Lapti for T-34

True, in recent times, according to the nomenclature of questions, the practices do not lag behind them, that they constantly “chew on plastic”, sawing and gluing together some products, which is thirty five times smaller than the original. Their questions, of course, are somewhat more specific and not so intricate in style as the “theorists”, but often much more complicated due to the lack of factual material.

Well, since both of them are actively interested in T-34, it is not hard to guess that most of the questions asked by everyone relate specifically to this combat vehicle. There are so many questions that it is time to open a special section, something like Club T-34 {in the manner of “airfield equipment of the forties” that Kolya Polikarpov led in M-Habbi, okzhe - Uncle Poe ”). And keep this heading in some or periodicals all subsequent years.

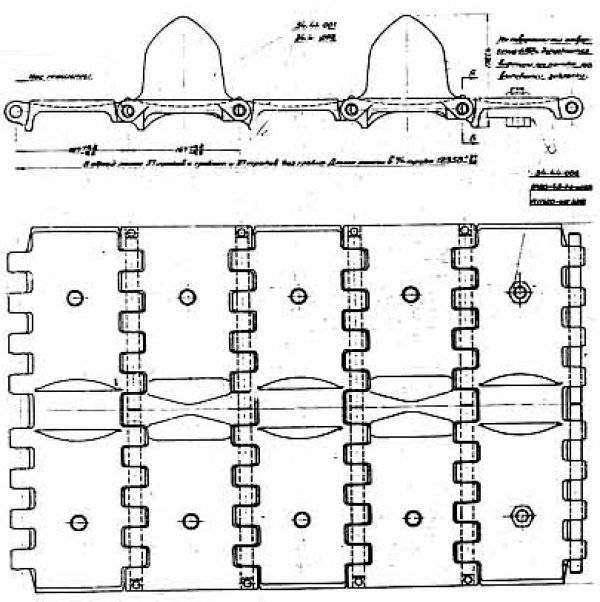

TODAY I WANT TO Talk with us about the T-34 tracks that were made and used during the YEARS of war. Immediately make a reservation - the article will focus only on those tracks that were officially adopted by the orders of the NKTP in those years. I couldn’t get the drawings for the T-34 tracks of all the varieties and therefore I bring only the drawings recovered from the photos.

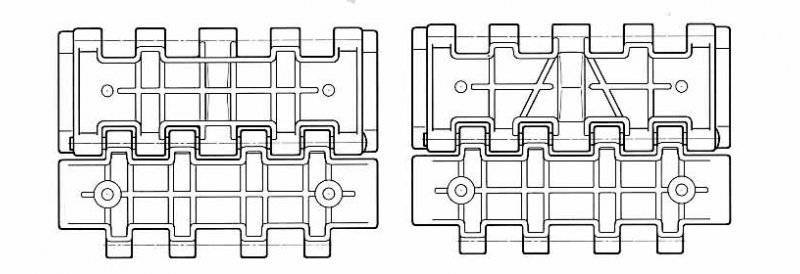

Initially, the T-34 tracks were similar in design to the tracks of their predecessors - BT-7 - L-20 and only slightly differed from them. They had a width of 550 mm (by no means 500, as some foreign authors write) and consisted of a stamped base with grouser on the front side and a curved working surface on the wrong side. Workers had a comb to engage the drive wheel, which was originally welded to a stamped “shoe”. Between themselves, the tracks were connected by two half-fingers, which were fixed in their sockets with screws (since the fall of 1940, split pins, or wedges). The front side of the track between the lugs was smooth, which led to poor tank maneuverability in mud and snow, but compared to T-26 tracks, for example. What was considered normal for a ten-five-pat-ton machine didn’t fit nearly twice as hard.

The lack of efficiency of tracks on soft and muddy soils, as well as on ice and snow, was supposed to be compensated by installing additional spurs on them. In accordance with the order of the People's Commissar, a smooth stamped truck with a welded comb was adopted for gross production in March, 1940 g, and was almost unchanged at the KTP until autumn. They managed to “rivet” them quite a lot and a large number of them in the form of finished products or semi-finished products were taken out during the evacuation of PA Vostok to Nizhny Tagil and Chelyabinsk.

