Krupp armor of the Russian Empire. Let's go for the record

This article, and the materials that followed it, appeared thanks to a large array of data on firing tests of domestic armor-piercing shells with armor-piercing tips in the period 1901–1903, given by E. A. Berkalov in his book “Design of Naval Artillery Shells.” Analysis of this information led to a number of very unexpected conclusions.

Features of tests and reports about them

Firing was carried out with unloaded armor-piercing shells from the Perm, Obukhov and Putilov factories against armor plates hardened by the Krupp method. The thickness of the armor plates varied from 127 to 305 mm. These slabs were installed on the frame of a single structure, which did not change depending on the thickness of the slab, with one exception.

In all cases, a flat vertical steel jacket one and a half inches (38,1 mm) thick was installed on the vertical buttresses (frames). The jacket, however, was not monolithic, but consisted of three half-inch (12,7 mm) steel sheets stacked on top of each other. A 4-inch (102 mm) pine lining was laid on top of the shirt, on which the armor plate was installed. The exception was armor plate No. 83 of the Obukhov plant. It was curved, so the thickness of the pine lining underneath varied from 2 to 20 inches (50,8–508 mm).

All tested projectiles were equipped with armor-piercing tips of the “Makarov” system - although the design of the tip is not directly indicated, but in 1901–1903. There simply could not be any other tips.

Almost all shots were fired at normal (90 degrees). Two cases are described when shells hit at angles of 25 and 28 degrees, but both of these shots were fired at a curved plate - it can be assumed that these angles were not formed by the intention of the shooters, but as a result of deviation of the projectile trajectory in flight due to dispersion.

Since during testing there were cases when the projectile hit a place weakened by previous hits, such results were recorded, but were not counted and were specially noted. I'll do the same.

For each shot the following is indicated:

1. Caliber and exact weight of the projectile. For a projectile of the same caliber they differed slightly. For example, the difference between the heaviest and lightest 120-mm shells from the Obukhov plant was 153 grams.

2. The number of the armor plate, its thickness.

3. The speed of the projectile at the moment of impact on the armor and the angle of deviation from the normal. With rare exceptions it is zero.

4. Descriptions of what was pierced, whether the projectile remained intact, and where it or its fragments were found, and other additional information, such as the calculated “manpower” of the projectile.

Typically, test descriptions are limited to these data. But E. A. Berkalov also cites other, extremely important data that I have not encountered before:

1. Theoretical penetration velocity for this plate for a projectile without a tip. This is the first time I have come across this indicator, and its value is difficult to overestimate - thanks to it we will see the durability of domestically produced Krupp armor as our ancestors understood it in 1901–1903.

2. Something that I never expected to see is an indicator called the “slab coefficient”. This coefficient showed how much this particular armor plate was superior to a standard plate of equal thickness in terms of durability.

Thanks to such comprehensive information, I had the opportunity to evaluate both the calculated and actual durability of domestically made Krupp armor, as well as determine the capabilities of the armor-piercing tip of the “Makarov” design.

Но обо всем по порядку.

Resistance of Krupp armor - calculated values

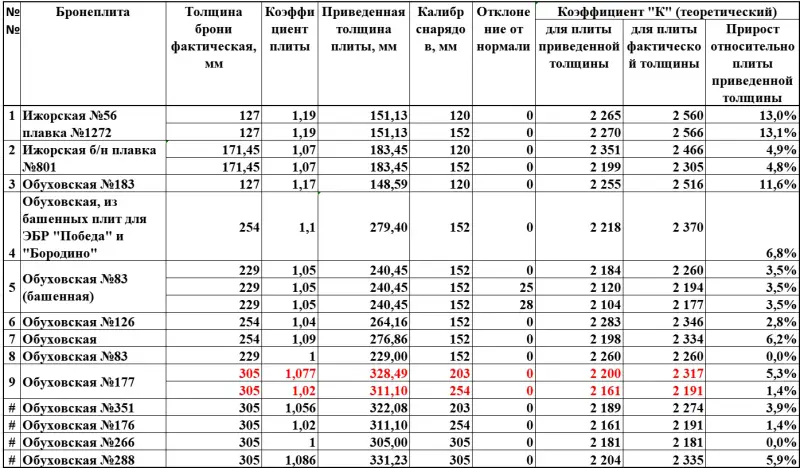

Based on the above data, I created a table, below there will be comments on it.

