Resistance of various types of armor, according to N. L. Klado and S. O. Makarov, in the light of tests 1892–1896

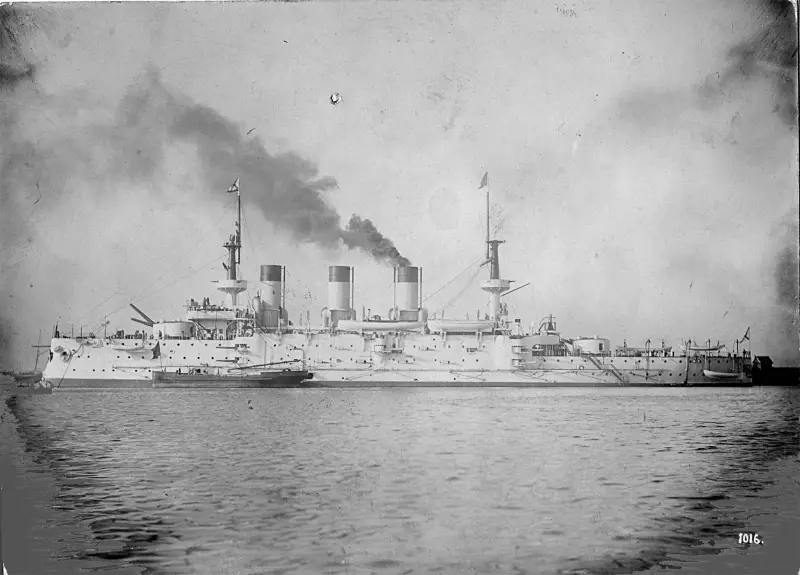

В previous article I presented the results of Russian experiments on steel-nickel and “surface-hardened” armor from various manufacturers, as well as testing the protection of domestic Poltava-class battleships.

During the first experiments in 1892, the Vickers garvey plate demonstrated a resistance of at least K = 1. However, subsequently the Russian Imperial Navy purchased products from the American Bethlehem Iron Company, which showed only K = 901 in tests in 1895. This is quite possible explain by assuming that here we are dealing with a standard spread in armor resistance, which could well fluctuate, say, within the “K” range of 1–717.

Again, let’s not forget that the Vickers slab presented for testing could have been manufactured by the company’s specialists specifically for testing and for the purpose of promoting their product, that is, on an individual basis, with the strictest control over adherence to technology. At the same time, the Bethlehem Iron Company products supplied for the squadron battleship Sevastopol were still serial.

In other words, the lower durability of the Harvey armor for the Sevastopol in comparison with the British one is quite understandable.

But how do you want to understand the solution for the battleship Petropavlovsk?

The crew of the latter had to be content with not cemented armor at all, but only steel-nickel armor with “K” = 1 from the same Bethlehem Iron Company. Which was inferior in strength not only to Harvey armor, but also to similar armor produced by the Obukhov plant, which in tests showed “K” obviously higher than 446.

Bribes? Negligence? Sober calculation?

And here, of course, I would like to understand the position of domestic specialists. Why did the Naval Department of the Russian Empire, instead of setting a standard and using the best armor according to the tests of 1892 (cemented according to the Harvey method of the Vickers company), made an inarticulate “hodgepodge”, ordering armor plates from different countries and different types for the newest battleships?

Why was Vickers armor never ordered for Poltava-class battleships?

Alas, I don’t have an answer to this question, I only have assumptions.

The fact is that the Vickers armor, which was quite remarkable for its time, found its place in the domestic navy – it was received by the Black Sea squadron battleship “Three Saints”. Let's not forget that the production of armor is a complex and lengthy process that requires a lot of special equipment, so it cannot be expanded quickly.

And it can be assumed that Vickers simply did not physically have time to supply the volumes of armor that the Russian Imperial Navy needed. That is, they bought as much from Vickers as the British could sell. The explanation, in my opinion, is quite reasonable, but perhaps there were other considerations.

In addition to Vickers products, the Three Saints received French armor, from different factories. Thus, the traverse armor plates were made by Schneider and Co., the casemates, conning tower and towers were made by Chamonet. And taking into account the fact that both the “Three Saints” and the Baltic battleships were laid down at approximately the same time, there is a feeling that the Russian Empire tried to reach as many foreign companies as possible in order to be able to test their armor and settle on the best.

On the other hand, it is possible that there was no such idea at all, but that they bought armor from everyone who could sell it simply because not a single manufacturer could provide the domestic fleet with the required number of armor plates.

