How the Soviet Union looked for a replacement for the V-2 tank diesel engine, but never found it

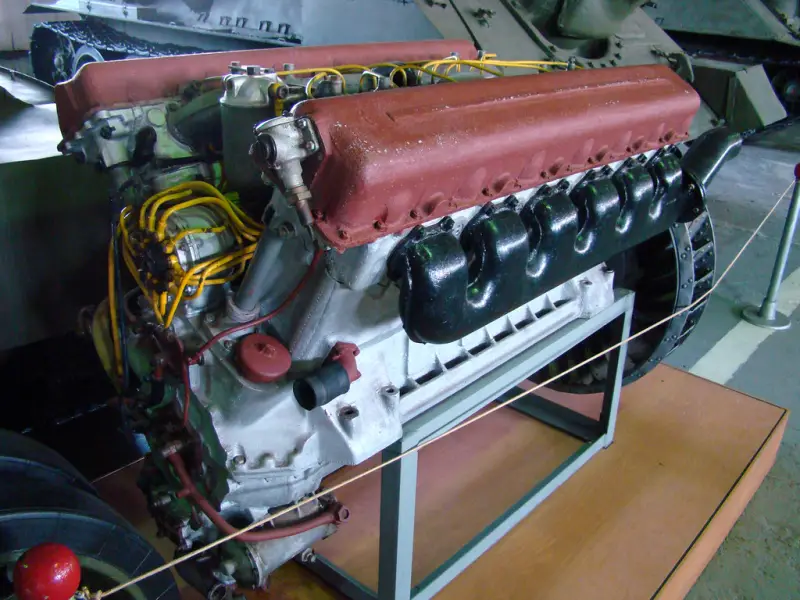

B-2-34

Searching for an alternative

The twelve-cylinder V-shaped diesel engine acquired the features of a serial product back in 1939. The engine is unique in its own way and for tank quite fit. Recently, a lot of critical materials have appeared about its build quality during the Great Patriotic War and design flaws.

Without going into all the details, one can agree with the opinion of historian Nikita Melnikov, who noted that “the desire of the Soviet leadership to have a modern powerful engine in service far outstripped the design potential and production capabilities of the domestic industry.”

Only these very “production capabilities” occurred at the time of the Nazi occupation of a large part of the Soviet Union, including Kharkov, where the B-2 was planned to be produced. If not for the war, tank diesel in the USSR would have reached its standard not in 1945, but in 1941–1942.

Therefore, it is worth considering the testimony of American experts about the unsuitability of the B-2 for tanks with a fair amount of skepticism. During the war, they tested the T-34 and KV-1 at the Aberdeen Proving Ground and came to disappointing conclusions - the weakest link in the vehicles was diesel.

To be fair, neither the Americans nor the Germans would have been able to organize such a complex production of diesel engines under conditions of evacuation into the interior of the country. Practically from scratch, assembly was established during wartime in Sverdlovsk, Chelyabinsk, Stalingrad and Barnaul. In places where there was not enough production culture even for relatively simple gasoline engines, not to mention precision diesel engines. And there were always not enough engines - the front devoured everything. Maybe this is why the V-2 began to issue the required warranty life of 250 engine hours only by 1945.

Why is this all?

Moreover, the V-2 tank engine revealed its true potential only after the war, due to getting rid of childhood diseases in normal peaceful conditions. And invaluable experience in combat operation also made it possible to eliminate design flaws. By adopting a diesel engine that was initially difficult to manufacture, Soviet managers provided tank builders with the foundation for modernization for many decades.

But this did not cancel the search for new designs, especially since the B-2 had many shortcomings.

First of all, the dimensions - with a cylinder block angle of 60 degrees, it is difficult to design a low profile of a combat vehicle. For comparison: the Americans have an AVDS-1790-2A diesel engine for the M-60A1 tank with a cylinder angle of 90 degrees. The German MB838 CaM-500 diesel engine for Leopard-1 has a similar design.

