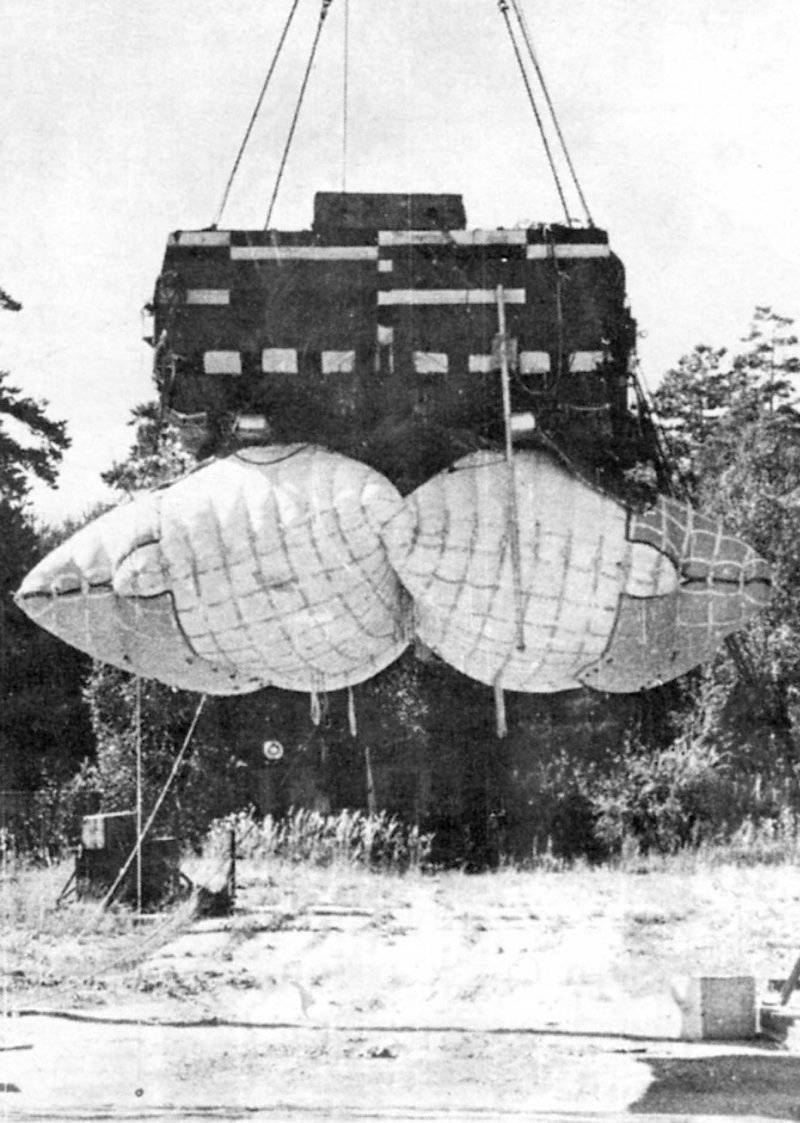

PBS-950 landing facilities

20 May 1983. The Resolution of the Central Committee of the CPSU and the Council of Ministers of the USSR No. 451-159 “On the development work on the creation of the 1990's airborne combat vehicle. and means of its landing. " The OCD received the cipher "Bakhcha" on the airborne assault vehicle, and Bakhcha-SD received the landing equipment.

When developing a new airborne assault vehicle and the means of landing themselves, the scale of the tasks assigned to the Soviet airborne forces in case of war and the complicated conditions for conducting airborne operations were taken into account. The potential adversary, of course, took into account the role assigned to the airborne forces, and the possibility of mass parachute landing in their rear of personnel and military equipment. In the course of the exercises of the armed forces of the NATO countries, questions of combating airborne assault forces were almost certainly worked out, and they were supposed to be assault forces from the battalion and above. In Great Britain, for example, in September 1985 conducted an exercise called “Brave Defender” with practical work on the tasks of fighting airborne assault forces throughout the country. The US statutes emphasized that commanders of all degrees when planning a military operation should decide the protection and defense of the rear of their troops. Means of reconnaissance were improved, short- and long-range detection and warning systems were deployed, and the air defense system was involved in the fight against airborne troops - from individual formations to the scale of a theater of military operations.

To combat the landing troops, in addition to the security forces of objects and bases in the rear areas of the troops, battalion, regiment, and brigade mobile tactical groups were formed from armored, mechanized, and airmobile units. Among the control measures provided for: the firing of military transport aircraft and landing during landing, an attack by an advancing enemy mobile tactical group with the support of tactical and army aviation, barrel and rocket artillery, using the initial disorganization of the landing, with the goal of either destroying or constraining its forces. The appearance of reconnaissance-strike complexes increased the possibility of landing assault in the area of landing.

It required a comprehensive solution to the problems of reducing the vulnerability of parachute assault, including increasing the surprise and secrecy of landing, increasing the number of equipment and personnel, landing one echelon, and landing accuracy, reducing the time of landing and the time between landing and the beginning of the landing operations.

