Easel machine gun "Shvartsloze" - a machine gun of Austria-Hungary in the First World War

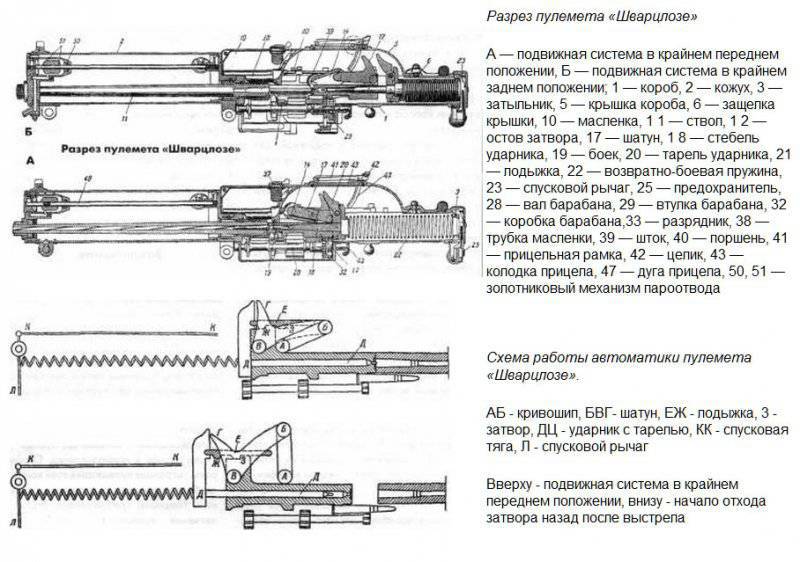

The skeleton of the machine gun was a receiver box (box) with a folding box cover and a barrel cover that is threaded to the box. The trunk was fastened to the box with the help of sector bosses of the breech and a latch. The barrel had a relatively short length - with this automation scheme, it was necessary to reduce the pressure in the barrel bore, and the bullet must leave the barrel before unlocking the barrel bore began. In the Schwarzlose system, unlocking was slowed down in two ways - by the resistance of two articulated levers, and also by redistributing the recoil energy between the parts of the gate. Two levers - the connecting rod, which is connected to the massive skeleton of the bolt, as well as the crank connected to the duct - were located near the dead center in the forward position. The percussion mechanism consisted of a drummer with a striker sliding in the channel of the skeleton of the bolt, a plate with a crest mounted on the tail of the drummer, and an ankle reinforced on the plate. After the shot, under the effect of recoil, the bolt moved back and carried the connecting rod with it. Between the axles of the crank pin in the vertical plane there was some shoulder that caused the crank to rotate and the crank rotated about its swing axis. When unfolding the levers, the slide retreat from the breech of the barrel slowed down. At the same time, the rear knee of the connecting rod pressed on the crest of the plate, taking the drummer and the massive plate back relative to the bolt body - this acceleration of the hammer took away some of the kinetic energy from the core. The ankle with the sear moved along with the plate — until the moment when the sear began to catch and the platoon of the upper crest of the bolt. After that, the plate could not move to the core. The mobile system in this form reached the rearmost point (with the stroke length of the shutter was 100 millimeters), after which it went forward under the action of a helical return-combat spring. Another cartridge was picked up by the skeleton of the bolt, was sent to the chamber, the levers folded, slowing the bolt, softening the blow at the front point, preventing the bolt from rebounding. Drummer after locking the barrel remained cocked, while the reciprocating-fighting spring remained preloaded.

The trigger mechanism consisted of a trigger thrust and a trigger lever located on the back plate. Manual fuse located in the release lever did not allow him to move forward. Trigger pull when you press the lever lifted the head of the ankle, turning the ankle. The shepherd and battle platoon disengaged. Drummer went ahead, smashing the cartridge primer. In the event that the lever was pressed, the triggering thrust remained in the rear position, and in the next cycle the shot was made by the automatics. The reloading handle, located on the right side of the box, was rigidly seated on the right neck of the crank.

