Amphibious conveyor XM-158 Drake. Drake to replace Ducks

Needs and Suggestions

The existing DUKW amphibian with 6,2 t curb weight could take kg of cargo on board 2250. The car kept well on the water and developed a speed of the order of 8-10 km / h. However, by the end of the forties, the US Army ceased to be satisfied with such characteristics. Initially, this problem was solved by reworking the hull and a more powerful engine. The resulting XM-147 Super Duck amphibian could take 4 tons of cargo, and on the water it accelerated to 10-12 km / h. However, this was considered insufficient, which is why the XM-147 did not join the troops.

In the mid-fifties, General Motors Canada (GMC), which had previously created DUKW and its upgraded version, proposed a new amphibious conveyor project. It proposed to radically redesign the existing design and introduce a whole range of new technical solutions. All this made it possible to raise the load capacity to 8 t and increase mobility.

Prototype XM-158. Photo Strangernn.livejournal.com

The new sample received the working designation GMC XM-158 (in some sources there is an erroneous spelling XM-157). The name Drake ("Drake") was also used - it was an allusion to the nickname of the serial DUKW, which was called "Duck" in tune.

To increase the carrying capacity, the promising Drake needed a whole set of innovations. GMC practically developed the hull-boat from scratch, created a new version of the power plant and transmission, as well as the chassis and screw group, which meet new requirements. As a result, Drake had only minimal external resemblance to its predecessors, but at the same time had to show advantages over them.

Design features

The amphibian XM-158 was built on the basis of a new hull-boat with characteristic contours. The body was made of steel and aluminum parts connected by welding and riveting; all seams were sealed with a special paste. The hull received a curved lower frontal part, above which an almost horizontal "deck" was placed. There were vertical sides with reinforcement and a vertical aft leaf. On the sides were niches under the wheels. The central part of the bottom formed a tunnel for the units.

"Drake" on land. Photo 477768.livejournal.com

The layout of the XM-158 resembled the previous amphibians. In the front of the hull placed the power plant. Various transmission units were located next to the engine, under the cab floor and under the cargo area. Behind the engine compartment, crew seats and a control post were located. Almost all other body volume was given under the “on-board body”. Behind it was a small platform for various devices.

Calculations showed that the Drake needs a power plant with increased power. This issue was solved with the help of two diesel engines GMC-302-55 with an output of 145 hp. with own transmissions. Power flows were not combined, which simplified the design. Each engine was coupled to its own Alisson automatic transmission with 12 speeds. Behind her was a transfer case with two gears, as well as a two-speed power take-off.

The workplace of the driver. Chronicle frame

The left engine set in motion the wheels of the first and third axles, the right - the second and fourth. Also, the engines were responsible for the operation of two propellers. On a good road, it was proposed to use only the right engine and have the wheel formula 8x4. On soft ground, the left motor should also be started, getting the formula 8x8. Both engines should have worked on the water, driving two screws.

The special power plant was characterized by high fuel consumption - about 90 liters per 100 km. Four tanks with a total capacity of 636 l, combined into a common fuel system, were placed in the casing.

The chassis included four axles with independent air suspension. As an elastic element, a reinforced rubber cylinder with compressed air was used. By changing the pressure in the cylinder, it was possible to adjust the clearance and suspension stiffness. In addition, such a suspension made it possible to pull the wheels upward when moving on water, slightly reducing drag. The chassis included eight single-wheel 14.75-20 wheels.

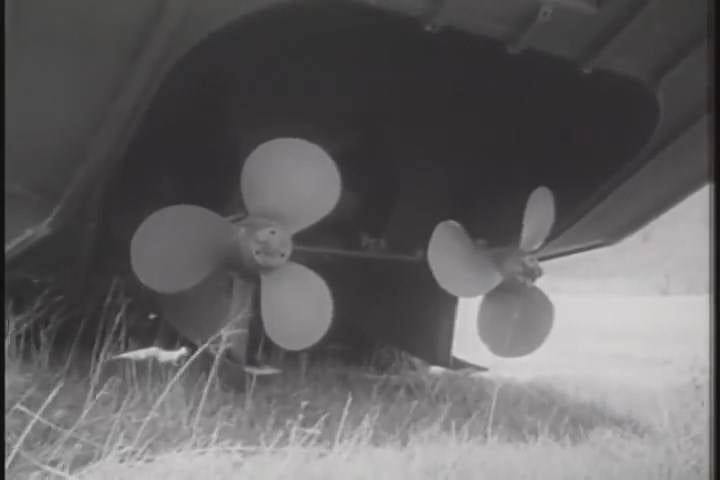

Propellers Chronicle frame

Under the stern of the hull was placed a swinging block in a vertical plane with two propellers. On land, he rose, protecting the screws from damage. On water, the unit lowered into working position. There was no separate steering wheel. Water control was carried out using the front swivel wheels and due to the differential change in the speed of two screws. A wave-reflective shield was provided on the nose of the case.

