Reactive mine clearance Conger device (UK)

At the time of the war, the army of Great Britain did not have highly effective means of mine clearance, capable at one moment to make wide and long passes in dangerous areas. The development of such devices started only in the early forties, and soon led to the desired results. In the future, some of the proposed ideas were developed and, ultimately, led to the emergence of modern concepts and techniques.

The first step to the emergence of the system "Conger device" can be considered a product Snake ("Snake"). At the end of 1941, the Canadian military offered to assemble standard elongated charges (so-called Bangalore torpedoes) into long, hard chains. With the help of a tank, such an assembly should have been pushed onto a minefield. The simultaneous detonation of several elongated charges was to destroy explosive devices in a strip several meters wide, sufficient for the passage of people and equipment. Soon the "Snake" was tested and was adopted by the entire British community.

The use of the Bangalore torpedo assembly made it possible to destroy mines, but was associated with certain difficulties. In particular, the Snake product was not sufficiently rigid and could break down when it was removed to a minefield — to avoid damage, it was necessary to limit the length of the assembly. In addition, the towing tank risked becoming an easy target for enemy artillery. For a more efficient solution of the demining tasks, a new technique was required.

In 1942-43, the Royal Engineers Corps carried out research work, during which he was able to find new effective ways to simultaneously clear large areas of terrain. One of the methods was supposed to speed up the process of mine clearance, and moreover, it was deprived of the main drawbacks of the Snake. It should be noted that in the future this concept, having undergone certain changes, found application in foreign armies.

As conceived by the designers, it was not a rigid chain of metal torpedoes, but a flexible hose with an explosive that had to be laid on the minefield. For its rapid deployment in the field should use the simplest solid-fuel rocket. The requirements for the latter were reduced due to the fact that the sleeve had to remain empty at start-up and laying: it was proposed to fill it with explosive after it was placed on the minefield.

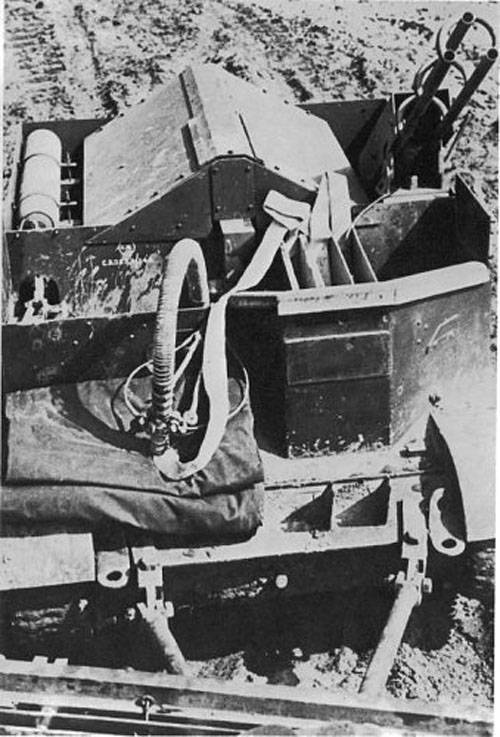

Installing "Eel" on the battlefield. Photo Mapleleafup.net

Soon, the composition of the equipment needed to solve the task in the proposed manner was determined, and in addition, the overall appearance of the future engineering machine was formed. Also, the new project was chosen a name - Conger device ("Device" Eel "). Indeed, one of the main elements of the new demining plant was similar to the corresponding fish.

The question of the mobility of the installation was solved in the most interesting way. It was proposed to build on the basis of the serial Universal Carrier armored personnel carrier. In this case, only the armored body and chassis were borrowed from the finished sample. From the machine should remove the power plant, the place of which should have been taken by new devices. Thus, the revised BTR received new functions, but at the same time needed a separate tug. In this capacity, first of all, Churchill tanks, actively used by the engineer troops, were considered.

