Metamaterials, graphene, bionics. New materials and technologies are striving to fight

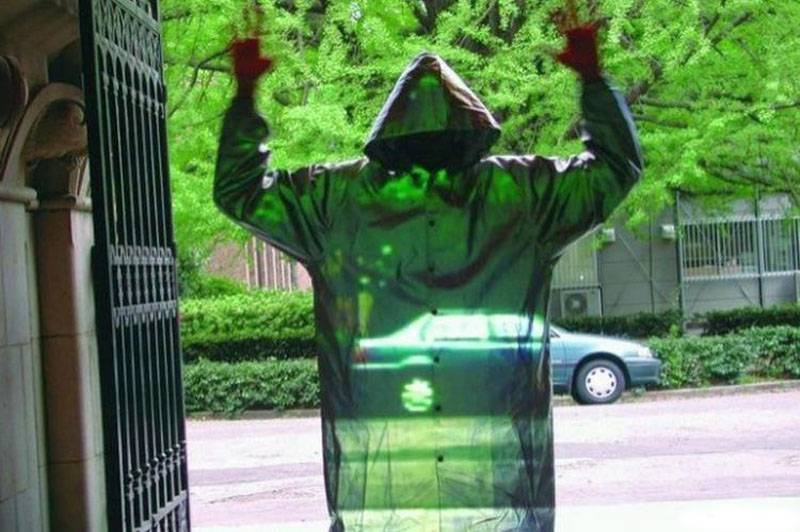

The possibility of creating material with a negative angle of refraction was predicted by Soviet physicist Viktor Veselago back in 1967, but only now the first samples of real structures with such properties appear. Due to the negative angle of refraction, the rays of light bend around the object, making it invisible. Thus, the observer notices only what is happening behind his back on a “wonderful” raincoat.

In order to gain an advantage on the battlefield, modern armed forces are turning to such potential breakthrough opportunities as, for example, advanced wearable protection and vehicle armor, nanotechnology. innovative camouflage, new electrical devices, superkkumulyatory and "intelligent" or reactive protection of platforms and personnel. Military systems are becoming more complex, new advanced multifunctional materials and dual-purpose materials are being developed and manufactured, and the miniaturization of heavy-duty and flexible electronics is proceeding in leaps and bounds.

Examples include promising self-healing materials, advanced composite materials, functional ceramics, electrochromic materials, “cyber-protective” materials that respond to electromagnetic interference. They are expected to become the basis of breakthrough technologies that will irrevocably change the battlefield and the nature of future military operations.

Advanced materials of the next generation, for example, metamaterials, graphene and carbon nanotubes, are of great interest and attract solid investments because they have properties and functionalities that are not found in nature and are suitable for defense industries and tasks performed in extreme or hostile space. Nanotechnology uses nanometer-scale materials (10-9) so that it was possible to modify the structures at the atomic and molecular levels and create various tissues, devices or systems. These materials are a very promising direction and in the future will be able to have a serious impact on combat effectiveness.

Metamaterials

Before proceeding, we will define metamaterials. A metamaterial is a composite material whose properties are caused not so much by the properties of its constituent elements as by the artificially created periodic structure. They are artificially formed and specially structured environments that have electromagnetic or acoustic properties that are technologically difficult to reach or that are not found in nature.

Kymeta Corporation, a subsidiary of the patent company Intellectual Ventures, entered the defense market with an antenna from the mTenna metamater in 2016. According to Nathan Kundz, the company's director, the portable antenna in the form of a transceiver antenna weighs about 18 kg and consumes 10 watts. Equipment for metamaterial antennas is about the size of a book or a netbook, has no moving parts, and is made in the same way as LCD monitors or smartphone screens using thin-film transistor technology.

Metamaterials consist of subwave microstructures, that is, structures whose dimensions are smaller than the wavelength of radiation that they must control. These structures can be made of non-magnetic materials, such as copper, and etched on a fiberglass substrate printed circuit board.

Metamaterials can be created to interact with the main components of electromagnetic waves - dielectric constant and magnetic permeability. According to Pablos Holman, the inventor of Intellectual Ventures, antennas created by metamaterials technology can eventually push out cell towers, landline lines, and coaxial and fiber-optic cables.

Traditional antennas are tuned to intercept the controlled energy of a specific wavelength, which excites electrons in the antenna, generating electrical currents. In turn, these coded signals can be interpreted as information.

