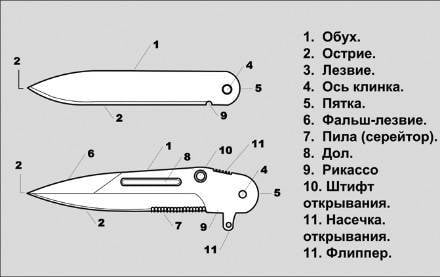

Folding knife anatomy

Blade - the main part of the knife. The cutting and piercing properties of the knife depend on it. The main factors determining the performance of the blade, is the material and technology of its manufacture, as well as its shape and cross section.

The blades of modern folding knives are made of corrosion-resistant steel. On blades of famous manufacturers, the steel grade is often stamped on the blade at the base of the handle. On cheap knives, you can often see the inscription on the blade - “stainless” or “rostfrei”, which means simply “stainless steel”.

Currently, several dozen different grades of steel are used in the knife industry. Since different countries have different standards for the designation of steel grades, the same steel may have different designations. The most common steel grades used to make folding knife blades are shown in the table.

For an inexperienced user, it is enough to take into account the fact that the more expensive the steel is, the longer it keeps the sharpening, but this increases the brittleness of the cutting edge and makes it harder to edit the knife at home.

The quality of the blade is largely influenced by the technology of thermal hardening of steel used by the manufacturer. With proper heat treatment, even relatively cheap types of steel provide good cutting qualities of a knife, and vice versa, even expensive types of steel with flaws in heat treatment will not allow for good quality blade. This is the reason for the high cost of folding knives of well-known manufacturers, who have modern equipment and carefully monitor the quality of the blade.

The hardness of the cutting edge is expressed in units of Rockwell. Usually, the blades of folding knives are hardened to 42 – 60 HRC units. The larger this number is, the more time the knife keeps sharpening, but for this you have to pay less resistance to shock loads and the complexity of sharpening the knife. And, on the contrary, at low HRC values, the cutting edge is more plastic, it is easy to sharpen, but it doesn’t hold up well. As hardness rises above 61 HRC, the blade of knives with a normal butt thickness becomes very fragile. Blade hardened to 42 units and less, it has low strength and it is difficult to cut ordinary materials. On the packaging of knives, this figure is not given. Even when describing a model on the manufacturer’s website, it is not always possible to see it.

When operating the knife, it is necessary to take into account the fact that the blade of the knife is very sensitive to temperature increase. That is why you should not rake the embers of the fire with a knife or use it to sharpen the electric tool for a plumbing or joiner's tool.

The surface of the blade can be polished, brushed, blued, chrome or have a special protective coating.

Polishing increases the resistance of the blade to corrosion, but such a surface glitters in the sun, which is not quite acceptable in tactical knives.

Matting increases the anti-glare properties, but worsens the corrosion resistance of the knife.

When bluing a blade, a thin layer of protective oxide film is created on its surface, and the blade becomes dark in color.

When chrome plating, a thin layer of chromium is applied to the surface of the blade, which prevents corrosion of the blade, but not its cutting edge.

In modern knives, blade coating from synthetic materials (epoxy resins, Teflon), which provide high resistance to moisture or an acid and alkaline environment, is becoming increasingly common. Since this coating prevents the blade from glare in the sun, it is often called "anti-reflective" and is often used for tactical knives. The disadvantage of such coatings is low wear resistance and scratch sensitivity.

Recently, with the cheapening of industrial production of Damascus steel, more and more blades are being produced from it. Damascus steel is produced by forging welding several layers of steel with different carbon contents. As a result, a beautiful pattern appears on the surface of the blade. Modern industrial production of Damascus steels allows you to pre-design the shape of this pattern ("mosaic damask").

The combination of low carbon steel strips providing ductility, and high carbon, providing hardness of the cutting edge, allows you to create blades with excellent performance. In addition, the cutting edge of Damascus steel knives has micro-pliers, which increase the cutting ability of the knife.

Knives with Damascus steel blades look very impressive. However, it should be borne in mind that the risk of obtaining a defective blade of Damascus steel is significantly higher than when purchasing a knife with a conventional steel blade. This is due to the rather complex technology of manufacturing such steel.

Doy, which are often called blood vessels, are longitudinal notches along the axis of the blade and serve to facilitate the weight of the blade. At the same time, they increase the rigidity of the blade in the transverse direction. Sometimes they are cutouts.

