Light at the end of the tunnel: domestic tank engines

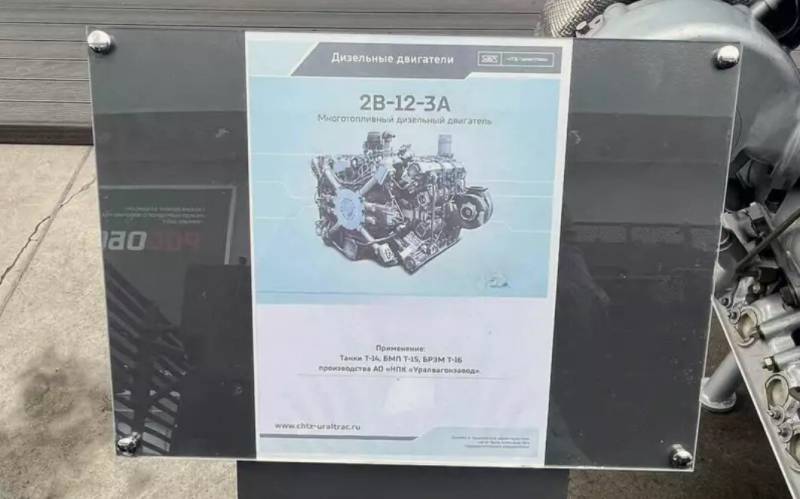

2B-12-3A at Army-2023

V-shape story

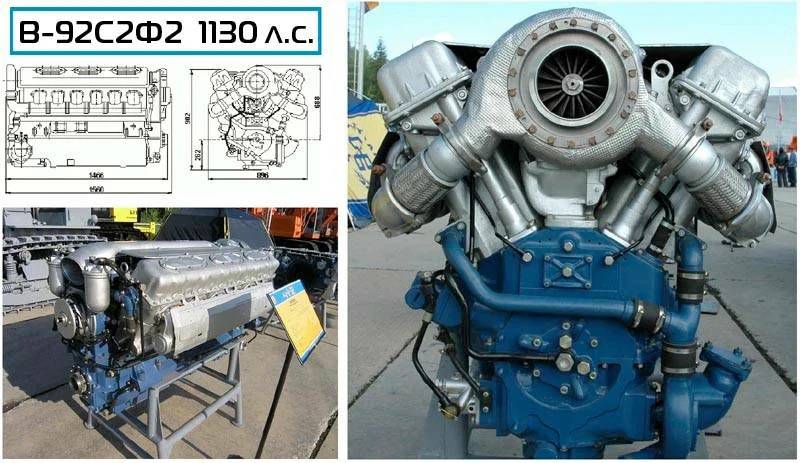

Currently the main tank The engines of the Russian army are V-92S2 and V-92S2F. The first is for the engine-transmission compartment of the T-72B3M, the second is for the T-90M “Proryv”. For the “seventy-two” the engine power is 1 hp. s., for “Breakthrough” - by 000 liters. With. more. The 130 hp gas turbine engine stands out. With. for T-1BVM.

According to the latest data, in Omsk they intend to resume production of the famous “flying tank” from scratch - now the BVM series is mainly produced on the basis of vehicles removed from storage. This means that GTD-1250 will soon be in great demand. This, by the way, is a greeting to everyone who buried the T-80BVM before the special operation.

Let's digress a little from the diesel topic and try to figure out why the production of a gas turbine tank should be restored. Is there really not enough capacity in Nizhny Tagil?

In the Urals everything is in order, they work rhythmically and cope with the load - the problem is precisely the T-80BVM power plant. Of the entire line of Russian tanks, it is the gas turbine that provides the necessary throttle response and high maximum speed, which is one of the important conditions for survival in the northeast military zone.

Approach the firing position, shoot off the ammunition and roll back - the faster, the less chance of getting under return fire. This works best in vehicles with high power density, for which the T-80BVM has no competitors.

No one is interested in the excessive gluttony of a gas turbine engine. This could have been critical in the early stages of the special operation, when there were tank breakthroughs, but now this is not relevant. The defensive nature of combat operations offsets the advantage of diesel vehicles in fuel consumption. The average daily mileage of a tank is tens of kilometers.

As a result, the main virtue of tanks is their high power density.