Modern antenna systems are bulky, since different frequencies require their own type of antenna. In the case of antennas from metamaterials, the surface layer allows you to change the direction of the bending of electromagnetic waves. Metamaterials show both negative dielectric and negative magnetic permeability and, therefore, have a negative refractive index. This negative refractive index, not found in any natural material, determines the change in electromagnetic waves when crossing the border of two different media. Thus, the metamaterial antenna receiver can be electronically tuned to receive various frequencies, and therefore developers can achieve broadband and reduce the size of antenna elements.

Metamaterials inside such antennas are assembled into a flat matrix of tightly packed individual cells (very similar to the placement of TV screen pixels) with another flat matrix of parallel rectangular waveguides, as well as a module that controls the radiation of the wave through software and allows the antenna to determine the direction of radiation.

Holman explained that the easiest way to understand the virtues of metamaterial antennas is to take a closer look at the physical apertures of the antenna and the reliability of Internet connections on ships, aircraft, drones and other moving systems.

“Each new communications satellite being put into orbit these days,” continued Holman, “has more bandwidth than the constellation of satellites several years ago. We have a huge potential for wireless communication in these satellite networks, but the only way to connect with them is to take a satellite dish that is large, heavy, and expensive to install and maintain. Having an antenna based on metamaterials, we can make a flat panel that can control the beam and aim directly at the satellite.

“Fifty percent of the time a physically controlled antenna is not satellite-oriented and you are actually offline,” Holman said. “Therefore, a metamaterial antenna can be especially useful in a maritime context, because the dish is physically controlled to be sent to the satellite, since the ship often changes course and is constantly swinging on the waves.”

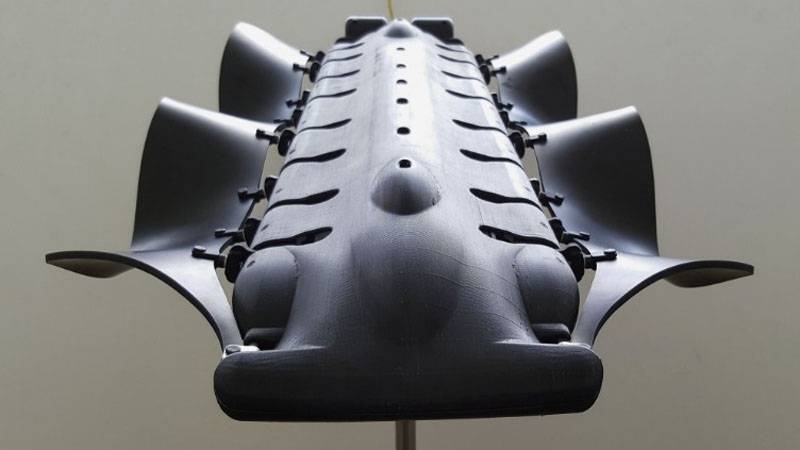

Currently, there is a rapid development of technology unmanned platforms with bionic properties. For example, APA Razor (scale model in the photo below) and APA Velox (above) imitate the natural movements of animals or plants, which is great for reconnaissance and secretive tasks

Bionics

The development of new materials is also in the direction of creating flexible multifunctional systems with complex shapes. Here an important role is played by applied science on the application in technical devices and systems of principles of organization, properties, functions and structures of living nature. Bionics (in the western biomimetic literature) helps a person to create original technical systems and technological processes based on ideas found and borrowed from nature.

The research center for the problems of the US Navy underwater warfare has a mine-finding autonomous underwater vehicle (APA), which uses bionic principles. imitating movements of marine life. Apparatus Razor length 3 meter can carry two people. Its electronics coordinate the work of four flapping wings and two propellers in the stern. Fly movements imitate the movements of some animals, such as birds and turtles. This allows the APA to hover, perform precise maneuvering at low speeds and develop high speeds. Such maneuverability also allows the Razor to easily change its position in space and float around objects to obtain their three-dimensional image.

The US Navy Research and Development Administration is funding the development by Pliant Energy Systems of a prototype of the optional Velox autonomous underwater vehicle, which instead of propellers used a system of multistable, non-linear, sheet-like bendable paper fins that generate repetitive wave-like movements similar to skate movements. The device converts the movements of electroactive, wavy, flexible polymer fins with a planar hyperbolic geometry into translational motion, freely moving under water, in the waves of the surf, in the sand, above sea and land vegetation, on slippery rocks or ice.