Ricasso - the not sharpened part of the blade at the handle serves for convenience of sharpening the knife.

False Blade It came from combat knives with a fixed blade, having a one-and-a-half sharpening.

In folding knives used a variety of forms of blades.

For normal household operations, knives with a straight blade or a blade converging to the tip are preferred.

The disadvantage of the classical form of the blade is its lower strength at the tip, since the thickness of the blade gradually decreases to the tip. From this lack of free blades in the form of "tantто" or "modified tant". At the beginning of this century, a special blade form with a reinforced point began to be applied first on knives with a fixed blade, and then on folding knives.

If the knife requires increased cutting properties (knives for self-defense), blades with a blade having a convex or wavy shape are used. At the end of the past - the beginning of this century, knives with a sickle blade, which is characteristic of Malaysian kerambit, came into vogue. Such a blade does not cut, but rips the surface of the target like a plow. Knives with such a blade are used for self-defense or for cutting car seat belts.

Knives in which the blade is located at an angle to the handle serve the same purpose. This idea received its maximum development in the knives with the pistol grip of the company "STI".

Flat wedge possesses high performance, combining the strength of the blade and a sharp blade. Due to the uniform distribution of effort well cuts soft materials of great thickness. Disadvantages - the complexity of sharpening, poorly copes with cutting hard materials.

Chisel profile - differs adaptability and ease of sharpening. It is widely distributed on the blades of Asian knives. It has excellent chopping properties, well cuts thin materials.

Flat wedge and its type is a flat-concave wedge with a lead - it is easy to manufacture, it is easy to fix and grind, it performs a shallow cut perfectly. Disadvantages - low mechanical strength, difficulty cutting thick materials due to protruding side ribs.

Wedge-shaped profile has excellent cutting properties. The disadvantage is the fragility of the cutting edge and the complexity of sharpening (it is necessary to sharpen the entire blade plane). From this lack freely wedge-shaped section with a supply.

Pentahedral profile combines manufacturability, durability, good cutting qualities, well-ruled. Disadvantages - the difficulty of sharpening when restoring the cutting edge.

In addition to the blade, folding pocket knives can have additional auxiliary tools - awl, corkscrew, can opener, bottle opener. In the so-called "Swiss Army Knives" (Swiss Army knives) the number of such tools can reach several dozen. Such multi-function knives are called "multitools".

For self-defense, knives with two working blades are also produced, which allow you to hit a target in forward and backward hands without changing the orientation of the knife or changing its grip.

Saw

Part of the blade of the blade may be sharpened in the form of a saw for cutting fibrous materials. In knife literature, such sharpening is called “seryitor” or “serator” (from English serrated - sawtooth). In self-defense knives, serhitornoy sharpening facilitates cutting through the upper dense clothing and can be performed on the entire length of the blade.

The configuration of the teeth of this mini-saw from different manufacturers may be different. The presence of the drill makes it difficult to sharpen the blade at home - for this you need to have a special tool and skills to work with it, or contact the appropriate specialist.

Structural elements for opening the knife

The design of most modern folding knives allows you to open them with one hand, both right and left. To do this, there are special elements at the base of the blade - cylindrical pins, round or square dies or holes in the blade (the round hole is protected by a patent belonging to the American company Spiderko and other manufacturing companies are forced to use other forms). It is more convenient to open knives with protruding elements - pins or dies, but they reduce the effective length of the blade.

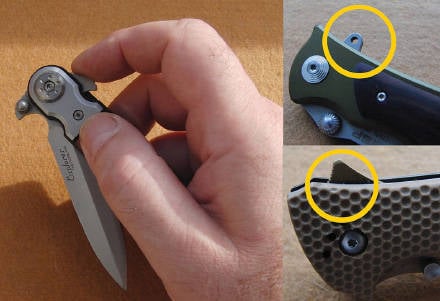

At the beginning of this century, a special device in the form of a hook on the butt appeared on the knives, which provides automatic opening of the knife when it is pulled out of the trouser pocket. Owners of such knives should be aware that if the pants are made of thin material, then after several cycles of getting the knife, they are likely to be broken.

Much less often a special semicircular cut on the blade is found on modern knives. Most often it is used in models that have several working blades or tools, or in knives without fixing the blades, which are well known to the older generation in Soviet times.

