Production of Russian 3D printers stumbles over stereotypes

The newborn Russian 3D industry can become competitive and large-scale if the consumers and the advantage and cheapness of the new mode of production are discerned, and large companies use them more widely. In the meantime, the market is growing at the expense of mobile small and medium-sized private companies and educational institutions.

Watching the birth of a new type of production, especially innovative, is extremely entertaining. Russia has been developing desktop 3D printers for three years now, and the first sales began at the end of 2011. During this time, six companies have already put their products on the market! On the one hand, everyone thinks this market is fast-growing and very promising. On the other hand, big business does not show interest in a new market niche. However, the production of 3D printers has become a lot not only small but also medium-sized enterprises. But can Russian production of 3D printers survive? One of the threatening trends is growing competition with Western manufacturers: this spring some market participants started talking about the beginning of a price war. Another factor in slippage is the conservatism of potential buyers, which could be numerous research institutes, design bureaus, and defense enterprises. But there is also a positive trend: this year 3D printers began to actively buy the education system - an additional and professional one. In addition, this year, wealthy Russians saw the “miracle printing” and began to buy 3D printers for home use. So far it is only fun - to “print” yourself any toy, cup, spoon or even shoes. But soon, many will realize that a 3D printer at home is just as necessary as a computer. And domestic companies have the opportunity to participate in the beginning 3D boom.

The explosive growth of 3D print

History 3D printing has been going on since 1948, when the American Charles Hull developed the technology of layer-by-layer cultivation of physical three-dimensional objects from a photopolymerizable composition (FPC). The technology is called "stereolithography" (STL). However, Hull received a patent for his invention only in 1986 year. Then he founded the company 3D System and began developing the first industrial device for three-dimensional printing, a prototype of which was presented a year later. It was he who helped Hull to become a multi-billionaire. His device grew a three-dimensional object simulated on a computer from a liquid photopolymerizable composition, applying its layer by layer onto a moving platform.

In the late nineties, other 3D printing technologies appeared - selective laser sintering (SLS), which allows the production of objects from metal, ceramic, gypsum powder. Then came the method of layering polymer filament (FDM). The essence of this technology is that in the print head the material (melt from plastic, metal, casting wax) is preheated to the melting temperature and enters the working chamber in a spray form.

In 2005, a RepRap project appeared in the USA, a self-copying device that can be used for rapid prototyping and production. The RepRap device is a 3D printer capable of creating volumetric artifacts based on computer-generated models. One of the goals of the project is “self-copying”, defined by the authors as the ability of the device to reproduce the components necessary to create another version of itself.

After the 2008 year, when Hull's patent expired, the open STL technology and others like it, along with RepRap technology, earned thousands of companies around the world. Printers began to bake like cakes. To the existing printers of the company added the modification any of components and branded. So began 3D - boom: the market was growing at 50, and in some places by 150% per year.

In recent years, from the production of large and expensive printers for industrial enterprises (costing from one hundred thousand dollars), the companies have moved to a new segment - the production of small cheap “desktop” printers that are suitable for use even in everyday life. As a rule, the majority of "desktop" 3D printers work on the technology of layer-by-layer overlaying of the melted polymer filament.

Pioneers

It is significant that in Russia the first domestic 3D printer did not appear at all from the monsters of the industry. It was made by enthusiastic students from Zelenograd. It all started with Robot. Fourth-year students of the Moscow Institute of Electronic Technology (MIET) Andrey Isupov and Maxim Anisimov defended their thesis by creating a six-fingered multifunctional robot.

“It all started in 2010, I was preparing a six-toed robot project. There was a need to create your own body for him. Then, on the Internet, I came across the project of the Opensource 3D printer RepRap and, having gone deep into this question, I understood that this is exactly what I need, said Expert Online Andrei Isupov. - The printer itself was inexpensive, and printing models cost several rubles per cubic centimeter of material. Print quality did not suit me and I decided to upgrade the printer. So, step by step, the first Russian 3D printer began to appear. ”

This is a classic start-up example. We started it ourselves, like the founders of Apple and Microsoft used to do - “in the garage,” or rather, in a one-room apartment. The first grant was received from the Borthink Foundation at the U.M.N.I.K.-200 thousand rubles competition. Zelenograd Nanotechnology Center (ZNTTs), who first invested in the project, noticed them here. Before investments there were also own investments, about half a million rubles.

