Knife blade design

The limiter is the part of the knife between the blade and the handle, which prevents the fingers from sliding off the handle onto the knife blade. Usually, the role of a limiter is performed by one (subfinger stop) or two bows (cross, cross). In the latter case, these bows can be straight or curved. The shape of the cross largely determines the use of a knife grip. The most functional crosshair, in which the arms are directed forward and have on their surface ribbing for the thumb. Cross - the obligatory accessory of combat knives.

In some models of knives, you can also find two limiters (sub hilt), but adding a second limiter does not provide any particular advantage.

The heel of the blade (Central Asian knives, some types of tourist knives, kitchen knives) or a deep sub-finger cut on the hilt of the handle near the blade can play the role of a limiter.

Small holes can be made in the survival knives limiter, which make it possible to transform them into an improvised spear or harpoon with a cord or rope.

The name of the guard, which is sometimes used in the description of the limiter, is associated with fencing bladed weaponswhere it served to protect the hand from the blows of the enemy’s blade and consisted of a crosshair and hilt.

Fencing knives "blade into a blade" is a thing of the past, but knives with a guard hilt are still being produced. Most often, this hilt is found on survival knives and knives for scuba diving, but its purpose is different - it allows you to hold the knife in your hand, leaving your fingers free.

Knives with hilt in the form of brass knuckles, leading their history from trench knives of the First World War, are now rare and in many countries are illegal.

Handle

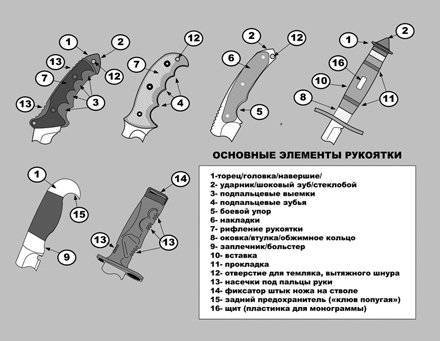

In the design of the handle, the following main parts are distinguished: black (part of the handle, directly covered by the hand), back (upper part of the handle), abdomen (lower part), cheeks - side parts, head of the handle (farthest part of the blade).

In knives for throwing the role of the handle performs the shank of the blade.

The handle itself is absent in small concealed carrying plate knives. Often, the size and shape of such knives correspond to a plastic credit card (card knives).

In addition to the main elements in the design of the handle may be additional, which provide ease of use with a knife.

In most knives which are not knives, the handle is in line with the blade. In some models, it can be located at an angle to the blade, perpendicular or parallel to it.

The handle located perpendicular to the blade is a characteristic feature of knock knives and daggers (push-daggers), originating from the weapons of the card cheaters of the Wild West. Since striking with such a knife does not require special preparation, such an arrangement of the handle is often used in personal self-defense knives.

Recently, tactical and combat knives with a displacement of the handle below the blade line have appeared, which increases its cutting abilities, worsening the piercing ones.

The indigenous population of Chukotka and Alaska has long used knives with a handle parallel to the blade in everyday life. Such knives can be successfully used in the modern kitchen, but this requires a cutting board with a circular recess in the middle.

Canadian hunting knives are characterized by a handle shifted above the blade line. Such knives are very convenient for the majority of work in everyday life and field conditions.

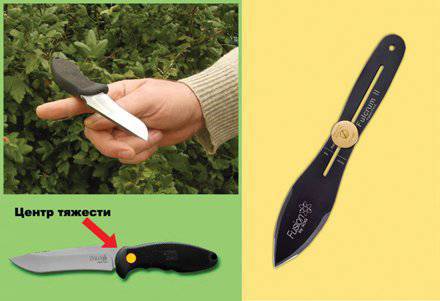

One of the important characteristics of a knife is its balancing, that is, the location of the center of gravity of the knife (Ts. T.). The most functional is the location of the TS. T. between the blade and the handle. Offset? P. T. to the tip increases the chopping properties of the knife and facilitates its throwing (survival knives, machete knives, throwing knives), and shifting to the middle of the handle facilitates knife maneuvering. To determine the balance of the knife is quite simple - you just need to find a position on the extended index finger, at which the knife will maintain balance in a horizontal position.