Another element that facilitates the opening of the knife is a flipper (from the English flipper - fin) - a special protrusion on the blade's butt. To open a regular knife, it is enough to move the blade a little by pressing the flipper with a finger of a hand, and then with an energetic swing movement of the hand to bring the blade into working position. In semi-automatic knives, the need for such a move is absent - the blade is adjusted to the working position by a spring mechanism automatically.

In addition, the flipper plays the role of a kind of guard, preventing the hand from slipping on the blade.

Structural elements for more reliable knife control

The most common grip of folding knives is straight diagonal (fencing) grip. In this grip the thumb is located on the butt of the blade.

For more comfortable control of the knife in the place of contact of the thumb on the butt of the blade, a special notch is made. The notch may have part of the handle adjacent to the blade.

Lever

The handles of most modern knives have a pack-type construction, consisting of an internal frame (frame) in the form of metal strips liners (liner) and linings. Inside the frame, the elements of blade fixation, the automatic opening mechanism (for semi-automatic and automatic knives) are mounted.

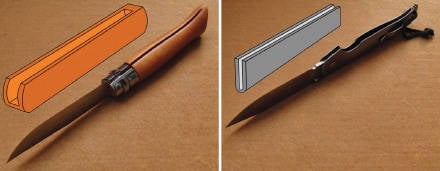

Simple monolithic handles with a groove for a blade or a handle from a bent steel strip are rarely found in modern knives - mainly in the French Opitel and the African Duk-duc.

Previously, the connection of the parts of the handle into a single unit was carried out using rivets. The axis of the blade also riveted. In modern models for this, as a rule, screw connections are used. The use of screw connections allows you to eliminate the razbaltyvanie parts that appear during the operation of the knife, to adjust the "softness of the blade," facilitates disassembly of the knife for maintenance.

Torx screws (torx) are used in most foreign folding knives. To work with such screws, you need a special tool - screwdrivers or socket wrenches with the appropriate head. Some companies include such keys in the scope of supply of the knife, otherwise they have to be purchased separately.

The shape of the handle, its cross-section, as well as the texture of the linings determine the convenience and safety of using the knife.

The rectangular cross-section of the knife is technologically advanced in production, but it is not convenient when performing long-term work with a knife. The handle with a round section fits comfortably in the hand, but it does not allow the touch to determine the orientation of the knife. Therefore, the most convenient handle oval.

The rectangular shape is compact, but it does not provide protection against sliding the hand on the blade. The wedge-shaped handle better protects the hand when working with the tip of a knife, but when you try to pull out a knife stuck in a dense material, the hand will slide off the handle. This form often have small penknives for small household work.

The concave shape of the handle provides a more secure grip, but not quite comfortable. The convex shape of the handle fits perfectly in the hand and is comfortable for work. This is the shape of the handle have proven knives Finnish type.

Even more convenient is the handle of a convex-concave shape and a shape that is often used on tactical knives.

Modern knives are increasingly used handles of complex shape, taking into account the ergonomics of the hand. However, its configuration is calculated as a medium-sized hand, and a person with a large or, on the contrary, small hand, will not be able to fully use its advantages.

Lining

For their manufacture can be used materials of natural (wood, bone, horn) and artificial origin (metals, plastics).

The main advantage of wooden linings is their “warmth” and beauty of natural material. In expensive authoring knives, exotic woods with a very beautiful texture can be used. The main disadvantage is weak wear and moisture resistance. Multi-layer lacquer in some way solves the problem, but it also reduces the reliability of holding the knife in his hand.

Another natural material is horn and bone. The handles of these materials are well polished and look very nice. The disadvantage is that they can crack and are easily scratched.

Metal plates are highly durable, but in the cold season it is inconvenient to use knives with such handles. In addition, they are difficult to hold in a wet or sweaty hand, even if they are notched. In modern knives for their manufacture are used titanium alloys based on aluminum or titanium. In expensive author's knives can be used and Damascus steel.

Materials based on synthetic resins can mimic the structure of natural materials and at the same time avoid their inherent flaws, although they lose by weight. One of the most popular materials of this type is one of the types of PCB - “Mikarta”.

Recently, more and more lining of various types of plastic, such as ABC, Zeitel (Zitel), Kydex (Kydex), etc. are being used. These materials are technological, waterproof, durable and resistant to the effects of the environment. They allow you to make lining of any shape with any texture pattern - from simple roughness inherent in the material of the lining itself, or a rectangular notch to specially designed surface types. So, in the knives of the series “For those who serve” the company CRKT uses a special honeycomb structure that prevents the knife from slipping in the hand.

