I-5 truck and its modifications

New modernization

The I-4 truck was a technical and technological upgrade of the previous I-3, which was technically and technologically deeply modernized. Its main difference was the engine, clutch and gearbox of the German company Mercedes. Engine power 54 HP (according to other sources, 70 hp) provided an increase in driving performance, and also increased the payload to 4 t. However, the USSR bought the whole 137 powertrain from Germany, and therefore the production of I-4 did not last too long.

Understanding the current situation, at the beginning of 1929, the YAGAZ design bureau engaged in reworking an existing project. The leadership of the automotive industry has found an opportunity to acquire new power units of foreign manufacture, this time it was a question of the components of American manufacture. Designers had to take into account the peculiarities of the new engines and transmissions, and with their application create an updated version of the I-4 truck.

During the tests and operation of the I-4 machines, we managed to collect a considerable amount of data on the operation of certain components, as well as on the convenience of drivers. All this information should also be considered when creating a new modification of the truck. Finally, the new engine of increased power gave more opportunities of a technical and operational nature. It soon became clear that the upgraded version of the machine is very different from the basic one, and therefore it can be considered a new model.

The new project was designated as I-5. In this index, the letter indicated the city of origin of the car, and the figure indicated not only the project number, but also the capacity of the car. The new power unit allowed the upgraded truck to be converted into a five-ton class. Thus, the Yaroslavl designers developed and brought to the series the first domestic "five-ton".

Improved design

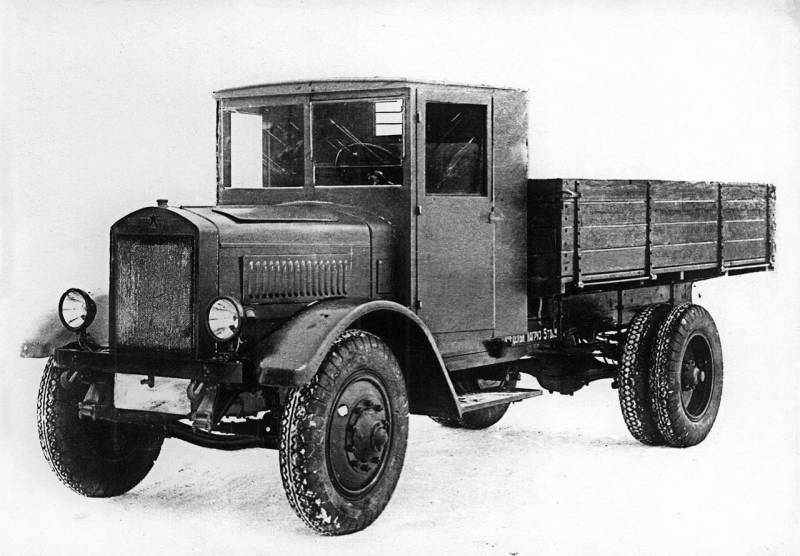

In general, I-5 was considered as a deep modernization of the existing I-4. The project provided for the preservation of the main features of the architecture and a number of units, but proposed a number of technical and technological innovations. As before, the car was built on the basis of a rigid metal frame with a front engine and received a two-axle rear-wheel drive chassis. The truck was supposed to be equipped with a flatbed, but later other options for a complete set were created.

