On trophy chassis

The first experiments on the re-equipment of captured self-propelled guns with domestic weapons were conducted at Moscow enterprises at the end of 1941 - the beginning of 1942 of the year. According to the memoirs of A. Klubnev, in early March 1942 of the year, six repaired at Moscow factories StuG III arrived at the 33 Army, where he commanded a platoon of T-60 tanks. Three of them had a staffing short-barreled gun, and three "were armed with guns from the early thirty-four."

About the same machine, “armed with a weapon from a KB tank” and hit by Germans not far from Medyn in the spring of 1942, said P. Minke, who also fought in the 33 army. However, it has not yet been possible to find any documentary evidence of such alteration, nor photographs of such machines. One can only assume that such re-equipment was carried out on individual ACS.

More active work in this area began in April 1942, when the plant director No. 592 of the People's Commissariat of Armaments (NKV) received a letter with the following content:

“Secret.

Chief of the repair department of the Abtu KS Brigadine Engineer Sosenkov.

Cc: Director of the Plant No. 592 Pankratov D. F.

In accordance with the decision taken by the Deputy. The People's Commissar of Defense of the USSR, Lieutenant-General of the tank forces, comrade Fedorenko, on the rearmament of the captured X-NUMX-mm howitzer artifacts with howitzers. 122 of the year at the factory number 1938, I ask you to give the necessary order for the repair and delivery to the factory number 592 of four trophy "artsturms". To speed up all the work, the first repaired "artturm" must be delivered to the factory before April 592. 25 April 13. Chairman of the Technical Council, member of the board of the NKV E.Satel (signature) "

It should be noted here that most of the equipment and workers of Plant No. 592 (the plant was located in Mytishchi near Moscow, now it is Mytishchi Machine-Building Plant) as early as October-November 1941 was evacuated. By February, the enterprise had only 1942 2000 workers and 278 machines, of which 107 required major repairs. The main products of the plant at that time were the manufacture of cases of hand grenades, air bombs, the casting of base plates for mortars and the construction of anti-aircraft armored trains.

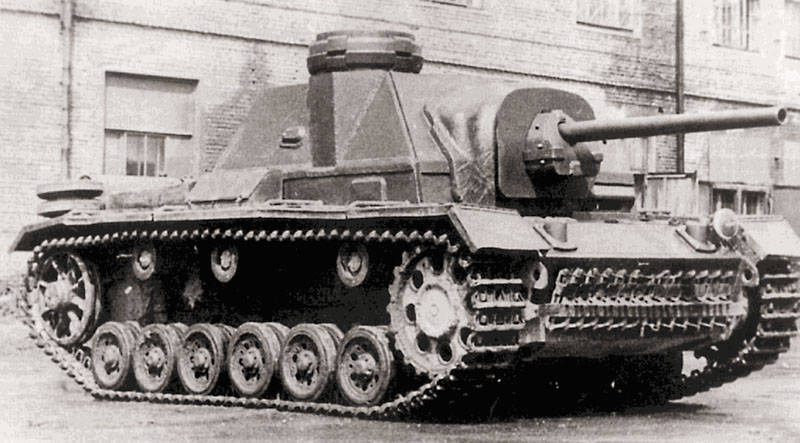

At present, it was not possible to determine the exact date of commencement of the design work on the 122-mm self-propelled howitzer, but on the remaining copies of the drawings there is April 1942. The project carried out by the design team under the supervision of A.Kashtanov was quite simple. As a base for the new machine used German assault gun StuG III with increased military conning. Such an increase in felling allowed the installation of an X-NUMX-mm M-122 howitzer in the fighting compartment. The new ACS has been called the “SG-30” self-propelled assault howitzer “art-storm”, or abbreviated as SG-122А.

According to the description of the prototype, SG-122A was remade from the StuG III assault gun. The conning tower of the assault gun with the dismantled roof was somewhat trimmed in height. On the remaining belt, a simple prismatic box of 45-mm (forehead) and 35 – 25-mm (sides and stern) of armor plates was welded on. For the necessary strength of the horizontal joint, it was reinforced from the outside and from the inside with plates of thickness of the order of 6 – 8 mm.

