German machine guns of the Maxim system during the First World War

In 1892, the Berlin-based Ludwig Löwe & Co. company, licensed by Maxim-Nordenfeld, began production of Maxim machine guns. In 1894, these machine guns with tripod machines were purchased by the naval fleet Germany. On the basis of the Ludwig Löwe company in 1896, the company Deutsche Waffen und Munishenfabriken (DWM) was established. In 1899, the German Reichswehr purchased machine guns for testing from this company. German Maxims were also acquired by Austria-Hungary, Russia and Spain. In 1901, "Maxim" with the designation MG.01 was adopted by the Kaiser army. The machine guns were equipped with Shlitten 01 or 03 skid machines. During the battle, the crew either moved the machine gun with a drag, or transferred it on the machine. The production of machine guns for the Navy continued, which differed from the army mounts on the installation.

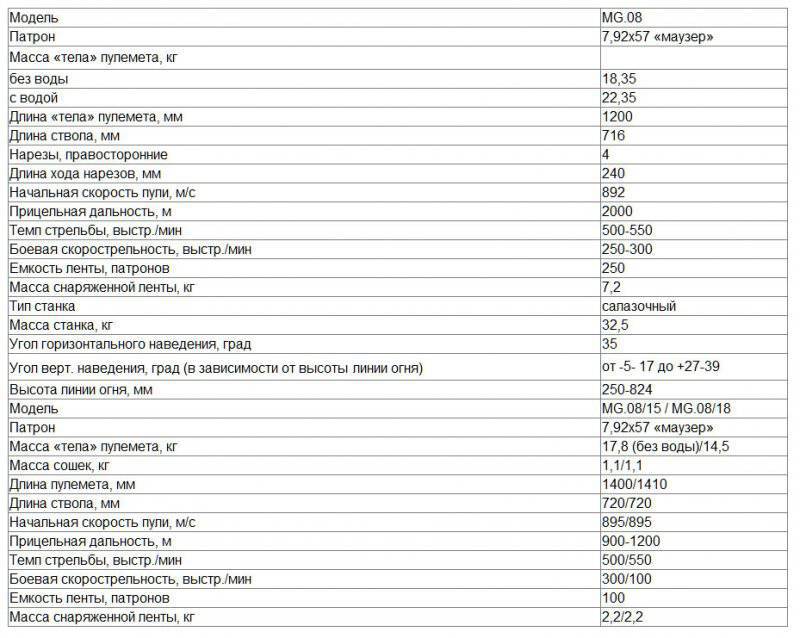

In the 1908, the MG.08 (Maschinen Gewehr 1908) version was adopted in which the 7,92-mm rifle-pointed Mauser cartridge was used. Replacing some parts from cast steel and bronze with parts made of alloyed steel made it possible to reduce the machine gun weight by 30% (from 26 kilograms MG.01 to 18,35 kilograms MG.08). Production MG.08 was adjusted to DWM, and already with 1911, and the state arsenal in Spandau, which became the main data producer of machine guns.

