Prospects for the Russian aircraft engine industry

At the end of the last century, a number of factors came to the fore, having a strong influence on the prospects for global aviation engine building - cost increase, increase in the full development timeframe and prices of aircraft engines. The growth of cost indicators of aircraft engines is becoming exponential, with the share of exploratory research on the creation of a leading scientific and technical reserve becoming larger from generation to generation. For the aircraft engine industry in the United States during the transition from the fourth to the fifth generation, this share increased in costs from 15% to 60%, and in time it almost doubled. The situation in Russia was aggravated by well-known political events and a systemic crisis at the beginning of the twenty-first century.

On a state budget basis, the United States today is conducting a national program of key technologies for aviation engine-building, the Institute of Scientific and Technical Information. The ultimate goal - to 2015 g. To reach a monopoly position, pushing all the rest from the market. What is Russia doing today to prevent it?

The head of CIAM, V. Skibin, said at the end of last year: “We have little time, but a lot of work.” However, the research carried out by the head institute does not find a place in the long-term plans. When creating the Federal Target Program for the development of civil aircraft before 2020, CIAM was not even asked. “In the FTP project we saw very serious questions, starting with the formulation of tasks. We see non-professionalism. In the draft Federal Target Program-2020, it is planned to allocate only 12% for science, 20% - for engine-building. This is not enough. The institutes were not even invited to discuss the draft federal target program, ”V. Skibin emphasized.

Andrei Reus. Yuri Eliseev. Vyacheslav Boguslaev.

CHANGE OF PRIORITIES

The federal program "Development of civil aviation technology of Russia on 2002-2010. and for the period up to 2015, ”it was planned to create a number of new engines. CIAM based on the forecast of the development of the aviation technology market has developed technical specifications for the competitive development of technical proposals for the creation of new generation engines provided for by the said Federal Targeted Program: 9000 hp for helicopters and light aircraft, GTN horsepower 14000 for helicopters and light aircraft, aviation piston engine (ADF) power hp 5000-7000 for helicopters and light aircraft and hp power xnumx-xnumx for ultralight helicopters and airplanes.

At the same time it was decided to reorganize the industry. The implementation of the federal program “Reforming and Development of the Military-Industrial Complex (2002-2006)” provided for work to be carried out in two stages. At the first stage (2002-2004), it was planned to carry out a set of measures to reform the backbone integrated structures. At the same time, the aviation industry was supposed to create nineteen integrated structures, including a number of structures for engine-building organizations: OJSC “Corporation“ Complex named after N.D. Kuznetsova ", JSC" Perm Engine-Building Center ", FSUE" Salyut ", JSC" Air Screws Corporation ".

By this time, the domestic engine leaders had already realized that it was pointless to hope for cooperation with foreign enterprises, but it was very difficult to survive alone, and began to actively build their own coalitions that would allow them to take their rightful place in the future integrated structure. Aviation Motors in Russia has traditionally been represented by several “bushes”. At the head were the design bureaus, at the next level - serial enterprises, behind them - aggregators. With the transition to a market economy, the leading role began to shift to serial plants that received real money from export contracts - MMPP Salyut, MMP them. Chernysheva, UMPO, Motor Sich.

By this time, the domestic engine leaders had already realized that it was pointless to hope for cooperation with foreign enterprises, but it was very difficult to survive alone, and began to actively build their own coalitions that would allow them to take their rightful place in the future integrated structure. Aviation Motors in Russia has traditionally been represented by several “bushes”. At the head were the design bureaus, at the next level - serial enterprises, behind them - aggregators. With the transition to a market economy, the leading role began to shift to serial plants that received real money from export contracts - MMPP Salyut, MMP them. Chernysheva, UMPO, Motor Sich.MMPP “Salyut” in 2007 was transformed into an integrated structure of the FSUE “Scientific and Production Center for the Gas-turbine Engineering“ Salyut ”. Its structure includes branches in Moscow, the Moscow region and Bender. The controlling and blocking stakes in the joint-stock companies NPP Temp, KB Electropribor, NIIT, GMZ Agat and JV Topaz were managed by Salyut. A huge advantage was the creation of its own design office. This design bureau quickly proved itself capable of solving serious problems. In the first place - the creation of modernized engines AL-31FM and the development of a promising engine for fifth-generation aircraft. Thanks to export orders, Salyut carried out a large-scale modernization of production and carried out a number of research and development.