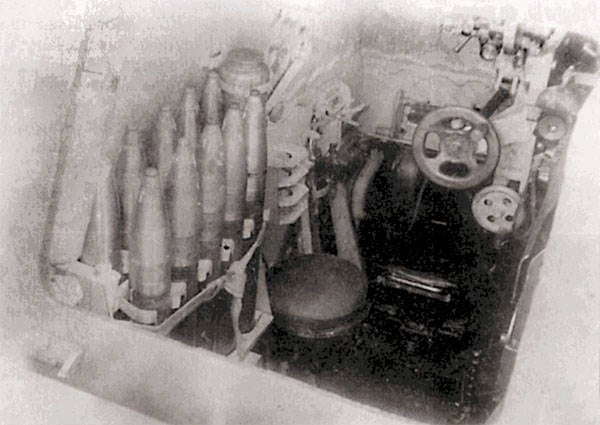

Inside the fighting compartment on the site of the 75-mm gun StuK 37 was mounted a new M-30 howitzer machine, made in the German style. The main howitzer ammunition located on the sides of the ACS, and a few shells of "operational use" - at the bottom behind the howitzer machine.

The crew of SG-122 (A) consisted of five people: a driver (who occupied the place from the left-in front of the conning tower); SAU commander, he gunner horizontally (located behind the driver left side forward); Behind him, the first loader (he is also a radio operator) was also located sideways along the machine; opposite the commander of the ACS, the gunner was positioned vertically along the vehicle’s right shoulder (the M-30 howitzer had a separate tip); behind him the second loader also stood with his right shoulder forward.

For the entrance and exit of the crew in the car there were two hatches. The main one was located in the aft of the cabin, and the reserve was located in the inclined part of the frontal armor of the cabin before the gunner vertically. For communication in the car was left a full-time German radio station.

Due to the lack of necessary equipment, materials and lack of personnel, the first sample of the howitzer was tested by mileage (480 kilometers) and shooting (66 shots) only in September 1942 of the year. The tests confirmed the high combat capabilities of SG-122А, however, they also revealed a large number of shortcomings: inadequate maneuverability on soft ground and a large load on the front support rollers, a large load on the SAU commander, a small power reserve, the inability to fire from personal weapons through airborne embrasures due to their unsuccessful location, fast gassedness of the crew compartment due to the absence of a fan.

The plant was ordered to manufacture a new version of the self-propelled howitzer, taking into account the elimination of the noted deficiencies. It was also recommended to develop a version of the conning tower for installing it on the PzKpfw III tank, the running gear of which was larger than the running gear of the assault guns.

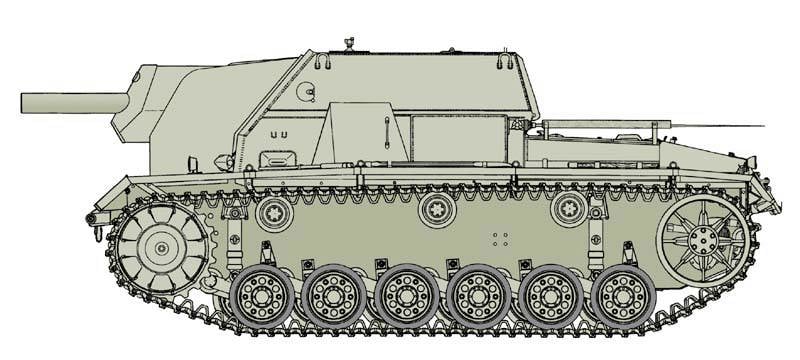

After revision of the project, Plant No. 592 produced two improved versions of SG-122, which differed in the type of chassis used (assault gun and PzKpfw III tank), which had a number of differences from the prototype.

So, the cabin was welded from thinner 35-mm (forehead) and 25-mm (side and stern) sheets. This allowed to slightly reduce the weight of the machine and slightly improve its throughput. The “staff list” of the crew of SG-122 was changed: now the gunner on the vertical, who received his own sunroof in the cabin, became the SAU commander. In addition, to review the area, the commander received an artillery reconnaissance periscope, which could be advanced in a special glass.

