Test results of improved Harvey armor in Russia and abroad

In this article I continue to study the test results of armor plates made using the Harvey method.

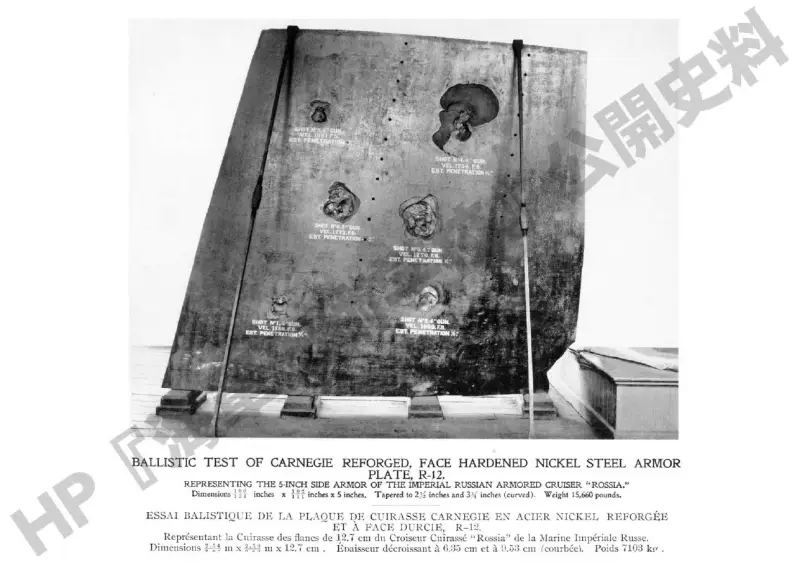

Testing the armor of the armored cruiser "Russia"

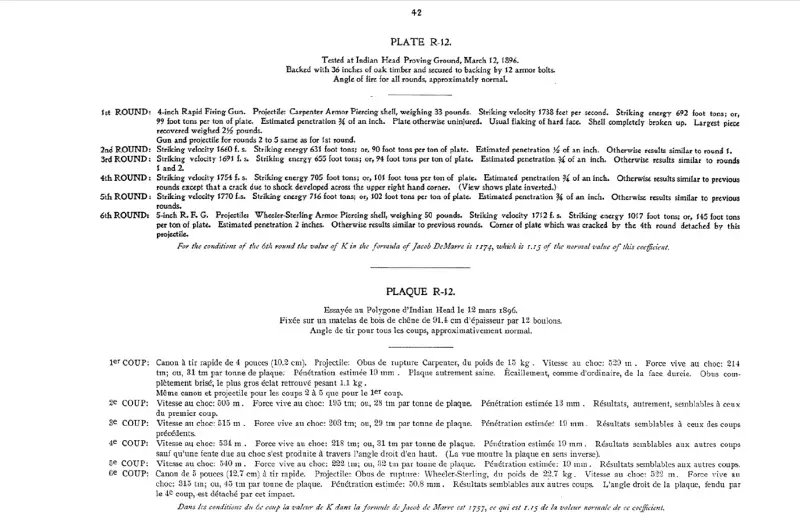

The results of tests of armor plates with a thickness of 127 mm and 203 mm, produced by the American Carnegie plant, are known, which were fired, however, not by Russian, but by American shells. Firing at the 127 mm armor plate took place on March 12, 1896.

Five shots of 102-mm projectiles weighing 15 kg were fired, while the speed of the projectile on the armor increased from shot to shot - it started at 505 m/s and ended at 540 m/s. Then they fired a 127-mm projectile weighing 22,7 kg with a speed of 522 m on armor.

In essence, the shooting was carried out according to the Russian method, which I described in the previous article.

If the armor had been penetrated by the first shot (102 mm, 505 m/s), then according to de Marre’s formula its “K” would have been 1, and if it had been penetrated by the fifth (631 mm, 102 m/s) - then 540, the sixth (1 mm, 746 m/s) - 127, but not a single shell penetrated the armor.

It is interesting, however, that my calculation according to de Marr almost did not agree with the American one, since they indicated 1, but the difference is negligible.

In fairness, it must be pointed out that, although the armor plate was not pierced, after shelling with 102-mm shells, a crack formed along the edge of the plate, and after being hit by a 127-mm shell, the corner of the plate fell off.

