Main T-80UD tank (Birch 478B Object)

MAIN TANK T-80UD (478B BIRCH'S OBJECT)

Work on the tank "Object 478 ″ in the HCBM them. A.A. Morozov began in the mid-1970s with the aim of improving the combat and technical characteristics of the T-80 tank and installing a diesel engine on it. It was supposed to establish a new turret, tested on tank 476. Two basic versions of the tank were designed - object 478, which differed in the installation of various types of diesel engines. As a result of long work on the machine, it was created and in 1987 the main tank T-80UD (object 478B) was adopted.

The project to improve the tank "object 478" was made KMBM them. A. Morozov in 1976 year, he received the designation - "478 object". The tank was supposed to use the Tent active protection complex, which defends the sector at the rate of 200 degrees, the number of cluster shots - 20 pcs, the probability of hitting projectiles - 0,7-0,8.

Works on the tank "object 478B" "Birch" were started KMDB them. A.A.Morozova (General Designer I.L.Protopopov) in the middle of 1970-ies (object 478) and ended in 1987 with the adoption of the T-80UD tank. As a result, during the creation of the tank, the Reflex guided weapons complex, 1А45 fire control complex, etc. were placed. The series began with the 1985 of the year. Sometimes referred to as T-XNUMHUD (informal name). In 80, the tank was upgraded.

In accordance with the Decision of the CM Commission on military-industrial issues from 21 in January 1977, the development of a more powerful diesel engine 6ТD-2 with a capacity of 1200 hp began in the modernized tanks. With the 1983, the engine began testing on pilot tanks, in 1992, its mass production began.

In 1988, the T-80 tank with the 6TD diesel engine was upgraded. It installed the built-in dynamic protection, finalized weapon systems. At the beginning of the 1990-ies, the tank was preparing for the adoption of the Soviet Army under the symbol - T-84. In the future, the designation T-84 received the next version of the Ukrainian modernization of the T-80UD tank.

During serial production for the Armed Forces of the Soviet Union, 800 T-80UD tanks were launched. After the collapse of the USSR, around 50 tanks were produced.

MBT T-80UD was demonstrated and tested in Pakistan in 1993 and 1995 as part of a tender for the supply of a new MBT for this country.

In 1996, Pakistan entered into a contract with Ukraine for the supply of 320 T-80UD. The first batch (15 machines) was delivered at the beginning of 1997, and in 1999, the contract was successfully completed.

From October 1996, Ukraine began shipping T-80UD tanks (478BE object, tank variant with new structural elements from the T-84 tank, including a welded turret of new design) to Pakistan, the total volume of the contract includes 320 machines. Until June, 1997 was supplied to 50 tanks, they were moved and modernized old, and the rest were made again. Tanks that have been upgraded with a cast turret, received an index "478BE", and again made with welded-rolled tower - "478BE-1".

Many systems and T-84 units, including a new welded-rolled tower, etc. were introduced into the machines of the last installments.

The main armament of these tanks is the 125-mm QA3 smoothbore gun (the 2A46М1 gun was installed in the USSR and Russia), charged with a conveyor-type automatic loader. The gun is equipped with an ejector of powder gases and a thermocasing. The barrel of the gun is quick-detachable and can be replaced in field conditions without dismantling the gun from the tank.

Ammunition for the gun is 45 shots of separate loading (projectile and charge), of which 28 are placed in the conveyor of the automatic loader, and the rest are in the control section and in the fighting compartment. Used ammunition: armor-piercing-sabot, cumulative, high-explosive fragmentation and missiles, controlled by a laser beam.

A feature of the tank is the presence of guided weapons, which allows firing from a cannon guided missiles with laser guidance at ranges up to 5000 m. The rocket consists of two parts. The first part includes a throwing device and a hardware compartment with a steering device. The second part consists of a main engine and a combat unit of tandem action. Both parts are stored in the conveyor automatic loader as well as conventional ammunition. Docking two parts of the rocket occurs in the barrel when fired.

The T-80UD is equipped with a modern fire control system, which provides firing by the gunner and commander at fixed and moving targets, both in motion and in motion, with a high probability of hitting the first shot.

The fire control system consists of the 1Г46 gunner sightsight, TO1-C1E gunner's night complex, PNK-4C commander-in-command complex, ZNG-7, zenith sight, 1CXXXXXXXXXXXXXXXXXXXXXXXXXX, XUXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXP 29EX1 and other devices.

