The same “Belka”: Morozov about his vision of a promising tank

“Object 490”, “Object 490B” or “Squirrel” - as they name the concept tank E. A. Morozov, which has long been the subject of controversy and various kinds of insinuations. Some say that the car is completely fictitious, while others say that the tank was almost made of metal.

In fact, the truth is in the middle: there was not a single full-fledged copy of this tank, but the developments that died at the preliminary design stage actually existed. Moreover, in the magazine “Bulletin of Armored Equipment” for 1991, a very voluminous article by Morozov was published about his vision of a promising tank. Of course, the idea is practically unviable, but it’s worth getting acquainted with the designer’s thoughts, which is why we are publishing it here, providing some illustrations.

Possible version of an unconventional tank layout

The advantages and disadvantages of the traditional classical tank layout are analyzed. A possible variant of a non-traditional tank layout is proposed, which provides an increase in its survivability compared to the classical one.

Currently, the army of almost every developed country in the world is armed with tanks. Despite the significant increase in the effectiveness of anti-tank weapons, they remain one of the main types of weapons of the Ground Forces. This is explained by the unique combination of powerful weapons, reliable protection and high mobility in a single vehicle.

It can be argued that the level of combat and operational qualities is greatly influenced not only by its tactical and technical characteristics, but also by the principle of constructing the overall layout of the vehicle.

For almost a quarter of a century, from the appearance of the first tanks in the army (1916) until the end of the 30s, there was a practical search for the appearance of this new type of weapon. During this period, tanks of different weight classes appeared - light, medium and heavy with various designs and layouts, with a crew of two to 12 people, on wheels, caterpillars and combined drives. They were armed with from one to five cannons of a relatively small caliber.

A characteristic feature of this design of tanks was the relatively weak bulletproof armor, since it was precisely from the growing number of rapid-fire small arms weapons the armor was supposed to protect the crew.

At the end of the 1930s, the T-34 tank was adopted by the Red Army, which, as the experience of World War II showed, embodied not only the optimal level of tactical and technical characteristics and high manufacturability of the design, but also determined the rational layout scheme of that time. It was appreciated and accepted as a role model by tank developers, both in the USSR and abroad, and was replicated many times in various tank designs during the Second World War, as well as in the post-war years.

The distinctive features of the layout of the T-34 tank include the following:

1) an armored body with large frontal plate angles and a differentiated level of protection in azimuth;

2) a 360° rotating turret with a cannon and combat crew (tank commander, gunner and loader);

3) engine-transmission compartment (MTO) with a diesel engine, located in the rear part of the hull;

4) control compartment with the driver in the bow of the hull.

This layout scheme gave a number of advantages to this tank, which became the most popular model of armored vehicles of the 40s. Analyzing this layout, we can note the following inherent qualities:

– Placing the main armament (gun) and its combat crew at the top of the vehicle provides a good overview of the battlefield and effective use of the tank’s firepower at long distances.

– Placing the driver in the bow of the hull allows him, in the 90...120° sector, to have a good overview of the route of movement at short average distances, which does not limit high average speeds in battle and on the march.

– The rear location of the power plant in combination with the engine systems, fuel and transmission and drive wheels ensures the compactness of the MTO systems with minimal communication routes, and its shielding by the front part of the hull and turret from the damaging effects of enemy fire supports the high survivability of the power plant, and, as a result, preserves tank mobility in battle.

– Refusal of the wheeled-tracked drive, which was equipped with pre-war high-speed tanks, and equipping them with a chassis with a purely tracked propulsion system made it possible to provide structurally simple and reliable means of ensuring high cross-country ability, acceptable agility and sufficient smoothness when driving over uneven terrain.

The layout scheme developed during the creation of the T-34 tank was so successful that since 1940 it has become traditional for world tank building. The rich experience of the Second World War confirmed its vitality and prospects. This is precisely what can explain the lack of serious attempts to change anything, as a result of which over the next 50 years the layout of the vast majority of Soviet and foreign tanks has not undergone fundamental changes, despite the fact that the level of tactical and technical characteristics of the tank has continuously increased over these years.