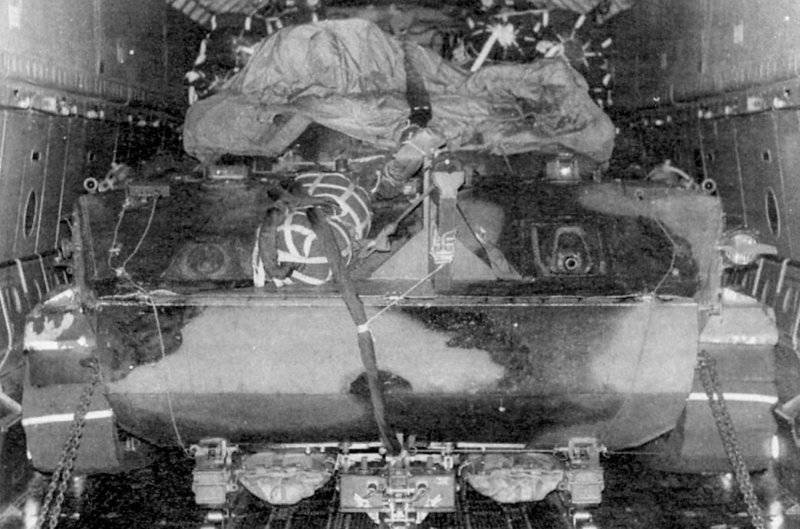

The main requirement for the family of airborne vehicles put forward by the Airborne Forces was the landing of military vehicles of the IL-76 (IL-76M) and An-22 military vehicles with full combat kit and fueling, as well as combat crews (two crew members and five man landing), placed inside the car. At the same time, the Il-76 was supposed to lift up to two vehicles with landing gear, the Il-76М - up to three, the An-22 - up to four. The landing was planned to be carried out on land (including high-altitude areas) and on water (with waves up to 2 points). The means of landing should have guaranteed a reduction in the minimum allowable height of the landing, the minimum possible ratio of their mass to the weight of the landed cargo (combat vehicle with ammunition and crew), application in different climatic and weather conditions. The likelihood of an airborne operation after striking the enemy and disabling the roads and a number of airfields required providing combat vehicles with the established parachute landing equipment to make a long march to the loading airfields to overcome water obstacles.

30 November 1983. The Air Force’s orders and supplies for the Air Force’s equipment and equipment issued the Moscow Aggregate Plant Universal, a tactical and technical assignment No. XXUMX agreed with the Ministry of Aviation Industry, to develop free-form landing gear for the new BMD. The development of landing facilities on the Bakhcha-SD theme began under the guidance of the chief designer and the responsible manager of the Universal plant, A.I. Privalov and Deputy Chief Designer P.R. Shevchuk.

In 1984, “Universal” issued a technical task No. XXUMX to the Research Institute of Automatic Devices (Research Institute AU) for the development of a parachute system. The work at the Research Institute AU was headed by the director of the Institute O.V. Rysev and Deputy Director B.N. Skulanov The design of landing facilities was carried out, of course, in close cooperation with the VgTZ development team headed by chief designer A.V. Shabalin and deputy chief designer V.A. Trishkin.

If the family of machines based on BMD-1 made it possible to create each subsequent set of means of landing on the basis of previously developed samples with a high degree of unification, now there could be no talk of succession over nodes and aggregates. The tactical and technical requirements for the “90-x combat parachute” (received during the development of the designation “950 Object”, in production - “950 product”) implied a qualitative improvement in its performance compared to BMD-1 and BMD-2 and a corresponding increase dimensions and mass. The planned mass of the new BMD (12,5 t) was more than 1,5 times the mass of the BMD-1 family of vehicles - the BTR-D. In combination with the need to drop the entire calculation inside the machine, with very strict restrictions on the mass of the means of landing itself, this forced to re-create the whole complex. Of course, a rich stock of technical solutions was used, previously found by specialists of the Universal and scientific research institutes of AU in the course of other works, but the design should have been new. In fact, it took a full range of research and development work.

Taking into account the novelty of the task, the Customer agreed that the final selection of the landing concept would be made at the stage of the technical project protection.

Of the two main schemes of strapless landing aids, worked out for machines of the BMD-1 family - the BTR-D (parachute or parachute-reactive system), a multi-domed parachute was chosen, providing greater reliability, which was paramount in view of the landing calculation. Placing the calculation on universal seats instead of special damped seats required developers to ensure vertical overloads when landing no more than 15 g. A multi-domed system in combination with energy-intensive shock absorbers could provide this. Therefore, the variant of the parachute-reactive system at the technical project stage was not considered.

In December, 1985 was held at the “Universal” plant a meeting of representatives of the Customer and the industry on the approval of the technical appearance of the “Bakhcha-SD” means. The meeting was chaired by General of the Army D.S. Sukhorukov, the deputy commander Lieutenant General N.N. Guskov, from the Customer - G.I. Golubtsov, from the plant "Universal" - N. F. Shirokov, who replaced A.I. Privalov as the head and chief designer of the plant, from the Institute of Investigations AU - Director of the Institute O.V. Rysev and the leader of its Feodosia branch, P.M. Nikolaev, from the Civil Code of the Scientific Research Institute of the Air Force - Head of the Department A.F. Shukayev.

The meeting considered three options for parachute parachute landing aids:

- a variant of the Feodosia branch of the scientific research institute AU was represented by P.М. Nikolaev It was, in fact, the modernization of landing gear type PBS-915 "Shelf" with self-filling air depreciation;

- version of the plant "Universal" with self-filled air damping "Kid." He reported the lead designer Ya.R. Gryshpan;

- a version of the “Universal” plant with forced air damping with overpressure inside kg / cm 0,005 2. According to him, the chief designer N.F. Shirokov.

