Production of T-80 tanks from scratch: a very interesting statement

It is worth admitting that sometimes the program “Military Acceptance” knows how to surprise. Thus, the gentlemen from the Zvezda TV channel, timed to coincide with Tankman’s Day, decided to dedicate one of the workhorses to a special operation in Ukraine - tank T-80BVM.

We talked about the laudatory reviews from the vehicle’s operators, and talked about improvements in accordance with the experience of combat use. However, the main thesis was the statement that the production of “eighties”, which was completely curtailed more than thirty years ago, is planned to be revived.

This was confirmed by the General Director of JSC Concern Uralvagonzavod, Alexander Valerievich Potapov:

The statement is very interesting and extremely ambiguous, therefore it has already managed to cause a strong reaction among the public. Taking it literally, some managed to declare that it was almost sabotage or sabotage - spending money and diverting forces on forgotten production instead of increasing the production of T-90M and T-72B3 in such a difficult time for the country. Others took Potapov’s words as a hidden hint that the losses of Russian tanks had reached such a scale that the storage bases had already been gutted to the last remnant.

We will not go to such extremes, but the question of the reasons for resuscitating the capacity to manufacture the T-80 from scratch still requires an answer. After all, the “eighty”, even in its best performance in the form of the T-80BVM, does not stand out radically in terms of combat capabilities compared to its diesel counterparts.

Of course, there are differences in operational and design aspects that testify in favor of the T-80BVM, and there are many of them. But the bottom line is that this tank is completely identical in main armament, ammunition and fire control system to the Tagil T-72B3 and partially T-90M, and in terms of armor it differs for the worse, which is compensated by the Relikt dynamic protection.

And even its main advantage in the form of a gas turbine power plant and transmission, which provide good mobility (including reverse speed), ease of motion control and the ability to start in harsh climatic conditions, are offset by huge fuel consumption, high cost and difficulties in maintenance.

There is nothing in this tank that would allow us to clearly say: it is better than the others, and we urgently need to establish its production in addition to the vehicles being modernized to this standard. Therefore, the demands of the military, which the general director of Uralvagonzavod spoke about, apparently have a somewhat different character than admiration for the characteristics of the tank.

We need more tanks

We need more tanks - a seemingly banal and tired statement, which quite accurately reflects the essence of what is happening. And this need lies both in the need for large-scale deliveries of combat vehicles to the front, and in the fact that one must also be careful with stocks of equipment in storage.

Currently, three factories are producing tanks for the front.

The main one in this matter, of course, is Uralvagonzavod in Nizhny Tagil, which simultaneously repairs tanks, modernizes vehicles taken from storage, and also produces T-90Ms produced from scratch.

By the way, previously the wording “made from scratch” was not applicable to the T-90M at all, since their production used a backlog of hulls available at the factory.

At the moment, the plant, having reached full capacity, according to various open sources, is capable of bringing into combat condition at least two or three battalion sets of tanks per month, received both from storage bases and military units, and from the special operation zone in Ukraine. As for the T-90M, according to some estimates, the company can produce a couple of hundred vehicles a year, taking into account the current workload of production lines.

Modernization of T-62M tanks

The other two are Omsktransmash and the 103rd Ataman armored repair plant in the Trans-Baikal Territory.

The first is upgrading T-80B/BV tanks to the T-80BVM standard, and the second is removing T-62M\MV from storage with subsequent modification to the T-62M\MV level of the 2022 model with a major overhaul and installation of thermal imaging sights. The total productivity of both is significantly more than 10 complete battalions per year.

Of course, now the industrial capabilities are sufficient to meet the needs of the military in the zone of special military operation. But the nature of combat operations is a fickle thing, so the need for combat vehicles, both due to losses and breakdowns, and, for example, due to the development of the offensive of troops, also fluctuates. Often in a big way, so the ability to make many tanks will always work. And you shouldn’t forget about reserves.

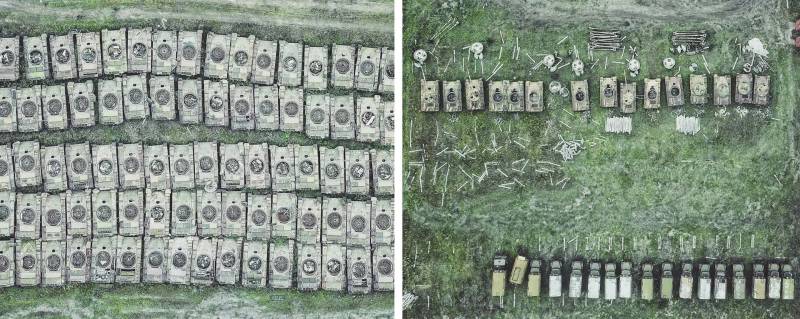

Train of modernized T-80BVMs

As you know, after the collapse of the Soviet Union, Russia received a huge number of tanks of various types and modifications, the lion's share of which were located at storage bases. Yes, that same stock, largely lost over thirty-odd years for various reasons, ranging from recycling programs and “cannibalism” to rendering machines unusable due to improper storage conditions.