This happened because, since September 1940, an order for the People's Commissariat for T-34 introduced a truck with a more developed working surface and a modified spur. And since the smooth tracks that had already been produced were not subject to refinement, they stamped their stamped shoes, in order to send it back to processing. Autumn stocks accumulated in this way were sold in 1942, when “smooth” trucks, under conditions of a total shortage of spare parts, were sent to the front in repair divisions with the permission of the Commissar.

In October-November, 1940, instead of a track with a welded comb, went into production an all-stamped truck, designed specifically for mass production at the Mariupol plant, and later on a solid-cast truck. Outwardly, the truck almost completely repeated its predecessor, but was simpler and more tenacious to break. However, it was not made for long, as soon, due to the lack of press equipment, it was replaced by cast everywhere.

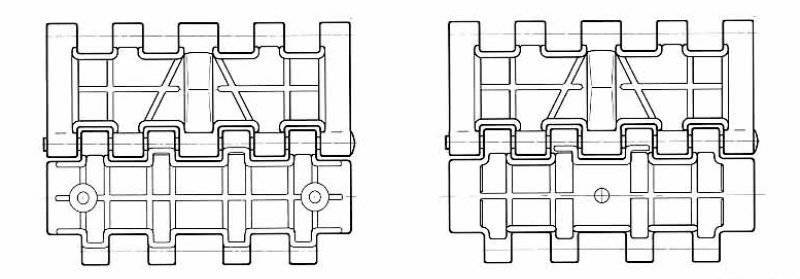

For the first time, a cast truck for the T-34 was introduced into production as early as September 1940. Since the cast parts were less durable. It had a tendency to break, the shape of the track was slightly modified. First, on 3-5 (up to 8) mm, but compared to stamped tracks, its thickness was increased and on 8-15 mm - the height of the grouser. In the central part of the working truck (where there was a depression from the ridge), to prevent freezing in the depression in the winter time: “cones” of snow and ice, as well as for better adhesion with the soil, a small comb of two additional teeth was added. In this form, trucks went to a limited extent on T-34 tanks of the one-and-a-half series (from October 1940) and the second series (from the middle of December 1940). Most of the cast tracks were used to complete the machines manufactured by the Stalingrad Tractor Plant (STZ), as there were not enough dies in Stalingrad before and they had first mastered their castings. The 194 cast iron crayons (1 g) were very good and differed from the stamped ones, mainly by their greater mass and rougher surface.

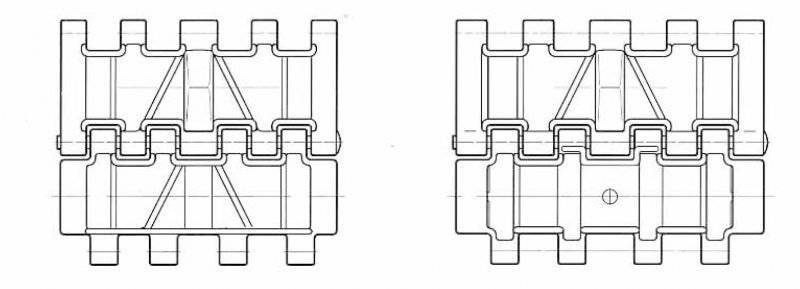

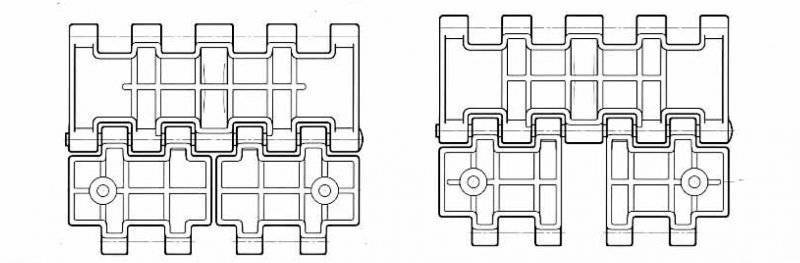

Design work and preparation for mass production of the A-43 sneaker (T-34 of major modernization) carried out in spring 1941, led to the fact that the tracks of the latter, having a width of 450 mm (instead of 550 mm in T-34), tested on T -34, showed good efficiency, and to the surprise of the military, the real traversal of the sneaker with the use of narrower caterpillars almost did not decrease.