The second center of gravity was NPO Saturn, in fact, Russia's first vertically integrated company in the field of aircraft engine building, uniting the design office in Moscow and the serial plant in Rybinsk. But, unlike Salut, this association was not supported by the necessary financial resources of its own. Therefore, in the second half of 2007, Saturn began a rapprochement with UMPO, which had a sufficient number of export orders. Soon in the press there were reports that the management of Saturn became the owner of a controlling stake in UMPO, a complete merger of the two companies was expected.

With the advent of the new leadership, OAO Klimov became another center of gravity. In essence, this is a design office. Traditional serial factories producing the products of this design bureau are Moscow WFP. Chernyshev and Zaporozhye Motor Sich. The Moscow enterprise had rather large export orders for the RD-93 and RD-33МК engines, the Zaporozhian residents remained practically the only enterprise supplying the TV3-117 engines for Russian helicopters.

Salyut and Saturn (if counted along with UMPO) mass-produced the AL-31F engines, one of the main sources of export earnings. Both companies had civilian products - SaM-146 and D-436, but both of these engines are of non-Russian origin. "Saturn" also produces engines for unmanned aerial vehicles. There is such an engine at Salut, but there are no orders for it yet.

Klimov has no competitors in Russia in the field of engines for light fighters and for helicopters, but in the field of creating engines for training aircraft, everyone competed. MMPP them. Chernysheva, together with TMKB Soyuz, created the RD-1700 turbojet engine, Saturn by order of India - AL-55I, Salut, in cooperation with Motor Sich, produces AI-222-25. In reality, only the latter is installed on production aircraft. In the field of remotorization of the Il-76, Saturn competed with the Perm PS-90, which remains the only engine that is currently installed on Russian mainline aircraft. However, the Perm "bush" was not lucky with shareholders: the once powerful enterprise passed from hand to hand, power was wasted behind the leapfrog of changing non-core owners. The process of creating the Perm engine building center dragged on, the most talented specialists moved to Rybinsk. Now the United Engine Corporation (UEC) is closely involved in the optimization of the management structure of the Perm "cluster". While a number of technologically related enterprises, which were separated from it in the past, are being connected to the PMZ. A project to create a unified structure with the participation of PMZ and Aviadvigatel Design Bureau is being discussed with American partners from Pratt & Whitney. At the same time, until the beginning of April of this year, UEC will liquidate the "extra link" in the management of its Perm assets - the Perm representative office of the corporation, which has become the legal successor of CJSC "Management Company" Perm Engine Building Complex "(MC PMK), which from 2003 to 2008. managed the enterprises of the former Perm Motors holding.

AI-222-25.

The most problematic issues were the creation of an engine in the 12000-14000 kgf thrust class for a promising near-medium-haul airliner, which should replace the Tu-154. The main struggle unfolded between the Perm engine builders and the Ukrainian Progress. Permians offered to create a new generation engine PS-12, their competitors proposed the project D-436-12. Less technical risk in creating the D-436-12 was more than offset by political risks. A seditious thought sneaked in that an independent breakthrough in the civilian segment had become unlikely. The market for civilian jet engines today is even more rigidly divided than the aircraft market. Two American and two European companies close all possible niches, actively cooperating with each other.

Several enterprises of the Russian engine industry remained aloof from the struggle. New developments of the AMNTK Soyuz were not needed, Samara enterprises had no competitors in the domestic market, but there was practically no market for them. Samara aircraft engines operate on strategic aviation aircraft, which were not built much in the Soviet era. At the beginning of the 1990-x was developed promising TVVD NK-93, but it was not in demand in the new conditions.

