Aircraft AD-1 with wing asymmetrically variable sweep "scissors"

The famous American aircraft designer Burt (Elbert Leander "Burt" Rutan), recognized as a genius during his lifetime (he is only 69 years old now). He created without a KB with a staff of thousands of people and without gigantic funding for the 367 concepts of aircraft, and 45 of them went up to the sky. One of his creations is the unique Ames-Dryden AD1.

The variable sweep wing design allows aircraft to fly at subsonic and supersonic speeds, even at the expense of lower flight efficiency at low speeds. The use of variable sweep allowed the creation of a number of revolutionary aircraft, such as the Grumman F-111, F-14, Rockwell B-1, Panavia Tornado, MiG-23 and Tu-160, but they all suffer from the complexity of the wing design and the weight of the wing turning mechanism.

NASA engineer Robert T. Jones (Robert T. Jones) in the 1945 year proposed the idea of turning the entire wing on one hinge pin, which should provide much lighter and more durable designs. It was supposed to turn the wing counterclockwise (as viewed from above), that is, the right wing would turn towards the nose of the plane, and the right wing towards the tail. The wing of an asymmetrically variable sweep or swivel, oblique wing (Oblique Wing) is popularly called the wing-scissors. Plans for the creation of large supersonic transport aircraft seemed about to come true. In fact, he was not the discoverer of the idea of the rotary wing. In 1944, several German companies were developing such aircraft to achieve higher speeds. The first of these was Blohm und Voss with a BV P 202, which later became Messerschmitt Me P 1109 with two swivel wings, upper and lower.

According to Jones' calculations, the plane with a slanting wing was supposed to increase the take-off weight of the aircraft by 17 percent or increase the flight range by 29 percent while maintaining the weight of the aircraft. A wind tunnel model test carried out at the Ames Research Center in Moffett Field, California, showed that an aircraft with a similar wing pattern would allow for a supersonic speed that would lead to twice the fuel economy compared to airplanes with conventional wings. during takeoff and at the transition of a supersonic barrier. In addition, wind tunnels showed that a plane with a scissors wing at speeds up to 1.4 Mach (1.4 times faster than the speed of sound) will have significantly better aerodynamic characteristics than airplanes with conventional wings. Based on these encouraging results, it was decided to build a prototype.

Many aircraft companies wanted to develop such an aircraft, but as it was, no one had money for this project. There was no money for him and NASA. However, in the 1975 year, two fellow students of Rutan, one working at Edwards airbase, another in NASA came to him with the proposal: “We heard that you made a VariEze aircraft for the 3 of the month. Why don't you design a plane with a swivel wing? " Soon a contract was signed with Rutan Aircraft Factory to develop the design of a low-speed aircraft for conducting a series of test flights and to study this unique flight mode outside the wind tunnel.