The housing of the Universal Carrier, in general, remained unchanged. The characteristic frontal part with a polygonal lower unit and broken upper lines was preserved. The hull sides formed large nadgusenichnye niche, increasing the useful protected volume. At the same time in the center of the body, on the site of the former engine compartment, a new armor cover appeared. It consisted of a rectangular box and a gable roof, the planes of which could be raised to access internal devices. The thickness of the armor of such a hull reached 10 mm, which was supposed to provide protection from bullets and shrapnel.

"Eel" did not have its own engine and was not equipped with a transmission, but it retained the chassis of the base sample. Used so-called. Horstman's suspension, with the help of which three support rollers were mounted on each side. In front of the hull, the guide wheels were preserved, while the rear stern lost their main function. Installation of mine clearance was to move around the battlefield using a triangular towing device on the front of the hull.

View of the installation from the roof of the towing tank. You can consider all the main units. Photo Mapleleafup.net

The layout of the case has changed in a noticeable way. The frontal part of the body, which previously housed the driver and machine-gunner's workplaces, was now intended for the storage of boxes with flexible sleeves. In the new casing in the middle of the case they placed an explosive tank and some auxiliary equipment. To his left was the launcher for the towing rocket. At the starboard - a small compartment for gas cylinders.

For laying an elongated charge on a minefield, it was proposed to use a very simple towing rocket. In this capacity, one of the solid-fuel rocket engines was used in the Conger project. Product caliber 5 inches (127 mm) had a simple cylindrical body, completely filled with solid fuel. On the case there were devices for towing cable pulling the sleeve.

For the rocket was offered a simple launcher. Its main element was a guide assembled from three longitudinal pipes connected by several open rings. The rear part of the guide was covered with a metal casing, designed to divert hot gases from other devices. The launcher was mounted on an axis and equipped with devices for vertical pickup. With their help, the calculation could change the firing range and, accordingly, the laying of the sleeve.

During the flight, the rocket had to pull a flexible hose out of the corresponding box. As the body of the extended charge, the designers used a textile hose with a diameter of 2 inch (about 50 mm) and a length of 330 yards (300 m). One end of the sleeve was made closed, and the open second had to be connected to the onboard systems of the installation. A sleeve several tens of meters in length was compactly placed in a metal box. The latter, when launched, was located directly in front of the rocket launcher, which ensured its smooth exit and expansion in the air.

The shock wave for mines in the ground was supposed to create a liquid explosive mixture 822C, made on the basis of nitroglycerin. 2500 pounds (1135 kg) of this mixture were transported in a tank placed inside the central armor casing. An uncomplicated system with valves and a hose was used to feed the mixture into the extended charge hose. From the tank, the mixture was supplied using the pressure of compressed gas coming from individual cylinders. It was proposed to explode the charge using a standard remote-controlled fuse.

According to some information, the means for working with an explosive mixture were not created from scratch. The tank, compressed gas cylinder, pipelines and other elements of special equipment were borrowed from the Wasp serial self-propelled flamethrower, which was also built on the basis of the Universal Carrier BTR. However, borrowed devices had to be significantly rebuilt.

The towed demining installation of the Conger device needed to be calculated from three or four people who were required to perform all the necessary operations during combat operations. However, she did not have any weapons for self-defense, and the calculation had to rely only on personal weapon and accompanying armored vehicles.

The widespread use of ready-made components led to the fact that in size and weight the “Eel” differed little from the base armored personnel carrier. The length still reached 3,65 m, the width was slightly more than 2 m. Due to the presence of a non-retractable launcher, the height exceeded the original 1,6 m. The combat weight with a full load of the 822C mixture slightly exceeded 3,5 t. The product could not move on its own, but was towed by a tank Accelerated to 25-30 km / h. This speed was quite enough for movement over rough terrain and exit to the firing position.

The Conger device differed from other means of mine clearance of its time by the original algorithm of operation. The towed system was to be displayed on the edge of the minefield, having a rocket on the launcher and a full supply of explosive mixture in the tank. One end of the flexible hose connected to the rocket, the second - with the mixture supply system.