Some throwing knives have a special weight that allows you to adjust the balance of the knife.

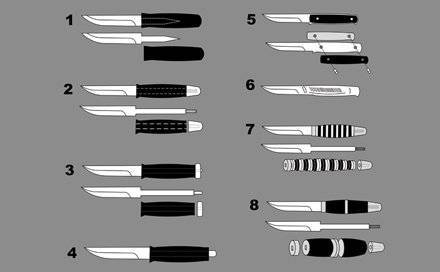

The handle can be fixed on the shank of the knife in various ways. The simplest of these is the mount of the handle. This is a non-collapsible design, in which the shank is shorter and already the handle (push tang). Since the shank is hidden in the body of the handle, outwardly it is impossible to determine its shape and size and, consequently, the strength of the whole structure. With a narrow and short shank, when the knife performs heavy work, the blade may break.

When screw and riveted connection narrow shank passes inside the handle along its entire length (hidden tang).

Modern synthetic materials allow die-casting to form the handles directly on the shank at the last stage of the knife production.

In the case of an overhead construction, the length of the shank is slightly longer than the length of the handle (full tang), and its width is equal to or slightly wider than the side plates - the handle cheeks. Fastening the cheeks (scales or slab) to the shank will be done with rivets, screws or hollow tubes.

The most practical and durable knife design with a threaded connection, cast handles or invoice design. The screw connection allows you to eliminate the backlash of the overlays of the handle, which may appear over time, or even replace the handle or cheeks if they are damaged.

A molded handle is formed from pieces of various materials (usually colored plastic, bark, or leather).

A variation of the handle is a composite handle consisting of several parts, as a rule, wood of different species, between which there are metal or plastic gaskets. Functionally, such handles have no advantages, but they are very aesthetic.

Traditional materials for the manufacture of knives are wood and bone.

Currently available are the most exotic types of wood for making handles with different texture and color.

The wooden handle has a beautiful appearance, fits tightly in the hand, and in the winter season it does not cool the hand. The disadvantages of wood is its low moisture resistance. Varnishing a tree helps overcome this drawback, but at the same time it becomes more slippery, especially in a wet hand.

To prevent cracking of the handle with strong blows with a knife edge in the front or rear of the handle, a special part is made of metal (sleeve, compression ring, forging, obimitsa). The same part of the handle in the front part of it, also called the bolster or shoulder pad.

Bone handles used in expensive knives authoring. In this case, as the material, the bone of exotic animals (walrus, elephant, mammoth, etc.) can be used.

Leather handles are very pleasant to the touch and sit firmly in the hand. But the skin is hygroscopic and rotting. Impregnating it with varnish avoids this drawback, but reduces the reliability of the grip.

In modern knife industry for the manufacture of handles are widely used various artificial materials - mikarta, polyamide (RA), polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS); G-10 fiberglass-reinforced plastics, carbon fiber. Especially convenient are soft synthetic materials (elastomers) - craton and santoprene.

All these materials have excellent resistance to water, resistance to various chemicals. Handles of these materials can be given a very different shape and texture.

To increase the reliability of holding the knife in the hand, the handle usually has a narrowing near the limiter and tops, ribs on the back and abdomen, a special rough structure of the cheeks, subfinger cutouts and notches. It should be borne in mind that subfacial cuts should correspond to the size of the wearer's brush, otherwise it will be very inconvenient to work with a knife. In addition, the asymmetric shape of such a handle limits the number of uses of the knife grip.

Recently, “rings” for the fingers of hands appeared on the handles of knives, which were borrowed from the design of the Malay knives kerambit. They can be located in the front of the handle or at its end. A knife with such a handle is almost impossible to knock out of the hand, and besides this it becomes possible to apply the handle of "brass knights".

The butt of the grip knives often has a hole for attaching a lanyard or a pull cord. The presence of a lanyard (rope or belt loop) in knives with a handle without a stop will protect the fingers from slipping on the blade of the blade. In addition, the lanyard allows you to release your fingers to do any work, without releasing the knife from your hand.