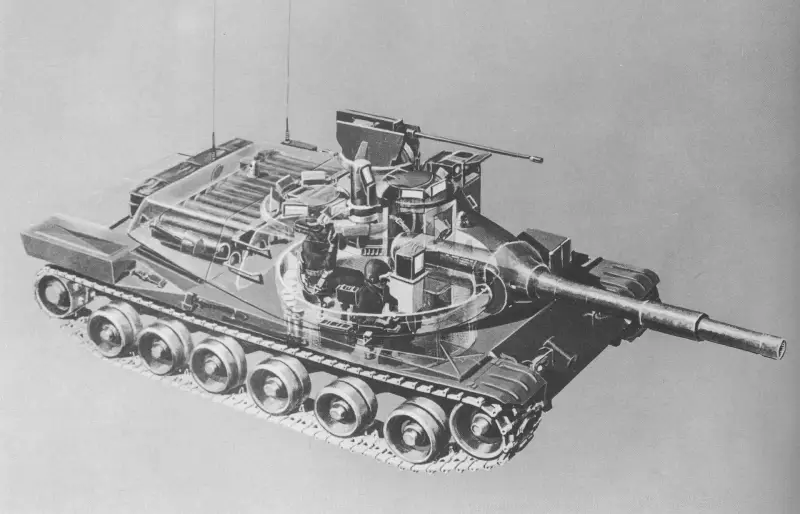

The M1 Abrams tank is one of the representatives of tanks with a classic layout

Thus, the caliber of the gun increased by 1,5 times, engine power by 2–3 times, and the level of armor protection by 5–8 times. An automatic loader for the main armament appeared, and the crew size was reduced to three people. Nevertheless, the above layout scheme has been preserved to this day, having received the name “classical” among specialists.

Those rare deviations from established traditions, represented by the Swedish turretless tank Strv 103B with a cannon rigidly mounted in the hull, and the Israeli Merkava Mk. 2, Mk. 3 with a front-mounted MTO, rather confirm than refute the general trends in global tank building.

At the same time, it should be noted that the constant increase in the combat properties of the tank, natural in the conditions of technical progress, and the rivalry of the main countries developing tanks encounter a number of technical difficulties in the layout plan, which gradually develop into contradictions and insoluble problems. Thus, increasing the security of a tank entails an increase in the mass of the tank, which negatively affects a number of important qualities and, above all, mobility. For example, the weight of the T-34 tank produced in 1940 was 26 tons, and the T-80U tank with a 6TD engine produced in 1990 reached 46,1 tons.

Dynamic protection, which was developed in the 80s and the equipping of mass-produced tanks with it, somewhat restrains the growth of the tank’s weight. Nevertheless, even today, weight reduction remains the most pressing and problematic issue for both domestic and foreign tank building.

The constant desire to increase the specific power of a tank, necessary to ensure the tank's superiority in mobility over its opponent in marching and combat conditions, forces the creation of power plants with high rated power, which reduce power utilization rates on the march and worsen fuel efficiency.

The increase in power of the power plant is caused primarily by an increase in the mass of the tank and the desire to improve its acceleration characteristics. The consequence of this is an increase in the volume of transported fuel, which adversely affects the balance of the reserved volume, especially since in order to increase the survivability of the tank, there is a tendency to reduce the volume of fuel placed outside the vehicle.

A number of complications are caused by the intensive growth in the caliber of the main weapons. An increase in the caliber and, consequently, the length of the barrel leads to an increase in the dimensions of the breech of the gun and the armored volume it sweeps during the vertical pumping of the gun and the horizontal rotation of the turret. In addition, the increase in the size of ammunition complicates their placement in the automatic loader and leads to a reduction in ammunition.

These and many other problematic issues that arise before the developers of promising tanks, in our opinion, can be resolved only if they move away from traditional solutions and, above all, in relation to the layout of the tank.

Tank MBT-70

In the 70s, foreign experts carried out in-depth studies of new tank layouts with fundamental differences from the classical design. In the USA, the development of the MVT-70 tank was undertaken, where the entire crew of three people was located in the turret. The driver's capsule had a corresponding counter-rotation when the turret rotated, due to which the driver was always oriented in the direction of movement of the tank.

In Germany, an experimental VTI tank of a turretless design with two guns in the hull above the tracked contours was being developed. The guns in the 105 and 120 mm variants were stabilized in the vertical plane, and in the horizontal plane, guidance was carried out by turning the vehicle. It was supposed to increase the probability of hitting with the first shot to 90% instead of 75% for a turret tank.