Airborne embrasures for firing personal weapons were redesigned. Now it was possible to fire through them not only from the "revolver", but even from the TT and the PCA, since the diameter of the opening of the embrasure was much larger than before.

The gun mount was lightened, and to facilitate loading, the gun was equipped with a folding tray. An electric exhaust fan was installed in the roof of the cabin.

In order to increase the power reserve on box shelves, SAU placed box-shaped fuel tanks from BT and T-34 tanks, while reducing the portable spare parts and entrenching tools.

Specially commissioned by plant No. 592 for SG-122, the “improved” Uralmashzavod (UZTM) developed and cast the armor of the gun, which was better adapted for serial production than the previous one, and also better protected from bullets and shrapnel. This made it possible to dispense with bulky side shields, which made it difficult to maintain the machine and increase the load on the front support rollers.

According to the report of the plant number 592 for 1942, a total of ten SG-122 were manufactured for the year (with the 63 plan for the year), one on the T-3 chassis and the rest on the StuG III chassis. By November 15 1942, at the artillery range near Sverdlovsk, there were five SG-122. One of the two SG-122 "improved" - on the chassis of the tank PzKpfw III - 5 December was delivered to the Gorokhovetsky landfill for comparative State tests with the U-35 (future SU-122) Uralmashzavod construction.

The order for 1943-mm self-propelled howitzers for plant No. 122 assumed for 592 was canceled, and 11 February 1943 for all SG-122 stored at the plant, by order of the NKV were placed at the disposal of the chief of the armored control for the formation of training tank-propelled divisions.

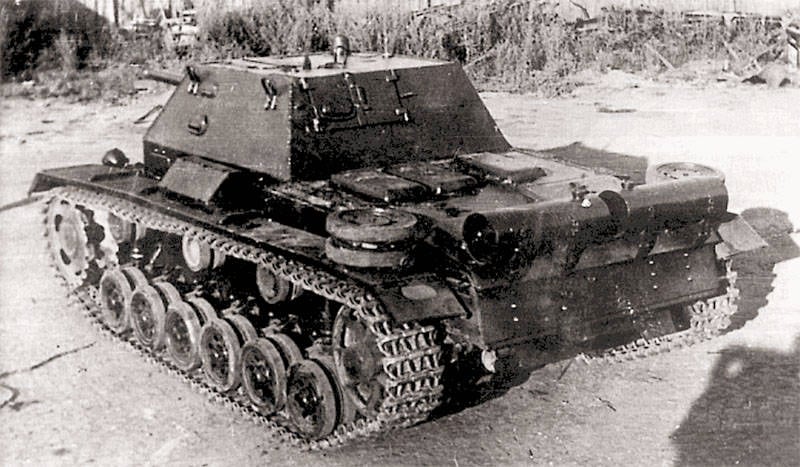

More mass became another ACS on the trophy chassis - SU-76I. History its appearance is as follows.

In January – February, 1943 began to occur massive transmission accidents, adopted by the SU-76 (SU-12). The cause of these accidents was the parallel installation of two twin engines operating on a common shaft, which led to the emergence of resonant torsional vibrations. The defect was considered structural, and its elimination required a lot of time. Thus, in February 1943, most of the SU-76 (SU-12) required repair and could not be used for combat. The Red Army was devoid of the most needed 76-mm self-propelled divisional guns.

It was urgently necessary to find a temporary solution for the manufacture of self-propelled 76-mm guns for the 1943 summer campaign. And here Kashtanov's proposal to re-equip SG-122 76-mm divisional gun had to be most welcome. In addition, according to reports of captured services, after the end of the Battle of Stalingrad, more than 300 German tanks and self-propelled guns were delivered to the repair enterprises of the People's Commissariat of the Tank Industry (NKTP) and the NKV. The decision to prepare the serial production of assault 76-mm ACS support on the trophy chassis was made on February 3 1943.

