Steel gratings on armor: why they are needed and how they work

Steel lattice screens on a variety of combat vehicles have already become familiar attributes of armored vehicles to the general public, flashing over and over again in footage from the special operation zone in Ukraine. However, despite their broad "anti-cumulative" status, they are primarily designed to counter a very narrow range of ammunition.

Lattice screens have long become one of the most common types of additional protection for a wide variety of military equipment, ranging from tanks and ending with armored vehicles - here and abroad. Moreover, thanks to their simple design and the availability of materials for manufacturing, they are the first object for handicraft production, as can be seen by looking at the various crafts in the Northeast Military District zone.

The purpose of these products seems to be clear and is to enhance the resistance of the combat vehicle to cumulative weapons when fired from different angles, especially in weakened projections of the sides and stern.

However, their functionality is often confused with that of platoon (solid) screens on armored vehicles, known since the Second World War and even earlier. Sometimes such incidents appear even in official documents - for example, in the British Ministry of Defense standard 23-10, where gratings are indicated as a means of ensuring the detonation of ammunition at a distance from the armor.

Of course, there is no truth in these statements. This is how side screens can work at heading maneuvering angles, when the projectile strikes at a very small angle from their surface, and the cumulative jet, before penetrating into the armor, travels a long way through the air and loses its penetrating ability.

But within the framework of all-aspect protection, additional shielding of a combat vehicle in order to detonate cumulative shells at a distance from its armor has long been a dubious activity, and sometimes even harmful. This is due to the peculiarity of almost all currently used cumulative warheads, which lies in the increase in their armor penetration with increasing distance from the point of detonation to the armored barrier.

Sometimes it reaches ten (or more) calibers of charge, therefore, for example, to guarantee protection from a conventional projectile with a warhead with a diameter of 100 mm, the screen must be located at a distance of significantly more than a meter from the object, otherwise the chance of hitting it will only increase. It’s not hard to guess how much the dimensions of an infantry fighting vehicle will increase if they want to surround it with such a fence. And there is no need to talk about its mobility, maneuverability and survivability of the “body kit” itself.

The only exception here is the “canopies” over the roofs of tanks and other equipment - their height is decent, and what they use to attack drones, often does not differ in outstanding characteristics of penetration and elongation of a cumulative jet.

The grilles, which are installed on the sides, stern and, in the case of light armored vehicles, even on the frontal parts, serve to protect against close combat anti-tank weapons.

The principle of their operation is primarily aimed at destroying attacking ammunition, which is achieved when they enter the space between the metal plates of the screen. True, with one very big nuance - these ammunition are mostly anti-tank grenades of the PG-7 and PG-9 type for the RPG-7 and SPG-9 grenade launchers, respectively.

This feature of counteraction is due to the vulnerability of the ammunition of this weapons. It lies in the shape of their warhead, the design of its elements and the piezoelectric fuse - with most other grenades and especially missiles that have a different “anatomy”, such tricks are useless and will end in a dangerous explosion for the carrier of the gratings.

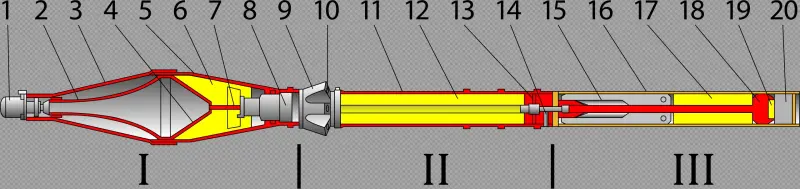

To understand the essence of the issue, it is necessary to look at what, for example, a typical PG-7 is in cross-section - PG-9 generally has the same device. In this case, only a few components are interesting, indicated in the figure below with the following numbers: 1 – head part of the piezoelectric fuse, 2 – conductive cone, 3 – fairing, 4 – cumulative funnel, 6 – explosive charge, 7 – electrical impulse conductor and the bottom itself part of the fuse numbered 8.

Under normal conditions, when the head of the fuse hits the target, the piezoelectric element generates an electrical impulse, which passes through a conductive cone into the bottom of the fuse, which initiates detonation of the explosive charge.

Next, the cumulative lining (funnel) collapses, a cumulative jet is formed and the armor barrier is pierced.