Published foreign reports on the further search for promising layout schemes are mainly limited to the development of remote and semi-external weapons, which makes it possible to reduce the area of the frontal and side projection and limit the increase in the mass of the tank.

In general, the revision of the classic tank layout is currently being carried out very carefully and is focused on the long term. At the same time, it is impossible to significantly increase the combat effectiveness of a tank without breaking established canons and traditions that have been established for many decades.

It is necessary to name the fundamental problems of the general layout of the tank, without solving which it is difficult to count on a way out of the current deadlock.

1. The size of the crew must be kept to a minimum and placed in a single compact habitable compartment. This will make it relatively easy to ensure reliable protection of only this compartment from the entire range of destructive agents, including chemical, bacteriological and radiation exposure, and to create the necessary comfort in the habitable compartment. Co-location of the crew radically solves the issues of mutual assistance and interchangeability, significantly simplifies the issues of internal communication and duplication of tank crew functions.

2. All ammunition of the main armament must be fully mechanized and placed in a single automatic loader with a simple trajectory and kinematics for delivering a shot to the gun breech.

3. The entire supply of reserved fuel (except for NZ) must be concentrated in a single container, divided into sections by several partitions to prevent significant loss when armor is penetrated.

4. The tank’s power plant must be able to operate in two modes:

a) maximum power – when driving and difficult road conditions and in combat;

b) in partial mode (~50% Mmax - when driving on good dirt roads and paved roads. Both modes should be equivalent in terms of efficiency, ensuring minimum specific fuel consumption. This is the most radical way to increase the cruising range of a tank with a limited amount of transported fuel .

5. In order to increase the survivability of the chassis, it is advisable to replace the 2-circuit chassis with a 4-circuit chassis with a drive for each circuit. This will make it possible for the tank to not lose mobility if one of the lines (or even two on different sides) breaks.

The implementation of the listed fundamental provisions should be included in the layout diagram at the early stages of design in conjunction with design solutions of the main components and systems, so that the individual tank systems, while performing their own functions, simultaneously contribute to achieving the specified performance characteristics for the vehicle as a whole.

For example, replacing a torsion bar suspension with a hydropneumatic one, in addition to solving the main problem - increasing average speeds by improving the smoothness of the ride - makes it possible to control the tank's ground clearance, which increases its maneuverability and survivability in battle. In addition, the controlled hydropneumatic suspension, by changing the trim of the vehicle, makes it possible to increase the gun pointing angles in the vertical plane. Thus, the introduction of only one system increases the mobility (direct effect), security and firepower of the tank (side effect).

The development of conceptual provisions for a promising layout scheme is only the first stage in the creation of a new tank. Then the most important thing remains - the unification of individual provisions into a single whole, the search for an optimal compromise in case of incompatibility of some initial requirements, the determination to sacrifice secondary indicators for the sake of implementing the most important ones.

Let's consider one of the possible non-traditional tank layout options.

The main principle implemented in this version is the conditional division of the entire vehicle into 5 compartments isolated from each other and their arrangement along the longitudinal axis from bow to stern in a sequence corresponding to their contribution to the combat effectiveness of the tank.

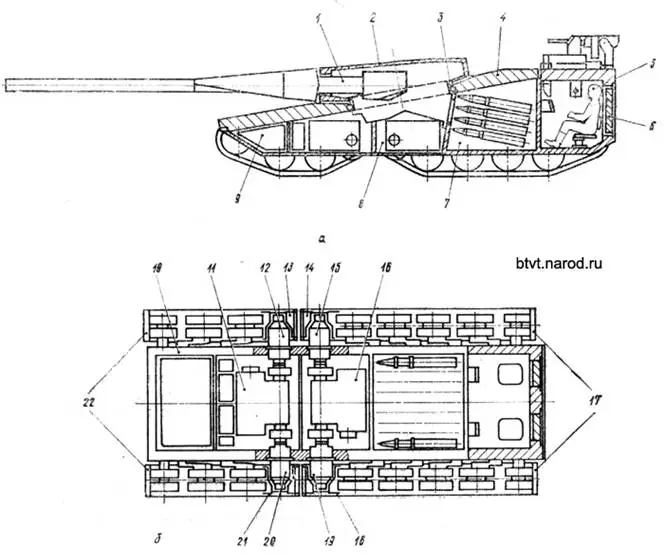

A variant of a non-traditional tank layout: a – longitudinal section; b – plan view with the turret and hull roof removed; 1 – gun; 2 – tower; 3 – turret shoulder strap; 4 – automatic loader compartment cover; 5 – crew compartment; 6 – crew aft hatches; 7 – automatic loader compartment; 8 – power unit compartment; 9 – fuel compartment; 10 – tank body; 11, 16 – engines; 12, 15, 19, 20 – onboard gearboxes for transmitting power to the drive wheels of the front and rear contours; 13, 14, 18, 21 – drive wheels of front and rear contours; 17, 22 – tracks of front and rear contours.

