Soviet machine gun "Maxim" in the interwar period and during the Second World War

Some changes were made to facilitate operation. The trigger mechanism was equipped with a fuse of a new design, which allowed to switch it off with one hand and press the trigger lever. A new flap butt pad box simplified maintenance of the trigger mechanism, as well as easier access to the breech breech during cleaning. Drummer and peen were made as separate parts. The shield received another attachment point in the form of a buffer-holder. The return mechanism was equipped with a spring tension indicator, which facilitates the adjustment of the main mechanisms.

TOZ led the production of machine guns model 1910 / 30 to 1940 year. Marking, which included the stamp of the plant, the year of manufacture, as well as the serial number (two-letter or five-digit numerical designation of the series and number) was placed on the spring return box and the box cover.

Part of the modernization was the adoption of the universal wheeled-tripod machine of Vladimirov in 1931, which allows fast transition from ground to anti-aircraft fire. For this purpose, the tripod with the swivel was removed from the wheel course, the telescopic legs were spread out, and it was placed in an upright position. On the body of the machine gun, a remote ring sight of a model 1929 of the year was set up, allowing fire on aircraft flying at altitudes up to 1,5 thousand meters at speeds of 320 km / h. The antiaircraft sight of the 1936 model of the year had five rings in the front viewfinder and ensured the destruction of targets at ranges up to 1,6 thousand m, altitudes up to 1,4 thousand m having speeds up to 500 km / h. The sight of the 1938 model of the year was a simplified version of the 1936 model of the year. In the 41 and 43 years, two more samples of anti-aircraft sights were adopted. The sight of the 1941 model of the year was unified with the DShK machine gun sight and differed only in the installation tools. The sight of the 1943 model of the year belonged to the ring angles. It was faster and easier to work with him.

For anti-aircraft fire, in addition to the universal machine, they used Kondakov’s folding tripod of the 1928 model of the year. This tripod had telescopic legs, an angle of elevation to 88 degrees, and circular shelling. Shooting was carried out from a knee or from a standing position. Lead - free, fixation in two planes carried clamps. The height of the line of fire - 1,5 m. A small mass of the tripod (16 kg) allowed one-man service and transportation along with the Sokolov machine in a bag. Tripod was used for anti-aircraft fire from DT and DP machine guns. The anti-aircraft tripod and universal machine greatly expanded the combat capabilities of the Maxim machine gun, but did not solve the “universalization” task, moreover, the Vladimirov machine, due to the large weight of the 39 kg, could not force out the Sokolov machine, was produced in smaller quantities and in parallel with him.

Non-ferrous metals to reduce the cost of production replaced steel - for example, the receiver, previously made of brass, began to make steel milling. The need for link metal tape was realized. This tape was used in the aircraft machine gun PV-1, created on the basis of "Maxim". The fact that this tape was not accepted for ground machine guns is explained by the absence of stamping and pressing equipment that allows its mass production.

To use small shooting ranges and save rifle cartridges, the 5,6-millimeter Blum training machine gun was used for ring ignition cartridge - the machine gun with the disk magazine was fixed on the usual Maxim, the trigger was connected to the machine gun (the Blum machine gun was also used to train the calculations of the DP).

Armed with the naval fleet the fleet was left with Maxumba's pedestal installations. In addition, he remained in service with armored cars and armored trains. One or two “Maxims” armed most DOS in fortified areas in the Far East, the Karelian Isthmus, and the Western border. Their installations, for better cooling allowing continuous fire, had steam and water inlet.

By the end of the 30-ies, "Maxim" has ceased to meet modern requirements, especially given the officially adopted concept of deep combat, which demanded high maneuverability from the infantry. The weight of the Maxim machine gun on the Sokolov machine (without water) was 66 kilogram, on a tripod of the 1928 model of the year - 35 kilograms, the weight of the box with cartridge belt was from 9,88 to 10,3 kilograms, and the boxes with spare parts and accessories - 7,2 kilograms. The machine gun on a campaign was served by a team consisting of 5-7 people. (machine gun compartment), during the battle of 2-3 people. At the same time, the most physically fit soldiers were selected for machine gun calculations. The equipment of the canvas ribbon was inconvenient even with the use of a typewriter equipment. In addition, for reliable operation of the machine gun required high accuracy during assembly and debugging, that is, the presence of highly skilled assemblers.