The power was supplied by a canvas ribbon designed for 100 or 250 cartridges. To facilitate loading, the tape was supplied with a leather tip. A drum-type feed mechanism was assembled from the bottom of the box. The hub carried a ratchet wheel, a drum - a gear for sleeves and bullets. Moving back, the shutter with its front lower ridge pressed on the tooth of the ratchet wheel, turning it to the left. The drum captured another cartridge by pushing the tape to the left. The cartridge captured by the extractor of the skeleton of the bolt for the cap of the sleeve was moved back and removed from the tape. After that, the cartridge was transferred into the groove of the drum and turned up the nose of a bullet. During the further rotation of the drum, the cartridge climbed the dismounting line along the guide bevels of the box. In this case, the next cartridge stood on the rack. Rotation of the drum was made while moving back and forth. This system required three times to turn the reloading handle while loading the machine gun, so that the first cartridge appeared in the chamber. Removing the spent cartridges produced spring-loaded ejector of the skeleton of the bolt. The reflector, assembled in the groove of the core, slid along the groove of the box by a protrusion and, resting on the rear edge of the groove, protruding beyond the shutter mirror, pushed the cartridge case to the left.

In order to weaken the grip of the liner and the walls of the chamber, as well as to prevent rupture of the liner during extraction, a lubrication mechanism was introduced into the structure (“axle”) - before the cartridge was sent to the chamber, it was oiled. The mechanism was installed in the lid of the box and consisted of an oil can and a pump whose piston was actuated by the right cage of the bolt's body — during the forward movement the pump sucked a portion of oil into the piston rod and squeezed oil onto the cartridge during reverse movement. In 1912, the machine gun was upgraded: improved machine design, improved manufacturability and reliability of the system, put a roller on the right crank neck to reduce friction during rotation, the extractor was replaced with a removable one. The external differences of the M / 07 / 12 modification were in the upper edge of the box cover, which served as a continuation of the trunk casing line.

A simple spool mechanism in the casing regulated the removal of steam. The adjustment depended on the angle of elevation of the trunk. Sector sight had a triangular slot of the rear sight, a drum, notched from 2 to 24 (200 - 2400 meters), and an input device for lateral corrections. The fly was attached to the casing. The aiming line was 686 millimeters. An excellent "find" was the horizontal control knobs located on the back plate.

The tripod had a rigidly welded to the base of the rear and hinged reinforced front legs, connected by stretch marks. By extending the legs, the height of the line of fire was adjusted. A conical swivel mounted on the Schwarzlose box was inserted into the upper base of the base. The mechanism of vertical pickup consisted of two toothed sectors and a gear reducer with a clamp and a handwheel. Horizontal guidance was carried out with a swivel and a slider, which moved along a horizontal arc with scattering restraints. The slider and ball heel of the machine gun were connected. Despite the rather large mass, the machine favorably differed from many of its peers in relatively small dimensions. A shield could be installed on the machine. Later, the machine was given the opportunity to conduct anti-aircraft fire. For firing anti-aircraft fire, lengthening pipes were attached to the legs, which allowed firing from the position of the knee, or the machine was tilted forward, and a special socket for a machine-gun swivel was installed on the back leg, like on an anti-aircraft stance.

The lightweight “manual” version of the Schwarzlose M / 07 / 12 / 16 machine gun was mounted on a light tripod or a bipod, had a removable shoulder rest, used a ribbon on 100 ammunition.

Like many other machine guns of the time, Schwarzlose was used in aviation. Modification M / 07/12 / R16 for aviation was air-cooled barrel. To increase the speed of fire, the machine gun was equipped with an additional buffer spring in the butt plate.

In addition to comparative simplicity, the advantages of the system were a small number of parts (166 units), their strength and large size. This machine gun had the first, successfully working in combat conditions, system with a semi-free gate. The disadvantages include the need for "osalki" cartridges and low ballistics. However, over time, the oiler was excluded from the M / 07 / 12 design, and the bolt was weighted for an additional delay in unlocking the barrel.

In Russia, part of the captured “Shvartsloze” in the workshops of the Petrograd and Kiev artillery depots was altered under the Russian patron - this work was facilitated by the fact that the Austrian-made machine guns were designed for the protruding rifle cartridges.

