Armor of 1944: what Soviet engineers could have borrowed abroad

British "Matilda" in the USSR

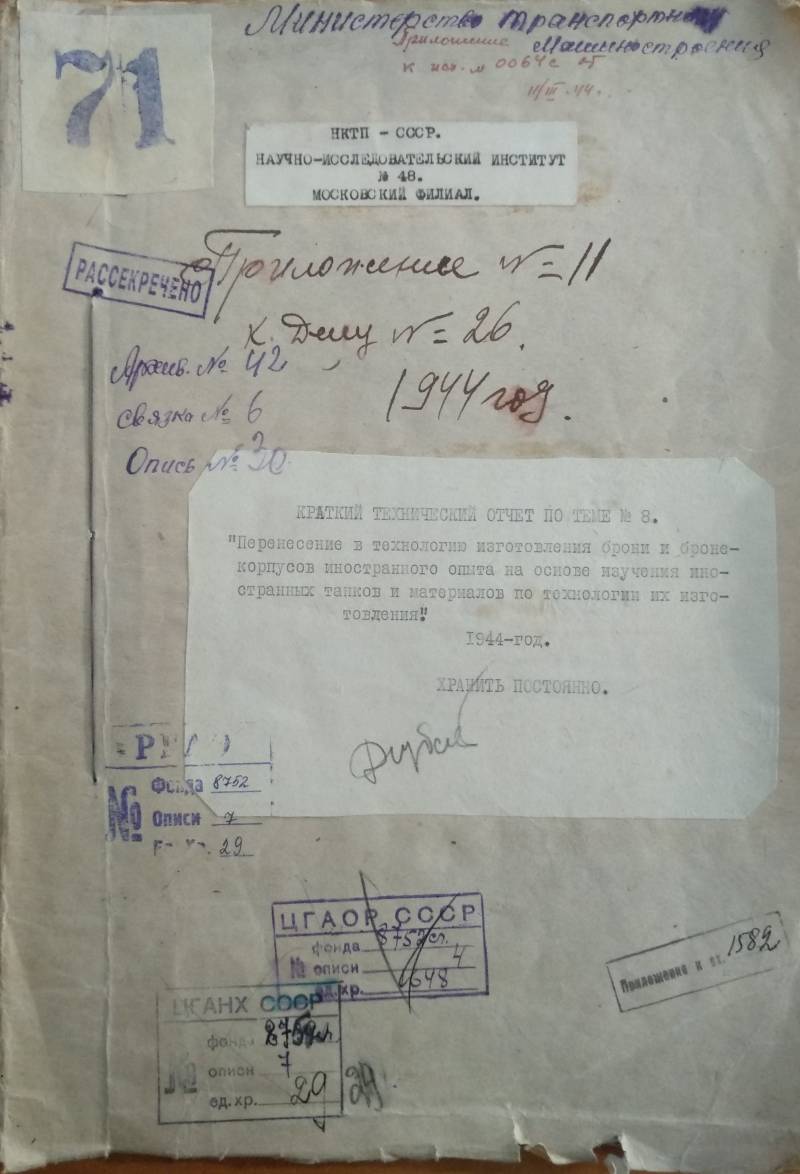

Topic No. 8

The key organization involved in domestic armor during the war of 1941–1945 is considered to be the “Armor Institute” or NII-48. Now it is known under the name of the Central Research Institute of CM "Prometheus" and is part of the Kurchatov Institute.

The famous institute was born in 1936 and at first it was a small armor laboratory at the Izhora plant. During and before the war, under the leadership of Andrei Zavyalov, unique samples were created tank armor, without which victory would have been impossible. We are talking about a high-hardness grade of armor 8C for the T-34 and medium hardness 42C for heavy KVs.

History The “cooking” of tank armor is multifaceted and has not yet been completely declassified. Piece by piece we have to piece together a picture of the events that took place several decades ago, which laid the foundation for the current state of affairs. One of the important sources is archival reports that have recently undergone the declassification procedure.

Unique of these invaluable sources of information was a brief technical report on topic No. 8 with a long title “Transferring foreign experience into the technology of armor and armored hulls based on the study of foreign tanks and materials on their manufacturing technology.” This analytical review dates back to 1944, and it was intended to select the best that could be used in Soviet tanks. The work was carried out by specialists from the Moscow branch of NII-48 mentioned above. As the authors themselves wrote,

"Matilda" undergoing winter testing in the Soviet Union

Of course, the experience of studying the armor of not only German tanks, but also the allies who supplied equipment to the USSR under Lend-Lease was generalized.

The first in line were three British tanks - Matilda, Valentine and Churchill. To be fair, Soviet engineers fell into the hands of outdated armored vehicles, which very indirectly reflect the technological level of British tank building in 1944. Soviet engineers did not find anything outstanding in foreign cars. But there were plenty of shortcomings.

