Anniversary of "Tankograd": Chelyabinsk Tractor Plant is 90 years old

The best of the best

If the Chelyabinsk Tractor Plant did not exist, it would have to be invented. First of all, for victory in the Great Patriotic War. Located in the strategic depths of the country, it has become the world's largest tank plant, better known as "Tankograd". On June 1, 2023, the glorious plant turns 90 years old.

Why did ChTZ appear in the Urals? First of all, because of the gradual agricultural development of the eastern regions of the country - the Trans-Volga, Urals, Trans-Urals, Siberia and Kazakhstan. Then these territories were called "the main reservoir of the country's forest resources." The second reason for choosing Chelyabinsk was the proximity of the metallurgical base of the Urals, primarily ferrous metallurgy.

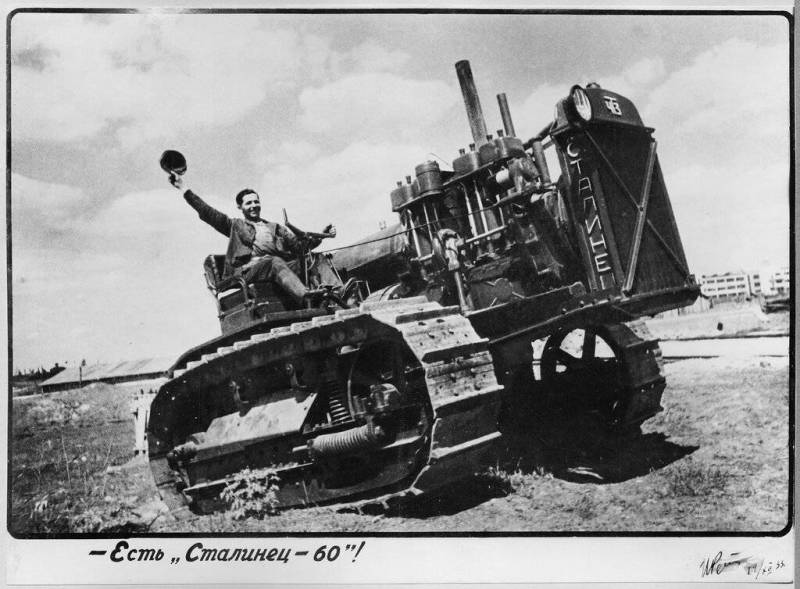

Interestingly, the first product of the Chelyabinsk Tractor was to be a 60-horsepower "Stalinets", a machine powerful enough for its time. By the way, a version of the American Caterpillar 60 adapted for Soviet conditions. The engineers wrote that

The choice of tractor power was based on an analysis of the production of tractors in the USA. By the end of the 20s, the production of tractors with a capacity of 50 hp increased overseas. With. on a tracked chassis. In the economic justification for the Soviet tractor plant from 1930, they wrote:

No sooner said than done.

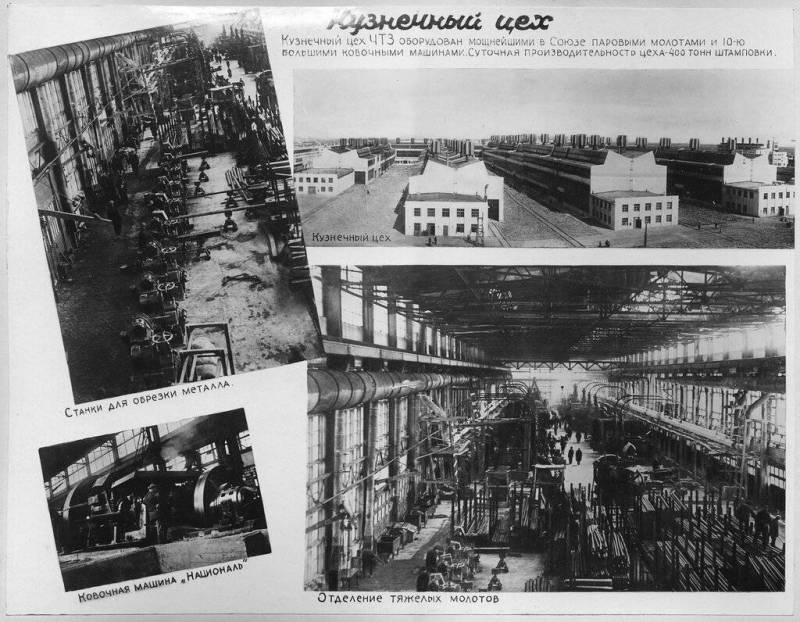

The plant consisted of the following workshops - iron-copper-casting, shaped-steel, forging, thermal, boiler-cold-forging, mechanical, assembly, instrumental, mechanical-repair, pilot plant, as well as an experimental department and laboratories. As can be seen from the list, the Chelyabinsk giant was a full-cycle enterprise - for example, in the gray cast iron foundry of the iron-copper foundry shop, they produced all the necessary nomenclature, with the exception of piston rings.