According to the representative of the company Pliant Energy Systems, the wave-like forward movement does not allow you to become entangled in dense vegetation, since there are no rotating parts, and minimal damage is caused to plants and sedimentary rocks. A low noise unit powered by a lithium-ion battery can improve its buoyancy to keep its position under the ice, while it can be controlled remotely. Its main tasks include: communication, including GPS, WiFi, radio or satellite channels; intelligence and information gathering; search and rescue; and scan and identify min.

The development of nanotechnologies and microstructures is also very important in bionic technologies, the inspiration for which is taken from nature in order to imitate physical processes or optimize the production of new materials.

Transparent armor is used not only for the ballistic protection of people and vehicles. It is also ideal for protecting electronics, high-energy lasers, hardened imaging systems, face protection masks, UAVs, and other mass-sensitive platforms.

The research laboratory of the US Navy develops a transparent polymer protection that has a layered microstructure similar to the chitinous shell of crustaceans, but is made of plastic materials. This allows the material to remain conformal in a wide range of temperatures and loads, which allows it to be used to protect personnel, stationary platforms, vehicles and aircraft.

According to Yasa Sanghera, the head of optical materials and devices in this laboratory, the protection available on the market is usually made of three types of plastic and cannot withstand one hundred percent of the 9-mm bullet fired from 1-2 meters and flying 335 speed m / s.

The transparent armor of this lab can reduce weight by 40% while maintaining ballistic integrity and absorbs more energy from the bullet by 68%. Sanghera explained that armor could be excellent for several military applications, for example, mine-protected vehicles, floating armored vehicles, supply vehicles and aircraft cockpit windows.

According to Sanghera, his laboratory intends, on the basis of existing developments, to create lightweight conformal transparent armor with multi-impact characteristics and achieve a weight reduction of more than 20%, which will provide protection against rifle bullets of caliber 7,62x39 mm.

The Advanced Defense Research Directorate DARPA is also developing Spinel (Spinel) transparent armor with unique properties. This material has excellent multi-impact characteristics, high hardness and erosion resistance, increased resistance to external factors; it transmits a wider range of medium-wave infrared radiation, which increases the capabilities of night-vision devices (the ability to see objects behind glass surfaces), and also weighs half the size of traditional bullet-proof glass.

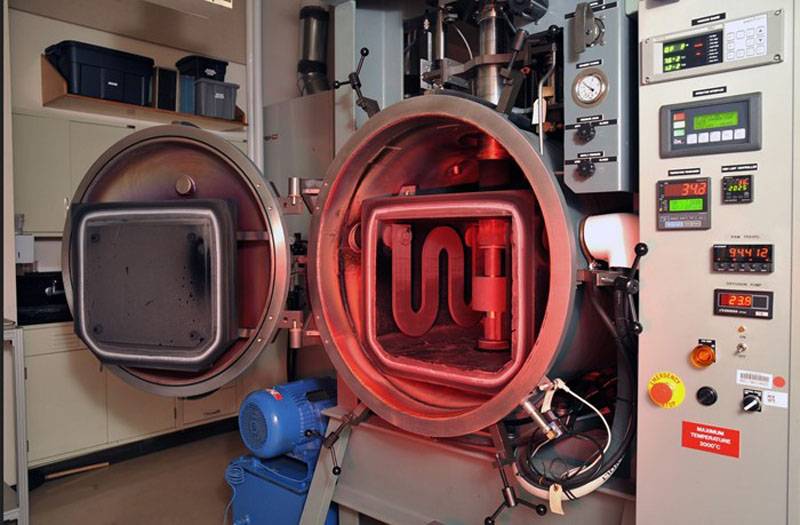

This activity is part of the DARPA program called Atoms to Product (А2Р), within the framework of which “the technologies and processes necessary for assembling nanometer particles (sizes close to the size of atoms) into systems, components or materials of at least millimeter scale are developed.”

According to the head of the A2P program at DARPA, John Mayne, over the past eight years, the Office has achieved a reduction in the thickness of the base transparent armor from about 18 cm to 6 cm while maintaining its strength characteristics. It consists of many different layers, “not all of them are ceramic and not all of them are plastic or glass”, which are glued to the substrate to prevent cracking. "You should think of it as a protective system, not as a monolithic piece of material."