Exhaust strap is most often used in conjunction with a plastic or leather sheath without fasteners and provides quick removal of the knife from them.

In tourist and survival knives, the handle can be hollow. In tourist knives, small musat is inserted into this cavity to undermine the knife in field conditions.

The survival knives in this cavity are stored NAZ (wearable emergency reserve) - fishing line, fishing hooks, matches, and so on. The cavity in the handle is sealed with a lid - top, into which is inserted a small compass. Such a handle is usually round. The round shape of the handle is not very convenient for working with a knife, but if necessary, you can insert a stick into it, turning the knife into an improvised spear.

The top handles of hunting and tourist knives are often performed in the form of an animal's head.

The end part of the handle may have a specific bend - a rear safety device that facilitates pulling out a knife stuck in a dense material. Because of its shape, it was called the "beak of a parrot".

In the topside of combat and tactical knives, there is often a special lug (shock tooth) for striking the handle end or breaking glasses in emergency situations (cullet).

Sheath

In folding knives when not in use, the blade is hidden in the handle, which ensures safe carrying of the knife without any additional devices. For awkward knives, in which the blade is always bare, you need a special case for the blade - the sheath. Sheath - an integral accessory knives of this type. The convenience of wearing and using a knife depends on them, including the speed of blade removal from the sheath, on which in many cases the life of the knife owner depends.

The design of the classic scabbard includes a “pocket” for the blade (its open part is called the mouth), elements for fixing the knife in the sheath and fastening elements on clothing or ammunition.

The design of the scabbard is largely determined by the purpose of the knife. For a combat knife, they must provide quick and silent extraction. Travel knives often have a special pocket for a grinding stone or musat, and survival knives also have compartments for a flint or an additional small type knife. The knife can be sold without a scabbard. In this case, the owner selects the finished sheath for himself or orders them, based on his preferences, first of all, the way he carries the knife, which determines the basic hold, the way the knife is used, and so on.

Previously, leather, wood or metal were used to make the sheath. Nowadays, metal sheaths are very rare, and wooden shells are mainly used in national knives, including those made as souvenirs for tourists. For designer art knives, the sheath can be made of bone and decorated with carving and inlay.

Leather sheath look aesthetically pleasing, they are durable and easy to use. However, the skin is not water resistant and exposed to microorganisms. As a result, the leather sheath warps, stretches and loses its shape. In addition, in case of poor quality of tanning, tannins remaining in the skin can have an adverse effect on the steel of the blade.

From these disadvantages are free sheath made of synthetic material. Most often, a special kind of nylon fabric - cordura (dense nylon weave with moisture-proof impregnation and a special fiber structure) is used for these purposes.

Leather and synthetic scabbards to prevent cutting through firmware stitches are often riveted along the seam line. For the same reason, a plastic liner is inserted inside the sheath of synthetic sheath, which also provides stiffness of the sheath. But the presence of the liner can cause knocking the knife when it is worn.

In modern clumsy knives, the sheath of plastic kaidex is very widely used. The properties of kaydeksa allow the manufacture of scabbards, exactly the shape of the blade. This is to some extent a disadvantage - the sheaths only fit a particular knife.

On the side of the edge of the blade, the plastic sheath may have a small vent.

Elements of fixing the knife in the sheath. To prevent the knife from falling out of the sheath, a strap (made of leather or fabric) with a buckle is often used. It covers the handle in the area of the limiter, its middle part or near the top. The most optimal is the location of such a strap - lock in the area of the limiter. If it is located near the top, then the knife will not fall out of the sheath, if the handle in this place has a narrowing. The least reliable strap - locking in the middle of the handle.

In knives, the shape of the blade which is different from the classic, the latch can be located in the blade.

The most simple fastener design came from the holster for pistols. It consists of a special pin in the form of a fungus, which is fixed in a narrow slot in a leather strap. This simple, time-tested design ensures reliable retention of the knife in the sheath and quick unlocking and locking of the fastener. Recently, such a fastener is rare, mainly on the sheath of bayonet knives.

In most modern sheaths, button fasteners and textile fasteners are used (in colloquial "Velcro"). The durability and reliability of their work is determined by their design and the materials used.