In addition, the plant purchased bearings, radiators, carburetors, magnetos and some electrical equipment. During the Great Patriotic War, this approach justified itself completely. The plant was minimally dependent on suppliers and could independently make changes to the design of tanks.

At the same time, enterprises tied to a mass of subcontractors often simply did not fulfill the plan, or drove frank marriage to the front. For example, Gorky's "Krasnoye Sormovo" produced the most low-quality T-34s according to this scheme, which were even nicknamed "Sormovo freaks".

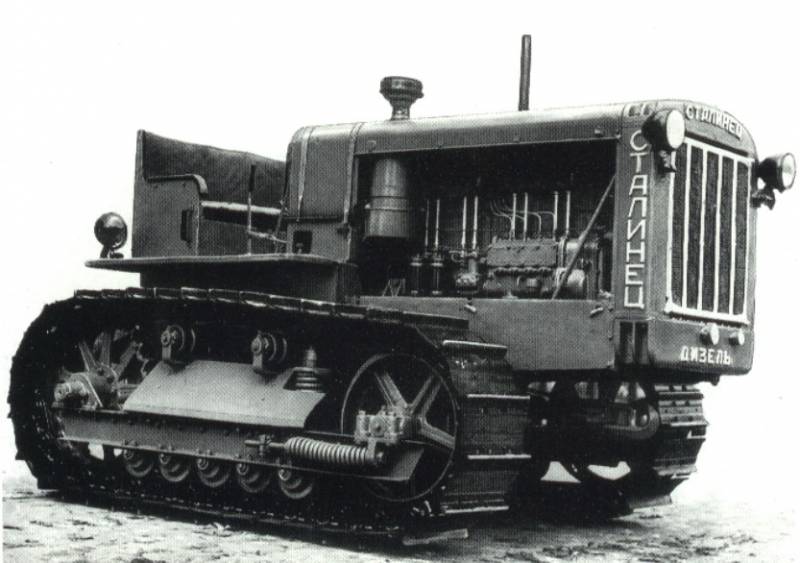

Diesel "Stalinets" for many years produced at ChTZ

June 1, 1933 was the official date of birth of the Chelyabinsk Tractor Plant, but it started work earlier. For the solemn ceremony, the first thirteen serial tractors were assembled in mid-May, tested, and on the first day of summer they were allowed to march in a parade column at a rally on the occasion of the opening of the enterprise. It is even difficult to imagine the atmosphere of good-quality Soviet storming that prevailed at ChTZ before the opening.

The pilot batch was supposed to be born on May 15, and these were not supposed to be prototypes on which technological processes were tested, but quite "combat-ready" tractors. Parts for the first machines were defective through one - the tolerances and workmanship were not respected.

A month before the launch of the plant, it turned out that some lines were incomplete. For example, in the engine assembly shop there was no electric bath for heating parts for a hot nozzle. I had to improvise and heat the gears with bearings in a bucket on the forge. On one of the conveyors, one of the assembly stations had to be urgently redone. And not just swap the nodes, but uproot the old from the foundation and concrete the new.

But in the end they did, and the first finished tractor S-60 "Stalinets" rolled out to the factory yard on May 15, 1933 at 15:40. Despite all the shortcomings and supply problems, the factory workers were able to produce forty more tractors in June. True, the quality of manufacturing machines left much to be desired.

This issue was acute throughout the first years of the plant's operation - the pursuit of the number of tractors inevitably affected the condition of the finished machines. It got to the point that in the defective department, finished machines were often dismantled for spare parts for other tractors - it was so difficult with production in the first months.

But this in no way detracts from the feat of the factory workers, who, in the end, mastered the assembly of complex equipment. In such stories, it is always worth remembering that twenty or thirty years ago no one could have imagined that such a thing could be built in a purely agrarian country. Already in 1937, "Stalinets" from Chelyabinsk took the Grand Prix at the international exhibition in Paris.

The plant turned out to be a grandiose not only by Soviet standards. An employee of the American office "Norton" rightly noted on the occasion of the opening of ChTZ:

And this can not be called flattery. Despite the fact that America did not supply its most advanced equipment to the Soviet Union, ChTZ was equipped very well.

