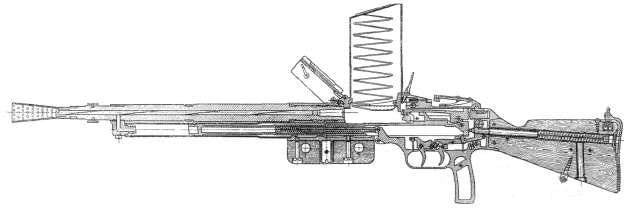

Manual machine gun Mle1924 / 29 "Chatellerault"

The 7,5x58 cartridge without protruding rim and having a bottle sleeve with a light taper was similar to a German-made 7,92x57 “Mauser”. Manufacture Nationale d arrmes de Chatellerault (MAC) created for this cartridge the Chatellerault machine gun. The first version appeared in 1921 year. Its design traced the influence of BAR M1918 (USA) and Berthier’s experimental system. In 1924, this machine gun under the designation M1-1924 was adopted. However, machine guns did not work satisfactorily, because of the overheating of the light barrel (made using cheap steel) were often torn when fired. The power of the cartridge seemed unnecessary, and the long sleeve caused frequent malfunctions in the operation of the extraction mechanism and the power supply system; therefore, they soon decided to shorten the sleeve. The Mle1924C cartridge, also known as 7,5x54 "French service" or Mle1929, appeared. The weight of an ordinary bullet was 9,07 grams. Also took an armor-piercing bullet mass 9,3 gram with a steel core.

The machine gun, which was combined from the constructive solutions of other samples, showed satisfactory performance and was adopted under the designation Mle1924 / 29.

Automation worked by the gas engine. The gas piston had a long stroke. The barrel and the receiver were threaded and fixed with a flag contactor. A conical perforated flame arrester was mounted on the barrel. Behind the barrel was closed with a butt pad with a butt, which was fixed by the closer - the use of flag closers is a characteristic feature for this machine gun. After 150 shots, barrel cooling was required. Locking the barrel asymmetrical (like most machine guns of the time), was made by tilting the bolt upward with a pair of hinged earrings on both sides connecting it and the bolt carrier.

The shot was made from the rear whisper. Drummer, embedded in the rack bolt carrier, when she came to the front extreme position, broke the cartridge primer. The ejection of the spent cartridge was made through the right window of the receiver. The shutter in the rear extreme position hit the rod of the buffer spring of the inertial mechanical retarder of the rate of fire installed in the back of the barrel, while the bolt frame hit the upper arm of the retarder lever and the plunger. The pusher released the lever, which, when turned, captured the combat platoon of the bolt carrier. The pusher retreated backwards and squeezed its spring, then came back under its pressure, turned the lever and released the bolt action platoon, which again went forward.

The trigger mechanism was installed in the trigger frame with a pistol grip and included two triggers: for continuous firing, the rear, for a single - front. The protrusion of the two shoulders trigger lever served as a sear. When pressing the front hook, he turned the front end of the trigger lever, and the sear released the bolt carrier from the platoon. During further rotation of the hook, the connecting rod fell off the lever, the trigger lever moved to its original position, the bolt carrier was picked up by the sear. By pressing the rear trigger, the front end of the trigger lever was lifted, leaving it in that position until the hook is released. Using a pair of triggers was a simple, but not very convenient solution; in addition, the front descent from the pistol grip was at a distance and was inconvenient for applying the index finger. Dissociation of the front trigger with a stall led to a double and solid shot instead of a single shot. Manual flag guard installed behind the rear trigger. The top position of the flag is “fire”, the bottom one is “fuse” (both triggers were blocked).

Food - from the direct box store placed on top. With the store removed, the vent and receiver windows of the receiver were closed with a hinged lid.