In total for three years, the company has attracted from various ventures to 6 million rubles. The brainchild was named PICASO 3D - now it is already a well-known trademark.

“Now we are continuing to develop the technology, we have filed applications for patenting our own technical, engineering and software solutions, thanks to which our printer surpasses many Western analogues in printing accuracy, quality and speed,” said Maxim Anisimov.

The company is located in three rooms in one of the historic buildings next to MIET. One office room and two production rooms with a total area of more than 200 meters. Here they actually collect and test printers. In total, about 3 people work in PICASO 30 D.

PICASO 3D prints by overlaying molten plastic layers - the most sought-after technology on the market. A total of five types of plastic are used, which differ in their properties. Today, the printer costs 99 thousand rubles, which is considered to be the best price for printing of such quality (most of the western counterparts cost an average of 150 thousand rubles). Sell printers PICASO 3D began early last year. The company received new growth when the new co-founder Nikolay Bobrov, the former top manager of Renault Avtovaz, joined the creators of PICASO 3D.

“I was fascinated by the X-NUMX D-printing theme itself, I was engaged in the services of 3D printing using professional 3D equipment of subcontractors,” recalls Nikolay Bobrov. - Then I realized that in Russia there is already a demand for small printers from design, architectural bureaus and others. He began to look for such abroad, and found here in Zelenograd. And he was surprised: there is demand, there is a printer, but no sales. When I joined the company, I began to streamline workflows and create a strategy for long-term growth. ”

The first model PICASO 3D Builder sold 250 pieces. He is now out of production, sold only PICASO 3D Designer. The main buyers are architectural, design companies, fashion designers, furniture makers, design offices, inventors.

“The most interesting thing is that we ourselves still do not fully know all the possible areas of application of 3D printers,” says Nikolai Bobrov. - Sometimes we are surprised at what our clients are doing on these printers. It was also once with computers. They exist for a long time, but they did not enter into mass use for a long time, because people did not know why they were needed at all. And only the creation of computer games was the first motive for the purchase of a home computer. Likewise with us - now began to appear buyers who buy printers for the home. Basically - for entertainment, and buy as a gift. "

Chance of survival

In the short time of its existence, the Russian market for the production of 3D printers could become competitive. But “lucky” here so far a few. The second manufacturer was the company from Nizhny Tagil, which opened the Reprap Russia website1. They created a modification of the 3D printer "Chameleon", which cost just 37500 rubles - more than two times cheaper than the "pioneer" PICASO 3D. But apparently, the business went wrong. Why, one can only guess, there is no connection with the producers of “Chameleon”.

The third producer is Pavel Pirogov, the founder of Maket-City from Kursk. His printer is made on an aluminum base and costs just 44 thousands of rubles. But for some reason, the creator of this printer does not see prospects for expanding production:

“I’m not selling 3D printers,” explained Pavel Pirogov, “Expert Online”. - But I did not set such a task - their mass release. At first, the idea was interesting, but then I realized that it is unrealistic to build small-scale production for small businesses. Although the market is promising, all the same, mass production will be dragged over by large companies that already have the technological base of employees. Just for now they have not opened this market for themselves. ”

The fourth creator of his own 3D printer is still struggling to survive. This is Print & Play from Novosibirsk, whose printer costs 35 thousand rubles.