Glasses from "Spinel" were made for installation on prototypes of FMTV trucks (Family of Medium Tactical Vehicles - a family of military vehicles of medium payload) of the American army for evaluation by the Research and Development Armored Center.

As part of the A2P program, DARPA has issued Voxtel, working with the Oregon Institute of Nanomaterials and Microelectronics, a contract worth 5,9 million dollars to research production processes that are scalable from nano to macro. This bionic project involves the development of a synthetic adhesive that replicates the capabilities of a gecko lizard.

“On the soles of a gecko, there is something like small hairs ... about 100 microns in length, which branch out wildly. At the end of each small branch there is a tiny nanoplate about the size of 10 nanometers. When in contact with a wall or ceiling, these plates allow the gecko to stick to the wall or ceiling. "

Maine said that manufacturers could never repeat these possibilities, because they could not create branching nanostructures.

“Voxtel develops production technologies that make it possible to replicate a similar biological structure and capture these biological qualities. It uses carbon nanotubes in a really new way, it allows you to create complex 3D structures and use them in very original ways, not necessarily as structures, but in other, more inventive ways. "

Voxtel wants to develop advanced additive manufacturing techniques that will produce "materials that are themselves assembled into functionally complete blocks, then assembled into complex heterogeneous systems." These techniques will be based on imitation of simple genetic codes found in nature and general chemical reactions that allow molecules to self-assemble from the atomic level into large structures capable of supplying themselves with energy.

“We want to develop advanced repeatable adhesive material. “We would like to get a material with the properties of epoxy glue, but without its disposability and surface contamination,” said Maine. “The beauty of the material a la gecko is that it leaves no residue and acts instantly.”

Other rapidly developing advanced materials include ultra-thin materials, for example, graphene and carbon nanotubes, which have such structural, thermal, electrical, and optical properties that will fundamentally change the modern combat space.

Transparent windows from "Spinel" were made for prototypes of US Army FMTV trucks

Graphene

Although carbon nanotubes have a good potential for use in electronic and camouflage systems, as well as in the biomedical field, graphene is “more interesting because it offers more possibilities, at least on paper,” said Giuseppe Duquino, a representative of the European Defense Agency ( EoA).

Graphene is an ultra-thin nanomaterial formed by a layer of carbon atoms one atom thick. Lightweight and durable graphene has a record high thermal conductivity and electrical conductivity. The defense industry is carefully studying the possibility of using graphene in those applications that require its strength, flexibility and resistance to high temperatures, for example, in combat missions carried out under extreme conditions.

Dakvino said that graphene is “at least in theory the material of the future. The reason why so many interesting debates are taking place now is that after so many years of research in the civilian sector it has become obvious that it will really change the battle scenarios. ”

“I will list only some of the possibilities: flexible electronics, power systems, ballistic protection, camouflage, filters / membranes, materials with high heat dissipation, biomedical applications and sensors. These are, in fact, the main technological directions. ”

In December, the EAU began a year-long study of possible promising areas for the use of graphene in the military sphere and its impact on the European defense industry. These works were led by the Spanish Foundation for Technical Research and Innovation, with which the University of Cartagena and the British company Cambridge Nanomaterial Technology Ltd. collaborate. In May 2017, a seminar of researchers and experts on graphene was held, where a roadmap for its use in the defense field was defined.

According to the EAW, “among materials that can fundamentally change defense capabilities in the next decade, graphene is on the priority list. Lightweight, flexible, stronger than steel in 200 times, and its electrical conductivity is just incredible (better than silicon), as well as its thermal conductivity. "

The EAA also noted that graphene has remarkable properties in the “signature management” area. That is, it can be used for the production of “radar absorbing coatings, which will turn military vehicles, aircraft, submarines and surface ships into almost undetectable objects. All this makes graphene an extremely attractive material not only for civilian industry, but also for military applications, land, air and sea. ”

The process of sintering by the method of hot pressing (above) The research laboratory of the US Navy uses to create transparent ceramics "Spinel". The powder is compressed under vacuum to obtain transparency. The resulting material (below) can be polished and polished like precious stones.