At the command of the operator, the rocket had to descend from the guide and set off along a ballistic trajectory, pulling the sleeve behind it. After the flight, he just pulled along the future passage. Then the calculation was to open the necessary valves and pump the explosives inside the sleeve. Then it was necessary to install a fuse on an extended charge and retire to a safe place. Undermining 2500 pounds of the mixture led to mechanical destruction or detonation of explosive devices in a strip up to 330 yards and a width of up to 3-4 m, which was enough for safe passage of people and equipment.

The new model of engineering technology passed the necessary tests, during which both its advantages and disadvantages were revealed. The main advantage of the rocket launcher was the possibility of simultaneously making a passage hundreds of yards long. Other demining systems of that time differed much more modest characteristics. Operation Conger device was not too complicated, although some of its features could lead to difficulties.

However, there were disadvantages. First of all, the reason for the significant risks was the presence of a large tank with an explosive, covered only with anti-bullet armor. Moreover, the 822C blend was based on nitroglycerin, known for its shock sensitivity. As a result, any projectile could instantly destroy the installation of mine clearance, and the main contribution to its death would have been made by its own "ammunition". An ambiguous feature of the new model should be considered the lack of its own power plant: it needed a separate tank-tower, which affected the work of the entire engineering unit.

Nevertheless, the command of the Royal Engineers Corps considered the installation "Eel" suitable for adoption. No later than the turn of 1943-44, the serial construction of such systems began. As far as is known, towed demining installations, like other engineering equipment, were not built with the largest series. According to various sources, no more than a few dozen Conger devices were built.

A sample from the museum is equipped with all the necessary devices. Photo by Massimo Foti / Picssr.com

In June, British troops landed in Normandy on 1944, and together with other engineering equipment, they used the Eel mine clearance unit. In this case, as far as is known, this technique was not used very often. Only one case of using a flexible extended charge on a real battlefield is reliably known. 25 September 1944 of the year, during battles in France, the 79-I armored division, armed with special models of equipment, used its rocket launchers to make passes. After the blast of an extended charge, cars and people passed through the battlefield. On other cases, the combat use of such technology is not available.

Also known about the presence of installations Conger in the Netherlands, but in this case we are talking about a terrible tragedy. October 20 1944 of the year, during the battles in the area of Iysendiyke, the sappers filled the Eel tank with an explosive mixture. Due to a number of factors, the mixture was transported by trucks in ordinary metal cans. Someone's negligence or coincidence led to the fact that the sensitive nitroglycerin exploded. The first explosion provoked the detonation of all the surrounding tanks with the mixture. Apparently, at least 2500 pounds of 822C blend exploded. The blast completely destroyed the demining plant itself and the two trucks standing nearby. Also, various damage, including the most serious, received four engineering tanks, which were nearby. Killed 41 people, 16 missing. Several dozen soldiers and officers were injured. Several buildings, next to which was a technique, were destroyed.

There is every reason to believe that it was this incident that determined the further fate of the entire project. The towed installation of mine clearance coped with its tasks, but at the same time it represented an extreme danger both for its own crew and for everyone around it. If an accidental explosion during maintenance resulted in casualties, what could have happened on the battlefield? As a result, by the end of the fall of 1944, the Conger device products gradually came out of active use.

Until the end of the war, this technique stood idle, and then it was disposed of as useless. Only one Eel has survived. A unique sample of engineering technology is now stored in the military museum in Overloon (the Netherlands). Together with this installation, a mockup of the rocket and a set of sleeves from an elongated charge are demonstrated.

The product Conger device used the new principles of work and became the world's first representative of the so-called class. reactive mine clearance systems. It had rather high characteristics, however it was excessively dangerous even for its own calculation, which determined its further fate. However, the ideas, first implemented in the British project, had a great future. Subsequently, in the UK and several other countries, new versions of demining installations were created, using flexible elongated charge with a rocket.

On the materials of the sites:

http://saper.isnet.ru/

https://fas.org/

http://mapleleafup.net/

https://secretprojects.co.uk/

http://bbc.co.uk/

Information