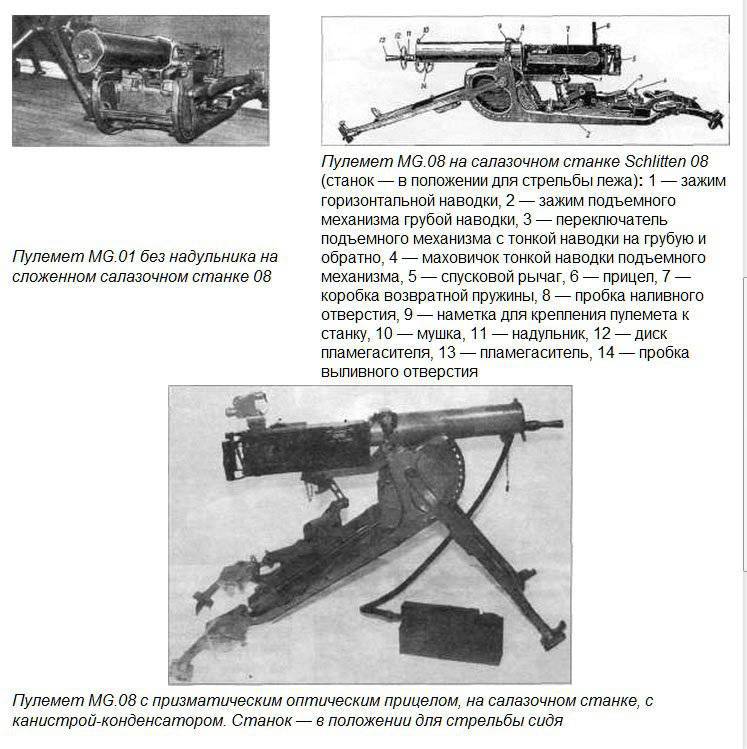

The MG.08 machine gun had several differences from the Maxim machine gun of the 1910 model of the year: in a muzzle, the push of gases was perceived not by the barrel thickening, but by the sleeve put on the barrel, the muzzle itself passed into a conical flame arrester, usually having a protective disk; front attachment point to the machine were two axle housing; the return spring box had a tension indicator (scale from 0 to 70); butt back box hinged on the hinge. The castle was distinguished by: integral locking levers; the pins on the lock body were the axles of the lifting arms; the upper and lower descents differed in shape, while the lower descent and ankle had tubular axes; tubular axle was attached combat spring; the locking levers had a tailed tail instead of a tube; it was not possible to regulate the gap between the stem of a stump and the war larva; combat larva performed without protruding flanges chambered for. In general, the design changes simplified the assembly and debugging of the machine gun. The mass of the barrel was 1,885 kilogram, the length of the rollback roll - 97,0 millimeters, the barrel - 15,0 millimeters. The folding rack mount had notches from 400 to 2000 meters, and the sighting line was 895 millimeters long. The trunk casing had a volume of 4 liters. The machine gun consisted of 258 parts.

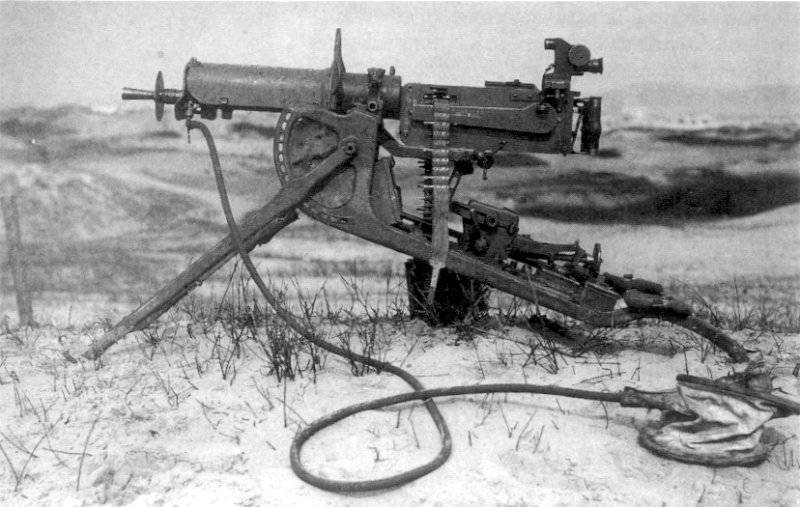

The Schlitten 08 sled machine consisted of a massive sled base with rear supports, front legs, a lifting mechanism with an accurate and coarse level switch. The machine gun was fixed in the swivel coupling. The height of the line of fire determined the angle of rotation of the legs. The fire could be from sitting or lying down. For fixing the crosstalk served clips horizontal and vertical pickup. The four-pronged design often prevented the machine from leveling, which in combination with the design of the swivel could lead to a machine gun stall. The massiveness of the machine ensured good accuracy, but difficult movement.

The machine gun was used with an optical sight of multiplicity 2,2-2,5х or a panoramic sight with multiplicity 2,5x, which was mounted on the left wall of the box. In order to shoot not direct fire using a panoramic sight, the machine was changed a little.

DWM supplied the Maxim machine guns to Brazil, Belgium, Persia, China, Peru, Serbia, Romania, Turkey, Switzerland, and Chile. As a result, before the start of the First World War, the Maxims of German production were in service with the belligerent armies on both sides.

On many machine guns in 1915, the muzzle was strengthened, accelerating the motion of the mobile system - this was not so much to increase the rate of fire, but to improve the performance of the power supply system and automation in the conditions of pollution and dust. Calculations from the use of armored soldiers refused, but began to protect the front of the casing with armored caps, since the casing penetration caused the machine gun to be out of order.

LMG.08 - aviation machine guns - differed in air cooling and a perforated casing, which reduced the weight to 15,5 kilograms, as well as a modified butt plate. On aircraft, machine guns were usually installed motionless.