To this end, the US Army is studying the use of graphene for vehicles and protective garments. According to engineer Emil Sandoz-Rosado from the US Army Laboratory for Military Research (ARL), this material has excellent mechanical properties; one atomic layer of graphene is 10 times harder and more than 30 times stronger than the same layer of commercial ballistic fiber. “The ceiling for graphene is very high. This is one of the reasons why several working groups in the ARL have shown interest in it, because its structural characteristics in terms of booking are very promising.

However, there are quite big difficulties. One of them is material scaling; the army needs protective materials that could close Tanks, cars and soldiers. “We need a lot more. In general, we are talking about the million or more layers that we currently need. ”

Sandoz-Rosado said that graphene can be obtained in one or two ways, either through the exfoliation process, when high-quality graphite is divided into separate atomic layers, or by growing a single atomic layer of graphene on copper foil. This process is well mastered by laboratories engaged in the production of high-quality graphene. “It’s not quite perfect, but pretty close to it. However, today it’s time to talk about more than one atomic layer, we need a full-fledged product. ” As a result, a program has recently been launched to develop continuous graphene production processes on an industrial scale.

“Whether it’s carbon nanotubes or graphene, you have to take into account the specific requirements that need to be met,” Dakvino cautioned, noting that the official description of the characteristics of new advanced materials, the standardization of precise processes for creating new materials, the reproducibility of these processes, the manufacturability of the entire chain (from basic research to the production of demonstration and prototypes) need careful study and justification when it comes to use in military breakthrough platforms such materials as graphene and carbon nanotubes.

“This is not only research, because in the end, you need to be sure that certain material has received an official description and after that you need to be sure that it can be carried out according to a certain process. This is not so easy, since the manufacturing process may vary, the quality of the product produced may vary depending on the process, so the process must be repeated several times. "

According to Sandoz-Rosado, ARL worked with the producers of graphene to assess the quality class of the product and the possibility of its scaling. Although it is not yet clear whether the continuous processes that are at the beginning of their formation have a business model, the corresponding capacities and whether they can provide the necessary quality.

Dakvino noted that progress in computer modeling and quantum computing could accelerate research and development, as well as the development of advanced materials production methods in the near future. “With computer-aided design and materials modeling, many things can be modeled: material characteristics and even production processes can be modeled. You can even create a virtual reality, where in fact you can consider the various stages of creating material. "

Dakvino also said that advanced computer modeling and virtual reality techniques provide an advantage by creating "an integrated system in which you can simulate specific material and see if this material can be applied in certain conditions." Here, quantum computations could radically change the situation here.

"In the future, I see even more interest in new ways of production, new ways of creating new materials and new production processes through computer modeling, since enormous computing power can potentially be obtained only with the use of quantum computers."

According to Dakvino, some applications of graphene are more technologically developed, and others less. For example, ceramic composite materials with a matrix base can be improved by integrating graphene plates that enhance the material and increase its mechanical resistance, while at the same time reducing its mass. “If we are talking, for example, about composites,” continued Dakvino, “or in the most general terms about materials enhanced by the addition of graphene, then we will get real materials and real processes of their mass production if not tomorrow, but maybe in the next five years old".

“This is why graphene is so interesting for ballistic protection systems. Not because graphene can be used as armor. But if you use graphene in your armor as a reinforcing material, then it can become even stronger than Kevlar. ”

Priority areas, for example, autonomous systems and sensors, as well as high-risk military spheres, for example, underwater, space and cybernetic, are most dependent on new advanced materials and the conjugation of nano and microtechnologies with biotechnologies, stealth materials, reactive materials and energy generation and storage systems.

Metamaterials and nanotechnologies, for example, graphene and carbon nanotubes, are experiencing rapid development today. In these new technologies, the military is looking for new opportunities, exploring ways to apply them and potential barriers, because they have to balance between the needs of the modern battlefield and long-term research goals.

The future is coming to us. Apparatus Velox Company Pliant Energy Systems

On the materials of the sites:

www.nationaldefensemagazine.org

www.metamaterial.com

metamaterialscenter.com

science.howstuffworks.com

www.kymetacorp.com

www.pliantenergy.com

www.darpa.mil

voxtel-inc.com

www.eda.europa.eu

www.facebook.com

habr.com

www.wikipedia.org

en.wikipedia.org

pinterest.com

eandt.theiet.org

Information