Today, according to Andrei Reus, Director General of OPK Oboronprom OJSC, the situation in Samara has changed dramatically. Samara "bush" plan 2009 g. Fully implemented. In 2010, it is planned to complete the unification of the three enterprises into a single NGO, and to sell the extra space. According to A. Reus, “the crisis situation for Samara is over, normal operation has begun. The level of productivity remains lower than in the industry as a whole, but there are positive changes in the production and financial sectors. In 2010, the UEC plans to bring Samara enterprises to a break-even operation. ”

There is also the problem of small and sport aircraft. Oddly enough, they also need engines. Today, from domestic engines, you can choose only one - piston M-14 and its derivatives. These engines are produced in Voronezh.

In August, 2007, at a meeting in St. Petersburg on engine development, then-President Vladimir Putin instructed to create four holding companies, which would then be merged into one company. At the same time, V.Putin signed the Decree on the merger of the Salyut with the FSUE “Omsk Motor-Building Association named after P.I. Baranova. The term for joining the "Salute" of the Omsk plant periodically changed. In 2009, this did not happen because the Omsk plant had substantial debt obligations, and Salyut insisted that the debt be repaid. And the state extinguished it, allocating 568 million rubles in December last year. According to the leadership of the Omsk region, there are no obstacles to the merger now, and this will happen in the first half of 2010.

Of the three remaining holdings, after several months, it was considered expedient to create one association. In October, Russian Prime Minister Vladimir Putin ordered 2008 to transfer to Oboronprom state-owned blocks of shares of ten enterprises and to provide a controlling block of shares of the UEC created in a number of enterprises, including Aviadvigatele, NPO Saturn, and Perm Motors , PMZ, UMPO, “Motor-Builder”, SNTK them. Kuznetsova and several others. These assets came under the control of the Oboronprom subsidiary, United Engine Corporation. Andrei Reus argued this decision as follows: “if we followed the path of the intermediate stage of creating several holdings, then we would never agree to make one product. Four holdings are four lineups that could never be brought to a single denominator. I'm not talking about state aid! One can only imagine what would have happened in the struggle for budget funds. The same project for the creation of an engine for MC-21 involves NPP Motor, Aviadvigatel Design Bureau, Ufa Engine-Building Production Association, Perm Engine Plant, Samara bush. NPO Saturn, while there was no association, refused to work on the project, and now it is an active participant in the process. ”

AL-31FP.

Today, the JDC’s strategic goal is to “restore and support the modern Russian engineering school in the field of gas turbine engines”. The JDC should have a foothold in the top five global manufacturers in the field of the CCD by 2020. At this point, 40% of UEC product sales should be focused on the global market. At the same time, it is necessary to ensure a fourfold and possibly fivefold increase in labor productivity and the mandatory inclusion of service in the engine sales system. The priority projects of the UEC are the creation of the SaM-146 engine for the Russian regional SuperJet100 aircraft, the new civil aircraft engine, the military aircraft engine, and the engine for the promising high-speed helicopter.

ENGINE OF THE FIFTH GENERATION FOR BATTLE AVIATION

The program to create the PAK FA in 2004 was divided into two stages. The first stage involves the installation of an 117С engine on the aircraft (today it belongs to the 4 + generation), the second stage involved the creation of a new engine with 15-15,5 tons. In the draft design of the PAK FA, the Saturn engine is “registered”.

The competition announced by the Ministry of Defense of the Russian Federation also included two stages: November 2008 and May-June 2009. Saturn was almost a year behind Salyut in providing the results of work on engine components. "Salute" did everything on time, received the conclusion of the commission.

Apparently, this situation prompted the UEC in January 2010 to still suggest that Salyut create a fifth-generation engine together. A preliminary agreement was reached on dividing the workload of about fifty to fifty. Yuri Yeliseyev agrees to work with UEC on a parity basis, but believes that the Salut should be the ideologue for the creation of a new engine.

