The hard part of the driver: tests of forces on the levers of tanks in 1945

IS-3 driver's seat

GBTU is testing

During the Great Patriotic War, few people thought about the ergonomics of the Soviet tank driver’s workplace. To put it mildly, this was a completely non-primary task for the designers. In the notorious triad “firepower – mobility – security” there is not a word about the working conditions of the crew.

The Americans were among the first to document their claims to the ergonomics of Soviet technology. In 1943, engineers and military personnel tested at the Aberdeen Proving Ground Tanks T-34 and KV. We will not dwell on ambiguous conclusions regarding security and firepower; we will talk about our impressions of the interior of the tanks.

What surprised the Americans about the tower was how crowded it was. In a secret report, the head of the GRU of the Red Army, Lieutenant General Ivan Ilyichev, writes:

The designers of the KV tank's transmission deserve special compliments. At that time, the allies of the Soviet Union noted:

At the same time, the Americans sang the real anthem to the Soviet tanker:

Truly, your name is unknown, your feat is immortal, Russian soldier.

T-34-85

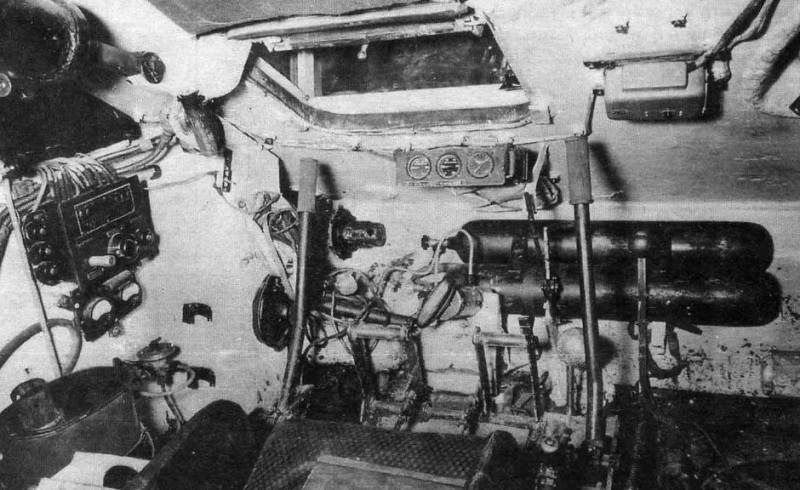

T-34 control department.

It cannot be said that the Soviet Union did not think about the working conditions of tank crews and, above all, the driver. According to legend, the appearance of a gunner-radio operator in the crew was due to the need to help the driver with shifting the terribly tight gearbox lever. If the comrade on the right somehow helped with the gearshift lever, then the tanker was left alone with the onboard clutch levers.

The difficulties of operating a tank were discussed at the highest level only after the war.

IS-3 mechanical drive location

In 1945, a secret report “Results of force measurements on control levers of T-34-85 and IS-3 tanks” was published. In the summer, military engineers from the Research Armored Test Site of the Main Armored Directorate of the Red Army tested four domestic tanks. Three T-34-85 and one IS-3. The main goal is to evaluate the level of effort on the tank control levers.

The T-34 trio was chosen for a reason. The military decided to find out how much the tank assembly conditions affect the ergonomics of the driver's seat. The first tank was produced in Krasnoye Sormovo near the city of Gorky (plant No. 112), the second - in Leningrad (plant No. 174), the third - in Nizhny Tagil at plant No. 183. The first two tanks covered a little more than 1 km, the last one is almost new with range of 000 km.

All tanks, including the IS-3, were produced in June-July 1945. Testers took the heavy Soviet tank from the Kirov plant with a range of 500 km.

A short excerpt from the test report:

a) with the tank in a static position, the effort required to disengage the side clutches until the drums began braking was determined;

b) when the tank was moving, the effort expended on complete braking of the drums, at which the tank rotated, was determined.

Before the start of the tests, the control drives of tanks from factories No. 112 and No. 174 were adjusted in accordance with the technical specifications. The tank from factory No. 183 was new and had factory adjustments that met the technical conditions.

The amount of lever travel was divided into six equal parts. In each of the six positions of the lever, the effort expended on its movement was determined.