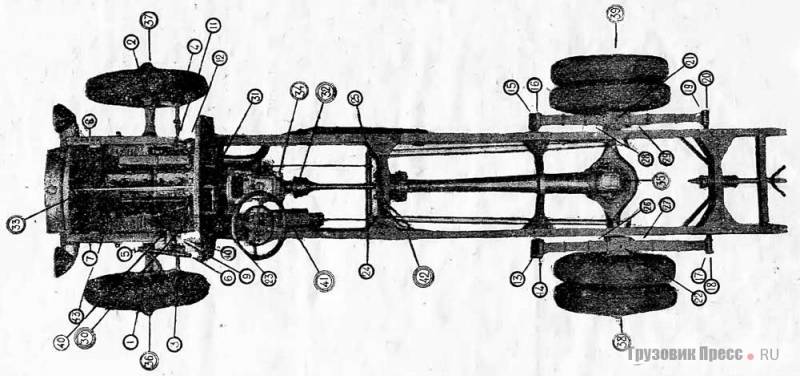

The frame for I-5 was borrowed from the previous project. It was a riveted assembly, assembled from standard steel channels No.16 (spars) and No.10 (crossmembers). On such a frame, the engine under the hood, the driver's cabin and the cargo platform were installed in series. In fact, the frame for the I-5 differed from the existing only by the location of the fixtures for the power unit and transmission parts.

Especially for the new car in the United States purchased gasoline engines Hercules-YXC-B with 93,5 horsepower. The straight six-cylinder engine was supplied complete with a carburetor, magneto and other devices. The engine was supplemented with a brass radiator of a cellular structure developed by YAGAZ. A multi-plate clutch from Brown-Lipe was connected to the engine. Also purchased gearbox "554" of the same manufacturer. The power unit was installed on the front of the frame, slightly “falling” down between the side members. As a result, the engine fan did not completely shut off the radiator, and the cooling of the power plant deteriorated.

From the gearbox, the torque entered the horizontal drive shaft open placement. It was connected with an inclined shaft, placed in a casing of conical shape. The latter connected the frame of the car with the crankcase of the main gear and ensured the transfer of loads. The main transmission remained the same, developed for the I-3 truck.

The design of the undercarriage was strengthened, but retained common features. Used front axle with driven single-pitch wheels. The rear axle with the main transmission was completed with gable wheels. Both axes were fixed on semi-elliptical springs, with the rear one having a greater number of sheets.

The American power unit almost did not differ from the German in its size and contours. Thanks to this, I-5 retained the existing hood. The functions of its front wall served as a radiator. There were blinds in the side walls and a pair of longitudinal flaps in the lid. In front of the radiator installed electric headlights. For access to the engine, the bonnet was mounted on hinges.

I-5 became the first truck from YAGAZ to receive a closed cabin. The frame of the cabin was made of wood and sheathed with metal sheets (front and side) and planks (rear wall). Roof made plywood. The windshield, as before, could rise. More than half of the board was given under the opening door. Glazing doors had a window regulator and locking nuts. Under the driver's seat saved tank on 120 liters of fuel.

In the I-5 project, an improved steering mechanism was used, but its characteristics left much to be desired. Due to the heavy loads on the steered wheels, I had to use a steering wheel with a diameter of 522 mm. However, in this case, management was not easy. The cab floor had a standard set of three pedals. Under the driver's right hand was the gear lever. Designers retained the previously used brake system with a vacuum booster.

Behind the cab was installed standard body with folding sides, developed in the course of previous projects. This time the truck could take on a payload of up to 5 t. However, in some conditions, for example, when working off-road, the load of the car should be reduced.

In the shop of the Yaroslavl State Automobile Plant. Photo by Gruzovikpress.ru

The new power unit almost did not affect the size and weight of the truck. The overall dimensions and performance of the chassis remained at the level of the base I-4. Curb weight increased to 4,75 t with the possibility of transporting 5 tons of cargo. The maximum speed on the highway was to grow to 50-53 km / h. Fuel consumption was 43 liters per 100 km - the tank should have been enough for about 300 km.

Start of production

The first engines "Hercules" and other American-made products arrived in Yaroslavl by the middle of the 1929 year. By this time, YAGAZ had almost completed the production of I-4 trucks, and the receipt of new components made it possible to build experienced I-5 trucks. The machine, built with a wide use of waste components, quickly passed all the necessary tests and received a recommendation to be put into series.

Until the end of 1929, YAGAZ managed to build a 132 new car, probably including experienced ones. The following year, the release of technology has grown to 754 units. 1931 had a peak production year - 1004 machines. In the future, the rate of release was reduced. In 1932 and 1933, 346 and 47 trucks were assembled. Only one, the last, I-5 passed in 1934-m - just before the start of the production of the next sample.