Truck A-43 had a developed bearing surface, greater tensile strength and a much smaller mass. In addition, it was noted that the designs of the track chains of the second variant (they used one finger fastened with a linch pin to connect with their fellows) are much more successful than those of the T-34 from the point of view of their combat operation. The release of A-43 tracks began at XTZ from the end of April 1941 and lasted until the end of the summer (almost before the evacuation began).

In the summer of 1941, a model X-NUMX-mm track A-450 was created and an 43-mm track was produced for the T-500. According to the beginning of the evacuation, the hundred production in Kharkov stopped, but, being restored at the Kulebaki plant, it lasted until the spring of 34.

Since during the war 550-mm tracks for the T-34 were not enough, and for the undeveloped A-43 tank there were quite a lot of them in the warehouses, 17 September 1941 of the tank industry ordered the acquisition of T-34 450-mm tracks tank A-43 (T 34m), and these tracks “survived” in the troops at least until the winter 1941-42, since in February 1942 g, in correspondence on the NKTP passes the order to introduce “road access plates to improve tank maneuverability” T-34. equipped 450 and 500-mm tracks. " The “tiles” or “tiles” were trough-shaped expanders, attached to single tracks using spur installations (two bolts), increasing the width of the track bearing surface to 600-680 mm.

However, the use of plits on a tank weighing more than 30 t. Turned out to be disadvantageous. The plates broke down and were not as effective as on light T-60 tanks. Therefore, they were soon abandoned to release and use, and the tracks were widened in the snow and liquid mud as follows (1942 / 43 gt recommended by the People's Commissariat in winter); The idle track was shifted out half the width, and the resulting gap was closed with a half of the track | with the introduction of “split tracks” such halves could be found without problems). At the same time, the efficiency of the caterpillar on the snow and liquid mud increased without complicating the design of the track.

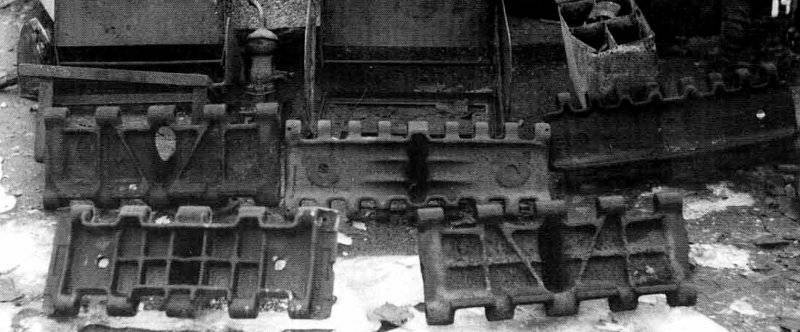

Today, pi is not a secret for anyone; that in 1941-42. T-34 tanks were released quite a lot, but few people know that their shipment to the front was delayed, including due to an acute shortage of tracks. 11, for example, in the 2 quarter of February, the 1942 of the UTZ in Nizhny Tagil was able to handle all 68% of the total number of tanks produced, since the rest were "loose". This led to the fact that the production of trucks were abandoned all more or less suitable enterprises. It would seem - here it is, the output, the result was deplorable. Up to half of the tracks supplied by non-core enterprises turned out to be unsuitable for operation due to numerous violations of the technological process. Trucks burst, fingers were deformed and torn, trucks from different manufacturers stubbornly "did not want" to dock with each other, although they seemed to be produced according to uniform drawings (by the way, similar "parsley" was observed at that time with the tracks of the T-60 tank).