“Now 3D printers are overvalued, since this is a relatively new phenomenon and many have decided to skim the cream,” Andrey Nuzhdov, the founder of Print & Play, explained to Expert Online. - A realistic price - 35 thousand, like ours. PICASO 3D actually has the most accurate printer, we took their first prototype - Gen X as a basis (finished production in 2012), and made our SibRap-K printer. According to reviews, the quality is slightly worse than that of PICASO 3D. And the price is almost three times lower, since we did not take loans, did not spend on advertising, did not lay down a high rate of return, in our country it is 15-20%. But sales are weak, 2-3 printers per month. This is because we cannot start mass production yet. But now we are negotiating with a large enterprise in order to organize mass production at their production base. "

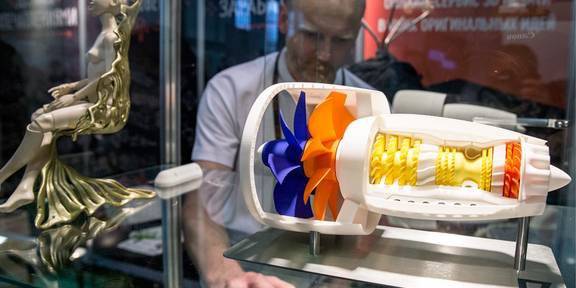

Items printed on an 3D printer

At the end of last year, PICASO 3D had the first strong competitor. The company from Moscow RGT (developing and producing equipment with numerical control) released in late October last year, the model PrintBox3D One, which costs just like the PICASO 3D 3D Designer - 99000 rubles.

“Consumer goods will be cheaper due to a reduction in print quality, but for professional use you need a machine, not a toy,” explained Expert Online Andrei Borisov, RGT Development Director. - Many are fired when buying cheap Chinese models. In fact, they buy a set of parts that must still be able to be assembled, and then set up or repaired, to understand the software. In this sense, domestic producers have great advantages. Well, we did not produce cheaper, because we are not making a toy, but a machine that requires complex systems and parts. However, soon we will put on the market a more compact and cheaper modification costing 50-60 thousand rubles, it will not be inferior in quality to PrintBox3D One ”.

RGT has its own production base. Here is a complete production cycle: they make the parts themselves, the boards, they write the software. From the acquired - except that the wires. That is why the RGT has every chance of becoming a large-scale manufacturer of 3D printers in Russia.

“Less large orders at ten printers are now being made mainly by design bureaus,” says Andrey Borisov. - Now here is the activity of the educational segment, but this is either pre-school education or resource centers. I think that in Russia the industry is slowed down partly due to the lack of specialists in 3D technologies, partly due to the conservatism of large companies and government agencies. Few people understand that 3D printing is a way to repeatedly reduce the costs and time for the production of many types of parts in small-scale production, and especially - models. Making molds and conveyors for several hundred parts is impractical, but they do it, which affects the high cost of production. ”

A vivid example of how state support can contribute to the development of new production is the emergence of youth technical centers in Moscow. The Department of Science, Industrial Policy and Entrepreneurship of the city of Moscow allocated funds to private companies for the opening of children's educational resource centers. Including due to the competition of the government of Moscow this month a new player appeared on the Russian market for the production of 3D printers - the company STANKIN-AT, a private enterprise attached to MSTU STANKIN. More precisely, this month they sold their first three Prusa Mendel 3D printers in just 39 thousand rubles.

“We have been developing the printer for a long time, but there were great difficulties with the organization of production,” explained Stanislav Konov, Associate Professor, STANKIN-AT LLC, Expert Expert, said. “With the funds allocated by the Moscow government, we organized the Center for Youth Innovative Creativity (TICIT), equipped with everything necessary for the production of a 3D printer. That is why they are the cheapest of all Russian. We also save on payroll. Software enthusiasts themselves are engaged in software, assembling, tuning and other things. And the remuneration is received upon the sale of the printer, and in other companies only at the design stage large labor costs are required. ”

In STANKIN-AT technology, they followed the same path as the rest: they didn’t create all the mechanisms from zero, but copied them, gradually replacing them with their own developments, which the students make again. Each new sample is ultimately different from the previous one.