The trouble with the situation is that deep modernization of the honored and legendary B-2 is impossible. With a high degree of probability it can be stated that the V-92S2F for Proryv is the final version of the engine, the pedigree of which goes back to the early 30s of the last century. The B-2 variation will definitely celebrate its centenary in one of the engine and transmission compartments of the domestic tank.

V-92S2F. Source: odetievbrony.ru

The only question that remains is - how did it happen that the tank forces are still exploiting the descendants of the B-2?

Turning to stories.

The first attempt to create something new was the infamous two-stroke 5TDF, equipped with two crankshafts and counter-moving pistons. In fact, the only advantage of the product was its high overall power - otherwise it was a crude motor. Which nevertheless was put into production. Not least due to the authority of the development team from Kharkov.

Theoretically, there was nothing criminal in the 5TDF scheme - it just required more time and resources for improvement. The collapse of the Soviet Union and the presence of two more tank engines (V-46 (ancestor of the V-2) and GTD-1000) did not allow the 5TDF to be brought to fruition. Like the T-64 itself, which turned out to be a real tank of extreme parameters, completely unsuitable for wartime.

Suffice it to say that the mastered production of the 5TDF tank engine, the most complex for its time, was mastered in Kharkov at a single plant. In the event of war, a massive missile strike on the workshops of the Kharkov Transport Engineering Plant would be enough to stop the production of the T-64 forever.

But work on the Kharkov engine was not completed and eventually resulted in the six-cylinder product 6TD and the deep modernization of 5TDFM. We must pay tribute: it was possible to bring the engines to an acceptable level of readiness for the series - the Ukrainian Armed Forces are still quite successfully fighting with tanks with such power plants.

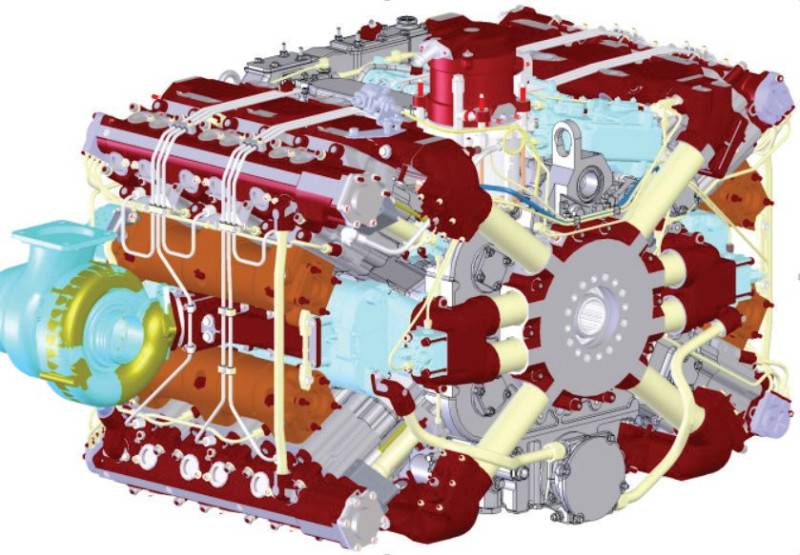

The difference between the 2V-12-3A for the Armata (above) and the V-92S2F for the Proryv is significant.

In the Urals, new engines other than the V-2 did not work out from the very beginning. On the one hand, the proven engine has been indispensable for decades.

Firstly, it could be produced at many factories throughout the country - Leningrad, Barnaul, Chelyabinsk, which was strategically very profitable.

Secondly, the engine turned out to be in demand in the national economy - which means that the V-2 can be produced in peacetime. Competencies and valuable production personnel will not be lost. But a replacement engine was needed back in the 70s and 80s. Not to mention the present.

In one of the modern scientific publications, engineers and scientists from Nizhny Tagil (E.V. Isupov, E.G. Gaev, D.V. Yudintsev and M.A. Badrtdinov) rightly note that

A motor is needed, but where can I get it?

Are they abandoning 2V-12-3A?

The history of the diesel engine for the Armata platform began in the last century. As the book “Tank Engines (from the history of tank building)” says,

The book was published in 1995 and at that time the circuit diagram of type 2B was not disclosed.