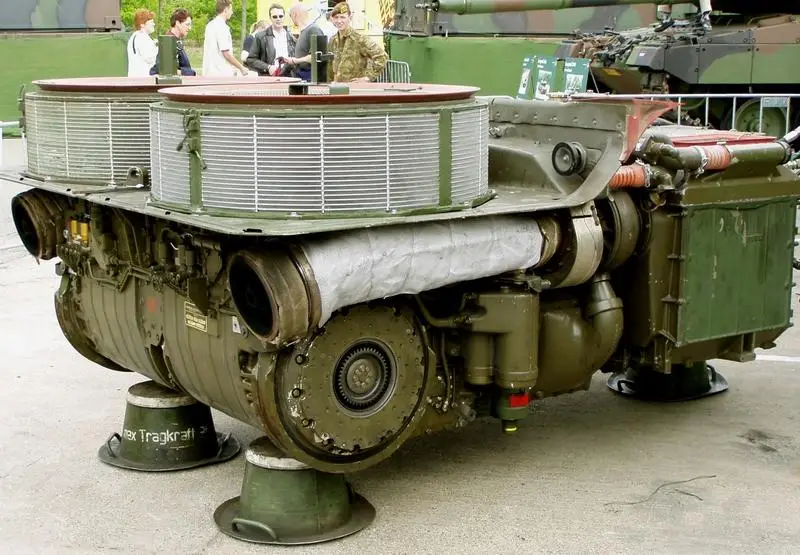

We can say that with the adoption of these NATO tanks, domestic diesel engines began to lag behind in technical terms. For example, the Germans on Leopard-1 combined the engine with a cooling system, lubrication and hydromechanical transmission into a single power unit, which greatly simplified the replacement of the unit in the field.

And, of course, the power of imported diesel engines - the Leopard-2’s MB873 Ka-501 engine produced 1 hp on the stand. s., while the newest domestic 500TDF is 5 l. With. And the descendant of the B-700, which traces its ancestry to the B-46, had 2 hp. With. The lag could not be called critical - the arsenal of the Soviet Army included the gas turbine T-780 with a capacity of 80 hp. s., which made it possible to get ahead of some NATO vehicles in terms of power supply.

The Germans can be called the leaders in diesel engine production for tanks. In one of the USSR-era engineering books, the authors admire the successes of their opponents:

MB873 Ka-501

Let us recall that the working volume of the most modern diesel tank engine V-92S2F does not differ from that of the V-2 and is 38,8 liters. However, increasing the displacement is only one way to increase power and is far from the most effective.

But the Soviet design school has a rich story the search for a replacement for the proven B-2, however, it did not always end in mass production.

Three directions

Diesel engine production literally blossomed after the war.

In Kharkov, at plant No. 75 in a special design bureau, they began to build a two-stroke turbo-piston diesel engine, which would later become 5TDF for T-64 series vehicles. In Chelyabinsk, at SKB-75, among other things, the design of the B-2 was finalized. The Kharkov Design Bureau clearly took the place of the most progressive office; traditionalists worked in Chelyabinsk, although they cannot be denied innovation.

In Barnaul, in turn, the OKB of the transport engineering plant worked on the UTD family - these were four-stroke engines with a cylinder angle of 120 degrees. Since 1964, the UTD-20 became standard for the BMP-1 and has not left domestic infantry fighting vehicles since then.

And these are not all the sites where they worked on tank diesel engines. In particular, their own versions of the B-2 were built at the Ural Turbo Engine Plant in Sverdlovsk. For example, engineers at the local design bureau created the V-14M, whose displacement was increased to 44,3 liters. The first prototype was ready by the beginning of 1945, and its power was 800 hp. With.

UTD-20 is a conditionally tank diesel engine, the design of which does not contain the legacy of the V-2

But let's return to Barnaul, where they built their tank diesel engine under the name UTD-30. The engine copied the V-2 in many ways, for example, the cylinder angle and the number of cylinders in the engines were the same. The unit developed 580 hp. s., which did not differ from the power of the Ural B-55.

The only advantage of the diesel engine from Barnaul was its low heat transfer - otherwise the UTD-30 turned out to be quite trivial. It was eventually recommended as a backup for the new medium tank, but that was the end of the story.

DTN-10

Things were much more interesting with diesel engines for heavy tanks. Let’s not focus on the numerous variations of the B-2, but rather look at some truly unusual ideas.

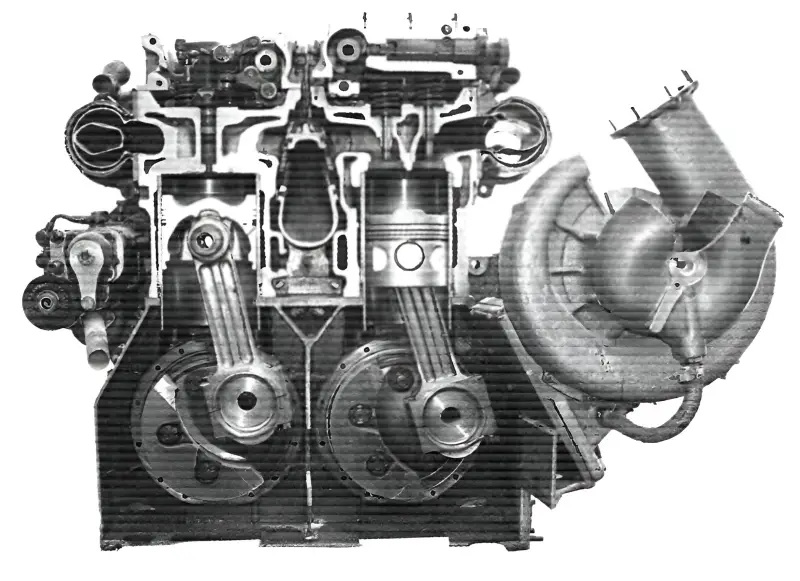

At the end of the 50s, the DTN-10 was created at the Chelyabinsk Tractor Plant - this is exactly the case when we are talking about Ural innovation. For compactness, the diesel engine was equipped with ten cylinders in two rows and... two crankshafts were designed. The torque from the two shafts was collected through a gearbox with a coupling. Here, for the first time in the country, a turbocharging powered by exhaust gas energy was used on a diesel engine.