The gunner's day sight 1Г46 has a line of sight stabilized in two planes, an integrated laser range finder and a guided missile control channel.

With a standard tank configuration, the gunner installed a TO1-KO1E night aiming complex with a TPN-4E sight (with an electron-optical converter), however, it is possible to install a Buran-Katrin-E thermal sight.

The sighting and observation complex of the commander PNK-4С consists of the combined day-night sight of the commander TKN-4С and the gun position sensor.

The commander's TKN-4C combined sight is stabilized in a vertical plane and has three channels: a daytime single channel, a daytime multiple channel with a magnification factor of 8x and a night channel with a magnification of 5,4x. The commander can switch from the day channel to the night channel (with the electron-optical converter) and back with the help of the lever.

The anti-aircraft sight allows the commander to fire at aerial targets from an anti-aircraft machine gun, while being protected by the turret armor.

The 1B528-1 ballistic computer for calculating ballistic corrections automatically takes into account signals from the following sensors: tank speed, target angular velocity, roll angle of the gun axle axle, transverse component of wind speed, distance to the target, heading angle. Additionally, the following parameters are manually entered for the calculation: ambient air temperature, charge temperature, barrel bore wear, ambient air pressure, etc. The calculator also calculates the time point of the explosion of the high-explosive fragmentation projectile over the target.

The so-called “shot clearance zone” is provided in the fire control complex, i.e. after pressing the firing button, the shot will occur only if the mismatch of the line of sight and the axis of the bore does not exceed the specified value. The size of the “shot clearance zone” is adjusted when setting up a fire control system as part of a tank.

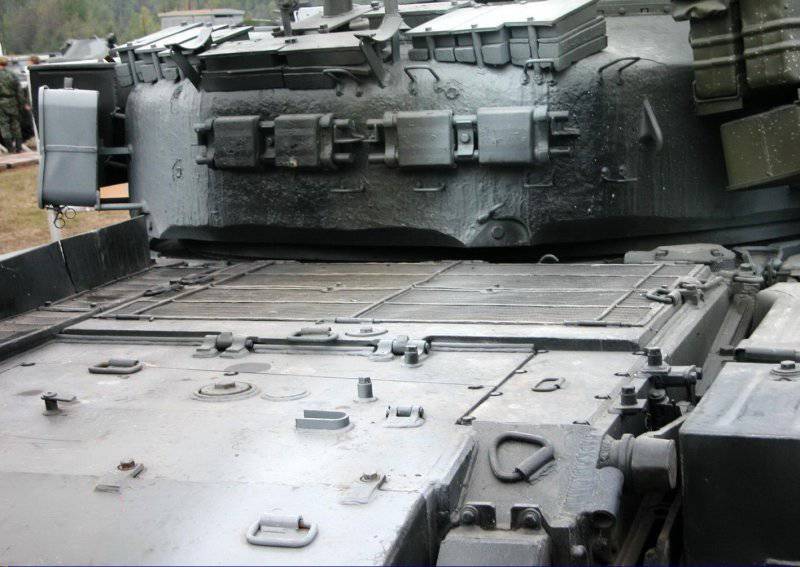

The T-80UD armor protection, which includes modern multi-layered armor and a set of built-in dynamic protection mounted on the tower and the hull, provides the tank with a high level of survivability on the battlefield.

The T-80UD tank can hide its location on the battlefield by setting a smoke or aerosol curtain. On the sides of the tower installed four launchers smoke grenades, which are driven electrically.

T-80UD can also install a smoke screen by injecting diesel into the engine exhaust system (i.e. using so-called thermal smoke equipment).

In order to reduce the visibility of the tank on the battlefield, the roof of the engine compartment T-80UD is equipped with special thermal protection.

On the main battle tank T-80UD installed 6-cylinder diesel engine 6TD-1 1000 hp power.

The engine air intake device provides air to the engine from the least dusty point of the tank. In addition, the air intake device allows the tank to overcome water obstacles to a depth of 1,8 m without training.

The air cleaning system consists of two main components: centrifugal pre-filters and an air cleaner cartridge. The system allows you to operate the tank in hot and dusty conditions in the amount of 1000-kilometer run without the need to change the filters, as well as in conditions of radioactive contamination.