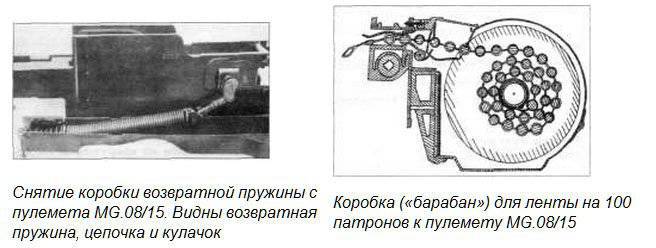

In 1915, Colonel Friedrich von Merkats, a member of the Probationary armory commission in Berlin-Spandau, became the head of a small design team whose goal was to develop a “lightweight” version of MG.08, which developed a fire of the same intensity, but managed and carried by one person. Soon, the machine gun MG.08 / 15 was adopted. Manual modification of the machine gun had a smaller casing diameter (89 mm instead of 109), and its capacity was 2,8 litas (instead of 4). Barrel weight - 1,8 kg. The muzzle and the shape of the box were changed, the thickness of the walls of the box was 3, not 4 mm, the under-barrel tube was excluded. The wooden butt was attached to the butt plate, and the pistol grip and the trigger were located at the bottom of the box. A flag fuse was installed above the pistol grip, with which the trigger was locked. The machine gun received a front sight of a triangular section and a sector sight. The length of the sighting line was 800 mm. The machine gun consisted of 197 parts. A round box was attached to the box to the right, with a 100-round ribbon placed in it (in the army, the box immediately received the nickname "drum"). The tape was wound inside the drum onto a reel, the weight of an empty drum was 1,85 kg. Along with the drum, a standard tape in a box of 250 rounds was used. In this case, the box was transferred separately. A massive triangular bipod was fixed on the back of the casing, around which the machine gun rotated in a horizontal plane. The machine gun was equipped with a gun belt.

The Reichswehr ordered MG.08 / 15 machine guns in the ratio of 5 light machine guns to 2 heavy machine guns, and Arsenal in Erfurt, the firm of Siemens, and Rashinmetall, Shashinenfabrik Augsburg-Nuremberg were engaged in production. Towards the end of the war, German soldiers, like the French, tried to use luminous fluorescent marks on their sights.

With the beginning of the release of MG.08 / 15, its “aviation” modification appeared, which received the designation LMG.08 / 15, and having air cooling, butt (for mobile installation) and without butt (for fixed). This modification was more successful than LMG.08 and soon changed it in production in Spandau. This aircraft gun was equipped with a mechanical counter shots.

“Universal” MG.16 machine gun developed on the basis of MG.08 under the leadership of Merkats could fire not only at ground but also at air targets from a tripod machine, as well as from a bipod. However, this machine gun did not get into service, because there was the difficulty of switching to the release of a modification with a lot of new. Limited to the assembly of an experimental batch in Erfurt. However, the lightweight Dreifuss 16 tripod machine with telescopic legs was adopted for the MG.08 machine gun. The total weight of the MG.08 and tripod was 58,4 kilograms. The same machine used with captured Russian and Belgian machine guns. Anti-aircraft machine-gun systems were not officially adopted, but found limited use.

The MG.08 / 18 air-cooled machine gun was initially used as an aviation one, but here it had a more successful competitor, the Parabellum. Toward the end of the war, the MG.08 / 18 machine gun was adopted for cavalry, scooters, and mountain infantry. His release was carried out in the arsenal in Erfurt. The MG.08 / 18 machine gun barrel was enclosed in a perforated casing with a diameter of 37 mm. The carrying handle was attached to the casing. Instead of a muzzle there was a barrel guide bushing screwed into the casing, the front sight was placed on a high stand, the bipods were attached to the casing with the help of a coupling. With the introduction of the MG.08 / 18 machine gun into the infantry, it became clear that firing could only be fired in short bursts due to the barren’s irremovability. Constructive solutions used in the MG.08 / 18, were later applied in the Soviet MT light machine gun.

Over the years of the First World War, about 260 thousand machine guns of the MG.08, 08 / 15 and 08 / 18 models were released in Germany, of which only 72 thousand were mounted.

To discharge the MG.08 machine gun, it was necessary to: Twice forward the handle and release it. Push the trigger lever. Remove the tape from the receiver by pressing the lower finger of the receiver. Push the sleeve or cartridge out of the lead tube with a suitable rod.

Assembling, unloading and disassembling the MG.08 / 15 and MG.08 / 18 light machine guns are generally the same as the Maxim machine gun.

Based on: S. Fedoseev - Machine Guns in the First World War

Information