The cab for the XM-158 was similar to the equipment of previous machines. The front of the driver and commander was covered by an inclined windshield with a narrow roof and side glazing. The driver was on the left and had all the necessary controls. A steering wheel, pedals for controlling two engines, as well as a whole set of levers from all transmission boxes and propeller controls were located at the control post.

Amphibian on the road. Chronicle frame

The bulk of the “deck” was occupied by a flat cargo area. In its flooring, hatches were provided for access to the internal units of the machine. A platform with a length of about 7 m and a width of less than 2 m could take up to 8 tons of cargo (on land). The carrying capacity when driving on water was reduced in accordance with weather conditions.

In front of the cabin and behind the "deck" there were numerous mounts for various equipment. Amphibian carried a trench tool, spare parts and various property. At the stern, modeled on DUKW, the winch was kept. With the help of additional arcs, the machine could be equipped with a removable awning to protect the crew and cargo.

Initially, the XM-158 Drake transporter did not have its own weapons. Later, after the adoption of the army, he could get a machine gun for self-defense. The crew and the landing also had to have a personal weapons.

Water test. Chronicle frame

The total amphibian length was 12,8 m - almost 3,5 m longer than DUKW. Width - 3,05 m, height along the rudimentary roof - 3,3 m. Curb weight was determined in 14 t. At maximum load 8 t, the total mass reached 22 t. On the highway, amphibian accelerated to 70 km / h, on water - to 14 km / h. Cruising range by land - 700 km.

Failure "Drake"

In 1956, GMC built a prototype of the new amphibious conveyor. In some sources it is mentioned that the Drake car remained in one copy. According to other materials, several such prototypes were built. One way or another, the number of Drake was minimal, but sufficient for testing.

All-terrain vehicle rises to the wave. Chronicle frame

During the tests, the prototype (s) confirmed the basic driving characteristics. The car briskly moved on land, both on the highway and on rough terrain, overcoming various obstacles. Comparisons with the serial amphibian DUKW clearly showed the advantages of the new model. The Drake successfully overcame the obstacles on which the lighter but less powerful Duck simply got stuck.

The payload characteristics were fully confirmed, and in this regard, the XM-158 was ahead of all existing American-made amphibians. She took as much load as two Super Duck or four serial DUKW.

However, not all the features of the new XM-158 suit the army. First of all, they criticized the overly complex power plant and transmission, as well as extremely inconvenient control systems. So, the lack of mechanical connection between the engines did not allow synchronizing the speed. This was not a problem on land, but made it difficult to navigate on water. The difference in speed made it difficult to maintain course; the driver had to constantly steer and control the operation of the engines. The control of the power plant and transmission in all modes was complicated by the ergonomics of the cab: next to the driver was a whole battery of levers for various purposes.

Thus, the resulting amphibian had fairly high characteristics and exceeded similar developments. However, the price was the overly complex and expensive construction of key units, as well as various operational difficulties. Probably, GMC designers could save their development from the identified problems, however, it was too complicated. In fact, a radical restructuring of the power plant and transmission was required, which could affect other systems.

Such a revision of the project was considered inappropriate. Amphibian XM-158 Drake did not enter service with the United States. An unfinished car with a lot of problems was not offered to foreign customers. Thus, the prototype (or prototypes) was left alone.

After testing

According to various sources, in the future, the experienced Drake was used as a platform for working out new solutions. He was later sold to a commercial company. For several years, a unique car drove tourists somewhere on the West Coast of the United States. Apparently, in this role, she worked out the rest of the resource, and then went for recycling. Unlike the XM-147 Super Duck, not a single XM-158 sample has been preserved.

In the fifties, GMC made two attempts to create an amphibious conveyor to replace the obsolete DUKW, and none of them were successful. The XM-158 Drake project stopped due to the excessive complexity of the design and the inappropriateness of its improvement. However, the US Army was not left without amphibians. In parallel with GMC, new companies developed new models, and their projects turned out to be more successful.

Information