By the way, the modern B-92 series still has drive turbochargers, which limits the growth of diesel power. The DTN-10 turned out to be not only unusual, but also powerful - the unit produced an impressive 1 hp for its time. With. Liter capacity 000 l. With. per liter of working volume significantly exceeded that of the most modern modification of the V-31,2-12B tank diesel engine at that time (6 hp/l.).

2DG-8M

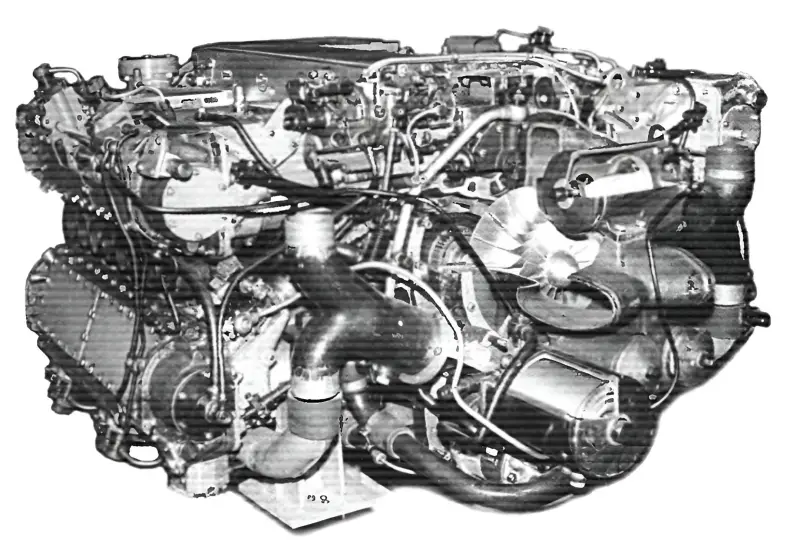

The 2DG-8M diesel engine from the Ural Turbo Engine Plant in Sverdlovsk turned out to be even more interesting.

The engine also had two crankshafts, but there were sixteen cylinders at once! The designers stacked two opposed eight-cylinder diesel engines, and solved the problem of power removal from two shafts by installing a gearbox with a clutch.

If we delve deeper into the design of the unit, it turns out that two diesel DG modules were stacked, which in turn were developed to replace the V-2. Unlike the DTN-10, the 2DG-8M puff engine had a drive turbocharger, and the liter power was 22,1 hp/l. All the tricks were only for the sake of the high overall (liter) power of the unit and small profile. In the best traditions of the Soviet school of tank building, the combat vehicle had to be as low as possible.

As you know, Kharkov engine builders have advanced the furthest in this, creating a two-stroke diesel engine with two crankshafts and counter-moving pistons in horizontally located cylinders. The above-described diesel engines 2DG-8M and DTN-10 were not continued due to the closure of the topic of heavy tanks in the Soviet Union. Similarly, the “long” DGM was unlucky, for which the engineers arranged 12 cylinders oppositely. Here they worked without revolutions, and the engine made do with one crankshaft.

In the early 60s, the star of the Kharkov 5TD rose, which conquered with its lowest height - only 580 mm and an exorbitant liter power of 42,8 hp / l. Only it required a truly aviation-level engine, for which the domestic tank industry had to grow for decades.

In many ways, the sad history of the mentioned replacements of the B-2 series is due to the fact that after the war the diesel engine was developed for a specific promising tank. As soon as they rejected a promising car, they immediately put the diesel project on the shelf. This clearly wasted resources. In addition, work on gas turbine engines was going on in parallel, which did not allow concentrating efforts on diesel issues.

At the same time, the B-2 itself allowed us to ignore promising designs, the potential for modernization of which seemed inexhaustible. And as soon as they realized that the ultra-modern T-64 and its 5TDF were too complex for mass production in wartime, the descendants of the B-2 settled even more firmly in the factories. The time to create a new four-stroke diesel engine was already lost at that time.

As a result, modern Russia does not have an adequate replacement for the B-2 series. It is unknown how much more the most powerful of the serial diesel engines, the V-92S2F, can be developed with the tanks constantly getting heavier.

Information