Once again about pistols, shotguns and cartridges by Johann Dreyse

A 14,73 mm Dreyse and Kollenbusch pistol made in the 1830s, with DC markings and a Prussian eagle on the breech. Smooth .58 caliber barrel. Solid lacquered walnut handle, flared at the rear. The firm Dreyse & Collenbusch existed from 1824 to 1834. Photo by Allen Dobress

and remains strong forever,

and lives and reigns

in the century of the century."

2 Ezra 38:XNUMX

History weapons. On the pages of VO we once already talked about Johann Dreyse’s rifle and the ammunition used in it. The material sparked a lively discussion in the comments. But words that are not supported by concrete data are, in general, useless. Well, numbers and diagrams are not always at hand. Sometimes you have to turn to a variety of sources for them and scrupulously verify data from various reference books. But since these weapons are indeed of great interest, it makes sense to delve deeper into this topic, which is what we will do here and now today.

Dreyse and Kollenbusch pistol, left view. 30s of the XIX century. Photo by Allen Dobress

So, let's start with the fact that Dreyse worked for Pauli (Poli - V.E. Markevich) and, having gained knowledge and ideas from him, returned to his home in Germany (Prussia), where his rifle with a needle ignition system was adopted in 1836 for service.

The Dreyse rifle could fire 5–9 rounds per minute, and the range of its bullet at the limit reached 800 meters. Moreover, this rifle was repeatedly modernized, improved and helped Prussia win a number of wars in Europe.

Dreyse and Kollenbusch pistol, Semmerde plant. To load the weapon, the lever located on the right side surface of the receiver had to be turned up and back. The cocking lever, which was eccentrically fixed to the base of the loading lever, moved back and, compressing the mainspring, cocked the needle striker. The charging lever had to be returned to the forward position. The paper cartridge was inserted into the barrel from the muzzle using a cleaning rod. When fired, the needle pierced the cartridge, reached the pin and pierced the capsule, which exploded and ignited the powder charge. The inconvenience of the system was the need to pull the needle back in time every time. Otherwise, it was possible to miscalculate the effort and push the cartridge further than it should, which could result in an accidental shot. Photo by Allen Dobress

The same handle in the position before the shot. Photo by Allen Dobress

All this has been written about many times already, but, as always happens in the case of incomplete knowledge, such brevity in the presentation of information often does not allow us to show the dynamics of the creative process of a particular inventor. That is, it turns out that Dreyse worked for Pauli, then he was somewhere unknown, and then he immediately came up with his own rifle. And sometimes this, or almost this, happens in life.

But in the case of Dreyse, the process of developing his rifle was much longer, and therefore more interesting.

This is where we will start...

It turns out that Dreyse in 1827–1828. worked on muzzle-loading shotguns and pistols that fired cartridges with a pallet, but not rifled ones, but smooth-bore ones. At the same time, he used different cartridges of his own design, including at first those with round bullets.

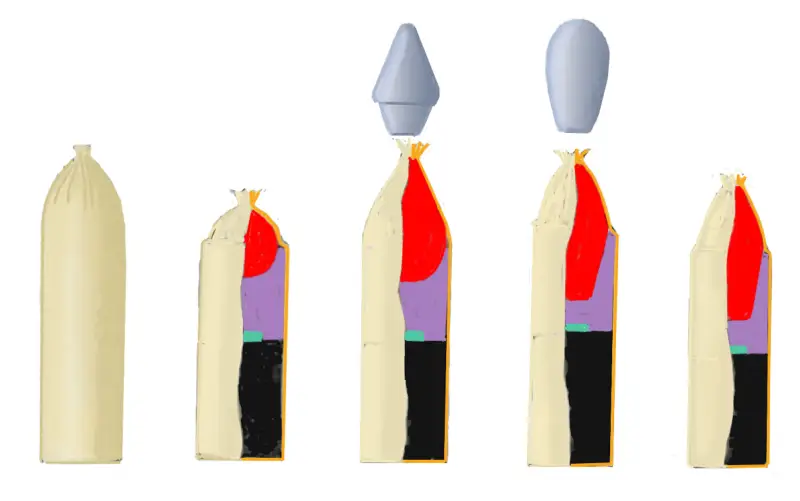

Cartridges of the Dreise design for needle pistols and shotguns with bullets of various shapes. Rice. A. Shepsa

In 1835, he designed the original breech-loading needle pistol. In it he used a rotating chamber, which actuated a lever on the right. It became much more convenient to handle him.

First of all, it was necessary to pull the needle along with its casing by the lever, and then return the casing to its previous position, leaving the needle cocked. This released the rotating bolt lever, which had to be turned so that the hole in the upper part of the barrel opened. The cartridge was inserted into this hole all the way, with the bullet forward, after which the lever returned to its previous position, and it was possible to pull the trigger and shoot.