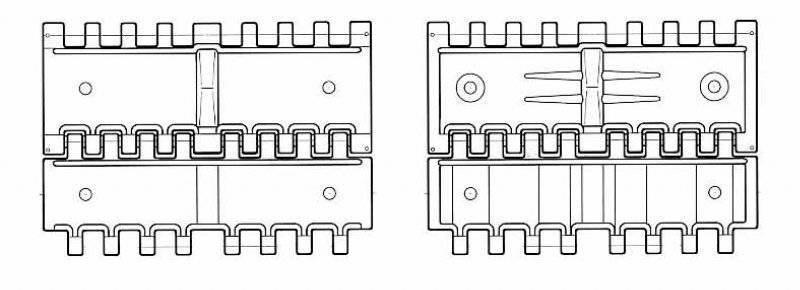

From January to the end of March 1942, the problem of trucks was handled by the service of the Chief Designer of NKTP under the leadership of S.A. Ginzburg. Joint efforts of WGC NKTP with engineers and technologists of the Mariupol Plant them. Ilyich, the former Kharkov Tractor Plant and the Chelyabinsk Kirovsky, developed two new types of cast tracks, for the production of which high-alloyed deficient steel was not required. In addition to the design of the truck, the technology of casting it by the group method was also developed (like composing tracks in modern plastic models). It is difficult to overestimate, because before each track could be cast only in individual molds (or in pairs).

The track bearing surface was grooved according to the Type used on the PzKpwi 111 tanks, KV. T-50 and A-43, This led to greater track strength with mail and unchanged weight (the track received many stiffeners) and better traction between the track and the soil. Despite the fact that initially the new truck was designed with a width of 550 mm, its weight was considered redundant (T-34 was already “pulled” on 3 (1 tons, against 25 tons calculated) and the second version of the track was narrowed in production before 500 mm From the spring-summer of 1942, the 500-mm track with a grooved "waffle" surface was accepted for mass production by all manufacturers, although some enterprises produced it earlier.

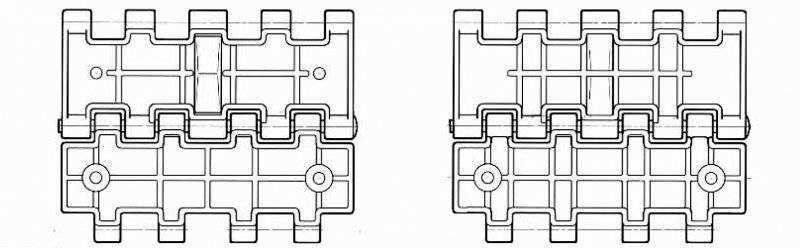

In the autumn of 1942, Uralmashzavod, which had connected to the release of the T-34, had a good furnace-pressing and press equipment, developed its own design of a single track manufactured by a tampon. This truck was called “split”, as it consisted of two half-races, between which there was a gap. However, the tanks with these tanks were almost not fully equipped at first, since by the time of its mass development (April-May 1943), the UZTM was completely switched to the production of S and U. So most of these "early split" tracks went to self-propelled SU-122 and SU-85 installations. And only the “late split” truck, used in the production of the SU-85, went to the tanks as well.

Further development of the T-34 truck was made at the 174 plant in Omsk. It was here that he was brought to its logical end. The same enterprise with 1943 G. becomes the leader in the production of tracks for T-34 and SAU on its base. Truck tracks of the Omsk plant are the highest quality and mass. Omsk plant also owns the honor of working out an improved finger for connecting tracks not only for T-34 and ACS on their base, but also for other tanks. Starting in the autumn of 1943, some small enterprises that manufactured tracks for T-34, are exempt from the given type of products.

The last design change of the T-34 tracks was made at the beginning of 1945, which would unify them in the T-34 and T-44 tanks.

However, pa photographs of the T-34 tanks of the war are often found tracks, not described in the documentation NKTP. Therefore, this article can not claim the ultimate truth.

In addition, the author asks not to treat images of crayfish as placed here, as to strict large-scale drawings.

Information