In total, as of 22 June 1941, the troops had 76,3 thousand machine guns. Considerable material losses in the first months of the war (during the second half of 41, 54,7 thousand machine guns were lost) forced to reduce their number in units. In July, a machine gun platoon was withdrawn from the state of a rifle company.

Tula weapons the factory remained the main producer. The release of "Maxims" after the termination of the DS series in the first three months of the Second World War increased by 7,5 times. From October 4 to October 12, the engineers of Yu.A. Kozarin and I.E. Lubenets under the leadership of the chief designer A.A. Tronenkov undertook yet another modernization of the Maxim machine gun at TOZ in accordance with the new combat and production and economic requirements. To fill the casing with ice and snow, it was equipped with a wide neck with a lid on the loop - this decision was borrowed from the Finnish “Maxim” model of 41, which the Soviet Army had to face in 1932. Due to the lack of optical machine gun sights, their use was refused. The main machine-gun sight was simplified - the scale for light bullets was removed, the mobile pillar was abandoned, the notch for a heavy bullet was increased to 1940 thousand meters. During the fighting, it became clear that the similarity of the bullet trajectories at a range of up to 2,7 meters allows the use of a single tie without a significant deterioration in accuracy, and firing is usually direct fire.

For the use of metal and canvas tapes Lubents was designed milled receiver, for ease of discharge it was equipped with a special switch of the upper fingers. The metal tape could be removed only after pressing the switch. In the new receiver, thanks to the lengthening of the upper knee of the slide lever, as well as an increase in the angle between the lower and upper slides of the slide, it was possible to achieve greater sliding of the slide to the right and reliable gripping of the cartridge in the tape. But, in order to maximize the use of significant stocks of canvas ribbons, receivers only for them continued to be produced throughout the war. To reduce the cost and speed up their production, changes were also made to the production technology. At the same time in October, the People's Commissariat of Armaments and the GAU approved design changes, but the improvement continued. Receivers with 1942, began to produce from silumin in injection molding or steel broach. In the meantime, the evacuation of production facilities from Tula began, and in November-December 41, the Tula Arms Plant produced 224 machine guns DS and 71 "Maxim", and during the siege they assembled 423 machine guns. The situation was critical.

At other enterprises also began production of "Maxim". For these purposes, the facilities of the State Union Motorcycle Plant were used in Izhevsk, which was named Plant No. 524. Production began in January 1942, and for the first month they collected 300 machine guns. However, the first 120 machine guns, which in the documents were called “object number XXUMX-503”, passed only in March. Issue by September reached 504 thousand per month. In total, during the war years, the plant produced 2,5 thousand "Maksimov" (according to other sources - 77 thousand).

In the formulation of new production faced with many difficulties. The most complex machine-gun unit was the locks, so the Tula locks were installed on the first Izhevsk “Maxims”, which turned out to be among the evacuated components (for some time they were supplied from Zlatoust). The manufacture of canvas machine-gun belts in Izhevsk was also not immediately successful.

It should be noted that the relatively complex and already outdated Maxim system was nevertheless designed for a well-established and well-functioning production, in connection with which machine guns made not for TOZ could not immediately achieve the required degree of reliability, especially if we take into account the characteristic for military time, lack of time, personnel and materials. With allowable 0,15% delays, the conditions for acceptance of Maxim machine guns collected at the newly delivered production at the site gave more than 1%. In conditions when the troops were in dire need of a weapon, they had to put up with it. The manufacturing technology of the machine has also been simplified.