Already in 1929, the production of a specialized I-6 chassis for the construction of buses began. It was an I-5 chassis with a larger base. This parameter has grown by 580 mm - to 4,78 m. I-6 type machines were handed over by auto repair shops in different cities, where single-volume bus bodies were built according to the standard design. The design of such a unit was determined by the manufacturer’s capabilities, and both metal and wood were used. The floor of the passenger cabin was at the level of the cargo platform, because of which stairs were provided under both doors of the bus.

Model bus on chassis I-6. Photo Denisovets.ru

It should be noted that it was I-6 buses that caused the reduction in I-5 truck production. In 1931, the delivery of imported power units was completed. As a result, it was decided to create a new truck with domestic production units. At the same time, they decided to leave part of the imported motors for buses. Up to and including 1932, YAGAZ built the 364 chassis I-6, most of which became public transport.

In 1931, YAGAZ received an order for the production of I-5 trucks for Mongolia. In accordance with its conditions, the cars were to receive onboard platforms of a new design. For greater convenience, they are set lower than in the basic configuration. In this case, the platform had to organize wheel niches. Loading was carried out through the folding tailgate. Also included were some changes in the cabin finish. This version of the truck was nicknamed "Mongol". Several dozen cars were produced, and everyone went to a friendly country.

With the help of various organizations, both with the participation of YAGAZ and without it, various machines for various purposes were created on the basis of the five-ton I-5. Tanks, vans, etc. were installed on the place of the standard cargo platform. The I-5 and I-6 chassis were used in the construction of fire engines, and the longer chassis proved itself better in this role.

During the operation of the equipment, various problems were identified. For example, one of the main reasons for criticism was excessively “heavy” steering. They got rid of this problem in 1932, when serial trucks began to equip the new steering system like the Ross 302. Later on, such devices were sent by auto repair shops for installation on previously released I-5 and I-6.

American-made engines were supplied to the USSR in large quantities, but it was not possible to adjust the supply of spare parts. For this reason, the operators had to cope on their own, get or independently make the necessary parts. With serious breakdowns, the Hercules-YXC-B engine had to be replaced with a domestic one. Most often available were AMO-3 or ZIS-5. They had less power, but without serious difficulties mounted on the frame and mated with the transmission. However, after such a revision the truck could not show the calculated characteristics.

Experimental samples

In 1932, an experienced truck was built with an updated frame. It still consisted of channels of different sizes, but welding was used to connect them. The new frame had advantages over the serial, but YAGAZ at that time could not master its production, and therefore was forced to continue production of riveted units.

The development of domestic trucks at the time was hampered by the lack of its own high-powered engines. Designers of various organizations offered new engines, and one of such projects was implemented jointly with YAGAZ. The emergence of a new diesel engine led to the construction of prototypes called Kocju I-5.

In 1933, the Special Design Bureau with the economic management of the OGPU under the leadership of N.R. Briling has developed a promising automotive diesel engine with the working title "Kocu" ("Koba-Dzhugashvili"). Specialists from the YAGAZ and the Scientific Autotractor Institute attracted the further development of the project. In November of the same year, YAGAZ assembled a pair of Koju experienced engines, which were soon installed on I-5 production trucks. On November 15, several cars of different types with differing engines, including the Kodju I-5 car, entered the Yaroslavl – Moscow – Yaroslavl mileage. Two experienced diesel trucks coped with the task.

In June of the following year, another run took place, this time I-5 crossed the path from Moscow to Tiflis and back. On the road length 5000 km took more than a month. During this time, I-5 trucks have shown their prospects in the context of the use of diesel engines. Their chassis best suited for such engines.