It is rightly pointed out that there was a small proportion of welded joints - individual elements of armored hulls were connected by riveting, bolted joints and goujons (a type of screw with a semi-countersunk or semi-circular head and a square above the head, which is removed after assembly). The chemical composition of the armor of all three tanks turned out to be similar and belonged to the chromium-nickel-molybdenum class. It was homogeneous armor of medium hardness.

It is unknown whether the researchers shared their results with the British (most likely not), but the report points to the unreasonably high nickel content in the armor of the Valentine and Churchill.

It is interesting that the chemical composition of the armor of the heavy British tank was very similar to the domestic naval armor of the FD7924 brand. The conclusion was simple:

Americans and Germans under a magnifying glass

American tanks were next in line.

In 1944, three vehicles were also examined: the M3 Stuart, the M3 Lee, and the M4A2 Sherman. The first was referred to in the report as mild M3, and the second as medium M3. The Stuart had mostly rolled armor, while the medium tanks had rolled and cast armor. The report pays special respect to the Sherman, indicating the high technical level of the design and manufacture of the tank. In comparison with “Stuart” and “Lee”, of course.

Manufacturers of armor for American tanks made steel from whatever they needed. The main thing is that the parameters of the armor steel do not suffer.

As the report showed, the Americans were slightly better at welding armor than the British. For example, for the light M3, both homogeneous and heterogeneous armor with a cemented layer were used. The Americans saturated the surface layer of the armor with carbon to a depth of at least 4,5–5,5 mm.

An important difference from British tanks was the wide variety of chemical composition of the armor of US medium tanks. The authors from NII-48 explained this for the following reasons.

First, the Americans learned how to build their own armored vehicles not long ago and have not yet developed uniform standards.

Secondly, armor manufacturers in America could, in theory, weld any steel as long as it met the technical specifications. For example, the Sherman is given, for which the armor was made at least in five factories. Ford did not add nickel to the composition at all, while the share of this alloying element in Henry Disston Steel and Republic Steel could be as high as 3,75 percent. At the Illinois Steel plant, among other things, they did without chromium in their armor - other manufacturers could not afford this.

In general, make armor from whatever you want, but it must produce the required parameters in any case.

The armor of German tanks attracted much more interest from NII-48 employees

The findings on American cars are somewhat more interesting than similar British ones.

Engineers note a gradual transition in hull assembly from riveting and bolting to welding. "Sherman" in this sense differs in a positive way. We noticed a gradual transition to cast parts and even assemblies, which in the near future will become a characteristic feature of American tanks. There has also been a trend in the use of alloying additives - from Stuart to Sherman, the proportion of nickel, chromium and molybdenum is decreasing. The Americans probably experienced a shortage of these metals by the end of the war.

In terms of armor hardness, the conclusion of domestic engineers turned out to be common for both tanks from America and Great Britain. The choice of medium-hard armor at thicknesses of 30–50 mm is unjustified from the point of view of armor resistance and is explained by the desire to simplify the technology. Medium-hard armor is most acceptable for mass production.

It is worth making a separate reservation - Soviet engineers did not work with the most modern technology for 8 within the framework of topic No. 1944. There was a war going on, and it was necessary to explore what captured teams and Lend-Lease supplies offered. Neither one nor the other could supply the latest versions of combat vehicles. At the same time, this does not in any way detract from the importance of the analytical report of NII-48 specialists.

It was more difficult to work with German tanks.

Firstly, there were more fascist armored vehicles - T-II, T-III, T-IV, TV, T-VI tanks, Artshturm and Ferdinand self-propelled guns.

Secondly, the Germans' armor evolved rapidly, and there was really a lot to learn here. More precisely, pay attention, unlike the Allied tanks.

But first, the characteristic features of Teutonic armor.

By 1944, the problem with alloying elements was quite acute in Germany. The younger the tank was, the less molybdenum and chromium were found in its armor, and, on the contrary, the more manganese and nickel.

All German tanks were distinguished by a high carbon content in their armor - up to 0,34–0,56 percent. A design feature of all German tanks was the unequal strength of the hull protection - more powerful armor in the frontal part in comparison with other projections. For the "Tiger" and "Ferdinand" the ratio between the thickness of the frontal parts and the side parts was approximately 2:1, which impressed Soviet designers. Quote from the report:

Why is this fact so important?

The fact is that domestic technologies spent almost the entire war fighting cracks in the welded joints of the T-34 hard armor. It was not possible to get rid of the disease everywhere and not always. The Germans' technology made it possible to avoid such defects. But the main feature of German armor was its heterogeneity - a fact that Soviet engineers considered the most important.

Final quote from the report:

It is well known that heterogeneous armor (hard face layer and soft cushion), when tested with sharp-headed projectiles and armor-piercing bullets, the caliber of which is smaller or close to the thickness of the armor, has higher resistance. Considering that modern armies widely use sharp-headed projectiles and anti-tank armor-piercing bullets, the fact that the Germans used heterogeneous armor deserves attention.

In light of the above, it is advisable to discuss the possibility of organizing in our country the production of heterogeneous heavy tank armor, one-sidedly hardened with the help of high-frequency currents.”

Information