The design team of Kashtanov was transferred to Sverdlovsk, on the territory of the evacuated plant No. 37, and by the order of the NKTP was transformed into a design bureau and began to refine the project SG-122. Time was short, as the prototype of the ACS should have been ready for 1 March. Therefore, the drawings of many nodes were already made in hindsight, measuring the prototype.

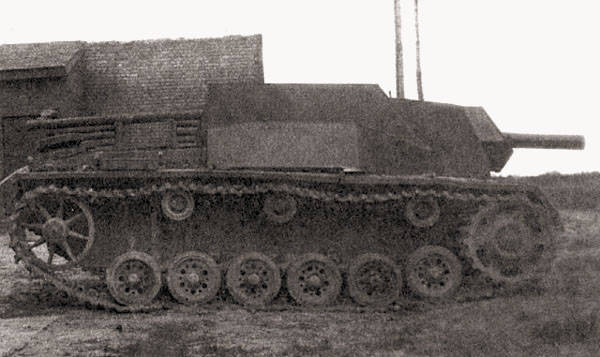

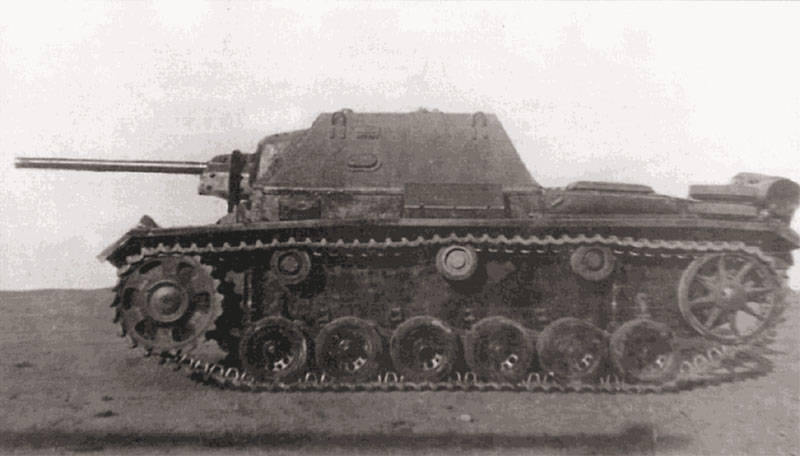

In contrast to the previously manufactured self-propelled howitzers, cutting in the new ACS received inclined sides, which increased their strength. Initially, it was planned to install an 76,2-mm ZIS-3 cannon on a machine fixed to the floor in the combat compartment of the SAU, but this installation did not provide reliable protection of the gun embrasure from bullets and shrapnel, as during lifting and turning the gun in the shield there were always cracks.

But this problem was solved by installing a special self-propelled 76-mm C-76,2 gun instead of the 1-mm divisional gun. This gun was designed based on the design of the F-34 tank gun and was very cheap. It was developed for light experimental self-propelled guns of the GAZ plant. From the F-34, the new gun was distinguished by the presence of a gimbal frame, which allowed it to be installed directly into the front hull sheet and freed up the useful volume in the fighting compartment.

15 February 1943 Head of the Department of the Chief Designer of the NKTP S.Ginzburg reported to the People's Commissar that “... plant No. 37 began manufacturing a prototype 76-mm self-propelled assault cannon C-1 ...” .

The trials were held in the vicinity of Sverdlovsk by mileage on roads and snow virgin lands with a locked and unlocked tool. Despite the severe weather conditions (thaw during the day and frost at night reaching 35 degrees), the car performed well, and 20 in March 1943 was recommended to be adopted by the SU C-1, SU-76 (C -1) or SU-76I ("Foreign").

The first five serial self-propelled guns of 3 on April 1943 were sent to a training self-propelled artillery regiment stationed in the suburbs of Sverdlovsk. During the month of service, the cars “rolled” from 500 to 720 km and assisted in training more than 100 future movers. Reviews about the car were good, and only the difficulty of starting the engine in the cold (for quick start often had to pour hot gasoline into the carburetors) was noted by all the technicians as “a lack of first importance”.