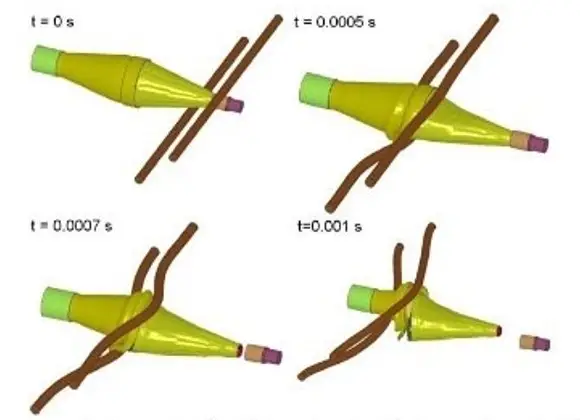

If the grenade lands exactly between the plates, the entire process described above is completely disrupted. Due to the high flight speed - in the PG-9 it generally significantly exceeds the speed of sound - the gratings (plates) turn into real knives, deforming and tearing the fairing and closing the conductive cone. The cumulative funnel (lining) is also subjected to the same deforming influences, which does not tolerate any change in geometry at all, since this makes the normal formation of a cumulative jet impossible.

An example of deformation of a grenade warhead on a lattice screen

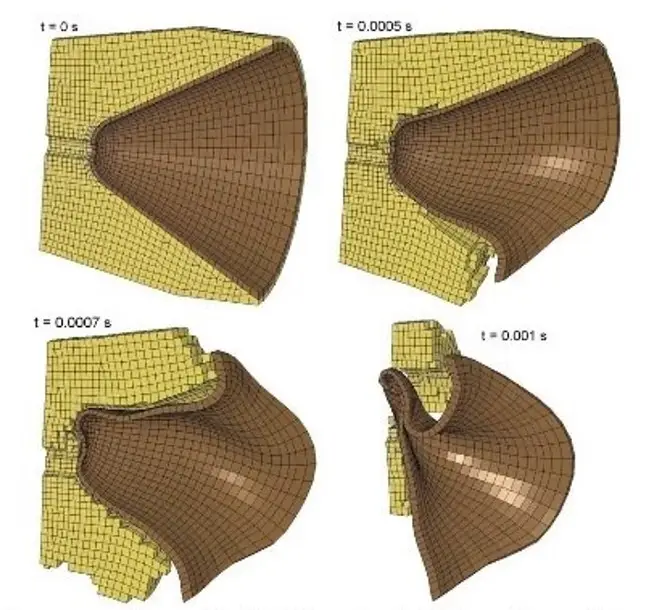

Deformation of cumulative lining and explosive charge when exposed to a lattice screen

Thus, when a lattice screen is exposed to an anti-tank grenade, the latter is either completely deprived of the possibility of detonation due to the closure of the conductive path, or, if this does not happen, it catastrophically loses its armor penetration due to serious damage to the cumulative funnel.

As a result: the only damaging factors of a neutralized grenade are the kinetic impact - the impact of the body of an unexploded projectile on the armor, and also, if the explosion did take place, the effect of the shock wave and fragmentation flow.

The result of the impact of lattice screens

For tanks and other heavy equipment, neither one nor the other poses a danger. The only exceptions are lightly armored objects, the armored hulls of which may receive some damage upon impact or explosion of broken ammunition, so manufacturers recommend installing additional dampers (sheets of steel or other hard material) behind lattice screens.

In practice, these recommendations are not always followed, due to the fact that double shielding increases the weight of the machine and is sometimes simply impossible due to its design features. But in any case, the damage from a deformed grenade that has lost its properties is incomparably lower than from a full-fledged one if there were no bars at all.

However, a reasonable question arises: the head of a grenade cannot always accurately fly into the space between the slats and complete its flight without destroying the combat vehicle. It can also fly into the plate itself, then there can be no talk of any protection - detonation will occur, and the distance between the screen and the armor will probably only enhance the penetrating ability of the cumulative jet.

Indeed, even in the West, grids and their analogues are often called “statistical armor”, the chance of which is not XNUMX% correct.

To determine this probability, multiple studies were conducted, taking into account the angle of attack and other factors. The figures there were different, but generally speaking, based on data from the domestic Steel Research Institute, the chance of destroying an anti-tank grenade is estimated as “up to 50–60%,” which generally correlates with foreign results.

This is quite enough to recognize this method of protection as working, which, coupled with the ease of manufacture, has made it popular in the armies of many countries.

But the conclusions suggest themselves - the product is not at all universal. With the current oversaturation of the modern battlefield with various anti-tank weapons, these screens have limited effectiveness. For every RPG-7, there are a dozen other grenade launchers and ATGMs, for which steel plates installed in a row will not become an insurmountable obstacle and will play the role of platoon screens operating in limited firing angles.

And at least on tanks they are completely useless. Russian tank builders, noticing this state of affairs, gradually began to abandon the grilles, replacing them with dynamic protection, which is clearly visible in the T-2022B72 produced since 3, which no longer sport steel structures in the area of the engine-transmission compartment and the rear of the turret.

But for such models as wheeled armored cars, armored personnel carriers and even infantry fighting vehicles, lattice screens remain the “drug of first choice”: when for one reason or another it is impossible to install dynamic protection, this method provides at least some guarantee of survival in battle.

Information