Anti-mine protection of modern armored vehicles - solutions and examples of implementation

Throughout the relatively short stories armored vehicles of the ground forces of about a hundred years, the nature of the conduct of hostilities has changed several times. These changes were of cardinal nature - from “positional” to “maneuverable” war and, further, to local conflicts and counter-terrorist operations. It is the nature of the alleged hostilities that is decisive in the formation of requirements for military equipment; accordingly, the ranking of the basic properties of armored vehicles (BTT) also changed. The classic combination of "firepower - protection - mobility" has been repeatedly updated, complemented by new components. At present, the point of view has been established, according to which protection is given priority.

A significant expansion of the nomenclature and capabilities of anti-armored vehicles made its survivability an essential condition for the performance of a combat mission. Ensuring the vitality and, in a narrower sense - the protection of BTT, is based on an integrated approach. There can be no universal means of protection against all possible modern threats, therefore, various protection systems are installed on the objects of armored vehicles that complement each other. To date, dozens of designs, systems and protective systems have been created, ranging from traditional armor to active protection systems. Under these conditions, determining the optimal composition of complex protection is one of the most important tasks, the solution of which determines to a large extent the perfection of the machine being developed.

The solution to the task of integrating protective equipment is based on the analysis of potential threats in the intended conditions of use. And here it is necessary to return again to the fact that the nature of the hostilities and, consequently, the “representative anti-tank outfit” have changed dramatically in comparison with, say, the Second World War. The most dangerous for armored vehicles at the present time are two opposing, both in terms of technological level and in terms of methods of application, groups of vehicles are highly accurate. weapon (WTO) on the one hand and the means of close combat and mines on the other. If the use of the WTO is typical for highly developed countries and, as a rule, leads to fairly quick results on the destruction of enemy armored vehicles, then the widest use of mines, improvised explosive devices (IEDs) and hand-held anti-tank grenade launchers from various armed formations is long-lasting. In this sense, the experience of US combat operations in Iraq and Afghanistan is very indicative. Considering precisely such local conflicts as the most characteristic of modern conditions, it should be recognized that mines and melee weapons are the most dangerous for armored vehicles.

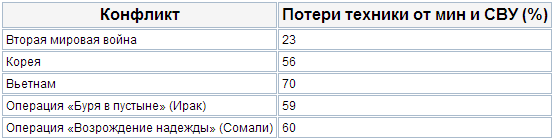

The level of the threat that mines and improvised explosive devices presently present is well illustrated by generalized data on the losses of US military equipment in various armed conflicts (Table 1).

Analysis of the dynamics of losses allows us to unequivocally state that the mine action component of the integrated protection of armored vehicles is particularly relevant today. The provision of mine protection has become one of the main problems facing the developers of modern military machines.

To determine ways to ensure protection, first of all, the characteristics of the most likely threats should be assessed - the type and power of the mines and explosive devices used. Currently, a large number of effective anti-tank mines, differing, including in the principle of action, have been created. They can be equipped with both push-type fuses and multichannel sensors - magnetometric, seismic, acoustic, etc. The combat unit can be both simplest high-explosive and with striking elements of the “shock core” type, having high armor-piercing ability.

The characteristics of the military conflicts in question do not imply that the enemy has “high-tech” mines. Experience shows that in most cases mines are used, and more often IEDs, of high-explosive action with radio-controlled or contact fuses. An example of an improvised explosive device with the simplest type of fuse is shown in figure 1.

Recently, in Iraq and Afghanistan, cases of the use of improvised explosive devices with striking elements of the “shock core” type have been recorded. The appearance of such devices is a response to the increased mine protection of armored vehicles. Although, for understandable reasons, it is impossible to manufacture a high-quality and highly efficient cumulative unit with “improvised means”, nevertheless, the armor-piercing ability of such IEDs is up to 40 mm of steel. This is quite enough for a reliable defeat light armor technology.

The power of the used mines and IEDs depends largely on the availability of certain explosives (BB), as well as the possibilities for their laying. As a rule, IEDs are manufactured on the basis of industrial explosives, which at the same power have much greater weight and volume than “combat” explosives. The complexity of the hidden tab of such cumbersome IEDs limit their power. Data on the frequency of use of mines and IEDs with various trotyl equivalents, obtained as a result of summarizing the experience of US combat operations in recent years, are given in Table 2.

Analysis of the data presented shows that more than half of the explosive devices used in our time have TNT equivalents 6 ... 8 kg. It is this range that should be considered the most probable and, therefore, the most dangerous.