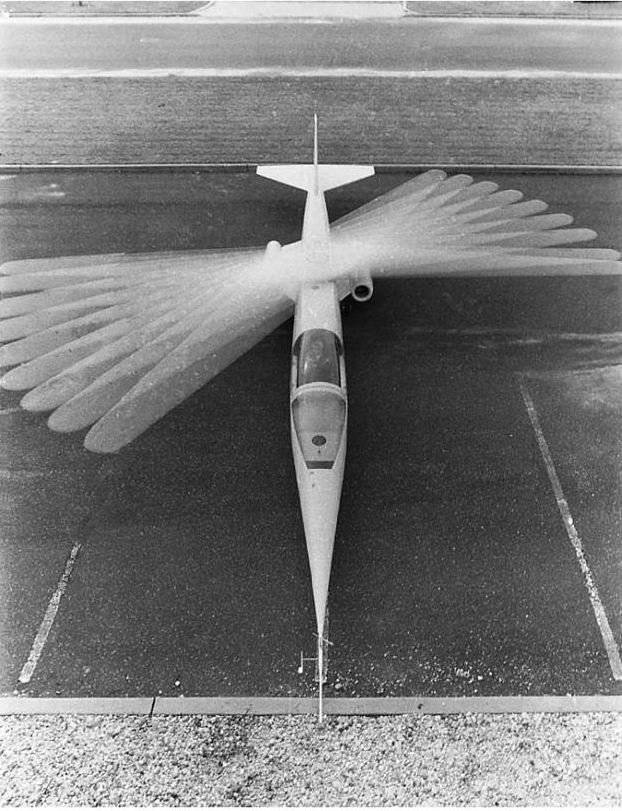

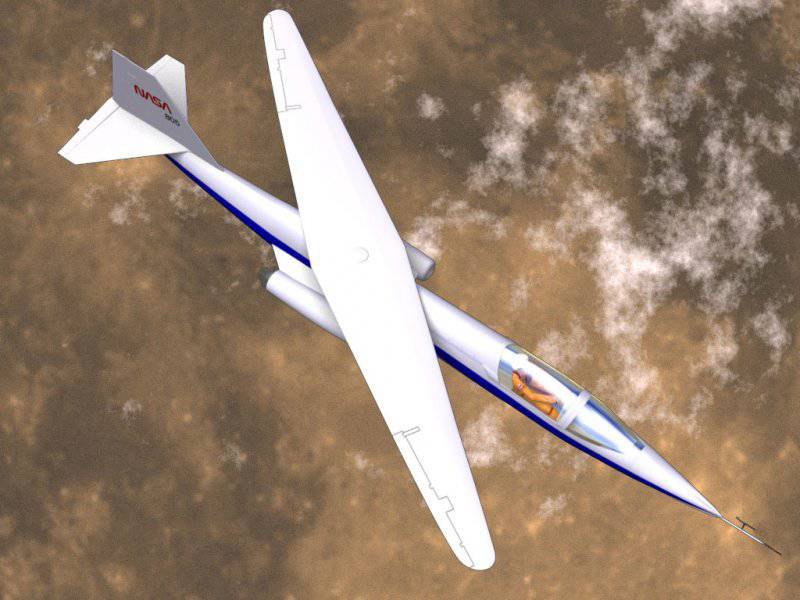

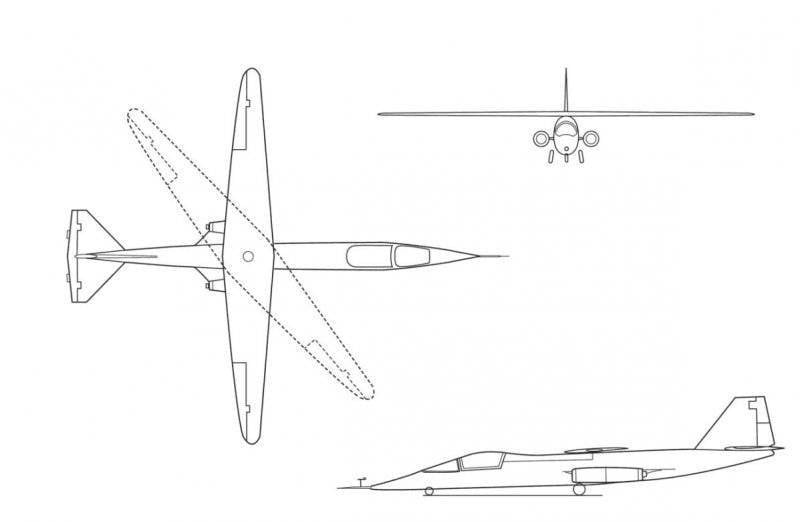

The creation of the AD-1 began on its own initiative by Rutan Aircraft Factory to meet the requirements of NASA in December 1975. In December, 1976, the Rutan Aircraft Factory, reported that they “completed the detailed design of a research aircraft for NASA using VariEze technology. The NASA aircraft turned out to be small, single-pilot, designed to test the handling characteristics of the future (in 1990s) rotary-wing aircraft ". NASA chose a design based on a geometric configuration provided by Boeing. The aircraft was made in scale 15% of the planned Boeing transport aircraft. The slanting wing remained perpendicular to the center line of the fuselage during the flight at low speed and turned at angles up to 60 degrees with increasing aircraft speed.

The design of the AD-1 allowed the project to achieve all the basic technical tasks. As expected, the aircraft demonstrated aero-elastic phenomena, as well as the connection of pitch and roll movements, which contributed to poor controllability at sweep angles above 45 degrees. The fiberglass structure has limited the rigidity of the wing, which could significantly improve aircraft controllability. Thus, after the completion of the AD-1 project, it was still necessary to investigate an oblique wing at supersonic speeds to evaluate the compressibility effect, structural strength, and analysis of flight characteristics at supersonic speeds.