Suspension - torsion. On each side of the hull - six double rubberized road wheels. The guide wheel is located in the forward part of the hull, the drive wheel is in the aft one. There are also supporting videos.

The upper part of the suspension is protected by side screens, which are armored in the forward part of the hull (with built-in dynamic protection).

A rubber screen is fixed at the bottom of the body to keep dust from spreading.

The standard equipment of the main battle tank T-80UD also includes a collective protection system, equipment for underwater driving, an explosion and fire suppression system, radiation protection (slaughter) and self-digging equipment (located on the lower inclined sheet of the aft hull).

The collective protection system provides protection for the crew and the internal equipment of the tank against the effects of nuclear explosions, radioactive dust, poisonous and bacteriological substances.

Underwater driving equipment allows the tank to overcome water obstacles to a depth of 5 m (water obstacles to a depth of 1,8 m, the T-80UD tank overcomes without preparation).

Fire extinguishing system provides detection and extinguishing of internal fires in the habitable compartment, as well as in the engine-transmission compartment.

Anti-radiation protection is designed as a tamping on the internal and external surfaces of the tank.

Self-digging equipment allows you to dig a tank caponier for 15-40 minutes, depending on the type of soil.

The main battle tank T-80UD can be equipped with various types of mine trawls (connected to the hull nose), including the KMT-6 knife-type mine trawl and the KMT-7 roller-type mine trawl. At the stern of the hull, two barrels with additional fuel can be mounted, as well as a log for tank self-pulling.

Today it is no secret that in the USSR after the Second World War there were excess capacities for the creation and production of tanks. This gave rise to a fierce competition between the three design bureaus - the developers - in Kharkov, Nizhny Tagil and Leningrad - for the right to supply their products to the armament.

This struggle was particularly aggravated in 1970-1980-s, and the experience gained then came in handy when several tender tests concluded a contract for the supply of a large batch of T-1997UD tanks from 80 to Pakistan. By this time all its components had been mastered in production, with the exception of the tank gun.

However, the customer’s demand - independence of supplies from third countries and statements by individual politicians forced them to speed up the organization of production of barrels at Sumy NPO Frunze, and the breech - at the Plant. Malysheva. As a result, in 1998, the development of the gun and the organization of its production were completed.

Currently, T-XNUMHUD tanks have improved armor protection, an improved fire control system. The tank can be operated at temperatures from -80 to + 40 degrees C.

On the basis of the T-XNUMHUD tank created:

commander tank T-XNUMHUDK;

Experimental object 478D with a Buran-E night-time TPN-4 surveillance device and the Anet system of high-explosive fragmentation projectiles, which undermine them at a given point; Experimental objects 478BK with a welded turret, manufactured three cars;

Experienced tanks - 478DU and 478DU2 objects with various types of running gear (with steel and rubber-coated rollers).

Currently T-80UD is in service with Ukraine, Russia and Pakistan.

After the collapse of the USSR, work on the further improvement of technology based on 478D was already indicated with the prefix "U". The “478DU object” (T-84) is similar to the “478D” tank, but has a T-64 undercarriage. Passed the test, made one copy.

In the "object 478DU2" compared with "478D" there was no auxiliary power unit and a new welded-rolled tower was installed. On the tower, the new built-in dynamic protection (VDZ), changed the installation of smoke grenades. Made a prototype, was tested. Not commercially available.

“The 478D4 object” was different from the “DXXUMX” by installing a new auxiliary power unit on the left fender. On the case - a new dynamic protection.

"Object 478DU5" participated in the early stages of testing in the Turkish tender. In contrast to the "DU4" there is air conditioning at the stern of the tower. Ankara’s demands were very tough, especially in terms of armament. It required the installation of 120-mm guns under NATO standard shells.

In a short time, the “478Н object” was developed, which received its own name “Yatagan”, with the required artillery installation and a new tape automatic loader on the 22 shot, located in the “fat tail” behind the stern of the tower. The remaining shells were placed in a mechanized packing in the body. One prototype was built, which passed the second stage of the tender in Turkey. According to the results of the competition, the documentation on the tank was finalized and prepared for serial production under the symbol “478Н1”.

Especially for the tender in Malaysia, the “object 478DU8” was made, taking into account the specifics of the region - the caterpillar is expanded to 600 millimeters.