After the run, NATI started fine-tuning the Koujou product and creating new modifications of it, which took several years. In 1938, the bench engine showed 110 horsepower. at 1800 rpm One of the new YAGAZ trucks equipped with such a motor showed a fuel consumption of about 25 liters per 100 km, while developing a speed of up to 70 km / h. The new engine was of great interest to car manufacturers, and in 1939 preparations began for its production at the Ufa Engine Plant. However, the plant was soon transferred to the People's Commissariat aviation industry, and the Koju project was closed due to the impossibility of starting production.

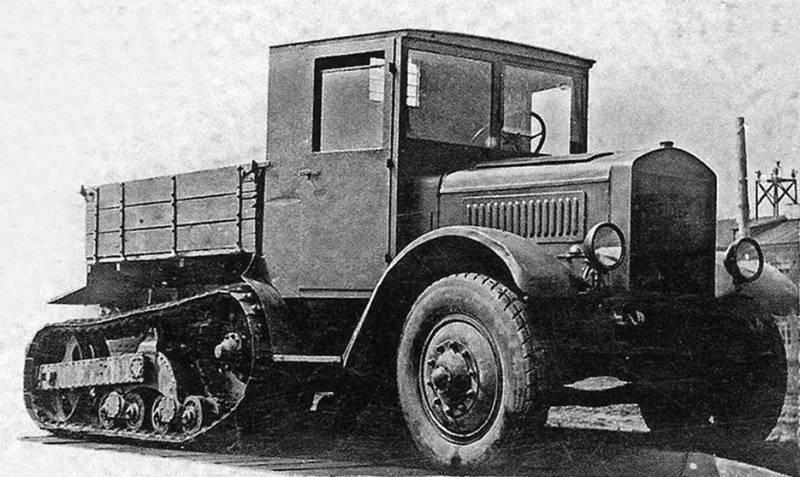

Since 1931, YAGAZ has been working on the creation of a semi-tracked artillery tractor based on a I-5 truck. However, the plant was busy with other projects, and as a result, a similar development from the Leningrad enterprise Red Putilovets was developed. At the beginning of 1934, an experienced tractor YASP was built in Leningrad. In fact, it was a truck without a regular rear axle, instead of which a crawler truck was mounted.

Fantasy on the further development of the platform. Perhaps in the future such samples could appear. Photo Denisovets.ru

During the tests, the only experienced YASP showed high technical characteristics and confirmed the possibility of using such equipment in the army. At the same time, the quality of manufacturing tracked carts left much to be desired. Tests are constantly interrupted for repairs, which was the reason for criticism. After completion of inspections at the landfill, the project was stopped and no refining was carried out.

Reserve for the future

From 1929 to 1932, the Yaroslavl State Automobile Plant No.3 built a little less than 2300 five-ton I-5 trucks. Apparently, this number also included the I-6 chassis for buses and fire engines. Just a few months after the start of production, I-5 became the most popular Yaroslavl truck at that time. He managed to keep this "honorary title" for a long time.

According to various sources, the mass operation of I-5 trucks and I-6 trucks continued until the end of the thirties. Separate samples remained in the ranks until the beginning of the forties, but by this time they had become obsolete morally and physically, as well as giving way to a newer technique. Unfortunately, as the resource worked out, all the trucks and other vehicles were written off and disposed of. Not a single machine of the I-5 family has been preserved.

It should be noted that within the framework of the I-5 project, the successful shape of a heavy-duty truck capable of carrying loads of several tons was finally formed. In the future, YAGAZ KB used this look when creating a whole range of new cars. The last trucks, which can be considered direct "descendants" of I-5, went to the series in the early forties - through 10-12 years after the appearance of their "progenitor". Thus, I-5, like its predecessor I-4, could rightfully be considered a landmark development, which had a serious impact on the development of domestic trucks.

Based on:

http://denisovets.ru/

http://gruzovikpress.ru/

http://autowp.ru/

http://autohis.ru/

http://opoccuu.com/

Shugurov L.M., Shirshov V.P. Cars Country of the Soviets. - M .: DOSAAF, 1983.

Dashko D. Soviet trucks 1919-1945. - M .: Automobile archival fund, 2014.

Information