As a result of a comprehensive study, it was decided to create a means of landing on the third option, providing greater energy consumption of depreciation and less overload on the body of the machine and the locations of the calculation at the touchdown. The development received the factory code "4P248", the customer assigned her the code "PBS-950".

The design of landing gear 4P248 (for the sake of brevity, also referred to as the “4P248 system”) was conducted in the 9 department of the Universal plant under the guidance of the head of the department G.V. Petkus, brigade chief Yu.N. Korovochkin and leading engineer V.V. Zhebrovsky. The calculations were carried out by the department headed by SS. Filler; The tests of the landing facilities at the plant were led by the heads of the testing departments of P.V. Goncharov and S.F. Gromov.

The main problems that the development team had to solve again, include the creation of:

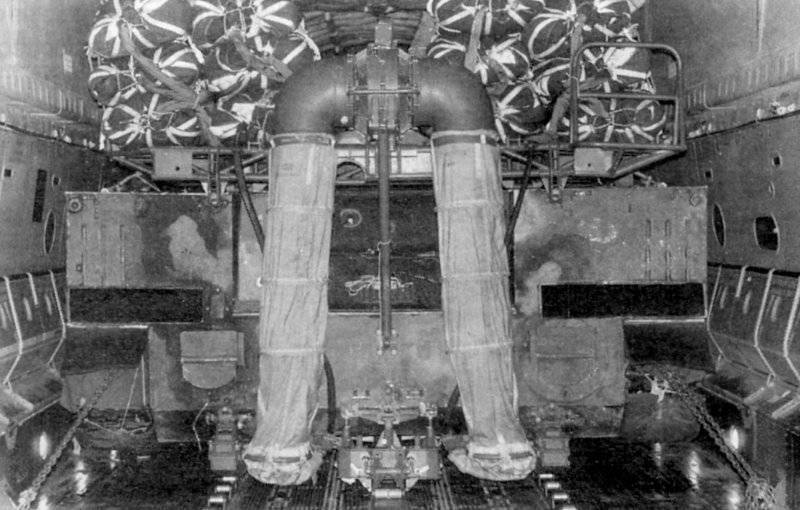

- a new installation-shock-absorbing device (skis with shock absorbers and a central hub), which would load the curb-loaded BMD into the aircraft, fix it in the cargo cabin of the aircraft on the roller table equipment, safely exit the car from the cargo cabin during the landing and automatically start the parachute operation and shock absorbing systems. The air damper of compulsory filling 4P248-1503 was designed;

- a unit designed to force the shock absorbers to fill the atmosphere with atmospheric air to ensure the kinetic energy of the load is quenched upon landing. The unit was called the “supercharging unit” and received the factory cipher “4П248-6501”;

- a multi-domed parachute system that would provide a safe landing and splashdown of the “950 Object” with full combat crews. The development of the parachute system MKS-350-12 was conducted at the Research Institute AU under the supervision of the Deputy Director B.N. Skulanov and sector chief L.N. Chernyshev;

- equipment that allows BMD with installed means of landing on a march to make a march up to 500 km with overcoming water obstacles;

- electrical equipment located inside the “950 Object” for issuing light information to crew members about the stages of the landing process, as well as for controlling the accelerated landing gear after landing.

The decision taken at the said meeting did not abolish the search for other possible options for implementing the depreciation device. Among them was the principle of air cushion. On the basis of the decision of the USSR State Committee on Military-Industrial Issues from 31 in October 1986, the Universal plant received a technical assignment for conducting research work “Study of the possibility of creating equipment for dropping vehicles and goods using the airbag principle”. "Universal", in turn, in 1987 was given the task Ufa Aviation Institute. Sergo Ordzhonikidze (AIM), who previously conducted a similar study in the framework of the research "Blowing". The newly opened research project received the code “Blow-1” and was completed in full.

In the course of this research, the landing of the 915 Object (BMD-1) was studied, but the possibility of using the same principle for heavier objects was also assumed. The damping device was an inflatable “skirt” mounted under the bottom of the combat vehicle, which was deployed during the descent with the help of pyrotechnic gas generators. There was no forced air injection under the “skirt”: it was assumed that when landing, the machine would compress the air in the volume bounded by the “skirt” due to its inertia, consuming a significant part of its kinetic energy. Such a system could work effectively only in ideal conditions and on a perfectly flat platform. In addition, the depreciation system proposed by AIM envisaged the use of expensive rubberized CBM fabric, was difficult to prepare for use. Yes, and this work was completed when the funds 4P248 already passed the stage of state tests. The final report on research and development, approved by the head of Universal in December 1988, recognized its results as useful, but read: “Using the principle of an air-gas cushion in a landing device for research and development“ Blowing ”and research and development“ Blowing-1 ”for developing landing systems is not feasible” .

In the framework of the work on the topic “Bakhcha-SD” other R & D projects were also opened. The previously developed strapless landing aids for BMD-1, BMD-2 and BTR-D - experienced ZP 170, serial PBS-915 (925) - included hydraulic orientation systems in the direction of the wind before landing. With their help, the reversal of the object at the parachute descent stage with a longitudinal axis in the direction of the wind drift ensured a safe landing at wind speeds in the surface layer to 15 m / s and thereby expanding the range of weather conditions for the use of parachute assault forces. However, the mechanical guide by the type used in PBS-915 (925), which effectively worked at wind speed 10-15 m / s, when it was reduced to 8-9 m / s simply did not have time to work: when the object was reduced, the slack of the linkyd link was formed , and he did not have time to stretch and deploy the object before landing.