MMPP "Salut" has already created the AL-31FM1 engines (it is put into service, available commercially) and AL-31FM2, moved to the bench working out AL-31FM3-1, followed by AL-31FM3-2. Each new engine is notable for its increased burden and the best resource indicators. AL-31FM3-1 received a new three-stage fan and a new combustion chamber, and the thrust reached 14500 kgf. The next step is to increase the thrust to 15200 kgf.

According to Andrei Reus, “the topic of the PAK FA leads to very close cooperation, which can be considered as the basis for integration”. However, he does not exclude that in the future a single structure in the engine industry will be created.

The SaM-146 program is an example of successful cooperation in the field of high technologies between the Russian Federation and France.

PD-14

A few years ago Aviadvigatel OJSC (PD-21, formerly known as PS-14) and Salyut, together with the Ukrainian Motor Sich and Progress (SPM-14), presented their proposals for a new engine for the MS-21 aircraft. . The first was a completely new job, and the second was planned to create on the basis of D-436, which allowed to significantly reduce the time and reduce technical risks.

At the beginning of last year, UAC and NPK Irkut finally announced a tender for engines for the MC-21 aircraft, having issued a technical assignment to several foreign engine-building firms (Pratt & Whitney, CFM International) and Ukrainian Motor Sich and Ivchenko-Progress in cooperation with the Russian "Salut". The creator of the Russian version of the engine has already been determined - UEC.

In the family of developed engines there are several heavy engines with a greater burden than is necessary for MC-21. There is no direct financing of such products, but in the long term, engines of increased thrust will be in demand, including for the replacement of the PS-90A on the aircraft flying now. All engines are more thrust planned to perform gear.

An engine with an 18000 kgf engine may also be required for a promising light wide-body aircraft (LSG). Engines with such a burden are also required for MC-21-400.

In the meantime, Irkut Research and Production Corporation decided to equip the first MC-21 with PW1000G engines. Americans promise to prepare this motor for 2013, and apparently Irkut already have reason to fear the US State Department’s bans and the fact that such engines may simply not be enough for everyone if they decide to retrofit Boeing 737 and Airbus A320 aircraft.

At the beginning of March PD-14 passed the “second gate” at a meeting in the JDC. This means formed cooperation in the manufacture of the gas generator, proposals for cooperation in the production of the engine, as well as a detailed analysis of the market. PMZ will produce a combustion chamber and a high-pressure turbine. A significant part of the high-pressure compressor, as well as the low-pressure compressor, will be produced by the UMPO. In the low-pressure turbine, options for cooperation with Saturn are possible, and cooperation with Salyut is also possible. The motor will be assembled in Perm.

In the draft design of the PAK FA, the Saturn engine is “registered”.

OPEN ROTOR MOTORS

Despite the fact that Russian aircrafts do not recognize the open rotor yet, the engines are sure that it has advantages and that “the airplanes will ripen to this engine”. Therefore, today Perm is conducting relevant work. The Cossacks already have a serious experience in this direction associated with the D-27 engine, and in the open-rotor engine family, the development of this node will probably be given to the Cossacks.

Prior to MAKS-2009, work on the D-27 at the Moscow Salute was frozen: there was no funding. 18 August 2009, the Russian Ministry of Defense signed a protocol on amending the agreement between the governments of Russia and Ukraine on the An-70 aircraft, Salyut began active work on the manufacture of parts and assemblies. To date, there is an additional agreement for the supply of three sets and components to the engine D-27. The works are financed by the Ministry of Defense of the Russian Federation, the units built by Salyut will be transferred to GP Ivchenko-Progress to complete state engine tests. The overall coordination of work on this topic is entrusted to the Ministry of Industry and Trade of the Russian Federation.

There was also the idea of using D-27 engines on Tu-95MS and Tu-142 bombers, but Tupolev does not consider such options, the possibility of installing D-27 on the A-42E aircraft was worked out, but then it was replaced by PS-90.

At the beginning of last year, the KLA and NPK Irkut announced a tender for engines for MS-21 aircraft.