For example, melting in a non-ferrous metal foundry took place in Detroit electric furnaces, and molding on Osborne International pneumatic machines. In total, several dozen American firms delivered their equipment to Chelyabinsk. According to the estimate for 1928–1929, the total cost of building the plant reached 133 rubles. The final exact price, perhaps, no one will name now.

Symbol of the Soviet era

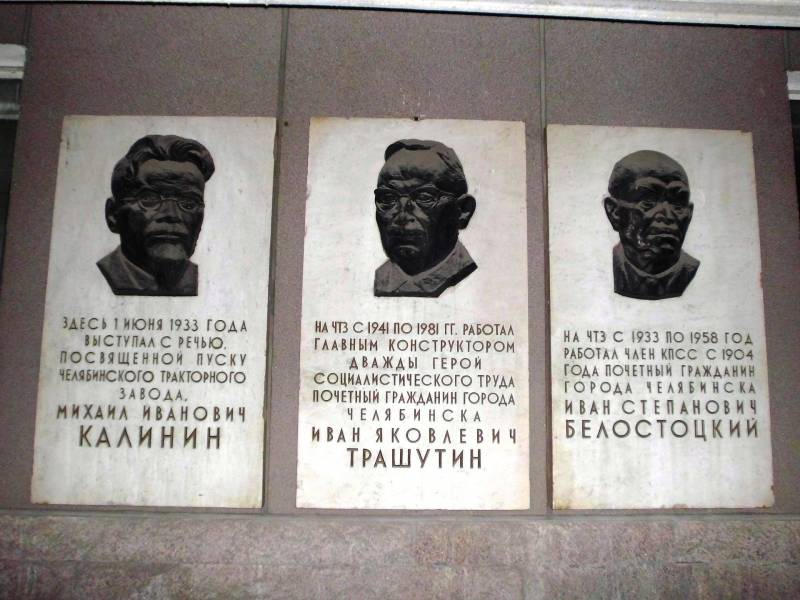

The opening of the plant according to all the canons was large-scale, and the main guest of the ceremony was the All-Union headman Mikhail Kalinin, about which there is still a commemorative plaque at the plant. As eyewitnesses say, during the inspection, Kalinin managed to stumble on a slab in one of the shops and work on the Herbert semi-automatic lathe.

Traditionally, congratulatory telegrams came to the opening from all over the Union - from the Central Committee of the All-Union Communist Party of Bolsheviks, the Council of People's Commissars, the Academy of Sciences and others. Probably the most unusual gift to the factory workers for the opening of the enterprise was presented by colleagues from Nizhny Tagil - 78 heifers and 15 bulls, which immediately replenished the herd of the auxiliary dairy farm.

The turning point came at the Chelyabinsk Tractor Plant, when it was entrusted with the production of tanks. In fairness, the heavy "Stalinists" have always been dual-use products - they perfectly towed corps guns in the army. But in 1940, factory engineers, technicians and designers had to master the production of the KV-1 tank. After the Winter War, the Soviet leadership decided to increase the production of heavy tanks, and the capacities of the Kirov plant were no longer enough.

They did not really manage to master the production (only 25 tanks were assembled), when the Great Patriotic War began. Further events for ChTZ developed rapidly. Already in October 1941, the Ural plant for the production of heavy tanks was formed as part of the Kirov Plant evacuated from Leningrad to Chelyabinsk, the Ural Plant of Heavy Engineering and the Ural Turbine Plant. Actually, from that moment on, we can talk about the formation of the legendary Chelyabinsk "Tankograd".

In conjunction with it, a car-building plant worked in Nizhny Tagil, where the Kharkov Plant No. 183 was transferred. By the way, the Kirov Plant did not fit completely at ChTZ, its diesel part was sent to the Ural Turbine Plant. In November 1941, the Chelyabinsk Tractor Plant stopped producing its main products and switched completely to a military footing. It was here that heavy tanks were put on the conveyor for the first time in the world. It was from here that more than 18 tanks and self-propelled guns, 48,5 legendary V-2 diesel engines, and almost 18 million blanks for shells were sent to the front.

The glorious "Tankograd" is again working for the strategic interests of the country.

Since last year, engine builders have been consistently increasing the production of tank diesel engines, the roots of which go back to the same V-2 during the Great Patriotic War. For the 90th anniversary of the plant, Chelyabinsk residents prepared a gift for the Motherland - they increased the production of engines for tanks by 12 percent compared to the best indicators of the USSR during the Cold War.

Happy holiday, dear factory workers!

Information