Data from N. L. Klado and S. O. Makarov in the light of armor tests 1892–1896

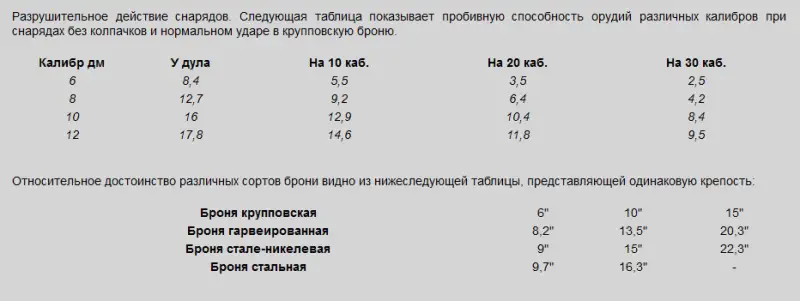

S. O. Makarov in his work “Armored Ships or Unarmored Ships” provides the following data on the armor penetration of various projectiles against Krupp armor and the comparative durability of different types of armor.

Obviously, calculations of armor penetration were not carried out according to the de Marre formula, because for this table it is impossible to derive a single coefficient “K” even for a projectile of the same caliber.

So, for example, if we assume that we are talking about penetrating armor with zero deviation from the normal, then for a 305-mm projectile at a distance of 20 cables K = 2, and at a distance of 150 cables – 30. If the calculation takes into account the deviation from the normal in the size of the angle of incidence of the projectile, characteristic of these distances, it turns out K = 2 and 132, respectively.

Unlike S. O. Makarov, Klado directly names the “K” coefficients according to de Marr, which, in his opinion, correspond to one or another type of armor.

S. O. Makarov reports that his calculations of the durability of Krupp armor refer to armor-piercing projectiles without an armor tip. The tests of the armor of ships of the Poltava type could not have been any different - in those years, tips were not yet installed on our shells, although experiments were carried out with them.

As for N.L. Klado, he, unfortunately, does not indicate for which projectiles the coefficients he uses should be applied - with or without tips. But taking into account the fact that its indicators are very, very close to both the calculations of S. O. Makarov and the actual test results that I wrote about earlier, it is quite obvious that he is talking about shells without armor-piercing tips.

Translating all this into a single coordinate system, we get the following table.

There is a certain correlation between the masters' assessments and armor tests. And it would be quite logical to assume that both S. O. Makarov and N. L. Klado in their calculations were guided by the minimum acceptable values, which were shown by Harvey and steel-nickel armor from various foreign suppliers.

As for Krupp armor, at that time its only supplier for the Russian fleet was the German Krupp plant itself, so there was simply nothing to compare its products with.

However, we can compare German-made Krupp armor supplied to Poltava with domestic armor manufactured under a German license.

Here too, there is a clear convergence of data. The armor of the Poltava when fired by a 203-mm projectile showed “K” = 2, while the resistance of domestically produced Krupp armor in relation to 150-mm projectiles gave “K” = 203–2 for plates of the given thickness (normative value) and 189–2 in actual testing. Of course, in this case, the German armor looks somewhat worse than the domestic one, but this can easily be attributed to the usual variation in resistance values during testing.

Based on the data presented, it can be assumed that the resistance of Krupp armor at the level of 2–150 was the standard not only in Russia, but also in Germany. If this is so, then we can state that our factories managed to master the licensed production of German armor without loss of quality.

But let's return to Harvey's armor.

About the durability of Garvey armor

So, at first glance, I was able to determine the comparative durability of Harvey and Krupp. And indeed, the Russian Naval Ministry was not only puzzled by the timely testing of surface-hardened Garvey armor, but also ordered it all over the world from a variety of manufacturers.

Naturally, the quality of the supplied armor was subjected to fire tests, similar to those carried out to protect the Poltava-class squadron battleships. Who else, if not Russian specialists, should know the strength characteristics of Harvey's armor?

And if they indicate “K” in the region of 1–687, then these were some minimum, standard resistance values that foreign Harvey armor demonstrated. Although, of course, as in the cases with Krupp armor, the resistance of individual armor plates could be significantly higher - remember the Vickers plate, which showed a “K” higher than 1.

But the fact is that the durability of Harvey’s armor throughout its life cycle, that is, from the moment of its appearance until it was replaced by Krupp armor, was not a constant. The technology for manufacturing hardened armor improved over time - for example, in the USA, the Carnegie Steel Company used reforging of cemented plates, which the hardening process did not initially provide for.

Therefore, in the next article I will present to the dear reader the results of other tests of Harvey armor that took place in 1896–1897.

Looking ahead, I note that in them Harvey’s armor showed significantly better durability than in those that I described earlier.

About the production of Harvey's armor in the Russian Empire

A respected reader may have a question: why was it even necessary to focus on a foreign manufacturer when analyzing the durability of Harvey’s armor? Did we not make such armor ourselves?

Oddly enough, Russia has really delayed the development of the production of cemented armor plates. Despite the fact that the experiments of 1892 demonstrated the obvious advantage of armor hardened using the Harvey method (early Vickers), the Russian Empire, according to the respected S. E. Vinogradov, mastered large-scale production of this type of protection only four years later in 1896 ( according to R.V. Kondratenko - since 1895).

Moreover, the century of Harvey's armor turned out to be extremely short-lived for the domestic industry, since already in 1898–1899. Russian armor business reoriented towards Krupp armor. The last garvey slabs in Russia were produced in 1900.