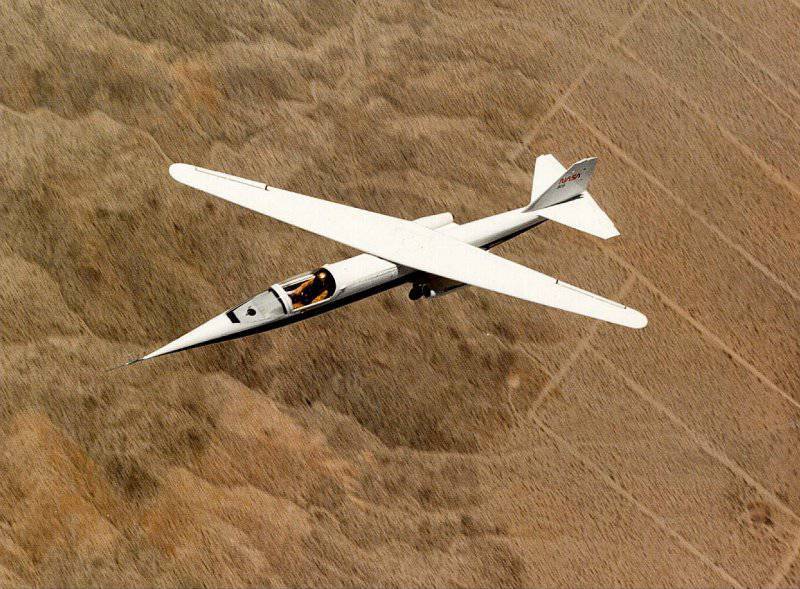

Rutan made a detailed design of the AD-1 between May 1976 and February 1977 under the contract for only $ 12,000. Ames Industrial Corp Corporation of Long Island (New York) won the production contract and began building the aircraft in December 1977 of the year under a fixed contract of $ 240,000. The AD-1 was the first non-self-made aircraft made using structural methods developed for the VariEze. In fact, his whole design was basically similar to the VariEze, about the same diameter, but was 12 meters long, 2 meters high and wingspan in 9.8 meters. It was made of plastic reinforced with fiberglass and weighed 658 kg empty. The aircraft was equipped with two micro-turbojet engines, each of which developed thrust at 1.8 kN at sea level. The wing was turned by an electromechanical drive located inside the fuselage in front of the engines. The wing was able to rotate 60 degrees horizontally. Lightweight design could not provide the necessary rigidity to eliminate poor handling. Due to safety concerns and a pair of weak turbojet engines, the aircraft was limited to a speed of 274 km / h.

Ames Corporation during the construction of the AD-1 met the budget and schedule, the final cost of the contract was only $ 239,000. While aviation the industry did not believe that it was possible to design and build a manned, two-engine prototype rotary wing aircraft for less than a few million dollars. “It is interesting to note that the work done by the Rutan Aircraft Factory and Ames Industrial Corp was done at a profit and at a much lower cost to taxpayers than NASA spends on supervising contractors and conducting simulations!” Commented Rutan in 1979.

The aircraft was flown to Dryden Flight Research Center in Edwards, California in February 1979, and was immediately subjected to tests that included jogging and static load testing. The first flight was made on 21 of December 1979 of the year, and last 7 of August of 1982 of the year. Both of these flights were performed by NASA test pilot Thomas C. McMurtry (Thomas C. McMurtry). A total of AD-1 79 departures during the test program.

NASA classified the wing-scissors project to high-risk projects. They were most interested in the behavior of the aircraft with such a wing at low speeds. The tests continued for 18 months, gradually increasing the angle of rotation of the wing. By the middle of 1981, the angle of rotation was reached in 60 degrees. The final flights of the aircraft were carried out at the annual Experimental Aircraft Association in Oshkosh, Wisconsin, making eight flights there in order to demonstrate the concept of the wing. On tests, the plane reached a height of 3800 meters.

A unique copy of the AD-1 was recently housed in the Hiller Aviation Museum of California.

Flight Specifications:

Modification: AD-1

Model Number: 35

Type: reactive, dual motor, experienced, with wing asymmetrically variable sweep

Board number: N805NA

Customer: NASA

Manufacturer: Ames Industrial Corporation

First flight: 21 December 1979

Wingspan: 9.84 m

Length: 10 m

Height: 2.05 m

Wing area: 8.64 m2

Empty weight 658 kg

Maximum take-off weight 973 kg

Engine type: 2 TRD Microturbo TRS18-046

Thrust: 2x 1.8 kN

Maximum speed: 274 km / h

Fuel tank capacity: 320 liters

Service ceiling: 3800 m

Crew: 1

Information