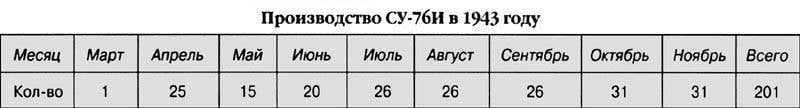

In the meantime, according to the refined drawings, the plant began the production of a “front-line” series from 20 SAU, which for the most part also fell into the training units. Only from May 1943, the SU-76 (C-1) began to arrive in the army.

The first self-propelled guns had a rather “spartan” look. Their conning tower was welded from armor plates with a thickness of 35 mm in the frontal part and 25 mm or 15 mm in the sides and stern. The roof of the cabin was originally cut out of a single sheet and fastened with bolts. This facilitated access to the combat compartment of the self-propelled guns for repairs, but after the battles of the summer of 1943, on many self-propelled guns, the roof was dismantled to improve habitability.

Since radio stations were in short supply at the beginning of 1943, they were installed on every third car, especially since most SAUs went to training units. But since mid-May, almost every SU-9I (C-76) was supplied with 1-P type radio stations.

At the end of July 1943 of the year, according to the experience of using the SU-76I on the Kursk Bulge, an “armored reflective shield” was installed on the rocking armor of the gun, the purpose of which was to prevent the gun from jamming with small pieces and bullets. At the same time, in order to increase the reserve, self-propelled guns began to be equipped with two external petrol tanks, which were installed along the stern on easy-reset brackets.

Initially, captured PzKpfw III were used as commander vehicles in self-propelled artillery regiments armed with SU-76I. In August, it was decided to manufacture also special commanding self-propelled guns, which were equipped with a PzKpfw III commander's turret and a high-power radio station with reduced ammunition.

The last SU-76I left the factory’s workshops at the end of November 1943. By this time, the shortcomings of the domestic SU-76 were eliminated, and they were shipped in the required amount to the front by two NKTP enterprises (Plant No. 38 in Kirov and GAZ in Gorky). Soviet self-propelled guns were cheaper and lighter than SU-76I, and besides, there were no problems with their supply of spare parts. In total, during the serial production of the SU-76I, 37 ACS was produced at the plant No. 201 (including the 20 “commander”).

Baptism of fire units equipped with SU-76I, received at the Kursk Bulge. It is known that by the beginning of July, the 1943 of the Central Front had a 13 SU-16 on the trophy chassis, and eight such vehicles were lost during defensive battles (three were burned). The Voronezh Front also had a certain number of SU-76Is, but in the report of the front at the beginning of the battles, only the total number of all SAUs with an 76-mm gun (76 pieces) was given.

It is also known that during the attack on the Eagle, the Central Front was reinforced by two self-propelled artillery regiments, one of which also had vehicles on the trophy chassis (16 SU-76I and one tank PzKpfw III).

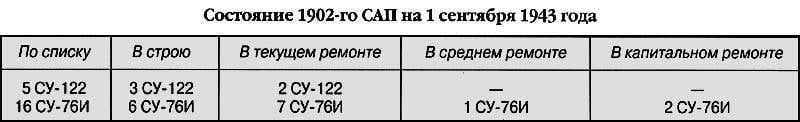

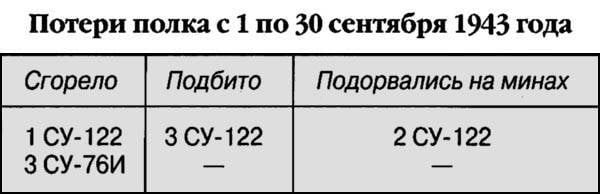

It is reliably known that the 5 th SAP in 2 SU-1943I arrived in the 1902 th August 15 army of the 76. Until 14 August, the regiment was not introduced into battle, but was engaged in repairing the ACS and waited for replenishment by vehicles (initially the number of cars in the SAP was 10% of the regular number). At the same time, five SU-122 were received for the recruiting of the regiment. From 14 to 31, the regiment participated in five battles (on average, there are more battles on 2-3 than any other army regiment). During this period, the self-propelled guns destroyed two tanks, nine guns, 12 machine guns and, up to 250, a man of soldiers and officers. According to the report of the regiment commander from 1 September, “all vehicles in previous battles are damaged. Individual machines were restored several times, the entire materiel SU-76 (based on T-3) is worn out and is in poor condition.