NII AU together with the Moscow Aviation Institute. Sergo Ordzhonikidze carried out the development of a solid-fuel orientation system (R & D “Air”). The principle of its operation was to turn the object to be landed by means of a reversible jet-jet engine with a solid-fuel gas generator switched on and off by an automatic control system. The commander of the landed machine received data about the landing height and the calculated direction of the wind drift from the aircraft navigator before the landing began and entered it into the automatic control system. The latter ensured the orientation of the object in the process of descent and its stabilization until the moment it landed.

The orientation system was tested with a joint landing complex (KSD) and with a BMD-1 mockup, the calculation was made for the means of landing of the 688М (Fable) and 950 (Bakhcha) combat vehicles. The prospects of the system for use in the Airborne Forces were noted by experts from the 3 Central Research Institute of the Ministry of Defense. R & D was completed in 1984, a report was released on it, but the topic did not receive further development - mainly due to the lack of ability to accurately determine the direction and speed of the wind near the ground in the area of the landing ground. In the end, any orientation systems were not used as part of 4P248. The calculation was made on the fact that two air shock absorbers in the process of air coming out of them after landing form shafts on the sides of the cargo, which will prevent tipping due to lateral drift.

Here it is appropriate to recall the research work on the selection of materials for depreciation of parachute platforms and containers, conducted abroad (primarily in the USA) as early as 1960. Foam plastics, kraft fiber, cellular metal structures were investigated. The most advantageous characteristics turned out to be metal (especially aluminum) cells, but they were expensive. Meanwhile, while American and British parachute platforms of medium and heavy payloads, air damping was already used. Its characteristics are quite satisfied customers, but later the Americans refused to air depreciation, referring to the difficulties of sustainability and prevent tilting of the platform after landing.

The MKS-350-12 parachute system was designed by SRI AU on the basis of a parachute block with an area of 350 м2, unified both with the already adopted PBS-915 systems (-916, -925, П-7 platform), and with the system being developed at the same time MKS-350-10 for landing means P-211 of the boat "Gagara".

Research conducted at the beginning of 1980-x showed that the most effective way to reduce the minimum height of the landing of cargo is associated with the rejection of the main parachutes of a large cutting area (as in the systems MKS-5-128М, MKS-5-128Р and МКС-1400 ) and the transition to "bundles" (or "packages") of non-pierced main parachutes of a small area. The experience of creating the MKS-350-9 system with the main parachute blocks with an area of 350 m 2 confirmed this conclusion. It became possible to develop multi-dome systems using a “modular” scheme: with an increase in the mass of the landed cargo, the number of main parachute blocks simply increased. Note that in parallel with the MKS-350-9, the MKS-175-8 system appeared with a half the dome area of the main parachute, designed to replace the single-dome system in the parachute-reactive facilities PRSM-915 (925) - with the same goal of reducing the minimum landing height .

In both systems, for the first time in the practice of parachute building, a method was used to improve the uniformity of loading and improve the filling characteristics of multi-dome systems through the use of small-area drag parachutes and an additional exhaust parachute. Brake parachutes were put into operation earlier than the main ones and reduced the rate of descent of the object to be dropped to a level that ensures acceptable aerodynamic loads of each of the main parachutes during their opening and filling. The connection of each of the domes of the main parachute with an additional exhaust parachute (DVP) by a separate link led to the fact that the DVP “automatically controlled” the process of filling the domes. In disclosing the main domes, a “leader” was inevitably formed - a dome that opened before the others and immediately took on a considerable burden. The effort from the hardboard could somewhat “put out” such a dome and prevent it from fully opening up too soon. Ultimately, this was to ensure uniform loading of the entire parachute system during deployment and improve its filling characteristics. In the PBS-915 system from the nine-dome MKS-350-9, this reduced the minimum landing height to 300 m with a maximum height of 1500 m and the aircraft flight speed range on the instrument (for the Il-76 aircraft) from 260 to 400 km / h. This altitude-speed range, it should be noted, has not yet been surpassed either in the domestic or in the foreign practice of parachute landing of loads of weight up to 9,5 t.

The same minimum landing height in 300 m was laid down in the tactics and technical requirements for the development of Bakhcha-SD, and it was even supposed to “work out the issue of reducing landing altitudes to 150-200 m.” The maximum landing height was set in 1500 m above the platform, the platform height above sea level - up to 2500 m, the flight speed of the instrument during landing was to lie within 300-380 km / h for the Il-76 (Il-76М) and 320- 380 km / h - for An-22.

The new automatic uncoupler PNNUMX with a non-duplicated unlock mechanism has been introduced into the 4P248 tools. Moreover, it was created in the development of automatic coupling 232П2 from the parachute platform П-131.

The production and technological requirements of the TTZ are interesting: “The design of the drop-off facilities must take into account the technology of serial manufacturers and the most progressive methods of manufacturing parts (casting, stamping, pressing) and allow the manufacture of parts on CNC machines ... Raw materials, materials and purchased products must be domestically produced. " The design documentation of the T letters (technical design stage) for the landing facilities 4П248-0000 was approved already in 1985. In the same year, the first three copies of the BMD “Object 950” (“Bakhcha”) passed factory tests and state tests of the parachute system MKS-350 took place -9.

