Project Goodyear Inflatoplane. Rubber and Nylon: Inflatable Airplanes

The main idea of the Inflatoplane project was to use a glider made from a special soft material. It was proposed to fill it with atmospheric air under pressure, which was to ensure the required rigidity of the structure. With the soft elements of the airframe it was proposed to combine various rigid units, such as the engine and the cabin.

It should be noted that the new project did not appear from scratch. Back in the early thirties, Goodyear engineer Taylor McDaniel proposed the concept of an inflatable rubber airframe. The necessary studies were carried out, and even a prototype rose into the air. However, it did not go further, and for more than twenty years the concept was forgotten. The next project of an inflatable aircraft was developed only in the mid-fifties.

In the first half of the fifties, against the background of the development of the armed forces, there was a need to create fundamentally new means of salvation, suitable for use in different fields. That is what made the designers return to the already forgotten idea of an inflatable aircraft. At the same time, it is not completely clear who exactly was the initiator of the launch of the new project. According to one source, Goodyear launched a new project as an initiative. According to others, the development began on the order of the Office of Naval Research, US Department of Defense.

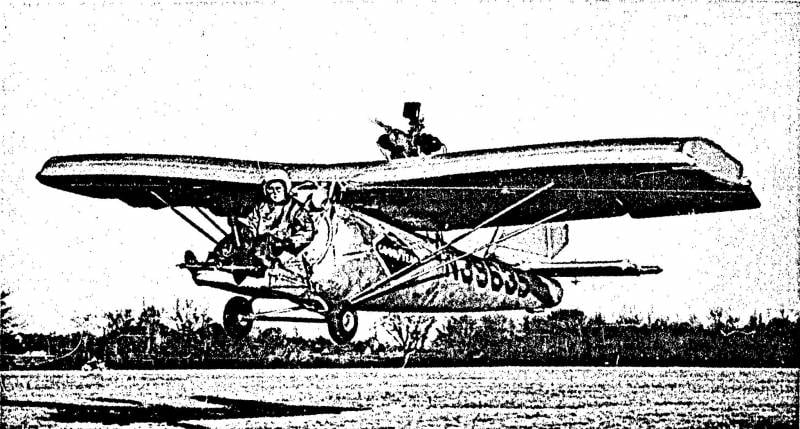

Preparing for the flight. Photo Airwar.ru

Perhaps Inflatoplane really was an initiative development, but the military soon became interested in them, as a result of which further work was carried out with their participation. The army wanted to get a light and compact aircraft, suitable for use as a means of rescue. A car with the ability to transport several people had to be transported in a container of no more than 1,25 cubic meters and prepared for flight in the shortest possible time. The required box with the plane could be transported by all available means of transport and parachute parachute landing.

In 1955-56, the aircraft manufacturer Goodyear Aircraft Company launched the development of a new project and carried out the bulk of the design work. The future inflatable aircraft received the appropriate name - Inflatoplane. Subsequently, for various versions of the project, and even for specific types of equipment, one or another additional designations or indices were used.

***

The development of the basic project, on the basis of which then a whole family of aircraft with different equipment and capabilities was created, took only 12 weeks - about 3 months. After that, it was possible to build and put to trial the first prototypes of new technology. The tests were carried out both by the manufacturer, and with the direct participation of representatives of the army and fleet.

The pump gives the aircraft a proper look. Photo Airwar.ru

Designers Goodyear Aircraft Company had to solve several basic problems. Home was related to the architecture of an inflatable glider. This product should have been easy to fold for transportation, but at the same time quickly transferred to a working state and have a high rigidity. To solve this problem, experts turned to the ideas of T. McDaniel, but implemented them using modern technologies and materials. The basis of the design of the aircraft formed a promising composite material called Airmat.

The Ayrmet material was a composite of several layers of nylon fabric, some of which were impregnated with neoprene. This combination of components allowed us to obtain the required tensile strength. From the new material it was proposed to sew and glue the shells of different shapes, which were airframe aggregates. Inside such shells, additional nylon mesh partitions were provided that served as frames. Also, the most loaded parts of the airframe should be reinforced with metal cables embedded in the structure of the base material.