Perhaps the least reliable cheap buttons with "O" -shaped spring. More reliable buttons with a spring in the form of "Ω", especially their version - "Lift-the-Dot", often used in military equipment.

The textile fastener is less durable, but in the event of its failure, it is easily replaceable.

There are two types of textile fasteners.

The first of them - “Velcro” (from fr. VELours - velvet and CROchet - hook), is known from the 1948 year and works on the principle of burdock. It consists of two ribbons, on the first of which there are micro hooks, and on the second - a pile, for which they cling. Its main advantage is low cost, and the disadvantage is short life, since in case of “pile” contamination it quickly fails. Its other drawback is the crackling sound produced when it is unfastened, which in some cases (combat and tactical knives) is unacceptable.

The second type of velcro is “Double Lock” (Dual Lock), in which plastic pins are placed on two tapes in the form of a fungus. Such fasteners are characterized by high reliability, durability (resource - up to 10 thousand cycles), as well as high strength of the connection, but also high price.

In any case, for convenient unzipping and fastening, the fastener must have a tongue that is gripped by the thumb and forefinger during manipulations with it. The absence of such a tongue on a cheap sheath does not allow you to quickly unbutton the fastener, especially in winter.

If the tongue has a metal edging or the fastener is installed on a hard plastic or metal tongue, then in this case you can unzip the fastener very quickly by hooking it with your thumb. But for knives used in the field, this design has a significant drawback - the spontaneous opening of the fastener, if the tongue caught on a branch or twig.

Recently, fasteners began to appear on the sheath - magnetic buttons. They are comfortable, durable and silent.

The sheath may not be present as such. For example, in the sheaths of Finnish knives, the knife is inserted into them to a depth from 1 / 2 to 2 / 3 the length of the handle. It is held in the sheath due to the friction force of the handle against the walls of the sheath. Such sheaths are especially convenient in countries with a cold climate - it is not so easy to unfasten the fastener in the cold. For ease of removal of the knife serves as an exhaust strap / lanyard, or mushroom top, typical of some models of Finnish knives. However, such sheaths are only suitable for knives without a limiter and do not allow the knife to be carried with the handle down.

In the plastic sheath, the shape of which exactly repeats the shape of the blade and handle, the knife is held due to the elasticity of the material, tightly fitting the knife in the area of the limiter. In the simplest sheaths of this type, the knife may thunder when walking. To prevent this deficiency, a special spring element is provided in the sheath, tightly pressing the blade against the walls of the sheath.

Hollow rivets, eyelets, are often found in modern sheaths. They serve for threading the cord, which greatly expands the options for carrying a knife. The same purpose is served by round or oval holes in the plastic sheath.

Fastening a knife on clothing or ammunition

In modern knives, a loop or a special spring metal or plastic clip (clip) is used to fasten the knife on the items of clothing. For combat and tactical knives, the sheath may have special fastening systems that allow the knife to be fixed in various positions on different parts of equipment and ammunition. Of these, systems with the use of synthetic belts or a plastic plate with several holes, to which the kaydex sheath is attached with screws (Tek-Lok system), are most widely used.

Small knives of personal self-defense can be carried around the neck with the help of a chain. Moreover, it does not require high tensile strength - otherwise it can be used by the enemy to strangle the knife owner. For the same reason, replacing the chain with a nylon or nylon cord is not allowed.

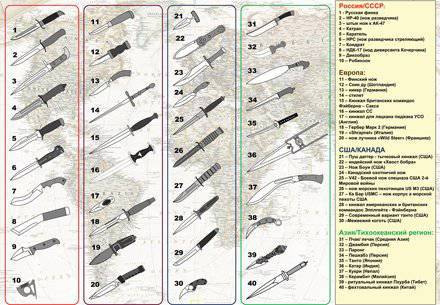

The various combination of the above elements determines the enormous variety of models and types of knives which are folded, the design of which has developed on the basis of centuries of experience in using them in different regions of the globe or as a result of searching for the most optimal designs by knife craftsmen and designers based on the achievements of modern technologies. Some of the known types and models of knives are shown in the figure.

Information