ENGINES FOR HELICOPTERS

Today, most Russian helicopters are equipped with Zaporozhye-made engines, and for those engines that Klimov assembles, the gas generators are still supplied by Motor Sich. This company is now significantly superior to Klimov in the number of helicopter engines produced: the Ukrainian company reportedly supplied 2008 engines to Russia in 400, while Klimov OJSC produced them in the amount of about 100 units.

For the right to become the head company for the production of helicopter engines for several years fought "Klimov" and MMP them. V.V. Chernyshev. The production of TV3-117 engines was planned to be transferred to Russia by building a new plant and taking away the main source of income from Motor Sich. At the same time, Klimov was one of the active lobbyists of the import substitution program. In 2007, the final assembly of the engines VK-2500 and TV3-117 was supposed to focus on the MMP them. V.V. Chernyshev.

Today, the production, overhaul and after-sales service of the TV3-117 and VK-2500 helicopter engines is planned by the UEC. Also in Ufa, they expect to launch the Klimovsky VK-800В series. 90% of the necessary financial resources for this purpose are expected to be raised under the federal targeted programs “Development of civil aviation equipment”, “Import substitution” and “Development of the defense industry complex”.

Engines D-27.

Production of gas generators to replace the Ukrainian should be established at UMPO with 2013. Until that time, gas generators will continue to be purchased at Motor Sich. The UEC plans to use the facilities of OAO Klimov “to the maximum” before 2013. What Klimov cannot do will be ordered at Motor Sich. But already in 2010-2011. it is planned to minimize the purchase of repair kits for Motor Sich. With 2013, when the production of engines at Klimov will be curtailed, the St. Petersburg company will restructure its premises.

As a result, Klimov received in the UEC the status of the head developer of helicopter engines and turbojet engines in the afterburner class to 10 tf. The priority directions today are to conduct OCD on the TV7-117В engine for the Mi-38 helicopter, upgrade the VK-2500 engine in the interests of the RF Ministry of Defense, and complete the OCD on the RD-33МК. The company also participates in the development of the fifth generation engine under the PAK FA program.

At the end of December 2009, the UEC Project Committee approved the Klimov project for the construction of a new design and production complex with the release of sites in the center of St. Petersburg.

MMP them. V.V. Chernyshev will now conduct mass production of a single helicopter engine - TV7-117В. This engine was created on the basis of the TV7-117CT aircraft TVD for the Il-112В aircraft, and its production is also being mastered by this Moscow enterprise.

In response, Motor Sich in October last year proposed the UEC to create a joint management company. “The management company can be a transitional option for further integration,” explained the chairman of the board of directors of Motor Sich, Vyacheslav Boguslaev. According to Boguslaev, the UEC could well acquire up to 11% of Motor Sich shares, which are in free circulation on the market. In March, 2010 of Motor Sich took another step by proposing to the Kazan Motor-Building Production Association to open production of engines for the Ansat multi-purpose light-duty helicopter at the facilities that were vacant from it. MC-500 is an analogue of the PW207K engine, with which Ansat helicopters are equipped today. Under the terms of the contracts of the Defense Ministry of the Russian Federation, Russian equipment must be equipped with domestic components, and the exception for Ansat is made because there is no real replacement for Canadians. This niche could occupy the KMPO with the MC-500 engine, but for now the question is about cost. The price of MC-500 is about $ 400 thousand, and PW207K costs $ 288 thousand. However, in early March, the parties signed a software contract with the intention to enter into a licensing agreement (50: 50). KMPO, a few years ago invested heavily in the creation of the Ukrainian engine

AI-222 for the Tu-324 aircraft, in this case, wants to protect itself with a license agreement and receive a guarantee of return on investment.

However, the holding company “Helicopters of Russia” sees the Klimov engine VK-800 as the power unit “Ansat”, and the version with the engine MC-500В is “considered among others”. From the point of view of the military, that Canadian, that the Ukrainian engine is equally foreign.

In general, to date, the UEC does not intend to take any steps to merge with Zaporizhzhya enterprises. Motor Sich has made a number of proposals for the joint production of engines, but they are contrary to their own UEC plans. Therefore, “properly built contractual relations with Motor Sich are quite satisfactory for us today,” said Andrei Reus.