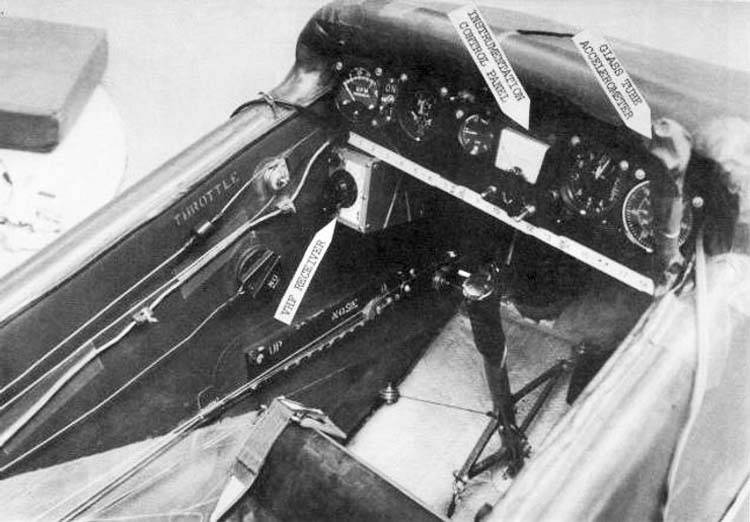

The cabin of the single-seat Inflatoplane. Photo Airwar.ru

The airframe of the inflatable aircraft was mainly composed of a soft composite, but it also had hard metal parts. So, part of the cabin walls and some elements of its floor were made of metal profiles. The rest of the sides and the nose cone were soft and could inflate. Behind the cockpit was provided a seat for the wing, behind which the tail boom began. All these elements also consisted of inflatable shells. At the same time, a light engine mount with an engine and fuel tank was placed on the center section. The motorama did not connect with the metal parts of the cabin, but the fuselage still showed the required rigidity.

The aircraft received a fully inflatable straight wing with aluminum tips. Mechanization included a pair of inflatable aileron. Despite the soft wing design, cable control wiring was placed in its internal cavity. The wing of an unusual design was connected to the fuselage with soft textile struts. Cables were also provided to connect it with the motor. The inflatable tail included a stabilizer and a keel with a small sweep of the leading edges. Both elements of plumage were equipped with rudders with cable wiring.

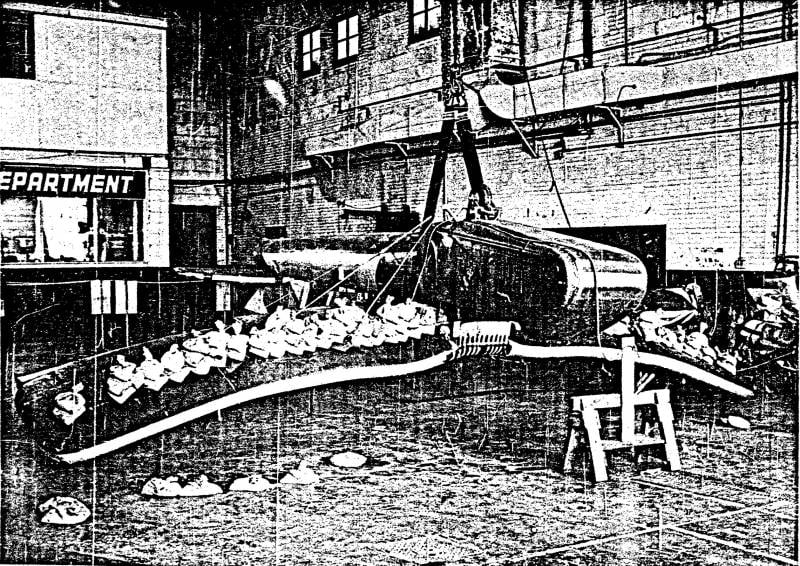

The use of a special composite material with special inner inserts led to the expected results. With an internal pressure of 170 kPa (1,7 atm), the glider had the required rigidity and could fly in any acceptable mode. The required pressure could be obtained using hand pumps or using any suitable compressor. For transportation, the plane could be “blown off” and folded into a compact container. The volume of the latter was slightly less than the amount specified by the customer.

Initially, the project Inflatoplane used a two-stroke gasoline engine of the company Nelson power of all 40 hp. The engine was equipped with a two-bladed propeller of constant pitch and was lifted above the center section with the help of a light engine. The plane was able to equip the fuel tank capacity of 76 l, with which you can stay in the air for more than 6 hours. In the future, the power plant improved. 40-strong engine "Nelson" replaced the engine power 45 hp Later, the product used McCulloch 4318 60 horsepower, which led to an increase in carrying capacity and flight characteristics.

Engineers from Goodyear Aircraft Company have worked through several cab options, which have different features. It was proposed to build single and double planes. The cabin could be fully open, or have a visor or a full lantern. At the same time, the cabin interior equipment differed slightly. All the proposed options had a pilot seat with the necessary set of equipment. The aircraft had the necessary controls and dashboard with indicators. It also provided for the use of a radio station.