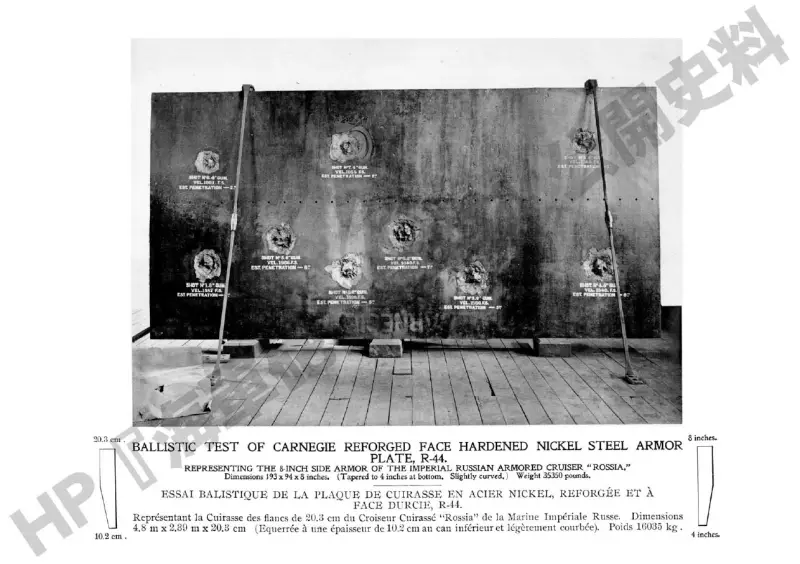

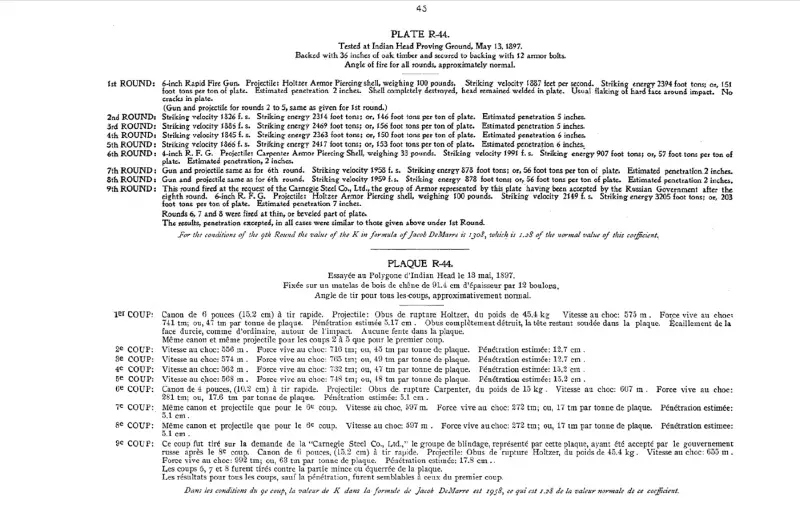

And here are the results of the next tests, which took place on May 13, 1897, when a 203-mm plate was already shelled.

The first eight shots were fired with shells of 102 mm and 152 mm caliber, weighing 15 and 45,4 kg, respectively. At the same time, the speed on the armor ranged from 556 m/s to 597 m/s, with 102-mm shells being fired at the highest speed. The most powerful shot was a 45,4-kg six-inch projectile with a speed on the armor of 757 m/s - if it managed to penetrate the armor plate, then its “K” would be 1.

But the slab, again, was not broken. The 102-mm shells managed to penetrate no more than 5,1 cm, and the 152-mm shells – no more than 15,2 cm, and it was quite obvious that the armor’s strength limit was far from being reached.

Then we decided to significantly tighten the conditions and fired the last, ninth shot with a 152-mm projectile at a speed of 655 m/s on the armor. If a 45,4 kg shell penetrated a 203 mm armor plate at that speed at the limit, then the “K” of the shell and armor would correspond to 1 (964, according to those who wrote the above report). But the American armor withstood this too. The projectile managed to penetrate only 1 cm, so the “K” of this armor exceeded 958.

We can safely say that Carnegie armor showed results significantly superior to those that Garvey armor had given before. And it is absolutely known that the excellent results demonstrated by the plates of this manufacturer were the result of improved technology: the Americans used reforging of cemented plates, which the Harvey armor production process did not initially provide for. Accordingly, the name of such plates indicated reforged, or double forged, which we can see in the above descriptions of tests of the armor of the cruiser "Russia".