For the same purpose are rubber inserts or structural elements-inserts like emery paper.

In the end part of the handles of many models of folding knives there is a through circular hole for attaching to it a lanyard or a pull cord.

Security elements

Although modern designs of blade retainers are quite reliable, nevertheless, as noted above, there is a possibility of accidental folding of the blade. To prevent this, there are special fuses in modern knives. For knives with a lock on the butt, they are usually located in the notch area of the fixing lever. In models with a linear lock, they are located in front of the handle under the thumb. Addition of blade clamps with fuses practically turns a folding knife into a knife with a fixed blade.

In order to safely carry semi-automatic and automatic knives, the fuse must prevent the knife from opening in a pocket of clothing when accidentally acting on the trigger. Therefore, in such knives, the fuse often has a double action - it blocks the blade in the closed and open state.

Clip for wearing

A practically mandatory attribute of modern folding knives is a steel spring clip. In knife literature, the term “clip” is often used to designate it (from English. Clip - clip, clip). It provides a comfortable carrying knife in the pockets of clothing or on a trouser belt.

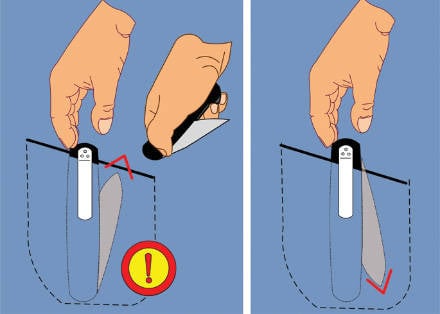

Many manufacturers of knives perform clamp adjustable - that is, it can be mounted on different sides of the handle, depending on whether the owner is right-handed or left-handed. In addition, sometimes you can change not only the side of the clamp mounting - at the base or at the end. In this case, the knife in the pocket will be oriented either with the tip down or up. Some experts believe that when wearing a knife with the tip upwards there is a chance of a cut when trying to get the knife out of your pocket, if for some reason the blade comes out of the handle. At the same time, with this orientation of the knife, it is brought into operation more quickly.

In some models of folding knives, the clip attachment point is not Z-shaped, but in the shape of the letter “G” or “P”. In this case, when wearing a knife in a pocket of clothes, the upper part of the handle is hidden from outside gaze - only the spring plate of the clip comes out of the pocket. Outwardly, it looks like an ordinary ballpoint pen.

Elements that expand the impact capabilities

In self-defense knife can be used, and without opening the blade. In this case, it is used as a palmar wand and the blow is applied by protruding parts of the handle from the fist. In tactical knives and knives for self-defense, the end of the handle to increase the effectiveness of such strikes often has a triangular shape or a special percussion element in the form of a cylinder, cone or pyramid.

Concluding the review of the designs of the folding knife, it should be noted that the legality of the knife, that is, that it is not cold weapons, according to the law can only determine the expert. Therefore, when purchasing a knife, you should always ask the seller a copy of the information sheet to the certification test report (in common parlance it is often called a “certificate”). The absence of such a document, whatever the seller may say, may indicate that the knife you liked did not pass the tests for belonging to cold weapons. And best of all, if such tests were carried out by the head organization - “Expert-criminalistic center of the Ministry of Internal Affairs”. It is better to always have a copy of this document with you, which will allow you to avoid unnecessary conflicts with law enforcement officials.

The majority of high-quality folding knives on the Russian knife market are products of foreign companies.

Unfortunately, the majority of serial domestic folding knives are inferior in almost all respects to foreign ones, and among them one can rarely find original models.

Russian craftsmen and knife companies prefer to create knives with a fixed blade, and among them there are very original models that have no analogues abroad, including Vitaly Kim’s knives, Kondrat knife, NDK-17 knife (Kochergin’s saboteur knife) . This is largely due to the more sophisticated technology and the expensive equipment necessary for it.

Among the Russian masters, only a few design and produce original folding knives of the author's work, which are not inferior to foreign ones (including the price). The folding knives of the Ural master Urakov and the workshop of the Shirogorov brothers are shown as an example.

The rapid pace of development of the Russian knife industry allows us to hope for the emergence of domestic folding knives, not inferior to foreign models.

Information