The first is the fuel compartment with the minimum permissible level of armor protection against the most widespread weapons of destruction of the tank. Damage to this compartment and partial loss of fuel in battle will not lead to the tank losing its combat effectiveness.

Behind the fuel compartment in the hull is the power plant compartment, and above it is the main weapons compartment. These compartments have a higher level of protection, since failure of the engine or gun significantly reduces the combat capabilities of the tank. The fuel compartment located in the bow of the hull serves as a screen for the power plant and increases its survivability during shelling.

The power plant includes two identical engines. The hydrostatic transmission allows you to adjust the amount of power transferred to each track. This makes it possible:

– use engines of moderate power with high power of the power plant as a whole;

– continue driving if one of the engines is damaged by combat;

– reduce travel fuel costs by using one of the engines or both together, depending on road conditions.

Then the automatic loader compartment (A3) with ammunition is placed, which has an even higher level of protection and is shielded from frontal fire by the previous three. Damage to this compartment, in addition to the tank losing its firepower, can lead to the detonation of charges with serious consequences. To neutralize the high pressures that arise in the event of detonation of charges, “knockout plates” are provided at the bottom of the compartment, acting as a safety valve. The length of the A3 compartment provides the possibility of placing unitary ammunition and simplifies the kinematics of feeding and sending ammunition into the gun chamber.

The last part of the tank is the crew compartment. The crew is located in a comfortable position - sitting, ensuring all ergonomic requirements. On the roof there is a complex of electro-optical means for searching for targets and controlling the main and additional weapons. This tank layout ensures differentiation of the level of protection and survivability of individual tank components in accordance with their importance.

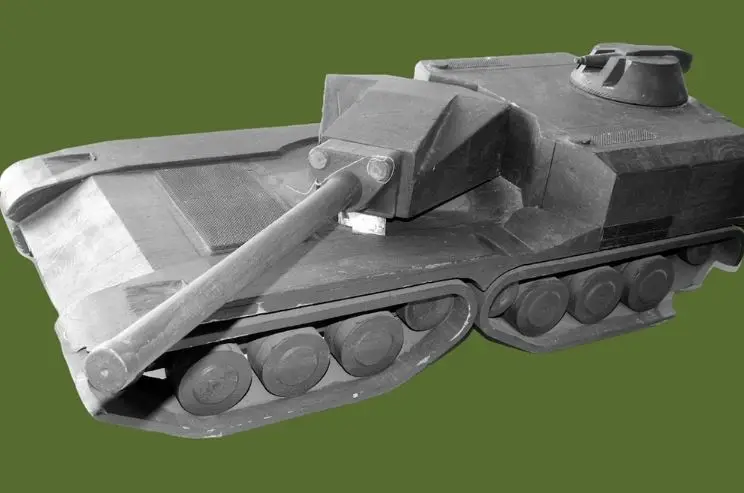

Possibly one of the models of the Morozov tank

If the first (fuel) compartment has frontal projectile protection at the level specified by the TTT, then the last compartment (crew) will be practically protected 2–2,5 times stronger. Since the creation of shells with such a level of armor penetration is impossible in the foreseeable future, the specified construction of the layout scheme makes it possible to ensure a high probability of tank survival in battle with a minimum mass of armor.

Hack and predictor Aviator

The proposed version of the non-traditional layout of the tank, which is divided into five isolated compartments with a consistent increase in the level of their armor protection, makes it possible to increase the survivability of the tank with a minimum weight.

[I]Source:

P. F. Gnedash, L. I. Mazurenko, E. A. Morozov Possible version of a non-traditional tank layout / P. F. Gnedash, L. I. Mazurenko, E. A. Morozov // Bulletin of armored vehicles. - 1991. - No. 7.

Information