From the point of view of the nature of the lesion, there are types of undermining under the bottom of the car and under the wheel (track). Characteristic lesions in these cases are shown in Figure 2. In case of explosions under the bottom, the integrity of the hull and the destruction of the crew are very likely both due to dynamic loads exceeding the maximum permissible and due to the impact of the shock wave and splinter flow. When explosions under the wheel, as a rule, the mobility of the machine is lost, but the main factor in the destruction of the crew are only dynamic loads.

Approaches to the provision of mine protection of armored vehicles are primarily determined by the requirements for the protection of the crew and only secondly by the requirements for preserving the operability of the vehicle.

The preservation of the performance of internal equipment and, as a result, technical combat capability, can be achieved by reducing the impact loads on this equipment and its attachment points. The most critical in this regard are the components and assemblies, mounted on the bottom of the machine or within the maximum possible dynamic deflection of the bottom during undermining. The number of equipment attachment points to the bottom should be minimized as much as possible, and these nodes themselves should have energy-absorbing elements that reduce dynamic loads. In each case, the design of attachment points is original. At the same time, from the point of view of the bottom structure, to ensure the operability of the equipment, it is necessary to reduce the dynamic deflection (increase rigidity) and to ensure the maximum possible reduction of the dynamic loads transmitted to the attachment points of the internal equipment.

The preservation of the performance of the crew can be ensured under certain conditions.

The first condition is to minimize the dynamic loads transmitted during the blasting on the attachment points of the crew seats or the landing force. In the case of mounting seats directly on the bottom of the machine, almost all the energy imparted to this bottom section will be transmitted to its attachment points, therefore extremely efficient energy absorbing units of chairs are required. It is important that providing protection at high power charge becomes doubtful.

When mounting seats to the sides or roof of the case, where the zone of local "explosive" deformations does not extend, only that part of the dynamic loads that apply to the body of the machine as a whole are transferred to the attachment points. Considering the considerable mass of the machines under consideration, as well as the presence of such factors as suspension elasticity and partial energy absorption due to local deformation of the structure, the accelerations transmitted to the sides and the roof of the hull will be relatively small.

The second condition for the preservation of the crew’s working capacity is, as in the case of internal equipment, the elimination of contact with the bottom at maximum dynamic deflection. This condition can be achieved purely constructively by providing the necessary clearance between the bottom and the floor of the habitable compartment. Increasing the rigidity of the bottom leads to a reduction in this necessary clearance. Thus, the performance of the crew is provided by special shock-absorbing seats fixed in places remote from the areas of possible application of explosive loads, as well as by excluding the contact of the crew with the bottom at maximum dynamic deflection.

An example of the integrated implementation of these approaches to the provision of mine protection is the relatively recent class of armored vehicles MRAP (Mine Resistant Ambush Protected - protected from undermining and attacks from ambushes), which have increased resistance to both the effects of explosive devices and small arms fire. It is necessary to pay tribute to the high efficiency shown by the USA, with which the development and supply of large quantities of similar cars to Iraq and Afghanistan were organized. This task was assigned to quite a large number of companies - Force Protection, BAE Systems, Armor Holdings, Oshkosh Trucks / Ceradyne, Navistar International, etc. This predetermined a significant disunification of the MRAP fleet, but allowed them to be delivered in the required quantities in a short time.

The general features of the approach to providing mine protection on automobiles of these companies are the rational V-shape of the lower part of the hull, the increased strength of the bottom through the use of thick steel armor plates and the mandatory use of special energy-absorbing seats. Protection is provided only for the habitable module. Everything that is “outside”, including the engine compartment, either has no protection at all, or is poorly protected. This feature allows you to withstand the undermining of rather powerful IEDs due to the easy destruction of the “outer” compartments and assemblies while minimizing the transmission of effects on the habitable module (Figure 3). Similar solutions are being implemented both on heavy machines, for example, Ranger from Universal Engineering, and on light ones, including IVECO 65E19WM. With obvious rationality in conditions of limited mass, this technical solution still does not provide high survivability and preservation of mobility with relatively weak explosive devices, as well as bullet shelling.

Simple and reliable, but not the most rational in terms of mass, is the use of heavy-gauge steel to protect the bottom. Lighter bottom structures with energy-absorbing elements, for example, hexagonal or rectangular tubular parts, are used for the time being very limited.

