, are ahead of their time and are too difficult to maintain. The seventh serial boat did not finish building, and cut right on the stocks. By the 1990, all (except one) of the submarines of the 705-th project were withdrawn from the fleet, having served substantially less than the period for which they were designed.

Last Alpha

K-123, which became an exception, lingered in the ranks until 1997, due to excessively prolonged repairs after a serious accident in 1982. When the boat was submerged in the Barents Sea, the “Fault Reactor” signal suddenly came on at the control panel in the central submarine of the submarine. Lieutenant Loginov went to reconnaissance into the uninhabited reactor compartment, who after a minute reported that he was watching the silver metal spreading along the deck: it was a highly active liquid metal fuel cell escaping from the first loop of the reactor. At the same time, the signal “Contamination of the reactor compartment” turned on. To leave the compartment! ”, And, as one crew member who survived the accident recalled later,“ they thought about Loginov in the past tense ”. But Loginov survived. After entering the gateway, through which the reactor compartment communicates with the rest of the boat, he left all his clothes there and went through a thorough bath. The reactor was shut down, the submarine surfaced, blowing its ballast tanks. As it was established later, the order of 2 t TMC had time to flow out of the first circuit. The boat was so polluted that the cruiser who had come to the rescue did not dare approach her to pass the towing cable. As a result, the cable was still brought with the help of a deck helicopter from the same cruiser. Repair of the K-123, during which the reactor compartment was completely replaced, ended in 1992, the submarine returned to service and safely served until the 1997 of the year. With her write-off infamously ended story 705 project.

Reserve parachute

Of the six submarines, there were only two inhabited nuclear submarines, one of which housed a pop-up rescue chamber created for the first time in the world, designed to rescue the entire crew (30 people) even from the maximum depth of the dive (400 m).

Ahead of time

The nuclear submarines of the 705 project boasted fantastic speed and maneuvering characteristics and many innovations: a titanium hull, a fast neutron reactor with liquid metal coolant and fully automated control of all ship systems.

On the submarine of the 705 project, pneumatic-hydraulic torpedo tubes were installed for the first time, ensuring firing in the entire depth range of the dive.

In order to control the submarine by the forces of a very limited crew of the time in 30 people, numerous automation systems were developed to keep all the mechanisms of the ship under control.

The hull of the boat was made of titanium, so the specialists of the Central Research Institute of Metals and Welding (Prometheus) and the Central Research Institute of Shipbuilding Technology had to develop special technologies for welding and joining titanium parts, and for metallurgists new corrosion-resistant alloys.

Liquid metal

Atomic ships are essentially steamboats, since their propellers are driven by steam turbines. But steam is not generated in conventional boilers with furnaces, but in atomic reactors. Heat of radioactive decay is transferred from nuclear fuel in the primary coolant circuit to the coolant, usually pressurized water (to raise the temperature to 200 ° C or more), which also serves as a neutron moderator. And the coolant already transfers heat to the water of the secondary circuit, evaporating it. But water under pressure has its drawbacks. High pressure means that the pipe walls of the cooling system of the primary circuit of the reactor must be thick and durable, and when the primary circuit is depressurized, radioactive steam penetrates into the most hard-to-reach places. One alternative is the use of fast neutron reactors with a coolant of low-melting metals in their liquid phase — for example, sodium or a lead-bismuth alloy. Thermal conductivity and heat capacity are much higher than that of water, they can be heated to higher temperatures without high pressure in the primary circuit, which allows you to create very compact reactors.

Information