To conduct preliminary tests 4P248 plant "Universal" and SRI AU in 1985-1986. prepared prototypes of landing aids, as well as dimensional mass models of the “950 Object”. At the same time, it was taken into account that the mass of the product presented at the state tests in 1986 was higher than the planned -12,9 t instead of the initially set 12,5 t (later the new BMD “becomes heavier”). The 4P248 means at that time already appeared under the changed Bakhcha-PDS code, i.e. "Parachute means."

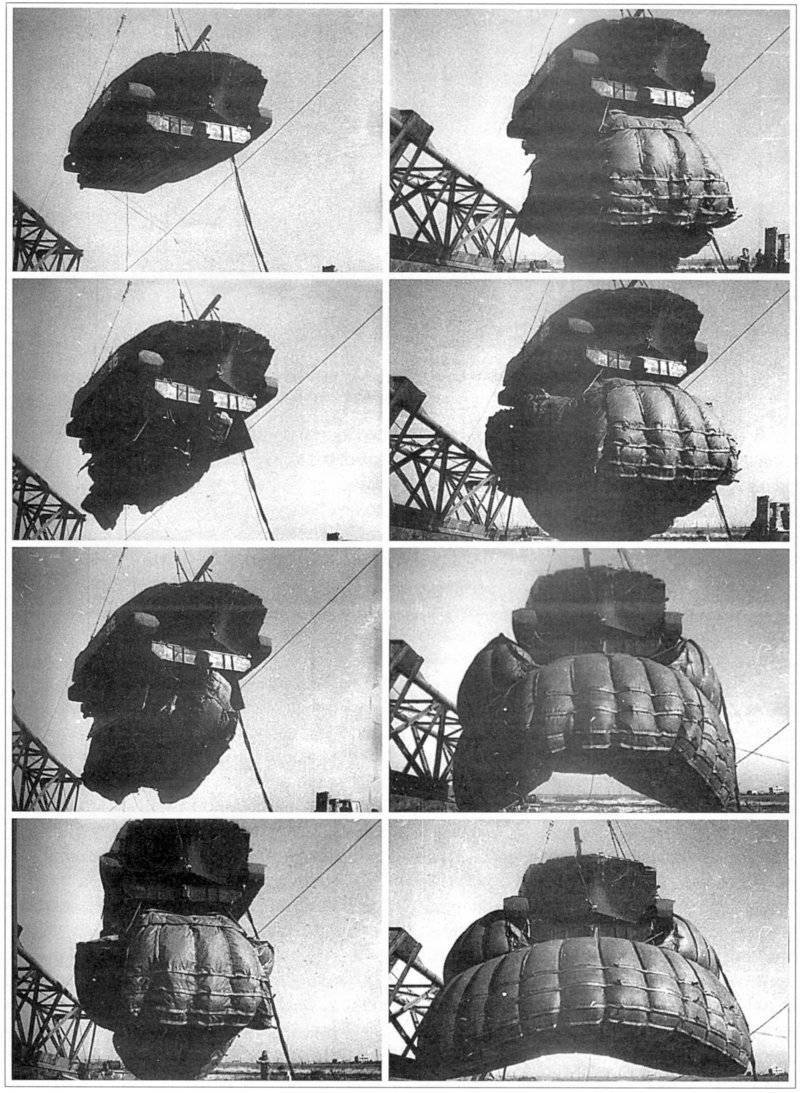

Preliminary ground tests of 4P248 took place from September of 1985 to July of 1987. During these tests, 15 of droppings were carried out, including physiological experiments, as well as drops on the water surface using a crane (in 1986). It was determined that "... 4P248-1503-0 air-dampeners with pre-pressurized cameras ensure the landing of the 950 product on the parachute system at vertical speeds up to 9,5 m / s with overloads on board the product no more than 14 units, and on universal seats in the parachute dropping position on the x-axis no more than 10,6, on the y-axis no more than 8,8 units and can be used once; universal chairs, taking into account the implementation of measures with the normal operation of depreciation means, ensure that the crew members are comfortable with landing conditions ... landing facilities 4П248-0000 when dropped onto water provide a landing on the parachute system at a vertical speed up to 9,8 m / s with overloads on board the product not more than 8,5 ; the resulting overloads do not exceed the maximum allowable, regulated by medical and technical requirements for these facilities. "

True, when landing, the exhaust valve diaphragms did not work, which greatly worsened the stability even on a smooth surface. Simulation of a wind drift with a speed up to 12 m / s during landing on the land did not result in overturning. During the flight tests, two models and one real “950 Object” were dropped with 4P248-0000 from the Il-76MD aircraft singly, in series and using the “Zug” method at flight speeds using the 300-380 km / h instrument. Preliminary flight tests with dropping from the An-22 aircraft took place only in 1988.

Although, in general, according to the 30 September 1987 preliminary test report, “950 4P248-0000 product drop tools ... have passed all kinds of preliminary tests with positive results,” a number of unpleasant surprises were revealed in the 12-dome parachute system . Already at the initial stage, it became clear that with large instrumental landing speeds, the parachute system is characterized by insufficient strength (sling breaks, tearing of the fabric from the power frame of the main parachute domes leading in the filling process), and at the lower boundary of the given altitude-speed range of application - unsatisfactory the fullness of the main parachute domes. An analysis of the results of preliminary tests revealed the causes. In particular, an increase in the number of deceleration parachutes (their number corresponds to the number of main ones) led to the formation of a noticeable zone of aerodynamic shading, which included those located closer to the center of the dome of the main parachutes. In addition, behind a bunch of braking parachutes, a zone of turbulence was formed, which had a negative effect on the process of filling the main parachutes in general. In addition, while maintaining the same length of connecting links in the 12-dome system as in the MKS-350-9, the “central” domes, whose filling was late, were clamped by the “leading” neighbors, and the “regulation” process of the opening process Fiberboard has not worked as effectively. This reduced the efficiency of the parachute system as a whole, increased the load on the individual domes. It was clear that a simple increase in the number of main domes could not be avoided.