The “478DU9” object (tank “Oplot”) was tested and adopted by the army of Ukraine, a series of ten vehicles was made in 2001 year. A new commander's sight with a laser rangefinder and the Ainet system are used.

The main battle tank Oplot was developed on the basis of the T-XNUMHUD, but differs from it in a number of improvements, namely:

- new welded-rolled tower

- built-in dynamic protection of the new generation, providing increased security in the anterior sector from both cumulative and armor-piercing projectiles

- thermal sight

- 6TD-2 engine with 1200 horsepower instead of the 1000-strong engine mounted on the T-XNUMHUD

- transition to digital technology in relation to the components of the fire control complex and related systems

- a complex of optical-electronic countermeasures

- auxiliary power unit

- accounting system for bending the bore

- navigation support system

- wider side screens that provide additional protection for the hull sides and undercarriage components against short-range anti-tank weapons used by enemy infantry.

By order of the US Army, four 478BEM-1 tanks were manufactured for four vehicles with the installation of the Drozd-1 active protection system (KAZ) and an auxiliary power unit (APU) on the left flank shelf and one 478BEM-2 tank with air conditioning at the stern of the tower and the APU on the left flank shelf.

28 May 2009, the tank "Oplot-M" - "an object 478DU10" was adopted by the army of Ukraine.

It is possible to supply the following main auxiliary machines, providing logistics for the T-80UD tank during its service life:

- armored repair and recovery vehicle (based on chassis T-80UD)

- armored bridge laying (based on the chassis of the tank Oplot)

- tracked conveyor capable of carrying 12 tons of cargo (its main components are similar to the components of the T-80UD)

various mobile workshops for servicing the tank (based on off-road vehicles)

The product "478BP" - an armored repair and recovery vehicle BRET "Atlet" is made on the basis of the chassis nodes of the tank "Oplot", which provides the car with comparable dynamic and mobile characteristics, the necessary level of protection and permeability. "Athlete" is designed to solve a wide range of technical support for tank units when they conduct all types of combat operations in various weather and climatic conditions: conducting technical reconnaissance on the battlefield day and night, towing defective and damaged armored vehicles to the nearest shelters and prefabricated points of damaged cars (SPPM), start of engines of serviced cars by electric and pneumatic methods, assist crews in carrying out maintenance, carrying out cargo opodemnyh work, pulling stuck and sunken samples of armored vehicles in all kinds of jams, crossing water obstacles along the bottom, entrenching, performing welding and cutting work, digging at the equipment SPPM, entrances and exits.

The product “478BM” is the MTU-84 bridge laying machine, the documentation for which was developed, but the prototype was not built.

Condition entered service in 1985

Developer KMDB them. A.A. Morozova

Manufacturer HZTM

Production series from 1985 to 1988

Combat weight, t 46

Dry weight, t 43

Length, mm:

- with gun forward 9664

- cases 7085

Width, mm 3589

Roof height

towers, mm 2285

Clearance, mm 515

Wed. beats. pressure on

soil, kg/cm2 0,93

Obstacle obstacles:

- rise, hail 32

- roll, degree 20

- ditch, m 2,85

- wall, m 1,0

- ford, m 1,8 (with OPVT -5)

Engine type diesel 6TD

- manufacturer of software "Plant im. Malyshev"

Maximum

horsepower 1000

Fuel reserve, l 740+560

Power density,

hp/t 21,7

Maximum speed

km/h 60

Power reserve, km 560

Reservation anti-cannon,

combined with hinged dynamic protection "Contact"

Staging Tools

smoke curtain TDA, 8x902B

Crew, people. 3

Armament:

- number x caliber, mm and type of gun 125 mm 2A46M1

(ammunition, pcs.) (45)

- number x caliber, mm and type of machine guns 12,7 mm NSVT

(ammunition, pcs.) (450)

- number x caliber, mm and type of machine guns 7,62 mm PKT

(ammunition, pcs.) (1250)

Rangefinder sight 1G46

Night Scope:

Type active-passive TPN-4 "Buran-PA"

- developer Krasnogorsk plant them. S.A. Zvereva

Manufacturer ROMZ

Target identification range, m up to 3000

Field of view angle, deg. 4 x 2,7

Magnification, fold. up to 11

Fire control complex 1A45

Control complex. armed 9K119

Navigation equipment GPC-59

Armament stabilizer 2E42

Radio station R-173

Information