The Schwarzlose machine guns were supplied not only to the armies of the allied states - Turkey, Bulgaria and Italy (until it took the side of the Entente) - but also to Greece, Romania, Serbia, and Australia, they came as trophies. Under license, the machine gun was produced in Sweden and the Netherlands. After Austria-Hungary collapsed, the Schwarzlose machine guns were in service in Czechoslovakia and Hungary. Czechoslovakia even produced Schwarzlose chambered in 7,92 mm. In the early 1930s in Austria, the machine gun was converted to the 8x56 cartridge. The armies of Italy and Hungary had the Schwarzlose in service until 1945. In World War I, the German Reichswehr used the Schwarzlose chambered for 7,92 mm; in World War II, the Wehrmacht kept these machine guns to guard airfields, in rear units, and the like.

To unload the machine gun “Schwarzlose” it is necessary to do the following: Press the discharger flag down (behind the drum box, from the bottom of the machine gun), pull the cartridge belt to the right. Move the cocking handle back to remove the cartridge from the chamber. Push the trigger lever.

Incomplete disassembly of the heavy machine gun "Schwarzlose" was made in the following order:

1. Turn the cover latch to the left and open it, lifting up before the stopper rests against the protrusion on the cover.

2. Rotate the back plate stopper for the flag (located above the trigger lever), then turn the butt pad 1 / 6 left to the left for the control handle and pull it back overcoming the return spring pressure.

3. Remove the recoil spring from the box (with the rear stop ring).

4. Remove the front thrust ring, for which it is necessary to pull it back through the opening of the box and turn it to the desired angle.

5. Take out the drummer and ankle. To do this, it is necessary to lift the ankle behind the head with the left hand, and with the right hand pull the drummer back to the cut-outs of the box and separate it; remove the ankle from the drummer.

6. Take out parts of the slowdown mechanism. To do this, pull back the shutter with the handle and, supporting the inner opening of the shutter and the handle, bring the shutter until the slots on the box and its projections coincide, lift the shutter up to the vertical position of the handle, turn the crank and other links to the right. Disassemble all links.

7. Remove the trigger pull by pushing on its back end and pull the pull down to the right by the raised upper end.

8. Remove the drum box with drum and lid. To do this, turn back the latch of the drum cover until it stops (on the right side of the machine gun) and push it to the right, pressing from left to right on the rear end of the box.

9. Disassemble the drum box. Taking the cover back and turning it to the right to separate it; move the drum forward, lift the back end, disengage the front neck and the box nest, separate the drum.

10. Disassemble the drum, for which: remove the stop of the drum spring, turn it to the left with the key and move it back, overcoming the spring pressure; remove the drum spring; From the rear end of the drum sleeve, remove the sleeve.

11. Separating the barrel (if its replacement, correction and inspection is needed, the barrel mass is 1,35 kg) by unscrewing the barrel nut. Unscrew the gland, turn the barrel latch so that the barrel can be turned; Turn the barrel to the right by turning the 1 / 6 turn to the right with a special key or the skeleton, remove the barrel.

For assembly, all actions were performed in the reverse order.

Specifications machine gun M / 07 "Schwarzlose":

Patron - 8x51R Mannicher;

The mass of the “body” of the machine gun is 19,9 kg (without cartridges);

Machine gun weight - 42,0 kg (with water, on the machine);

The length of the "body" of the machine gun - 1066 mm;

Barrel length - 530 mm;

The grooves - 4 right;

The length of the stroke rifling - 240 mm;

Initial bullet speed - 625 m / s;

Sighting range - 2000 m;

The rate of fire - 500 shots per minute;

Combat rate - 250 shots per minute;

Tape capacity - 250 cartridges;

Type of machine - tripod;

Machine weight - kg 19,0;

The height of the line of fire - mm 250-600;

The angle of vertical guidance is from -35 to + 25 degrees;

Horizontal guidance angle - 35 degrees

Based on: S. Fedoseev - Machine Guns in the First World War

Information