The regiment was constantly understaffed, the training of personnel was satisfactory. ”

In September 1943, the regiment participated in 14 battles, which were simultaneously introduced from two to seven SPGs. The fire of self-propelled units provided substantial assistance to the infantry in repelling enemy attacks.

The most effective battles took place during 20 – 23 September of 1943, while pursuing a retreating enemy, when a group of six SU-76I destroyed three enemy tanks.

Usually, during attacks or pursuit of an enemy, the SAU would immediately follow the tanks, and the SAP commander’s report noted that if “tanks and SAU were used more massively, the regiment’s losses would be significantly reduced.”

The regiment participated in combat operations until the end of November. 25 November 1943, the 1902 th Kremenchug self-propelled artillery regiment, which lost all of its vehicles, departed to re-form its domestic materiel.

In addition to the 1902, SU-76I self-propelled units were equipped with 1901 and 1903 regiments, which were also used in August-September during the Belgorod-Kharkov operation.

In addition, during the Kursk battle in some shelves there were captured self-propelled guns. For example, in 1938 of the SAP 7 of the Guards Army as of 10 in August 1943 there were two SU-122, two SU-76 and two SU-75 (StuG III).

Self-propellers loved SU-76I for the fact that, given the presence of a closed combat compartment, it was not as close as SU-85, or captured StuG 40. Often they had to perform typical "tank" tasks - supporting and escorting infantry, fighting enemy firing points. And only the presence of one hatch (and in the 1943 of the German chassis with onboard "hatches" almost did not exist) made it difficult to evacuate from the SU-76I in case of its fire.

A curious testimony of the SU-76I is in the intelligence documents of the German units. Thus, on October 25 1943, the headquarters of the Wehrmacht’s 1 tank army sent the Abwehr Army Intelligence Agency to the Foreign Armies-East Directorate report: “In the 177 tank regiment of the 64 mechanized brigade (it was part of 7- go to the mechanized corps of the Red Army. - Approx. avt.) there are four companies of 11 tanks in each. These tanks are designated Sturmgeschuts 76mm. They are made on the chassis of the German tank Panzer III with a Maybach engine. The new wheelhouse has armor thickness in the frontal part of the 3-4 cm, on the sides - 1-1,5 see. The wheelhouse is open at the top. The gun has angles of horizontal pickup 15 degrees in each direction and vertical pickup - plus or minus 7 degrees. "

It is not quite clear what this is about - after all, the SAUs could not be part of the tank regiment of the Red Army Mehbrigade, and even in such numbers - 44 machines. Most likely, this is a question of a self-propelled artillery regiment attached to a mechanized brigade (in this case, the number of self-propelled guns is doubled). An interesting fact is that SU-76I (and it’s about the document that we are talking about) does not have a roof. Apparently, they were dismantled to improve the actions of the crews.

In August, an attempt was made at A. Kashtanov's design office 1943 to strengthen the SU-76I armament. 14 September, Chief Engineer of Plant No. 37 received a letter from the head of the technical department of the NKTP Frezerov: “The project you developed for installing the 85-mm D-5-C-85 cannon on the T-3 base (SU-85I) is currently not being implemented. may be due to the lack of a sufficient number of guns D-5 and the ambiguity of the issue with the further delivery of T-3 tanks.

I consider it expedient to temporarily stop this development, retaining the developed material for possible future use. ” This project ended the development of domestic ACS on captured chassis.

At the beginning of 1944, an order was issued by the head of the GABTU Fedorenko to transfer all SU-76Is from combat units to training units and to replace them with SU-76М.

In the training units, these combat vehicles met until the end of 1945, after which they were put in for scrap metal. In Kubinka, the existing model SU-76I existed for a rather long time and was written off in 1968.

A single specimen of SU-76I has survived to this day. Almost 30 years he lay on the bottom of the river Sluch, then was raised and installed as a monument in the city of Sarny, Rivne region in Ukraine, where it is still.

Information