US Navy standards

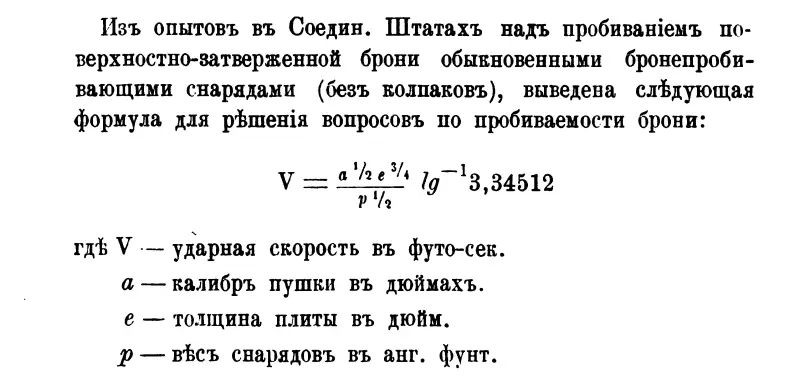

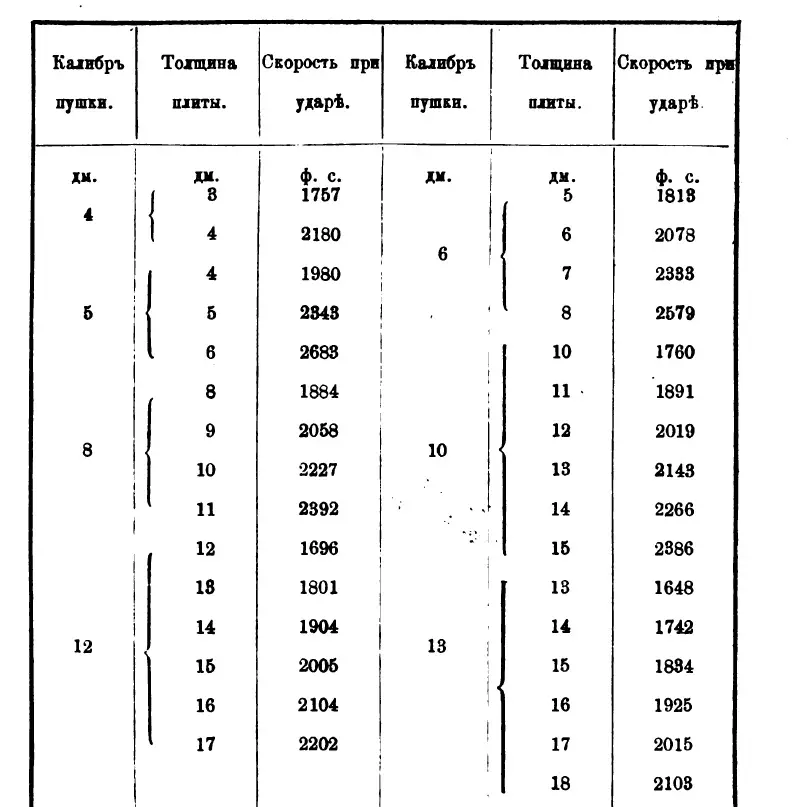

In the "Nautical Collection" No. 1 for 1898, material was presented which was a free translation of an article by Mr. Cleland Davis in the United States Naval Institute magazine for 1897 and another article published in the same year in the Naval Annual. Both publications are devoted to various experiments on shells of American, British, and German armor, cemented according to the methods of Harvey and Croup, and contain extremely interesting materials. Including the officially accepted formula in the USA for calculating the durability of cemented armor.

As well as information about the resistance standards of American cemented armor and the requirements for projectiles used in the process of acceptance tests of both, which I have already published in this series earlier.

So, the “Russia” armored armor produced in the USA, when fired by American shells, showed a “K” coefficient of over 2.

The above materials fully confirm this. For example, according to US standards, a 305 mm projectile had to penetrate armor equal to its caliber, having a speed on the armor of 1 feet per second, or almost 696 m/s. In those years, the Americans used unloaded 517-mm shells weighing 305 English pounds or 850 kg for testing. The “K” coefficient in this case will be 385,55, and we can safely say that the armor supplied for the “Russia” fully complied with the standards of the US Navy.

Unfortunately, Mr. Cleland Davis's article does not answer an extremely important question: was the American shell supposed to penetrate the armor while remaining intact, or was it allowed to be destroyed in the process of penetrating the armor?

About the decrease in the resistance of armor with increasing thickness and about the quality of projectiles

As you know, extensive experiments carried out on shells and armor in 1920 revealed an interesting pattern.