Up to the fifth position of the control levers (inclusive), the efforts expended to disengage the clutches were measured. In the sixth position of the levers, the forces required to tighten the brake bands before braking are recorded.

The tests were carried out on a horizontal area with dry, soft soil, without turf.”

GBTU sums up disappointing results

The first thing that catches your eye in the report is the gigantic efforts on the clutch control levers. The driver was forced to pull the levers with a force of 21 kg to 46 kg! The engineers recorded the maximum force on the right lever when the tank was moving in second and third gears. This example of the tank was produced in Leningrad at factory No. 174. The other T-34s were a little better (just a couple of kilograms).

It’s interesting that the smallest force on the lever was determined on that very “Sormovo monster” - that’s how tanks from factory No. 112 were called for poor build quality. It was on it that the force on the levers in all modes did not exceed 40 kg. Relatively speaking, it was the easiest of the medium tanks to control. There was also a difference in the applied forces between the right and left levers - in some modes it reached five kilograms. This was the fault of the tank from Krasnoye Sormovo. For other vehicles, the difference did not exceed 1,5–2 kg, which probably indicated better build quality of the tanks.

The heavy IS-3 had a more advanced transmission compared to the T-34. The planetary turning mechanisms were supposed to make the tanks somewhat easier to control. But everything was compensated by the increased weight of the car, although the forces on the levers actually decreased somewhat. The main difficulty was to pull the lever off the ground when the tank was in a static position. This required at least 30–32 kg. This is a lot - in similar conditions, the T-34 driver was supposed to pull with a force of 20–26 kg. The hardest stunt on the IS-3 was turning on the spot in third and fourth gears - the levers required at least 30–40 kg.

At the end of the report, GBTU military experts came to a logical conclusion:

A dry formulation that hides the unparalleled heroism of the Red Army tank crews even outside the battlefield.

The test results look especially impressive against the background of similar experiments included in history with the report “Results of force measurements on the control levers of foreign and domestic tanks.” The location and time are the same - the training ground in Kubinka, summer 1945. Only there are more main characters - Hitler’s Jagdtiger B self-propelled guns, TV Pantera, T-VI Tiger tanks, the American heavy tank T-26E3 (M26 Pershing), light M-24 and medium M4A2 Sherman with a 76-mm cannon. Also present in the company were the British cruiser tank A34 Comet and the golden Soviet troika - IS-3, T-44 and T-34-85.

Pershing in 1945 in Kubinka. In terms of ease of control, it turned out to be little better than the Soviet T-34-85 and IS-3.

An attentive reader will ask how the American Pershing got to the Soviet Union?

It was never supplied under Lend-Lease. The United States provided one production tank for study in April 1945. The vehicle arrived in Murmansk with convoy JW-66 and was already thoroughly studied by the military in Kubinka in the summer. The rest of the Allied tanks arrived in the Soviet Union in a similar manner.

The testing method for the controls was simple - measuring the forces on the control levers during a full turn in place.

Interestingly, the loss of domestic tanks in this test was not total. Yes, in first gear, considerable effort had to be applied to turn - 39–41 kg in the IS-3 and 32–34 kg in the T-34. But the American heavyweight Pershing was little better: 34–35 kg at the lever. The average M4A2 Sherman is also not easy to drive - up to 30 kg on the levers.

As they wrote in the report, “the lower forces on the M4A2-76 tanks compared to the T-26E3 tank with a similar design of the turning mechanism are explained by the lighter weight of the tank and the longer length of the control levers.”

Of course, the Germans defeated everyone with their transmission servos - forces from 4,5 to 14 kg. The easiest to drive was the 72-ton Jagdtiger B with a steering wheel instead of levers.

The T-44 turned out to be relatively comfortable for the driver: no more than 10–11 kg of effort on the levers for turning in all modes.

Separately, it is worth noting that the features of the planetary gearboxes of all Germans and the British A34 Comet allowed the cars to turn on the spot in neutral gear. But this didn’t make things any easier for the driver-mechanic of the A34 Comet. Firstly, during the tests it turned in this mode the third time, and secondly, the forces on the levers amounted to an impressive 20 kg.

Information