The sector view with a diopter has a whole notch from 200 to 2000 meters with 200 steps. Diopter in the stowed position evolved. The loading handle was on the right and remained motionless when firing. The wooden butt was equipped with a folding shoulder pouch and a rear folding support, although there was little use of the latter. An integral bipod was installed on the trunk, which, in the divorced position, was fixed with the help of spacers. A machine gun with a light barrel was placed on the machine only for anti-aircraft fire. The design consisted of 193 parts, including 39 screws and 19 springs.

Serial production of the machine gun started in 1930 year at the MAC plants (Chatellerault) and the Manufacture d'Armes de St Etienne (MAS, Saint-Etienne). It lasted until 1940. Marking, embossed on the receiver on the right side, included the inscription "Mle 1924 / 29" and the serial number. Although in the troops of Mle 1924 / 29 recognized successful, having entered on branch on one machine gun, purchases went slowly. New weapons were reluctant to release money, since the Maginot Line was eating up a significant portion of the budget. But she also demanded a machine gun: the casemates of the Maginot Line had a single machine gun and from 2 to 15 casemate installations with armored doors, caponiers of “ensembles” - according to 4 machine guns.

In this regard, a “serf” modification of the Mle 1931 machine gun (Mle 1931 C1) was developed, which has an elongated barrel, a 150 round round magazine magazine, mounted on the left side. The rate of fire was increased to 600 rounds per minute, leaving only a trigger that allows continuous fire, excluded the fuse. The cartridge case reflected down. The emphasis-handle was mounted on a modified butt plate. A forced cooling system injected a portion of water into the chamber after removing the sleeve - however, the value of such a system remained unclear. The same modification of a machine gun weighing 16,3 kg (there was no forced cooling system) was used as tank machine gun. There was also a motorcycle installation of a Chatellerault machine gun. Developed and aviation machine gun with magazine or belt power.

Manual machine gun "Shaterlro", which worked perfectly in different climatic conditions, served for a long time. Part of the machine guns were supplied abroad - for example, they were used by Chinese troops. In 1940, a large number of them went to the German army, which used them under the designation 24 / 29 (f). During the German occupation, their production continued. A lot of "Chatellerault" was used in the organization of antiamphibious defense of the English Channel and the islands.

The French army used Chatellerault machine guns until the beginning of the 50s. A large number of them remained in service in the former French colonies.

Order unloading machine gun

Pull down the fuse box, disconnect the magazine, take the loading handle back. Inspect the chamber through the shop window. Put the safety catch in the upper position, press one of the triggers while holding the charging handle, return the charging handle forwards. Close the receiver window cover. Pull the safety catch down and pull the store latch back until it locks.

Procedure for incomplete disassembly of the Chatellerault machine gun

1. Unload a machine gun.

2. Unscrew the backstop plug, separate the backplate and the butt.

3. Separate the trigger frame.

4. Remove the bolt carrier and bolt from the receiver.

5. Push out the axis of the earrings and separate the bolt from the slide frame.

6. Remove the return spring from the bolt carrier.

7. Turn up (in the “D” position) flag of the piston guide tube contactor and separate the tube to the right.

8. Turn down the stem lock box and unscrew the barrel.

To build a machine gun, all actions were performed in reverse order.

Specifications machine gun Mle1924 / 29:

Caliber - 7,5 mm;

Patron - 7,5x54 "French service";

Weight weapons - 8,93 kg (with bipod, no store);

The mass of the store - 0,28 kg (empty) / 1,0 kg (curb);

Weight of bipods - 0,66 kg;

The length of the weapon is 1082 mm;

Barrel length - 500 mm;

The grooves - 4 left;

Barrel weight - 2,315 kg (with front sight and gas chamber);

Initial bullet speed - 823 m / s;

Target firing range - 1200 m;

Effective range - 800 m;

Sighting line length - 645 mm;

The power supply system is a box-like magazine with a capacity of 25 cartridges;

The rate of fire - 450-500 shots per minute;

Combat rate - 52 / 100 shots per minute;

The height of the line of fire - 320 mm.

Information