The resistance of Krupp armor up to 300 mm increased in proportion to the increase in armor thickness, but after 300 mm it no longer did. In other words, the coefficient “K” according to de Marr fell with an increase in plate thickness above 300 mm, as a result of which, for example, a 356-mm plate actually had the resistance that, according to the formula, 343-mm armor should have.

At the same time, according to American data, Harvey's armor demonstrated the opposite. According to the formula adopted in the USA, with increasing thickness of the slab, “K” increases - if for a 305-mm projectile and a 12-dm slab it is 2, then for a 011-dm slab it is already 13, for a 2-dm - 021 and for 14-dm - 2. That is, it turns out that the growth rate of resistance, on the contrary, is faster than the growth rate of armor thickness.

The question arises: is this a property of Harvey’s armor, or is it just an error in the formula developed by the Americans?

This question can be answered indirectly by analyzing data from an advertising brochure from the Wheeler-Sterling company, praising the quality of its own-produced shells. In it, in addition to the usual extolling of the qualities of the company’s products for advertising material, the result of experimental firing of an 850-pound (385,55-kg) Wheeler-Sterling projectile on a 356-mm garveyed nickel steel armor plate is presented. Unfortunately, the armor manufacturer is not specified.

So, the said projectile confidently penetrated 14-inch armor at a speed of 1 ft/s (848 m/s), while remaining intact. Well, not entirely intact, the warhead was deformed, but the explosive chamber remained sealed, and if the projectile had been equipped with an explosive and a fuse, it would have caused a full rupture behind the armor.

The result of this shot corresponds to “K” = 1, while according to the American acceptance standards, armor plates should have penetrated it only at a speed of 971 ft/s or 1 m/s, which would correspond to “K” = 904. As you know, the “K” coefficient does not determine the durability of the armor plate, but the ratio of the durability of the plate and the quality of the projectile. It turns out that the use of a high-quality Wheeler-Sterling projectile led to a decrease in the “K” coefficient by 580,34 units from the standard.

However, if we assume that the durability of Harvey's armor is subject to the same law of diminishing returns as Krupp's armor, then the 356 mm armor plate should be equivalent in durability to the 343 mm. If we take this assumption into account when calculating “K”, then “K” becomes equal to 2, which is fully consistent with the standards of the American fleet.

True, in this case, the Wheeler-Sterling shell itself turns from “shells against which no armor made in America or any other country can withstand” into ordinary high-quality, but not at all super-strong ammunition... Or not?

Generally speaking, the fact that the armor was penetrated within the range of plus or minus 60 de Marr units from the standard value does not at all do the American projectile any special honor. In my article “Tests of 120 mm and 6 mm naval shells 1901–1903. on Krupp armor" I demonstrated that the range in which, by some chance or another, the armor could be successfully penetrated was significantly greater. That is, a decrease in the speed of a projectile on armor by 56 ft/s cannot in any way be a circumstance that allows us to call the projectile the best in the world.

But if we assume that according to American standards, penetration with destruction of a projectile was allowed, then everything falls into place. It was precisely the fact that the projectile, without being destroyed, and even at a lower speed, overcame the plate, could just become the basis for the legitimate pride of the Wheeler-Sterling company.

Tests of Harvey's armor in the USA in 1897

These tests are interesting as an illustration of the above standards.

A 305-mm armor plate “surface-hardened” by the Harvey method produced by the Carnegie plant was tested. To do this, the slab, which was 12 feet long and 8 feet wide (roughly 3,65 m by 2,43 m), was secured to the frame so that it had a 305 mm oak spacer and two half-inch sheets behind it. Fastening was carried out with 18 armor bolts.

Then two shots of twelve-inch shells weighing 850 English pounds (385,55 kg) were fired at the armor plate. One, made by Wheeler-Sterling, struck the plate at 1 ft/s (769 m/s) and the armor held. The shell crashed, its head part was “welded” into the armor, but did not penetrate it, and there were no cracks. If the projectile had penetrated the armor at the limit, then “K” would have been 539,2, however, it is quite obvious that in this case it was very far from penetration.

Noteworthy is the fact that in one case, a 12-inch Wheeler-Sterling projectile overcomes a Harvey armor plate with a “K” equal to either 2 or 023, and in another case, it does not even show 1.