So, the first thing I did was to calculate the “K” coefficient using the de Marre formula for both the actual and the reduced thickness of the armor plates. The method is very simple.

Let's take, for example, Izhora slab No. 56 of melt No. 1272 - its thickness was 127 mm. It is indicated that the coefficient of this slab is 1,19; and it must be penetrated by a 120 mm projectile weighing 20,17 kg without a tip at a speed of 2 feet per second (535 m/sec). In this case, calculations using the de Marre formula show “K” = 772,7. This will be the calculated value of the durability that is expected from this particular armor plate.

But you need to take into account that this particular slab turned out to be extremely good, and its durability is 19% higher than the standard. Therefore, it corresponded to 151,13 mm armor plate of standard resistance. Substituting into the calculation instead of 127 mm the actual thickness of the plate 151,13 mm, I get “K” = 2 - it was this coefficient that characterized the durability of a standard domestically produced Krupp plate in relation to a 265-mm projectile.

Here, perhaps, I would like to once again draw the attention of the dear reader to the peculiarity of the armor penetration formula derived by de Marr. The increase in the thickness of the armor is not directly proportional to the increase in the speed of the projectile at which it penetrates this armor (the speed of the projectile changes in proportion to the thickness of the armor to the power of 0,7). The “K” coefficient, on the contrary, changes in direct proportion to the speed. Therefore, an increase in the resistance (thickness) of armor by 19% requires an increase in “K” and the projectile speed to penetrate it by only 13,02%.

I would be happy to give not only the calculated values of the “K” coefficient, but also the projectile velocities required to penetrate armor, but in this table this is impossible, since these velocities, although slightly, still differ depending on the mass of the projectiles. In the future, when I publish descriptions of each hit, these speeds, of course, will be presented to the dear reader.

The question arises: how was the actual durability of a particular armor plate determined?

E. A. Berkalov’s textbook does not contain a direct answer to this question, but it is indicated that for Obukhov plates No. 176 and 177 for 254-mm shells, this parameter was determined by test shots. It can be assumed that for other slabs it was installed in a similar way.

Conclusions

1. The most important conclusion that follows from the above calculations is the huge variation in the strength of domestically produced Krupp armor plates; the durability of individual copies could exceed the established standard by as much as 19%.

2. Exceeding the standard resistance of armor plates was the norm. Of the 13 armor plates, only 2 had strength that met the standard, the rest turned out to be stronger.

3. The durability of armor plates was calculated taking into account specific types of projectiles. So, for example, the same Obukhov plate No. 177 exceeded the standard one when exposed to 203-mm shells by 7,7% (plate coefficient 1,077), and when exposed to 254-mm shells - by only 2% (1,02). Which, of course, once again emphasizes that the coefficient “K” according to the de Marre formula determines the resistance of protection not “in general,” but in relation to a specific projectile.

4. The calculated “K” values for non-curved armor plates fluctuate even within the same caliber of projectiles:

– 120 mm shells: 2–255 for slabs of given thickness and 2–265 for actual ones;

– 152 mm shells: 2–198 for plates of reduced thickness and 2–283 for actual thickness;

– 203-mm shells – 2–189 for plates of given thickness and 2–200 for actual ones;

– 254 mm shells – 2 for plates of given thickness and 161 for actual thickness;

– 305-mm shells – 2–181 for plates of given thickness and 2–204 for actual ones.

5. In general, there is a noticeable tendency that relatively thin plates in relation to projectiles of fairly small calibers show better resistance than plates of greater thickness under the influence of large calibers.

6. There is a strangeness in the calculations of the durability of a curved slab - the greater the deviation from the normal, the lower its calculated durability.

7. Curved armor has less durability than “flat” armor. Two armor plates with a thickness of 229 mm were subjected to fire from 152 mm shells, but the minimum “K” for a curved plate was 2, and for a flat one, 104.

Hypothesis about the difference in armor resistance

How could it happen that when making cemented slabs there was such a variation in durability? Here, alas, I can only speculate.

Obviously, if we take two absolutely identical workpieces and carry out absolutely identical operations on them, then as a result we will get two absolutely identical armor plates. But in life, of course, this does not happen - the composition of the workpieces varies, and the operations in the technical process are not carried out identically, but with some tolerances.