Photo courtesy of Concern "Tractor plants"

Cars of the “Typhoon” family (figure 4) developed in Russia also belong to the MRAP class. Practically all currently known technical solutions for ensuring mine protection are implemented in this family of vehicles:

- V-shaped bottom,

- multi-layer bottom of the habitable compartment, anti-mine pan,

- internal floor on elastic elements,

- crew location at the maximum possible distance from the most likely place of explosion,

- aggregates and systems protected from direct weapons impact,

- energy absorbing seats with seat belts and head restraints.

The work on the Typhoon family is an example of cooperation and an integrated approach to solving the problem of ensuring security in general and anti-mine resistance in particular. The lead developer for the protection of vehicles developed by the Ural automobile plant is OAO NII Steel. The development of the overall configuration and layout of the cabs and functional modules, as well as energy absorbing seats was carried out by EurotechPlast OJSC. To perform a numerical simulation of the impact of the explosion on the design of the car, experts of Sarov Engineering Center LLC were involved.

The current approach to the development of mine protection includes several stages. At the first stage, a numerical simulation of the impact of the explosion products on the draft design is performed. Further, the external configuration and the overall design of the bottom, mine pallets are clarified and their structure is tested. The testing of structures is also performed first by numerical methods, and then tested on fragments with a real undermining.

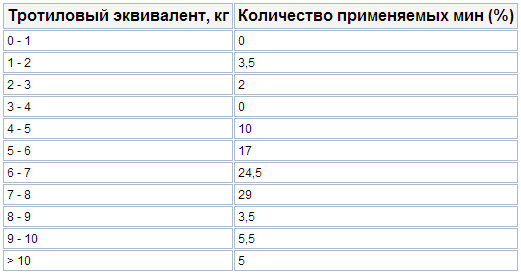

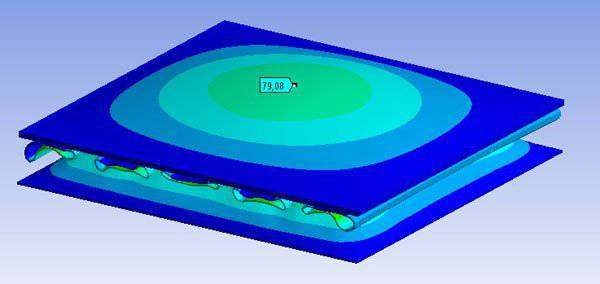

Figure 5 shows examples of numerical modeling of the impact of an explosion on various structures of anti-mine structures made by NII Steel as part of work on new products. After completion of the detailed design of the machine, various versions of its detonation are modeled.

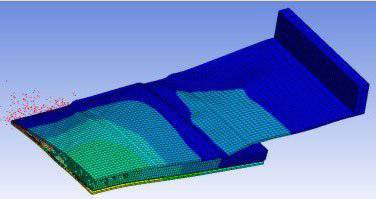

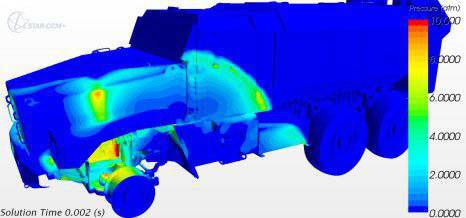

Figure 6 shows the results of a numerical simulation of an undermining of the Typhoon car, performed by the Sarovsky engineering center. According to the results of the calculations, necessary improvements are made, the results of which are already being verified by real tests for demolition. Such a multistage development makes it possible to evaluate the correctness of technical solutions at various stages of design and, in general, reduce the risk of constructive errors and choose the most rational solution.

A common feature of the developed modern machines is the modularity of most systems, including protective ones. This allows you to adapt new machines to the intended conditions of use and, conversely, in the absence of any threats to avoid unnecessary costs. With regard to mine protection, such modularity allows us to quickly respond to possible changes in the types and capacities of used explosive devices and effectively solve one of the main problems of protecting modern armored vehicles with minimal costs.

Thus, the following conclusions can be made on the problem under consideration:

- one of the most serious threats to armored vehicles in the most typical local conflicts today are mines and IEDs, which account for more than half of the losses of equipment;

- To ensure high mine protection of armored vehicles, an integrated approach is needed, which includes both layout and design, "circuit" solutions, as well as the use of special equipment, in particular, energy-absorbing crew seats;

- samples of armored vehicles with high mine protection have already been created and are actively used in modern conflicts, which allows analyzing the experience of their combat use and identifying ways to further improve their design.

Information