Another projectile, produced by Golzer with an armor velocity of 1 ft/s (almost 811 m/s), achieved somewhat more. Verbatim: “The top of the projectile just pierced the bulging part of the slab at the back, knocking out a cylindrical part of the slab, which went through the lining and fell behind the slab. The bulge ended up being 5/8″ tall and about 3/5′ in diameter. The face fracture diameter is 21 inches, the hole diameter is 13,5 inches.”

If the projectile had passed through the armor plate, even if it had been destroyed in the process, then its “K”, according to de Marr, would have been 2, but in fact it turned out to be even higher. That is, at the level of the Krupp serial armor supplied for the battleship Poltava.

As you know, testing the durability of armor is a delicate matter. After all, the “K” coefficient, which we take as a characteristic of the strength of an armor plate, in de Marr’s formula has a slightly different meaning and depends not only on the durability of the armor, but also on the quality of the projectile.

So, maybe the high quality of American armor for the US Navy in general and the armored cruiser Rossiya in particular was dictated by the low quality of American shells?

Tests of American garvey slabs in Russia in September 1895

In "Appendix I to the MTK Artillery Report for 1895" information is presented about the shelling of the products of the American Carnegie plant and the French Chatillon Commentry, which took place in September 1895. In this case, 10 mm and 152 mm shells were fired at 229-mm plates. At the same time, for six-inch ones, the speed on the armor is 2 feet per second, which is obviously a typo. Converted to the metric system, this is almost 890 m/s, and in Russia there were no guns capable of imparting such a speed to a six-inch projectile.

For the 229 mm projectile, however, a very reasonable 1 fps is quoted at 880 pounds, that is, 446 m/s at 573 kg. The result turned out to be exactly the same as three years ago when firing at the Vickers armor plate - the plate broke, but the shells also broke, “K” was 182,6.

As in the case of Vickers, it is not possible to calculate the resistance of the plate according to de Marr for penetrating the armor of a projectile in its entirety, but the increase in resistance is obvious: the same result in the case of tests in 1892 was achieved at K = 1, and in 901 - already with “K” = 1895. Moreover, these are not only my personal considerations: significant progress in the resistance of armor was noted by the authors of “Addendum I to the MTK report on artillery for 2.”

Here it is completely impossible to try to justify the difference in armor resistance by different quality of shells, because both the Vickers plate and the Carnegie plant plate were fired with a Russian 229-mm shell of the same type.

Thus, it can be considered confirmed that the resistance of the Carnegie armor recorded in tests was at the level of the serial Krupp armor acquired by Russia for the battleship Poltava, in which the “K” was 2.

The British don't sleep

Surprisingly, even such durability was not the limit for Harvey’s armor.

In September 1896, in Portsmouth, on the Nettle block, a 152-mm armor plate from the English Kammel plant was fired upon. They fired 100 lb Holzer forged steel projectiles with an armor impact velocity of 1 ft/s or 960 m/s.

A total of 5 shots were fired, of which 4 did not penetrate the slab, “and only in one case did the top of the projectile pass through; all the shells crashed, their warheads lodged in the slab.” Unfortunately, the source does not provide a description of the effective 5th hit. It is most likely to assume that the armor plate was penetrated to the limit, perhaps the shell broke in the process: this, according to de Marre’s formula, gives “K” = 2, and since 192 shells still did not penetrate the armor, it should be assumed that in this case “K "was even higher.

Conclusions

Based on the foregoing, it can be assumed that the resistance of Harvey's armor in its “original” form for armor plates that included nickel was “K” in the range of 1–700 without the requirement for the projectile to penetrate the armor as a whole.

After specialists from the American company Carnegie came up with a way to improve its durability, the “K” of Harvey plates increased to 2–000, apparently also without the requirement for the projectile to pass through the armor as a whole, and thus came close to Krupp’s armor. But still not achieving it, since the best values of Harvey's armor plates reached only the normative ones, that is, the minimum resistance values of Krupp armor.

Apparently, it was this improved Harvey that became the standard for the American fleet no later than 1897.

Unfortunately, based on the above, it is absolutely impossible to figure out exactly which Harvey plates protected this or that ship - even within the same country. Take the same USA: there is a case when at the same time (1895), in the same country (USA), one manufacturer used the latest armor production technologies at that time (Carnegie), and another (Bethlehem Iron Company) ) - produced armor without their use.

From the data available to me, it can only be assumed with some probability that the ships for which armor was ordered before 1895 carried the original version of Harvey's armor plates, and in 1896 and later - the improved double forged.

This concludes my analysis of Harvey's armor and moves on to Krupp.

Продолжение следует ...

Information