The production of the Maxim machine gun and machine tools for it in Zlatoust was established at the beginning of 1942 on the basis of the evacuated Podolsk mechanical and Tula machine-building factories, although it was necessary to equip the shops already during production. The engineering plant, returned to Tula in 1942, was immediately involved in production and, within two years, gave 50 thousand. Maksimov and 20 thousand machines to them.

Simplification of technology and design changes helped to quickly increase production. Already in 1942, the 55258 Maximov was released.

During the war, attempts were made to increase the combat capabilities of the Maxim machine gun. In the army, the shield was often removed from the machine gun - fast speed and disguise were the best defense. In addition to painting for camouflage on the casing wore covers. In winter, the Maxim machine gun was installed on sleds or skis, in winter battles of 41-42 - on a dragging boat, which was often fired (a dragging boat was also used in swampy areas).

In the Central Research Institute №15, an armored collapsible cap "NTP" was created, which allows to quickly organize DOS with Maxim machine guns. The thickness of the armor plates is 10-13 millimeters. Shortage of anti-aircraft specials. installations forced (as during World War I) to include in the statutes and send descriptions of handicraft installations to the troops.

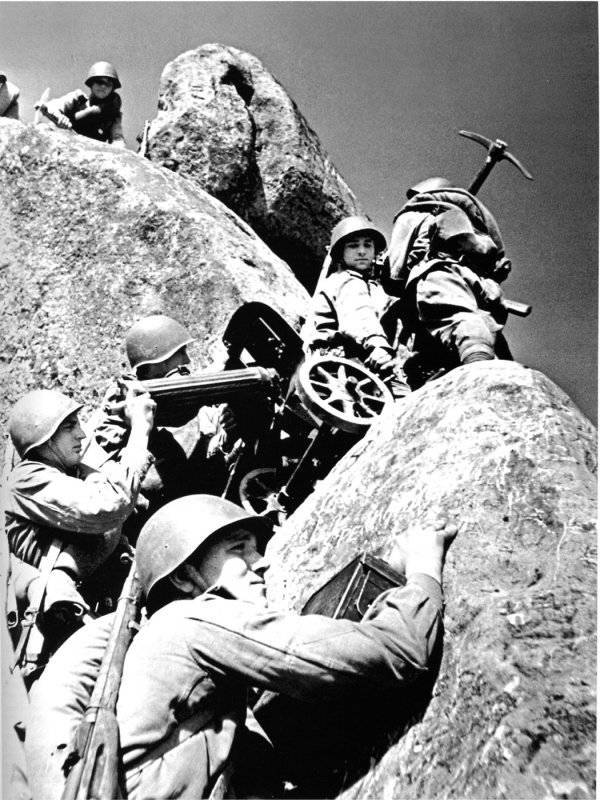

The upgraded versions could not eliminate the main drawback of the Maxim machine gun - a large mass, on average, it exceeded modern foreign models on the 20-24 kilogram. The supply of machine guns with cooling liquid also caused great difficulties. With the "Maxim" it was difficult to act in the mountains, instead of regular machines in the troops, they used hand-made tripods. However, despite the fact that the SG-43 machine gun of Goryunov was adopted, the “Maxims” were produced before the 1945 year (apparently, the latter were training) and retained the role of the main machine-gun.

With increasing speeds of air targets, the effectiveness of anti-aircraft fire of one machine gun sharply decreased. This required an increase in the number of machine guns on one installation, that is, integration. In the summer of 1928, the PKB of the Tula Arms Plant proposed to design a twin, build and quadruple anti-aircraft machine-gun installations designed for the installation of Maxim machine guns. By 1930, the designers N.F. Tokarev, A.I. Panov, S.A. Prilutsky and GG Kurenkov completed the task. The best result of the tests turned out to be a quad unit proposed by Tokarev, which already in 1931 was put into service, almost simultaneously with a large-caliber machine gun. The Tokarev anti-aircraft machine gun installation was widely used as a self-propelled, stationary, ship-mounted, installed on the roofs of buildings, in armored trains, car bodies, railway platforms.