NTC Airborne Forces, headed by Major General B.M. Ostolderhov, constantly paid close attention to the development of both the 950 Object and the 4P248 facilities, as well as the refinement of airborne transport equipment of military transport aircraft - all of these issues required a comprehensive solution. Moreover, besides the already existing IL-76 (-76М) and An-22 aircraft, the combat vehicle was supposed to parachute from the IL-76MD that had just entered service and the An-124 "Ruslan" that was still undergoing state tests. In 1986, in January and September of 1987, and in 1988, at the initiative of the Airborne Forces, four operational evaluations of the 4P248 tools (PBS-950) were conducted, the results of which also made changes to the design of both the BMD itself and the means of landing.

The need to finalize the rolling equipment of the cargo cabins of military transport aircraft was already apparent at the preliminary testing stage. In the IL-76M (MD) aircraft, in order to ensure the landing of three objects, the end section of the monorail was extended, and an additional mount was installed on section No.6 of the monorail. Two reloading rollers on the internal roller tracks were replaced: so that the machine, rolling over the ramp edge, did not touch the side inner contours of the tail section of the cargo compartment, they installed rollers with ring grooves that kept the machine from lateral displacement (a similar solution was previously used when developing the П-211 system for the boat "Gagara"). Require improvements and landing-transport equipment of the aircraft An-22.

From January 5 to 8 1988, the 4P248 parachute system MKS-350-12 (with the optional exhaust parachute DVP-30) passed state tests. They were directly supervised by the head of the testing department of the GK NII VVS colonel N.N. Nevzorov, the leading pilot was Colonel B.V. Oleynikov, the leading navigator - A.G. Smirnov, leading engineer - lieutenant colonel Yu.A. Kuznetsov. Various landing options were tested at various sites, including (at the final stage of state tests) onto the water surface. The act of state tests was approved on November 29 1988.

In the “Conclusions” section of the act, it was stated: “The Bakhcha-PDS landing gear” to the tactical and technical task No. XXUMX and to the supplement No. XXUMX basically correspond, with the exception of the characteristics specified in paragraph .... The compliance tables of this act and provide parachute landing on the ground surface of the BMD-13098 airborne combat vehicle with a flight weight of 1 kg with 3 combat crew members deployed on universal seats inside the vehicle, from altitudes 14400-7 m to landing sites with elevations above sea level to 300 m, at wind speed from the ground up to 1500 m / s ... Means of landing "Bakhcha-PDS" ensure the safety of the technical characteristics of the BMD-2500, its armament and equipment after the parachute landing in the next version of the machine configuration:

- fully equipped with ammunition, supplies, service equipment, full refueling of fuels and lubricants, with seven members of the combat crew combat weight 12900 kg;

- in the above configuration, but instead of the four members of the crew, 400 kg of additional ammunition is installed in the standard capping with 12900 kg combat weight;

- with a full refueling of fuel and lubricants, complete with supplies and service equipment, but without combat crew and ammunition with a total weight of 10900 kg ...

The landing of BMD-3 on the Bakhcha-PDS landing gear on the water surface is not ensured due to tilting the machine on 180 ° at the time of splashdown with the wind in the surface layer to 6 m / s and waves less than 1 points (i.e. , much more “softer” than those provided by the TTZ. - Auth. note.) ... The flight to land a BMD-3 airborne combat vehicle using Bakhcha-PDS flight weight of up to 14400 kg, taking into account the features set out in the flight assessment , the complexity is not and is available to pilots who have experience of landing the pain The cargo from IL-76 (M, MD) and An-22 ... aircraft. The probability of uptime, determined with a confidence level 0,95, is in the range from 0,952 to 1, 0,999 is set by TTZ (without taking it off to the water surface) ".

According to the results of state tests, the 4P248 landing aids were recommended for acceptance for the supply of the Air Force and the Airborne Forces and for launching into mass production, but after the elimination of deficiencies and carrying out control tests.

The problems of the parachute system reappeared: the destruction of one or two domes of the main parachutes, sling cliffs at the limiting altitude and speed modes, in two cases the failure of two domes when dropping a BMD at speeds of 300-360 km / h from the heights of 400-500 m.

The analysis of the comments and the possibilities for their elimination forced the release of an addendum to the TTZ. In order to prevent a long delay in launching the landing means into mass production, the requirement to land on the water surface was simply excluded, and the flight speed of the device during the landing was set at 380 km / h to ensure safe exit of the product from the cabin and deployment of the parachute system. However, the same document implied the conduct of additional flight-experimental studies to ensure the landing of BMD-3 on the water surface. This requirement was by no means formal - at the same time, at the end of 1980, research showed that even in the case of a non-nuclear large-scale war in the European theater of military operations, half the time would be flooded due to the destruction of hydraulic structures. sushi surface. And this had to be taken into account when planning possible airborne operations.