To the hard part of the fuselage bottom fastened lightweight tricycle landing gear. Different prototypes used different chassis designs. Devices with a nose wheel or a tail crutch were used. In all cases, small-diameter wheels were used without any shock absorbers. The impact cancellation occurred only due to the elasticity of the legs and the airframe.

***

At the very beginning of 1956, the first prototype of the Goodyear Inflatoplane aircraft was manufactured. This prototype received its own designation GA-33. The first checks were planned to be carried out using a single-seater with a fully open cockpit. He had to show his main characteristics, as well as confirm or deny the correctness of the applied design solutions. Tests started with tests on the ground. To carry them out, the airframe was mounted on a car using a set of racks and carried along the runway in this form. After confirming the expected characteristics of the aircraft allowed to fly.

The first flight took place on February 13 at the airport Wingfoot Lake (pieces of Ohio) and, in general, passed without any complaints. Inflatable glider elements coped with the load and ensured a stable flight. At the same time, the existing wing structure was imperfect and gave increased risks. In this regard, the designers had to develop a new version of the internal structure of the plane. Other elements of the airframe showed themselves well.

Soon a second prototype, called GA-447, was submitted for testing. First of all, it was different from its predecessor, an improved wing. In addition, he received a fully enclosed lightweight lantern, which improved the working conditions of the pilot. GA-447 continued testing and allowed to establish all the main characteristics of the new technology. Also, the second plane was used in experiments with the chassis. It tested new versions of the three-wheeled chassis, the design with a single wheel under the bottom, as well as floats for landing on the water.

The GA-33 and GA-447 aircraft were in fact technology demonstrators and did not fully meet the requirements of the military. However, after their testing and confirmation of the potential of the proposed design, the development of special aircraft for the army began. The customer was immediately offered two aircraft with a maximum degree of unification and some differences in design and capabilities.

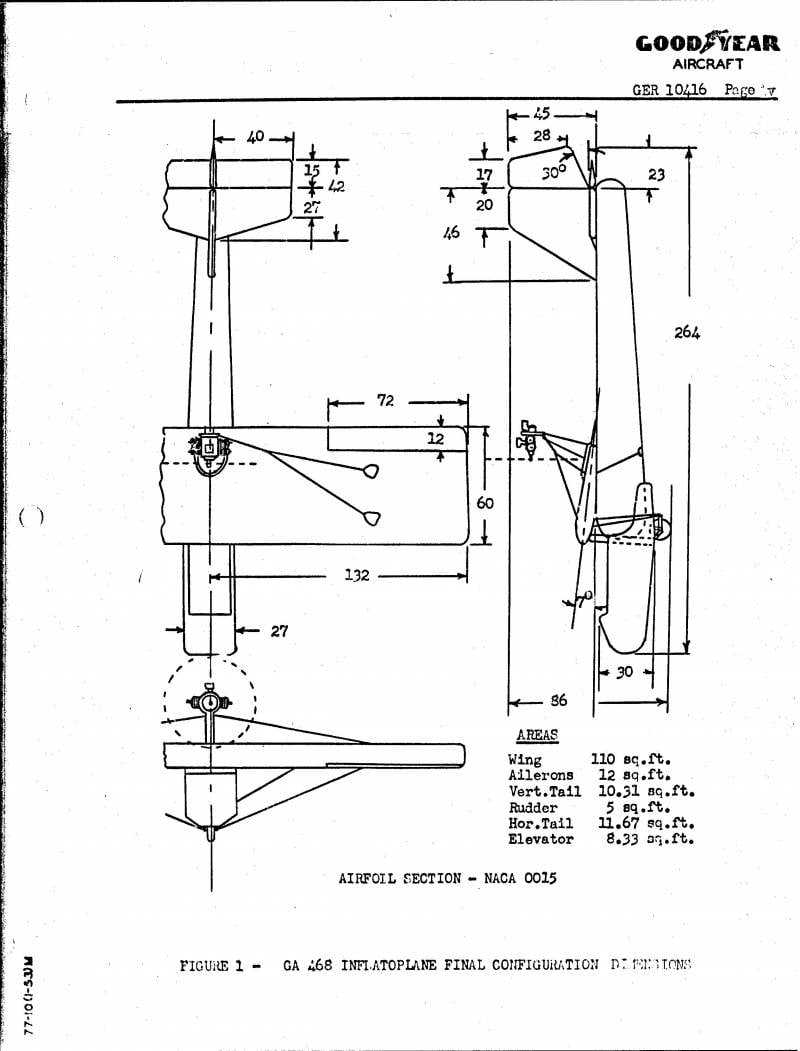

The GA-468 product was a direct development of prototype aircraft. It was a single-seater with a closed cabin and a 40-strong two-stroke engine. In working position, it had a wingspan of 6,7 m with a length of 5,97 m. Take-off weight - 340 kg, of which 110 kg accounted for the payload, including the pilot. The maximum flight speed reached 115 km / h, cruising - 96 km / h. Range defined in 630 km. For the takeoff, the car only needed 75 m. The take-off distance with an exit to the height of 15 m is less than 175 m.