The unit had a pedestal base, a swivel with cartridge boxes, a swinging frame with counterweights, shoulder pads and trigger pull, a zenith sight and a forced cooling system. The change in the height of the line of fire was carried out using a rack-gear lifting mechanism. Bearings were used to rotate the swivel. Four Maxim machine guns with a single cooling system, common aiming devices and descent were mounted in a row on a tubular frame. On the swivel there were boxes with ribbons with a capacity of 500 cartridges. Shoulder arches helped the gunner to direct a unit weighing more than 80 kg to the target.

Initially, an anti-aircraft machine gun was used with an anti-aircraft ring sight of the 1929 model of the year. In order to change the range settings in range, a special shaft with a handwheel was made on the frame. Later, sights of the 1936 and 1938 types were installed. For firing at ground targets was used rack mount the second left (main) machine gun. The installation had a high combat rate of fire, a quick tip and maneuverability of fire, and in many respects surpassed foreign counterparts that appeared later. The installations were armed with anti-aircraft machine-gun companies, among which were air defense troops and NKVD troops. True, mobile installations were performed on vehicles with limited maneuverability, without armor protection.

In addition, the beginning of the Second World War did not have enough ZPU. The letter from the Chief of the Main Directorate of Air Defense against 16 in July 1941 indicated a shortage of “anti-aircraft quad and large-caliber guns in anti-aircraft defense units in 3 thousand units” and asked to “adapt anti-aircraft gunfire up to 1,5 thousand units. paired DA-2 and 1,5 machineguns for thousands of PV-1 machine guns taken from aircraft. At the anti-aircraft artillery ground, a quad installation was reworked: the Maxim machine gun, the second from the left, was saved, and the other three were replaced with PV-1. However, such an alteration was very difficult for mass production, therefore N.F. Tokarev developed a simplified installation of the PV-1. In the 41 year, 626 of such installations were manufactured; they were also made in the 42 year, used for the defense of Stalingrad and Leningrad. YES-2 installed on the pivot anti-aircraft installations.

Only in February, 43, 7,62-millimeter machine-gun systems removed from the composition of the anti-aircraft divisions of the RGC and anti-aircraft regiments as obsolete. In fact, the insufficiency of 7,62 mm caliber anti-aircraft installations due to the increased survivability of the aircraft was clear even before the war. Installation "Maxim" remaining in the army continued to use.

After the war, a large number of Soviet "Maximov" came to Poland, China, the DPRK, from which later on to other countries.

Technical characteristics of the 7,62-mm Maxim machine gun of the 1910 / 30 model of the year:

Cartridge - 7, b2-mm sample 1908 of the year (7,62x54R);

The mass of the "body" machine gun - 20,3 kg (without water);

The length of the "body" of the machine gun - 1067 mm;

Barrel length - 720 mm;

Grooves - 4 right;

The length of the stroke rifling - 240 mm;

The initial speed of the light bullet - 865 m / s;

The initial speed of a heavy bullet is 800 m / s;

The longest firing range - 3900 m;

Sighting range - 2300 m;

The rate of fire - 600 shots per minute;

Combat rate - 250-300 shots per minute;

Food - canvas tape with a capacity of 250 cartridges;

Weight curb tape - 7,29 kg;

Calculation - 4-5 man (including ammunition carriers).

Technical characteristics of the Sokolov machine:

Machine weight - 43,5 kg (with shield);

The maximum length of the machine gun on the machine - 1350 mm;

Sector of fire - 70 degrees;

Elevation angle - 18 degrees;

Declination angle - 19 degrees;

The height of the line of fire - 500 mm.

Technical characteristics of the universal machine Vladimirov sample 1931 year:

Machine weight - 39 kg (with shield);

Elevation angle - 75-80 (anti-aircraft version) and 23 (ground version) degrees;

Declination angle - 38 (anti-aircraft) and 30 (ground) degrees;

The shelling sector is 360 (anti-aircraft) and 170 (ground) degrees;

The height of the line of fire about - 1400 (anti-aircraft) and 400 (ground) mm.

Information