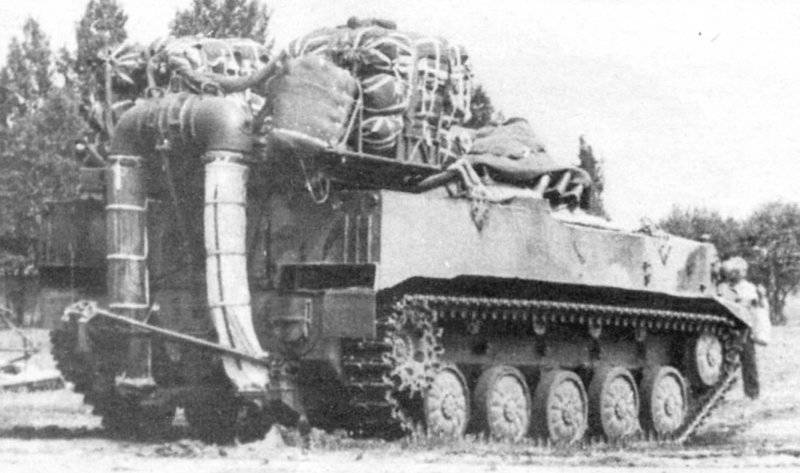

The main improvements of the system were completed within a month. To speed up the BMD-3 mooring from the landing facilities, retractable sliders and a single mooring point were inserted into the central assembly. In addition, they introduced screw supports and strengthened the fastening of the pipes of the central assembly. Additional compensators between the lever and the lock body, the control pin, to ensure reliable control of the lock in the closed position, appeared in the lock fastening the object to the monorail; the lock rod was modified to speed up its installation in the nest of the monorail. Improved supercharging unit in order to reduce its mass. We changed the design of the tracks of the tracks in order to reduce the likelihood that the tracks of the “950 Object” would touch over the elements of the landing gear at the exit from the “deflated” shock absorbers after landing. On the machine itself strengthened brackets for mounting skis. The construction of the removable fence of the BMD tower was improved, ensuring the safety of the tower elements when the parachute system was put into operation: during state tests, for example, the bracket of the OU-5 illuminator on the tower was destroyed and the fence itself was deformed.

The comments indicated that the means of landing, installed on the machine in the stowed position, allow the BMD to march "over rough terrain with speed 30 — 40 km / h to the distance to 500 km”, but the requirements of the TTZ are not met, since the placement of the means of landing on the machine "Worsens the visibility of the commander from his workplace in the position on a marching day and with infrared instruments." The same applied to the survey from the workplace of the driver. Given the possibility of making long marches and overcoming water obstacles, the requirement was important. It was necessary to modify the fastening elements of the means of landing on the machine in a traveling manner. Clarified the requirements for the design and installation of universal seats BMD.

Experts of the Research Institute AU remade the parachute system MKS-350-12. In particular, to strengthen the canopy of the main parachute, 11 tapes of an additional circular frame made of technical nylon tape LTKP-25-450 and LTKP-25-300 were stitched on it in the pole part. To improve the loading capacity and uniformity of the parachute system, 20-meter extensions were introduced, which allowed the main parachute domes to disperse further from each other before opening. Changed the procedure for placing the brake parachute in the camera. This did not solve all the problems mentioned, and when launching PBS-950 into production, it was necessary to limit the multiplicity of application at the limiting altitude-speed modes, and to add an additional unit of the main parachute to the spare parts kit for the ISS-350-12 system - speed mode.

From 29 December 1988 to 27 in March 1989, preliminary flight tests of the modified 4P248-0000 tools took place on an IL-76М aircraft owned by the Research Institute AU. The impact of the changes made to the design was checked at all stages of preparation for the landing and the landing itself. In particular, it was determined that the calculation from 7 man loads the “950 Object” with the modified landing means into the IL-76М aircraft during 25 minutes (however, the installation time of the UPN-14 of each object was not taken into account). The time of disconnecting the landing gear from the product after landing was 60 with the use of the accelerated de-mooring system and no more than 2 minutes for manual de-mooring by the forces of the 4 calculation person.

Changes were also made to the airborne transport equipment of the aircraft, in particular, with the aim of increasing the safety of airborne escort calculations with individual parachutes (this requirement was also included in the list of measures based on the results of state tests). Modified equipment with a reinforced monorail 1P158, manufactured by Universal, was installed on the Il-76 aircraft with the Design Bureau named after S.V. Ilyushin and quite justified. The report on these tests, approved by the heads of Universal and XI NUMX AU 30 March 1989, stated: “The 4 248 landing gear for the 950 product, which was finalized according to G.I.’s comments and on the operational assessment of 4, provided for five times their use with parts replacement disposable ... The 248P950 landing aids ensure safe landing of the 11,0 product with overloads not exceeding the values of ny = 1,4, nx = 2,2, nz = 4 ... Constructive changes of the main elements of 248P350 means: parachute system MKS-XNUM The X-12, the central power unit, the pressurization unit and other units, carried out according to the comments of the state tests and according to the comments revealed during the present tests, were tested during the tests and their effectiveness was confirmed ... The means of landing 4P248 correspond to TTZ No. 13098 and can be presented for control tests. Except for: the loading time of the product “950” into the IL-76М by TTZ — 15 mines actually received 25 mines, and the landing gear after landing was performed with 3’s exit from the product. ”

Not without emergency situations. In one of the flight experiments, the BMD "Object 950" after landing, simply tilted upwards by caterpillars. The reason was the collision of the machine during a side demolition with a frozen snow shaft in height 0,3-0,4 m (it was still winter) - and this case was considered a “non-standard landing”.