At the same time, the process of creating a cemented slab using the Krupp method is very difficult. I will give it briefly according to the description given by the respected P.V. Sakharov in his work “Making armor plates using the Krupp method.”

First, steel of a certain chemical composition is welded. Then it is melted in open-hearth furnaces and cast into cast iron molds into ingots that weigh 70% more than the weight of the plate in its final form.

Then the ingots are cooled, released from the mold, heated again and rolled to a state slightly thicker than necessary. Rolling lasts 40–55 minutes, and then back into the oven.

The workpiece, heated to 600 degrees, is now sent under a press, then cleaned of slag and impurities.

Then two slabs are taken, installed with cemented surfaces to each other so that the distance between them is several centimeters, and there, heated to almost a thousand degrees, these slabs stand for 7 to 20 days, and gas is released between them in order to “carbonize” surface to be cemented.

The hot plate is cooled in oil, while the oil itself is cooled by circulating water, heated again and then immersed in water. And then - again under the press, now giving the future slab the desired shape. Moreover, this process can be repeated if necessary if the required state of the workpiece is not achieved the first time.

And then back into the oven, but the process is more complicated than the previous one, because the task of hardening is to bring the temperature of the cemented layer to 800–900 degrees, while the non-cemented side should warm up to no more than 650 degrees. German engineers achieved this by laying the uncemented side of the slab on wet sand, which conducts heat well while the cemented surface remains exposed.

And finally, after this treatment, final hardening occurs with jets of water falling on the cemented plane.

Of course, the process of making Krupp plates in different countries was not identical, but remained to a certain extent similar. And it can be assumed that some deviations in the composition of the workpieces, as well as in the technological process (temperature conditions, etc.) led to the difference in the durability of armor plates shown above.

And here the second question arises - if there were a lot of armor plates whose durability exceeded the standard values, then how many armor plates were there that did not reach the standard?

It is impossible to say that there were none simply on the grounds that they were not used in testing the shells, since this would be a typical “survivor’s mistake.” Who knows, maybe some of the armor plates submitted for testing were rejected as a result of test shots, and Professor E.A. Berkalov simply did not indicate this in his work, since this was in no way related to the design of projectiles?

I assume (but this is only a hypothesis) that the standard strength of a domestically produced Krupp plate is the minimum, or close to it, resistance, which is achieved by observing the chemical composition of the steel and the requirements of the technical process. That is, the standard is the minimum strength that the slab will show, even if the vast majority of chemical and technological tolerances work against it. A decrease in durability below the standard occurs when the chemical composition of the workpiece initially does not meet the requirements, or violations of the technical process were committed, in other words, there was a deviation beyond the maximum permissible tolerances.

In support of this hypothesis I can say the following.

Obviously, there are some minimum and maximum values of resistance that an armor plate can have if the boundary requirements for the chemical composition of its workpiece and the technical process are met. Simply put, if all the tolerances are a plus, we will get a slab of the best strength, and if, on the contrary, it is a minus, then the strength will be minimal. Between these minimum and maximum the durability of the armor plates produced will vary. But it is quite difficult to imagine that the deviations and tolerances were such that the durability of the slab varied by plus or minus 19% from the average value.

Again, if we assume that, for example, the standard resistance was set at a certain average level, then in this case approximately half of the armor plates would be below the required level and would not be accepted by the customer. But then we would have evidence of regular and massive discarding of armor, which I have never come across in the sources. Yes, there were defects, yes, some batches were rejected, of course, but not half of what was produced.

So I think my hypothesis is correct. I also assume that it is fair and applicable to armor not only from domestic, but also from foreign manufacturers.

Very important note

As mentioned above, the firing tests, on the basis of which the above conclusions were made, were carried out in the period 1901–1903. But we must not forget that the requirement that the projectile, while penetrating armor, remain intact was formulated later - only in 1905.

This leads to a very simple conclusion: the above “K” coefficients meet the requirements for penetrating armor without preserving the integrity of the projectile. If we set the condition for preserving the projectile as a whole, then in order to fulfill it, the projectile speeds on the armor must be greater, and the “K” of domestic armor will be higher than those given in the table in this material.

Next we will look at the results of firing tests for all calibers: from 120 mm to 305 mm.

To be continued ...

Information