STANKIN-AT and TsMIT are currently working on a new multi-function device that will combine the 3D printer, milling machine and contact scanner to simulate parts. So far, no one has succeeded.

“Our equipment allows us to set up small-scale production, but so far there are no orders, although at a price we have a clear competitive advantage,” says Stanislav Konov. - Frankly, there is no time to do marketing. But we will participate in different exhibitions, it will help promote products. ”

Abroad destroys prices

Will the Russian market for the production of 3D printers be able to withstand competition from Western manufacturers, who have had time to set up large-scale production and save on costs? It seems that all the prerequisites for this are. Despite the fact that some foreign manufacturers of 3D printers began to reduce prices in the spring (from an average of one hundred thousand rubles to 50-70), ours have other distinct advantages.

“Our company was the first to bring 3D printers to Russia,” Expert Online reported Julia Sokolova, sales manager of the 3D printers LLC 3D Development, customer service manager. - This is the model “UP!”, The developer of which is a company from the USA, and the collector is China. He was chosen because of the simple software. Many customers find it difficult to understand the software for 3D printers, so they made a bid for simple solutions. But domestic producers are now taking revenge. They are chosen by people because it is Russian companies that means that a service is available, there will be no problems with setting up, with details. And software in Russian, which is important to many. "

For example, start-up company Hyperbok, the manufacturer of the Hyper-Box, a Russian home-based robot, made a bet on the domestic PICASO 3D printer. “Hyper-Kolobok” is an electronic toy that can perform not only the programmed actions - this robot can be safely called the world's first robot friend, thanks to its ability to think. The robot has its own character and ability to grow. Every day he learns about events happening around him, and remembers what his owner likes and what he doesn’t like. Can even check the child doing homework.

“I chose PICASO 3D, because printing accuracy is very important for me - in order to refine the details, as they say, with a file,” explained Lyubov Orlova, Hyperbok Development Director, Expert-Online. - In our 45 kolobok complex parts that all must interact with each other, and for this very high accuracy is necessary. We do not use 3D printing services, because logistics is also important to us. There while you order, while in the queue you wait until they deliver. And so we in one day can alter the same engine, having printed the parts themselves. ”

The creators of the first android robot in Russia, Alice, also preferred the Russian printer of the company PICASO 3D. It prints piecework for Alice, which would be too expensive to cast on the molds.

“The market is growing mainly due to the fact that regional companies have begun to discover the 3D technology,” says Yulia Sokolova. - More recently, the main sales accounted for Moscow and St. Petersburg. Many requests have gone lately from educational institutions. But the problem is that the Ministry of Education has not developed a methodology for working and teaching on 3D, therefore this principle cannot be used in the educational standard. But for additional school education does not require clear standards, these are circles, and for them they buy printers. 3D high school printers, especially architectural and design, also began to take an active part. Another trend - at the end of last year began to buy more printers for home use, entertainment. Some people buy printers for free. ”

By the way, due to the resource centers of children's creativity, the PICASO 3D is expanding its business: now negotiations are underway to supply 3D printers, where children will master the new printing technology.

Another possible development vector for the production of 3D printers is large companies. But here the problem is in stereotypes and banal ignorance of the benefits of the new technology.

For example, so far from large customers only S-7 has addressed the Moscow RGT. They needed 3D printing for the manufacture of several dozen parts for aircraft. Judged that it is cheaper to purchase your own printer than to place orders for manufacturing.

“But can you imagine what the needs for low-volume cheap production at defense enterprises are! - says Andrey Borisov. - But everyone there works the old-fashioned way and doesn’t think about the price, because there is a government order. If large companies turned to 3D, we could provide demand and go to the large-scale production of printers. It’s even harder with government agencies - it’s generally difficult to stir this colossus, although in the same entity there could be a great demand for 3D prints. ”

Now in Russia declared a course for the universal reduction of costs. 3D printing is an excellent option for multiple cost reductions in small-scale production. So now it’s time for the state to pay attention to the emerging industry and at least start talking about the need to support this innovative business.

Information