Over the entire period of 4P248 testing, during tests (not counting the controls), 15 dropping BMD mockups to test air dampers was carried out; 11 drop-offs of the “950 Object” (of which there are four physiological experiments), 87 flight experiments with the “950 Object” mock-ups, 32 flight experiments with the “950 Object”, four of which are physiological, with two testers inside the machine. So, 6 of June 1986, on the landing site near Pskov, test-paratroopers of SRI AU A.V. Shpilevsky and E.G. Ivanov (landing height - 76 m, aircraft flight speed - 1800 km / h). 327 of June of the same year, paratroopers and testers of the Scientific Research Institute of the Air Force, Lieutenant Colonel A. A. Danilchenko and Major V.P. Nesterov.

The report on the first flight physiological test, approved by 22 July 1988, noted: "... at all stages of the physiological experiment, the testers maintained normal performance ... The physiological and psychological changes of the crew members were reversible and reflected the body's response to the upcoming extreme exposure. " It was confirmed that the arrangement of the members of the calculation on the universal seats when landing prevents any part of the body from hitting the body or the internal equipment of the combat vehicle. At the same time, the parachute system still did not provide the required fivefold application. Nevertheless, the decision of the Commander-in-Chief of the Air Forces of November 16 of 1989. The airborne assault equipment of the PBS-950 was taken to supply the Air Force and the Airborne Forces and introduced into serial production, provided that the research institute AU (in 1990 was renamed the Scientific Parachute of the Parachute Engineering) -350-12.

To confirm the effectiveness of improvements landing facilities in 1989 and 1990. conducted additional control and special flight tests. As a result, the appearance of the 4P248 landing gear (PBS-950) was finally formed, the design documentation for them was assigned to the letter O, i.e. an installation batch of products for the organization of mass production could already be made on it. During 1985 — 1990 For the development of the 4P248 system, five copyright certificates were obtained, relating mainly to the depreciation device.

Decree of the Central Committee of the CPSU and the Council of Ministers of the USSR No. 155-27 of February 10, 1990 for arming the Soviet Army and the Naval Fleet The BMD-3 landing vehicle and PBS-950 airborne landing equipment were adopted. The resolution, by the way, said: “To oblige the USSR Ministry of Aviation Industry to finalize landing equipment and equip the Il-76, Il-76MD, An-22 and An-124 aircraft with BMD-3 loading devices with PBS-950 airborne landing equipment ".

BMD-3 with landing aids 4P248 in the stowed position

Order of the Minister of Defense of the USSR No. 117 of 20 in March 1990 read: “Designate an airborne combat vehicle BMD-3 and airborne assault equipment PBS-950 to complete the parachute units of the Soviet Army and naval units of the Navy along with the airborne combat vehicles BMD-XNMX BMD-1, parachute-jet systems PRSM-2, PRSM-915 (925) and parachute free-form systems PBS-916, PBS-915 ”. By the same order, the Office of the Deputy Commander-in-Chief of the Air Force for Armament was determined by the general customer for the means of landing. Minaviaprom was obliged to create facilities designed for the annual production of 916 sets of PBS-700. Of course, they did not intend to use this (maximum) performance. Real orders were planned a lot less. But they actually did not take place.

The first production batch of PBS-950 in the amount of ten sets was made in the same 1990 directly at the Universal factory and transferred to the Customer. This batch corresponded to the batch of ten BMD-3 previously ordered by VgTZ. Total MCPC "Universal" made 25 serial sets PBS-950. At the time of the adoption of landing facilities for CBE-950 for the supply of their production was organized in Kumertau. But soon the events in the country made their adjustments, and the mass production of PBS-950 was transferred to the Taganrog APO.

Despite the extremely unfavorable situation in the Armed Forces, work on the development of a few BMD-3 and PBS-950 in the troops was nevertheless conducted, albeit with a considerable delay. The ability to reset the BMD-3 using PBS-950 with all seven members of the calculation inside the machine was tested in 1995 using a drop-ram. The first landing of the entire crew in the BMD-3 with PBS-950 passed 20 on August 1998 in the course of the demonstrative tactical exercises of the 104 Guards. paratroop regiment 76 th Guards. airborne division. The landing was carried out from an Il-76 aircraft with the participation of military paratroopers: senior lieutenant V. V. Konev, junior sergeants A. S. Ablizina and Z.A. Bilimikhova, corporal V.V. Sidorenko, privates D.A. Goreva, D.A. Kondratyeva, ZB Tonaev.

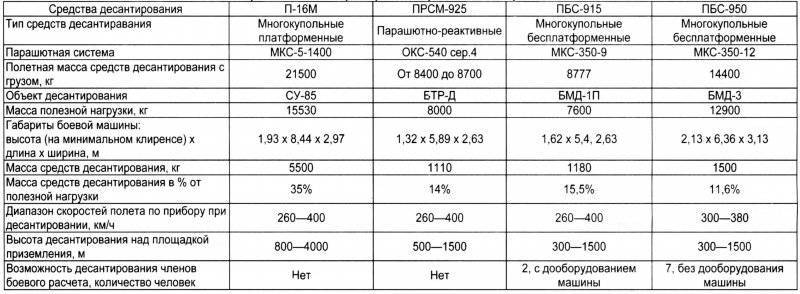

Information