In 2022, The Military Balance magazine gave cautious figures of 10 tanks, but the exact number of “live” tanks being mothballed is unknown to anyone except responsible officials in uniform.

From this reserve we drew resources to replenish the equipment of tank units, modernize tanks to the T-72B3 and T-80BVM standard, and now we are using it to make up for losses during a special military operation in Ukraine.

At the same time, it is also necessary to take into account the plans voiced by the president that this year it is planned to produce one and a half thousand tanks and, as it becomes clear, most of them are from storage.

But all supplies sooner or later tend to run out. Undoubtedly, this cannot be attributed to the SVO - there is a foundation, and it will last for a very long time, but who knows what will happen later.

Moreover, there is no reason to say that after the end of the active phase of the fighting in Ukraine, all this will not develop into a sluggish war and will not lead to new hot spots on the map of the planet in which our military will have to take part. And this does not take into account the formation of new military units in the military districts of the Russian Federation, which will also require the material they are entitled to.

So, increasing the production of tanks in parallel with the modernization of equipment from storage bases is already a necessity, both for today, when a lot of them are needed now, and for the near future, in which the role of the reserve will need to be downplayed in order to preserve it.

Based on this situation, the resumption of T-80 production does not look like some kind of idea divorced from reality.

Yes, again there are problems with the unification of the Soviet-style tank fleet, but we did not escape from it. The transition to the same type of tanks was very illusory even before the special operation and would have found its implementation only in 10–20 years at best, but in the current realities we can forget about it for now.

The reason why the choice fell on the “eighty” is explained by the fact that today, in addition to the Tagil UVZ, the only enterprise in the country that can theoretically produce tanks is Omsktransmash. At the same time, his involvement to increase the production of tanks became unofficially known back in the spring, so Potapov’s current statement is not so exclusive. But there are enough problems there, so the general director of Uralvagonzavod spoke about new capacities for a reason.

By the way, it is important to note one interesting point here: engines for the “eighty”, contrary to widespread rumors that there is nowhere and nothing to produce them now, can be produced. They can still be made, albeit in small batches, by Kaluga Engine or CADVI, which has been involved in these tasks since Soviet times. In general, therefore, turning a small series into a large one is much easier than reviving Omsktransmash, which has not been making armored vehicles from scratch since the 90s.

During the Soviet years, the latter produced T-80 tanks of various modifications: before the collapse of the USSR, it produced more than 5 T000B/BV/U units and another 80 T-231U tanks in the period from 80 to 1992. But over time, the production sites of Omsk residents, as they say nowadays, fell into disrepair.

It is noteworthy that the enterprise experienced a period of lack of money in the 90s and XNUMXs, but comparatively easier than some other representatives of the Soviet military-industrial complex. In general, workshops and production buildings were not rented out to businessmen due to its not the most convenient location, and grave fences, like on the industrial sites of the Steel Research Institute, were not made there, but the lack of funding, various frauds and other matters hurt the potential of the plant in any case .

One way or another, part of the “production capacity” was still lost - some equipment left the balance sheet both due to unusability for one reason or another, or due to formal write-off. In the future, the size of the lost property will be shown by a revision and audit, but as a preliminary result: despite the theoretical existence of equipment for producing tanks from scratch, Omsktransmash today cannot do this at once. This is especially true for armored hulls and tank turrets, which require a wide range of machine tools and steel production.

The personnel issue is also acute: a lot of specialists are needed to “reanimate” the production of the T-80, both blue-collar workers and engineers and technologists. And given that there are not so many workers left who have real experience in tank building, we will have to think about creating human resources first of all.

The revival of this entire economy is a slow process. Restoring the necessary equipment for the manufacture of tanks will require purchases somewhere on the foreign market (possibly in China), since even in Soviet times, many of the machines, with the developed machine tool industry within the country, were purchased from “capitalist countries” such as Germany.

A heavy burden will fall on the shoulders of subcontractors - for example, in order to expand the production of T-72B3 and T-80BVM instead of Sosna-U sights, it was necessary to temporarily transfer modernized tanks to simplified thermal imagers, so the strain with an even greater influx of equipment will be expected to be higher. Not only for sights, but for all components. And if at first the shortage of some parts can be covered by cannibalizing the machines in storage, then in the long term, reviving the production of Omsktransmash without reviving adjacent offices is impossible.

All this will require a lot of effort and time. For example: in the early 90s, the American military calculated the possibility of resuming the previously completed production of Abrams tanks - then this event was estimated at approximately $1,1 billion at those prices, and the period for restoring the production of tanks was more than four years.

Our situation is different, and we cannot waste time, but the process will clearly go beyond this year and, most likely, even next year. But in the future, it will be possible to expand the production of heavy combat vehicles by resuscitating the existing reserve capacity in addition to those involved in the production of tanks at UVZ.

In addition, there is some probability that the Omsk projects “Burlak” and “Black Eagle”, once shelved, will be at least partially introduced into production in the form of design solutions.

Information