Here it is, this pistol, in the hand of popular weapons expert Ian McCollum. Photos forgotten weapons

The same gun. Loading unit on the barrel. A cartridge can be inserted into the bolt hole. Photos forgotten weapons

The needle is armed. Photos forgotten weapons

The cartridge used in this rifle consisted of a paper casing, a bullet, a sabot, a primer and a charge of black powder.

The bullet, 15,4 mm in diameter, is shaped like an acorn, with the wider end forming a point, and the primer is attached to a folder tray (spigel), into which the bullet is inserted with its narrow part. Together with the pallet, it is placed in a “paper case” (we usually call it a sleeve), with a glued cardboard circle - the bottom. All this is separated from the bullet as it exits the barrel.

Inside the cartridge case was a powder charge consisting of 4,8 g (74 grains) of black powder. The upper end of the sleeve is folded and tied with thread. When the trigger is pulled, the tip of the needle pierces the back of the cartridge, passes through the powder and strikes the primer mounted on the base of the pan. Thus, the combustion front in the black powder charge passes from front to back.

This front-to-back combustion pattern minimizes the effect seen in rear-fire cartridges, where some of the powder at the front of the charge is wasted as it is forced out of the barrel and burned in air as a muzzle flash. This also ensures that the entire charge is burned at the highest possible pressure, theoretically minimizing unburned residue.

Therefore, a smaller charge can be used to achieve the same velocity compared to a rear-fire load of the same caliber and weight. This also increases the safety of handling the cartridge, since accidental firing of the primer is almost impossible.

A blank cartridge was also developed for the needle gun. It was shorter and lighter than the live cartridge, since it did not contain a bullet, but was otherwise similar to it in design and powder charge.

Dreyse rifle (below) and ammunition for it. Drop-shaped bullets and bullets inserted into the spygel are clearly visible

An important design feature is the device of the pallet and bullet.

The bullet itself is smaller than the caliber of the barrel, but it is inserted into a deep slot in the folder tray, which, when fired, crashes into the rifling, compresses the back of the bullet and gives it rotation.

An interesting question: did the bullet itself touch the rifling of the barrel?

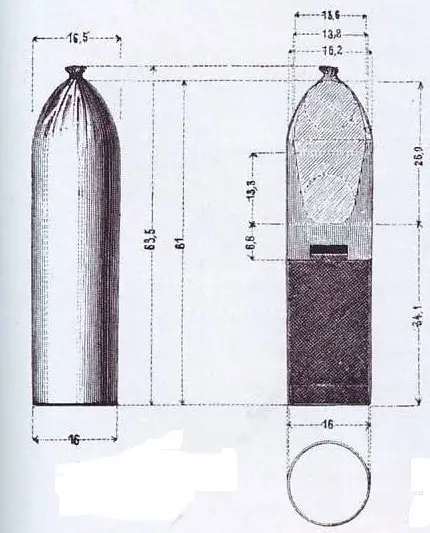

To do this, just look at the diameters of the bore, pan and bullet. The caliber of the Dreyse rifle barrel was 15,43 mm. The depth of the rifling fields is 0,78 mm. The diameter of the cartridge is 16,5 mm. The outer diameter of the folder tray is 15,2 mm, the inner diameter is 13,8 mm. But the maximum diameter of the bullet was 13,6 mm (13,5 mm - according to V. E. Markevich).

Geometric dimensions of the Dreyse cartridge

That is, the folder tray completely filled the rifling of the barrel when fired, so that the bullet simply could not, no matter how much he squeezed its tail part, ring out so much that its diameter was greater than its diameter!

In addition, being lighter, it was the first to begin moving along the bore after the shot, and the bullet, due to its greater mass and inertia, began to move after it, and there was no way it could jump out of the pan and press into the rifling.

Well, the cardboard itself also could not compress the bullet with such force that it would seriously change its geometry.

That is, as soon as the shot took place, this pan was pressed into the rifling of the barrel by the powder gases and, squeezing the bullet, forced it to take part in its rotation along the rifling.

Moreover, all the authors who wrote about the Dreyse rifle noted as its significant drawback that the bullet in the pan was often unevenly fixed and flew out of the barrel, having a disturbance in alignment. Therefore, the firing range from this rifle was short, somewhere around 500 m, and the accuracy was not very good.

Another disadvantage was that the unburnt remains of the cartridge case in the barrel interfered with the movement of the bullet, which again affected accuracy.

Meanwhile, nothing like this would have happened if the bullet had moved along the rifling in the barrel!

But in this photo you see a revolver from 1850, designed by Franz Dreyse, the son of the famous Johann, who received the title of nobility and the prefix “von” for his rifle. He also followed in his father’s footsteps and tried to produce a pin-screw revolver, but this weapon could not stand the competition with the new cartridge revolvers. Photo by Allen Dobress

Information