In fact, it is a 12-cylinder x-shaped design, providing the necessary compactness with high power. The motor was developed at the Chelyabinsk Tractor Plant and was based on V-2 solutions. If you go deeper, you will find that even the diameters of the cylinder are the same - 150 mm. The new product only has a different piston stroke - reduced from 180 mm to 160 mm.

Motor 2B, like its predecessor B-2, could have several configurations. At the end of the 80s, six- and even sixteen-cylinder versions were tested, but the main one, of course, was a twelve-cylinder engine for the tank. The first vehicle to try on the new product was the T-72. This suggests that the dimensions of the product fit into the engine compartment of a production tank.

A total of three T-72s with 2B engines were tested - the operating time of each reached 200 hours. A dispute broke out between Kharkov and Nizhny Tagil, at the very end of the Soviet Union, whose product is better - 6TD or 2V-12?

The reason for everyone was the collapse of the country and the further degradation of the Kharkov school of tank and engine building. But in Russia they were unable to bring to fruition the concept of an x-shaped engine. First of all, the fate of the engine in civilian life is unclear. The exotic design does not imply ease of use in civilian life. You can’t put a 2V on the St. Petersburg Kirovets - it’s not a dual-purpose motor.

Hence the question - how to maintain the economic feasibility of production on a tank conveyor? Don’t forget, Russia lives in a market economy, and it may happen that even a fully developed 2B-12-3A will simply not be needed by anyone except tank crews. A small series means an exorbitant cost, which entails a lot of problems.

They claim that the Armata engine has been modified

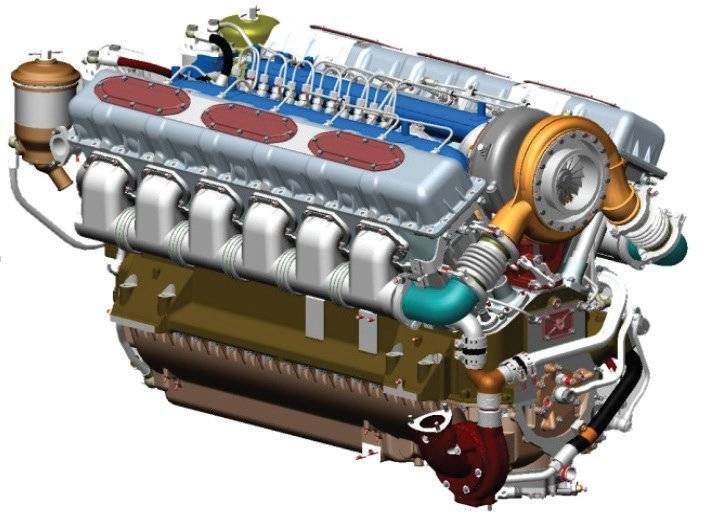

That is why the above authors from Nizhny Tagil (employees of the Ural Design Bureau of Transport Engineering and the Nizhny Tagil Institute of Technology) propose a completely different concept for a tank engine.

In the article “Defining the requirements for the engine of a promising tank” there is a provision that new tank engines

That is, we are no longer talking about the x-shaped layout, and the v-shaped layout with a camber angle of 60–90 degrees is considered “the most optimal, both from the point of view of the layout of the engine itself and its placement in the engine-transmission compartment (MTO) of the tank, and and from the point of view of manufacturability and less labor intensity in production compared to other schemes.”

The power of the promising engine is no less than 1 hp. pp., and the service life before the first overhaul is 700 hours or more. It’s hard to disagree with the authors’ arguments, especially in terms of unification with other engines. To put it completely simply, the Tagil residents propose to build the same B-2, only at a modern level, developing the product from scratch. And this is being done clearly in defiance of the Chelyabinsk 000V-2-2A engine for the Armata.

I would like to believe that this is the light at the end of the tunnel, and in Nizhny Tagil there is already developments on a promising engine.

But this is not a quick story. In the conditions of a special operation, the front needs massive and battle-tested vehicles. Now, of course, it’s not 1943, but no one will be involved in putting a new tank engine on the assembly line.

The notorious “tank of maximum parameters” with the corresponding power plant will definitely be built in Russia, but this will happen after a special operation. The intrigue is whether it will be an Armata with 2B-12-3A or something else.

Information