Also created a two-seater aircraft called GA-466. It had a wingspan of 8,5 m and was shorter than a single-seater analogue on 50 mm. Mass remained the same. Above the inflatable fuselage fit engine McCulloch 4318. Recycling the airframe allowed to take on board two people - the pilot and passenger. Part of the flight characteristics remained at the level of a single sample, but the range was reduced to 440 km.

GA-468 and GA-466 were developed in accordance with the wishes of the customer and using the necessary components of standard types. During the tests, which took place under the supervision of the military, the new technique wore official army designations. Goodyear Inflatoplane with single cabin called XAO-3-GI, double-seat machine - XAO-2-GI. In the future, after being put into service, the letters “X” and “GI” should have disappeared from such designations. Serial technology planned to designate as AO-2 and AO-3.

One of the built AO-3. Photo of Wikimedia Commons

In general, the customer favored the new technology. Despite the specific technical appearance, promising aircraft met all the basic requirements and could well be used in the army. However, the military showed reasonable precaution. The rubber-fabric glider did not look too durable and reliable, although the tests directly indicated the opposite.

Flight tests promising technology continued until the end of the fifties, but then were suspended indefinitely. The reason for the work stoppage was a disaster during the next flight. Because of problems with the control system, a crash occurred, in which Army test pilot Lieutenant Wallace was killed.

As it later turned out during the investigation, during the flight one of the control cables flew off the pulley and stuck the control stick of the aircraft. Due to the inclination of the handle, the machine began to increase the roll. On the ultimate mode, one of the planes bent in the direction of the fuselage and hit the propeller. The rubber-fabric shell was torn, and the aluminum ending flew to the pilot and hit him on the head. The pilot was still able to get out of the cockpit and fall out of the plane through the nose. However, he failed to open the parachute and escape.

By the time of the disaster, Goodyear Aircraft had time to build the 12 inflatable aircraft of the Inflatoplane series. This number included a pair of early prototypes and a dozen machines such as the GA-468 and GA-466. The crash on trials forced the Pentagon to suspend the test program until all the causes were rectified and the deficiencies were eliminated. As it became clear later, the temporary stop was the beginning of the end of the whole project.

Over the next few years, aircraft manufacturers from Goodyear tried to improve existing designs and offered updated versions of inflatable airplanes. The built cars were refined and tested several times. However, now they had no real prospects. Narrow specialization, a certain complexity of production and the tragedy of the trials affected the future of the project. Already in the early sixties, the US military stopped to consider the Inflatoplane series of equipment as promising and suitable for practical implementation.

In 1962, the military declined further support for the project, and the developer was finally forced to stop it. According to some reports, a few years later, Goodyear tried to revive the project. The reason for this was the beginning of the Vietnam War, during which special rescue aircraft could be useful to the air forces. However, the military did not want to return to the old project.

Over the course of the work, a dozen of the Goodyear Inflatoplane family have been built. After the project was closed, the manufacturer sent some of this equipment for storage, and donated several cars to museums. Now in different aviation US museums exhibit three similar samples of different models. For example, the Museum of the Smithsonian Institution owns a single-seat GA-468 aircraft.

***

The first experiments of T. McDaniel, conducted in the early thirties, showed the fundamental possibility of creating lightweight inflatable aircraft. However, at that time such an idea did not interest anyone and did not advance further than the first studies. They returned to it only in the fifties, and this time the project turned out to be more successful.

Aircraft manufacturers from Goodyear Aircraft Company, using modern materials and technologies, were able to create a fairly successful sample of aircraft with an unusual appearance. The new planes of the Inflatoplane series had a chance to enter service with the US Army and find application in various fields. However, numerous doubts and a catastrophe during the trials adversely affected the real fate of the project. Inflatable airplanes stayed in stories American aircraft industry, but did not hit the troops.

Based on:

https://airandspace.si.edu/

http://stonehengeairmuseum.org/

http://airwar.ru/

https://popmech.ru/

http://dtic.mil/

https://strangernn.livejournal.com/

One-Place Inflatoplane GA-468 Contract No. XXUMX (2368) Final Engineering Report on Modifications and Testing Goodyear Aircraft Corporation. Akron. Ohio. September 00.

Information