PS-90А2.

PS-90

In 2009, PMZ built 25 new PS-90 engines, the production rate remained at the level of 2008. According to Mikhail Dichesula, Managing Director of Perm Motor Plant OJSC, the plant fulfilled all contractual obligations, not a single order was disrupted. In 2010, PMZ plans to start production of PS-90А2 engines, which passed flight tests on Tu-204 aircraft in Ulyanovsk and received a type certificate at the end of last year. This year it is planned to build six such engines.

D-436-148

The D-436-148 engines for An-148 aircraft are delivered today by Motor Sich together with Salut. The program of the Aviant Kiev Aviation Plant on 2010 laid down the production of four An-148, Voronezh Aviation Plant - 9-10 machines. To do this, you need to put about 30 engines, taking into account one or two backup engines in Russia and Ukraine.

D-436-148.

SаМ-146

More than 146 test hours were conducted on the SaM-6200 engine, of which more than 2700 hours were in flight. According to the program of its certification, more than 93% of the volume of planned tests was performed. It is necessary to additionally test the engine for throwing of the middle flock of birds, for the break of the fan blade, to check the initial maintenance, pipelines, oil filter blockage sensors, pipelines in salt fog conditions.

SaM-146.

Obtaining a European certificate (EASA) for a typical engine design is scheduled for May. After that, the engine will have to receive validation of the Interstate Aviation Committee Air Registry.

In March of this year, the managing director of Saturn, Ilya Fedorov, once again stated that “there are no technical problems for the serial assembly of the SaM146 engine and its commissioning”.

Equipment in Rybinsk allows production of up to 48 engines per year, and after three years their production can be increased to 150. The first commercial delivery of engines is scheduled for June 2010 g. Then - two engines each month.

D-18

Currently Motor Sich manufactures D-18T 3 series engines and is working on the D-18T engine of the 4 series, but the company is trying to build the upgraded D-18T engine of the 4 series in stages. The situation with the development of D-18T 4 series is compounded by the uncertainty of the fate of the modernized aircraft An-124-300.

AI-222-25

AI-222-25 engines for the Yak-130 aircraft are produced by Salyut and Motor Sich. At the same time, the financing of the Russian part of work on this motor was practically absent last year - Salyut did not receive money for half a year. In the framework of cooperation, we had to switch to barter: change the D-436 modules to AI-222 modules and “save the programs of the An-148 and Yak-130 aircraft”.

The afterburner version of the AI-222-25F engine is already undergoing tests, it is planned to begin state tests at the end of 2010 or at the beginning of 2011. A tripartite agreement has been signed between ZMKB Progress, OAO Motor Sich and FSUE MMPP Salyut to promote this engine to the world market with equity participation of each of the parties.

* * *

Last year, the process of forming the final structure of the JDC was almost completed. For 2009, the total revenue of JDC enterprises amounted to 72 billion rubles. (in 2008 g. - 59 billion rubles.). A significant amount of state support allowed the majority of enterprises to significantly reduce payables, as well as provide settlements with component suppliers.

On the field of aviation engine-building in Russia today there are three real players left - UEC, Salyut and Motor Sich. How the situation will develop further - time will show.

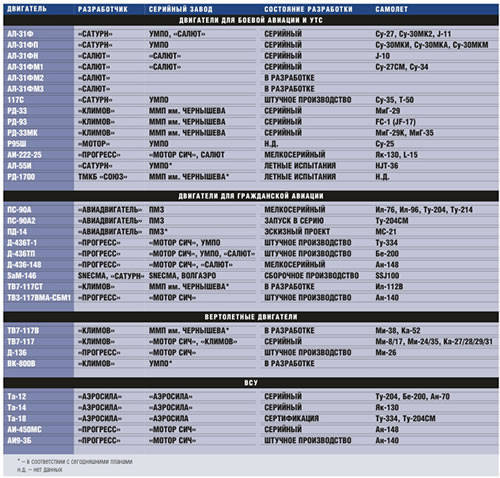

Information