Such a late transition to harveying can be explained by several reasons.

Firstly, of course, the inertia and slowness of the Maritime Department.

But I also came across another point of view.

The test results of the armor plate for the battleship Poltava demonstrate that Russia has mastered the production of very high-quality steel-nickel armor. At the same time, starting in 1892, very intensive experiments were carried out in Russia on the creation of armor-piercing tips, which were effective only on cemented plates, but did not give any effect when shooting at steel-nickel.

Accordingly, it can be assumed that the Naval Department was deliberately in no hurry to transfer domestic production to garvey plates, fearing that the appearance of “Makarov tips” would reduce the advantage of cemented armor to nothing.

However, in light of what will be said below, this version gives me very serious doubts - I am sure that it is incorrect.

For everyone interested history In the domestic armor industry, I strongly recommend that you read the work of the respected A. G. Matveenko, “Production of armor for the needs of the fleet in the Russian Empire.” In this work, the author has compiled a lot of interesting information from sources available to him, supplementing them with his own considerations, which are noted separately so as not to cause confusion.

So, according to the sketches of the history of the factories that A.G. Matveenko used, the Naval Department did not acquire a patent for the production of Harvey's armor and did not use any foreign assistance. Simply put, representatives of the factories studied, as far as they could, the technological processes for producing garvey slabs abroad, and then reproduced them at the Izhora plant.

It can be assumed that it was this “reverse engineering” that led to a significant delay in the development of the production of Garvey armor. The Naval Ministry wanted to receive such armor for the armored cruiser "Russia", but was forced to order it abroad, since the domestic manufacturer did not have time.

It is possible that the domestically produced Harvey armor was used in the construction of the coastal defense battleship Admiral General Apraksin, but what is certain is that the bulk of the Harvey armor on the squadron battleships Peresvet and Oslyabya was of domestic production.

However, there are nuances here too.

Firstly, it is reliably known that for Peresvet the casemate armor was ordered in the USA from the Carnegie company. In addition, according to the Most Valuable Report on the Naval Department for 1897–1900, 170,9 tons of armor were manufactured for Peresvet by the Krupp plant, this, according to the calculations of A.G. Matveenko, “was only enough for the lower ring of the aft turret barbette and the lower and middle rings of the barbette of the bow tower, which, due to the great loss of their slabs, could cause the greatest difficulties for the Izhora factories.” Obviously, the Krupp plant would not produce armor using Harvey's technology.

Secondly, A.G. Matveenko quite rightly points out that the armor of the supply pipes (barbettes) for the Oslyabi, manufactured somewhere around 1900-1901, was also most likely Krupp armor.

It can be assumed that, faced with the difficulties of “reverse engineering,” the Naval Ministry did not want this to happen again and entered into an honest, albeit very expensive, contract with Krupp to organize the production of his armor in Russia. This was very expensive - in the first 6 years, F. Krupp had to be paid 100 rubles for each ton of slabs cemented by his method produced in the Russian Empire, but not less than 100 rubles per year.

In the next 6 years, the “hundred-ruble” tariff was retained, but the minimum annual payment amount was not established. For uncemented Krupp armor they paid half as much - 50 rubles/t. At the same time, changes and additions to the method of manufacturing armor by Russian factories were not grounds for canceling payments.

But there was also a very interesting condition in favor of the Naval Ministry - if, after three years from the start of production in Russia, some factory in the world came up with armor that was more than 10% superior to Krupp’s, then further payments could be stopped.

Of course, in this case, the Naval Ministry decided not to skimp and to accelerate in every possible way the introduction of the best type of armor on domestic ships, even at a high price.

As for the quality of domestically produced Harvey armor for the Oslyabi and Peresvet, it remains a mystery to me.

Most likely, ours managed to “spy” and reproduce exactly the early technology of Harvey’s armor, in which the lower limit of “K” was something like 1, and the upper limit hardly exceeded 700.

This version is supported by the fact that both S. O. Makarov and N. L. Klado, dealing with issues of armor, could not help but know that Harvey’s armor could be much more durable - after all, an improved “Harvey” "produced by the Carnegie plant was supplied for the cruiser "Russia" and, probably, for the casemates of "Peresvet" (although there is an opinion that the latter received casemates from Krupp armor).

However, both of them in their works indicated data on the “early” Harvey - is it not because for Russian industry it was “K” within 1 that was established as the minimum resistance values?

Again, a fairly logical picture of what is happening is emerging: Harvey armor is being created in the world, we are mastering its production with a considerable delay, and then suddenly the same “Harvey” appears, but much more durable, and also Krupp... With such initial conditions it becomes more than The desire of the Naval Ministry, no longer taking into account costs, to master the most durable type of armor is understandable.

The final answer about the strength of the armor of “Peresvet” and “Oslyabi” could be given by acceptance tests of the armor by shooting, which, alas, I do not have.

To be continued ...

Information